Patents

Literature

57results about How to "Meet mixing needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-toughness epoxy resin material for hot-mixed epoxy asphalt and preparation method thereof

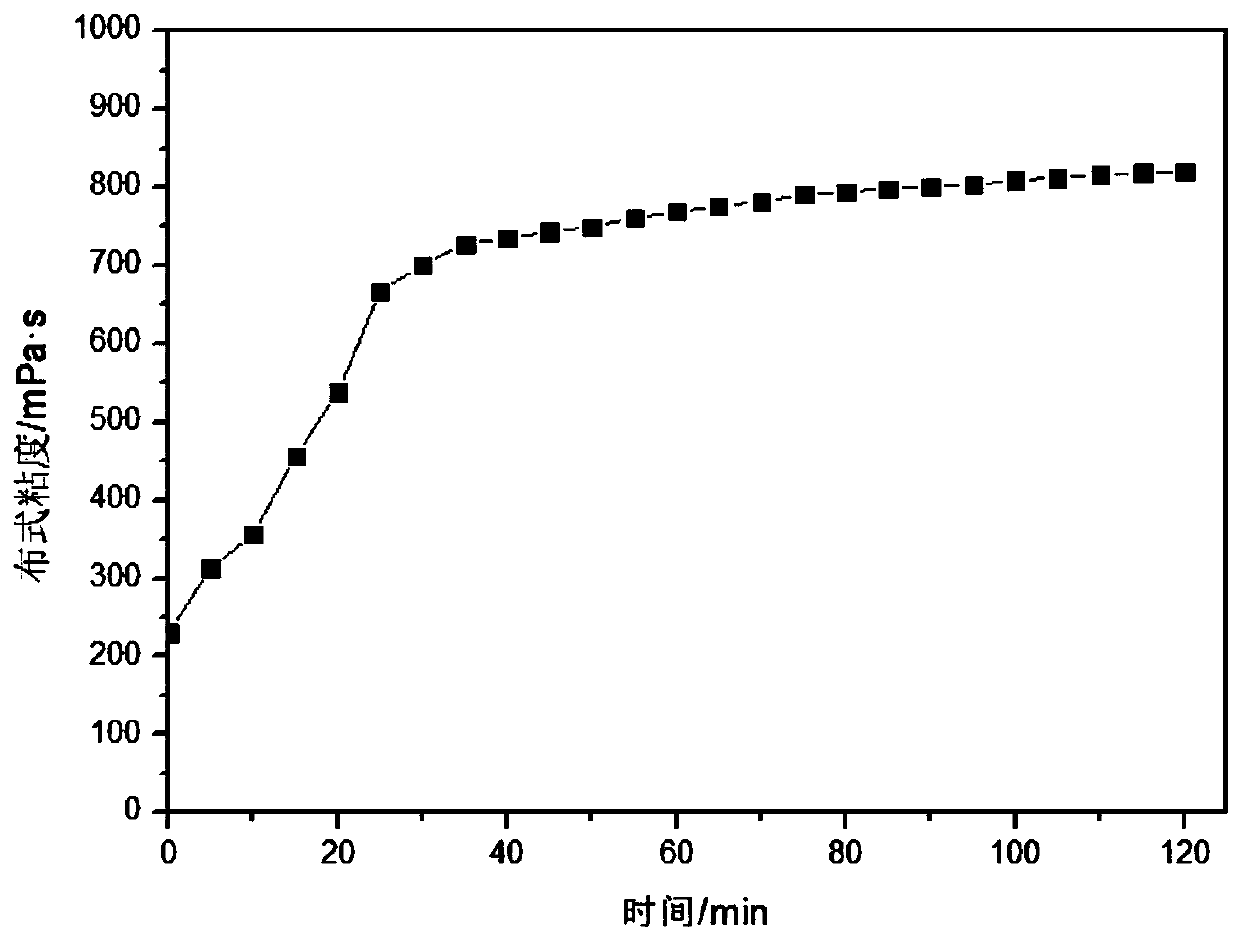

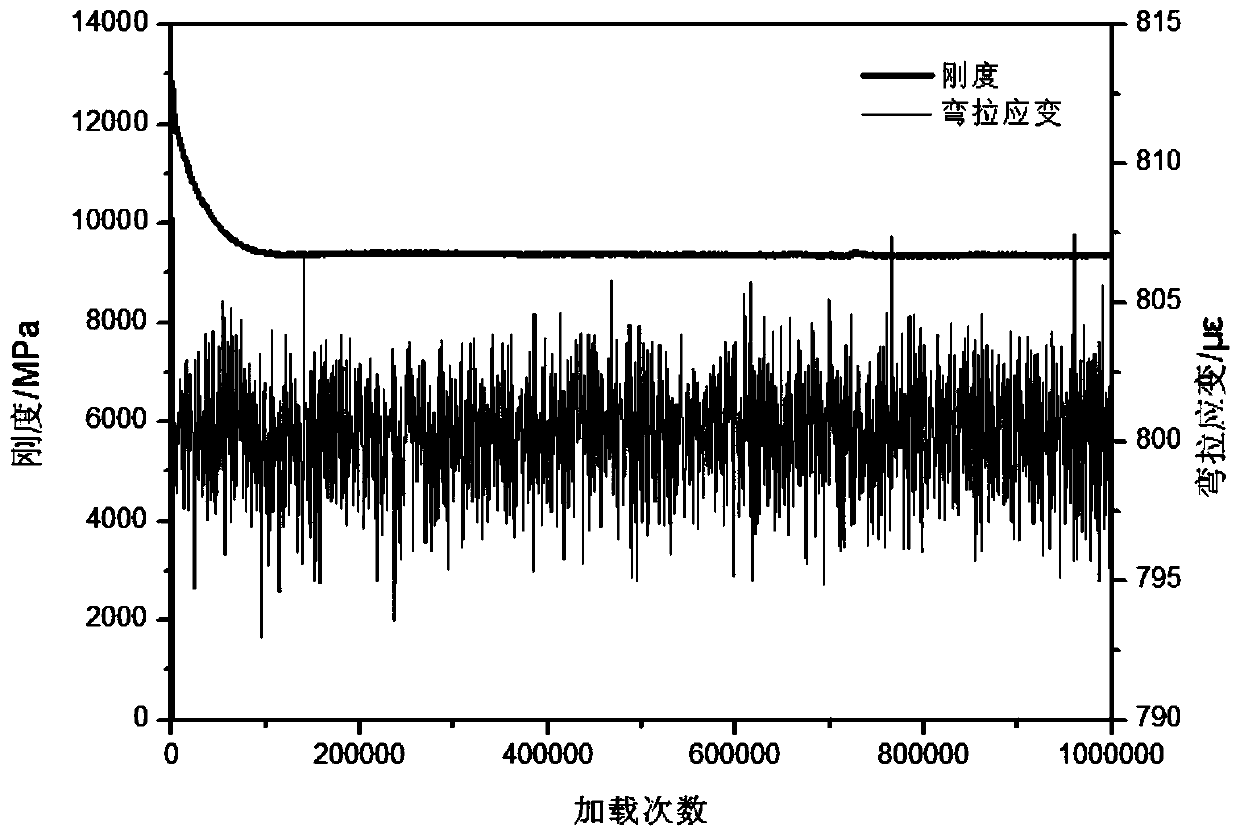

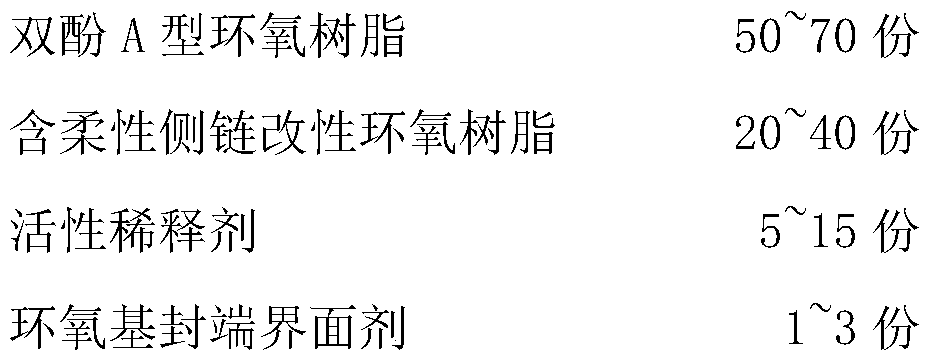

ActiveCN110713695AReduce crosslink densityGuaranteed viscosityBuilding insulationsPolymer scienceSide chain

