Ultrahigh-toughness epoxy resin material for hot-mixed epoxy asphalt and preparation method thereof

A technology of hot-mixed epoxy asphalt and tough epoxy resin, which is applied in building insulation materials, building components, buildings, etc., to achieve the effect of increasing chain segment length and excellent phase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: super high toughness epoxy resin material and preparation method thereof for hot mix epoxy asphalt

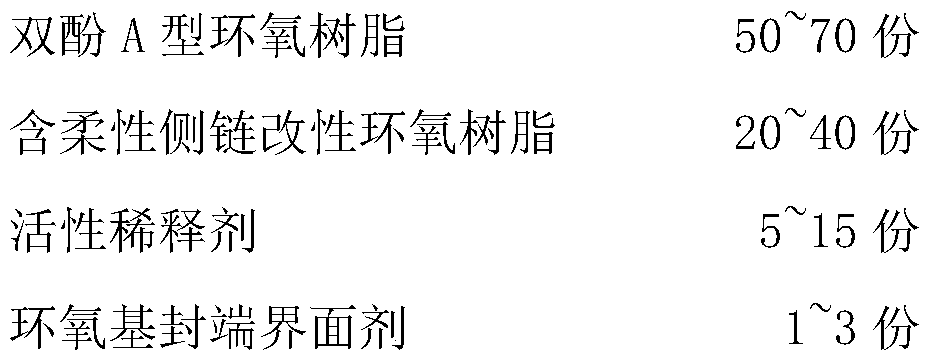

[0046] The raw materials used in this embodiment are as follows:

[0047] Polyethylene glycol monomethyl ether: MPEG-1000, Jiangsu Haian Petrochemical Plant;

[0048] Toluene diisocyanate: TDI-100, Hebei Cangzhou Dahua Group Co., Ltd.;

[0049] Bisphenol A type epoxy resin (I); DER331, U.S. Dow Chemical Company;

[0050] Toluene: industrial grade, Suzhou Kai Nuobin Petrochemical Co., Ltd.;

[0051] Bisphenol A type epoxy resin (II): DER331, American Dow Chemical Company;

[0052] Phenyl glycidyl ether: XY690, Anhui Xinyuan Technology Co., Ltd.;

[0053] 3-Glycidyl etheroxypropyl trimethylsilane: SilguestA-187, American Momentive Advanced Materials Company;

[0054] 9,11,13-octadecatrienoic acid: T160, Anhui Ruifende Oil Deep Processing Co., Ltd.;

[0055] Liquid ammonia: industrial grade, Nantong Runfeng Petrochemical Co., Ltd.;

[0056] Ammonia: 25%...

Embodiment 2

[0072] Embodiment 2: super high toughness epoxy resin material and preparation method thereof for hot mix epoxy asphalt

[0073] The raw materials used in this embodiment are as follows:

[0074] Polyethylene glycol monomethyl ether: MPEG-750, Jiangsu Haian Petrochemical Plant;

[0075] Toluene diisocyanate: TDI-80, Hebei Cangzhou Dahua Group Co., Ltd.;

[0076] Bisphenol A type epoxy resin (I): DER331, U.S. Dow Chemical Company;

[0077] Toluene: industrial grade, Suzhou Kai Nuobin Petrochemical Co., Ltd.;

[0078] Dibutyltin dilaurate: DY-12, Shanghai Deyin Chemical Co., Ltd.;

[0079] Bisphenol A epoxy resin (II): NPEL-128, Nanya Electronic Materials (Kunshan) Co., Ltd.;

[0080] Butanediol diglycidyl ether: XY622, Anhui Xinyuan Technology Co., Ltd.;

[0081] 3-Glycidyl etheroxypropyltriethoxysilane: KBE403, Japan Shin-Etsu Chemical Co., Ltd.;

[0082] Cis-12-hydroxyoctadecene-9-acid: RA-10, Anhui Ruifende Oil Deep Processing Co., Ltd.;

[0083] Liquid ammonia: indus...

Embodiment 3

[0098] Embodiment 3. super high toughness epoxy resin material and preparation method thereof for hot mix epoxy asphalt

[0099] The raw materials used in this embodiment are as follows:

[0100] Polyethylene glycol monomethyl ether: MPEG-2000, Jiangsu Haian Petrochemical Plant;

[0101] Toluene diisocyanate: TDI-60, Hebei Cangzhou Dahua Group Co., Ltd.;

[0102] Bisphenol A type epoxy resin (I): DER317, U.S. Dow Chemical Company;

[0103] Dibutyltin dilaurate: DY-12, Shanghai Deyin Chemical Co., Ltd.;

[0104] Bisphenol A epoxy resin (II): WSR6101, Bluestar Chemical New Materials Co., Ltd.;

[0105] Polyethylene glycol diglycidyl ether: XY205, Anhui Xinyuan Technology Co., Ltd.;

[0106] 3-Glycidyl etheroxypropylmethyldiethoxysilane: SCA-87F, Nanjing Nengde New Material Technology Co., Ltd.;

[0107] Cis, cis-9,12-octadecadenoic acid: L80-3, Anhui Ruifende Oil Deep Processing Co., Ltd.;

[0108] Liquid ammonia: industrial grade, Nantong Runfeng Petrochemical Co., Ltd.; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com