The invention discloses an ultrahigh-toughness epoxy resin material for hot-mixed epoxy asphalt and a preparation method of the ultrahigh-toughness epoxy resin material. The key points of the technical scheme are as follows: the ultrahigh-toughness epoxy resin material for the hot-mixed epoxy asphalt consists of a main agent A and a curing agent B, wherein the main agent A comprises bisphenol A epoxy resin, modified epoxy resin containing a flexible side chain, a reactive diluent and an epoxy terminated interface agent; the curing agent B comprises following components in parts by weight: long-chain fatty primary amine and an accelerant. The crosslinking density of an epoxy cured product is controlled by synthesizing monofunctional long-chain fatty primary amine, and finally, the operabletime of the hot-mixed epoxy asphalt material is longer than 2 hours; the compatibility problem between an asphalt phase and an epoxy phase is solved on the basis of a 'reaction induced phase splitting' technical principle; by introducing the modified epoxy resin containing the flexible side chain, the fatigue resistance of the hot-mixed epoxy asphalt material is greatly improved.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD +1

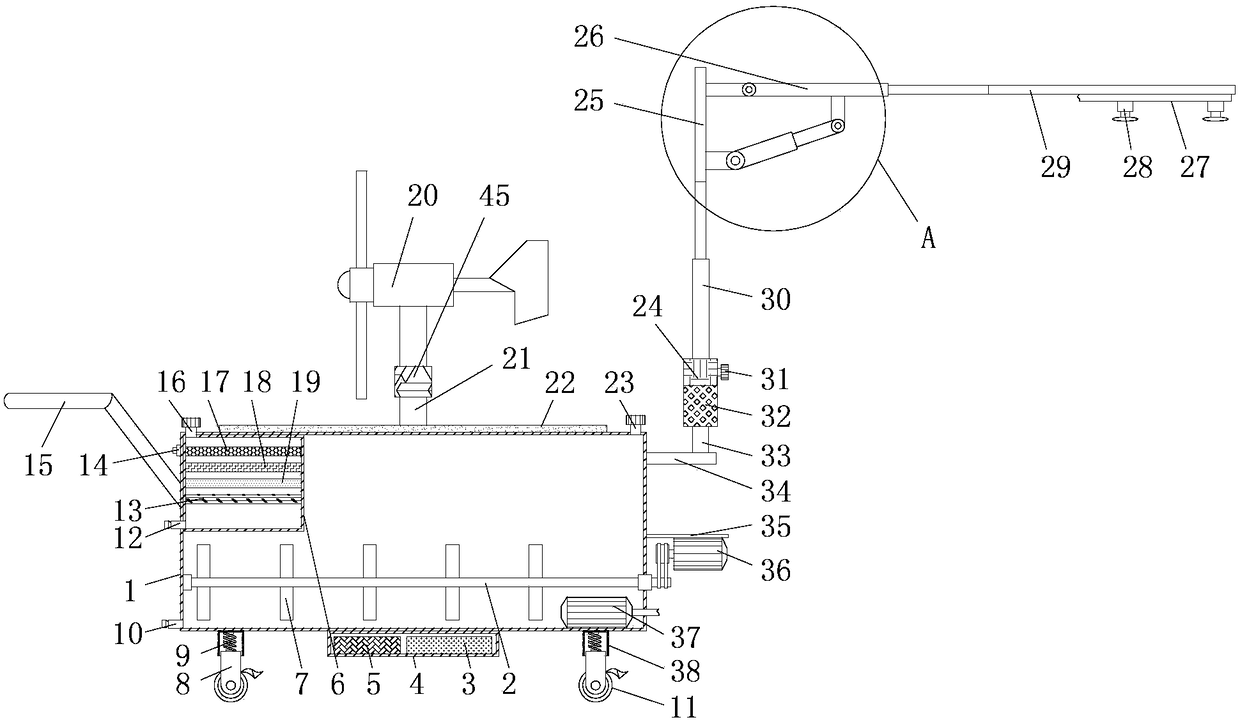

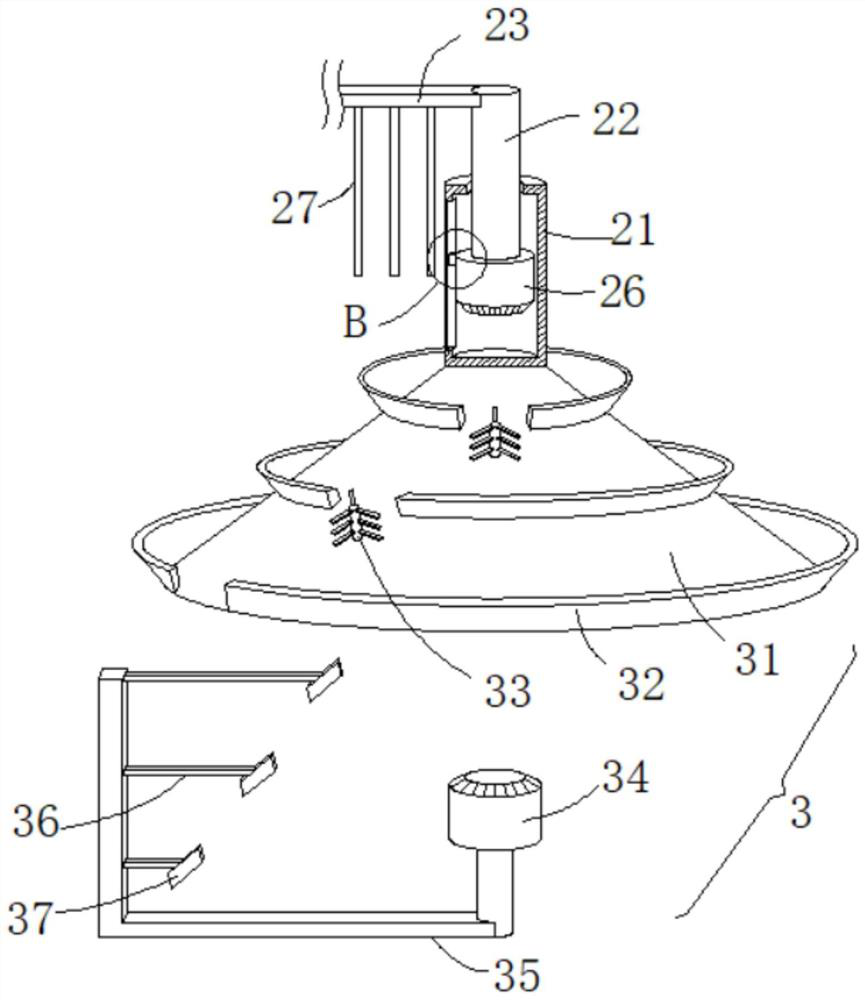

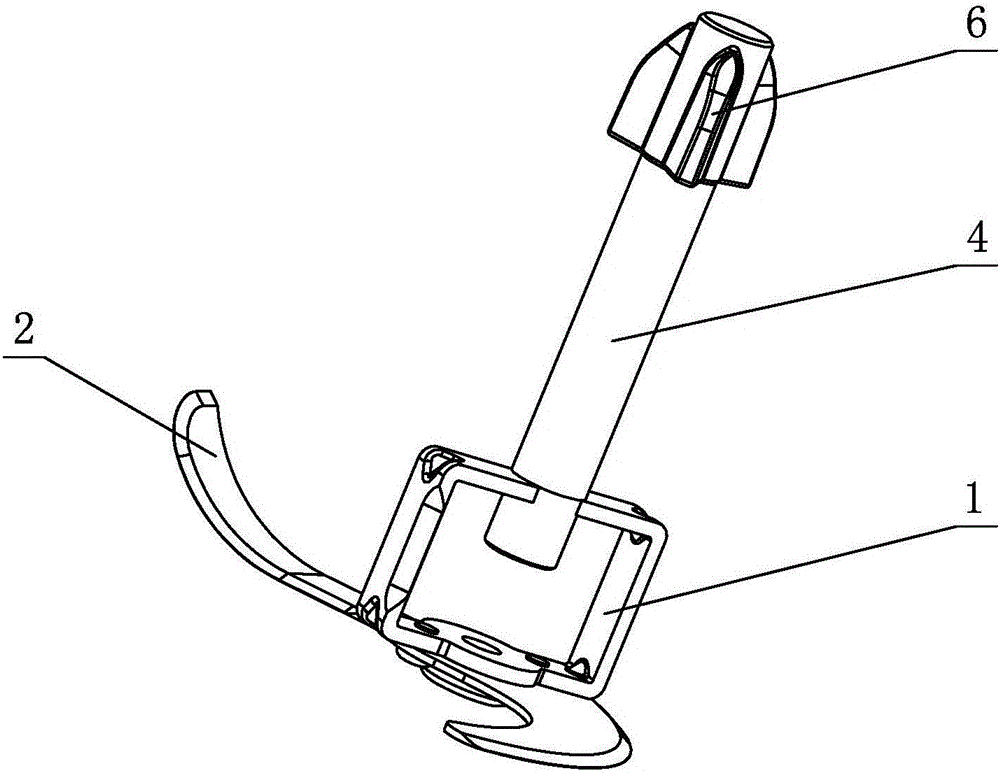

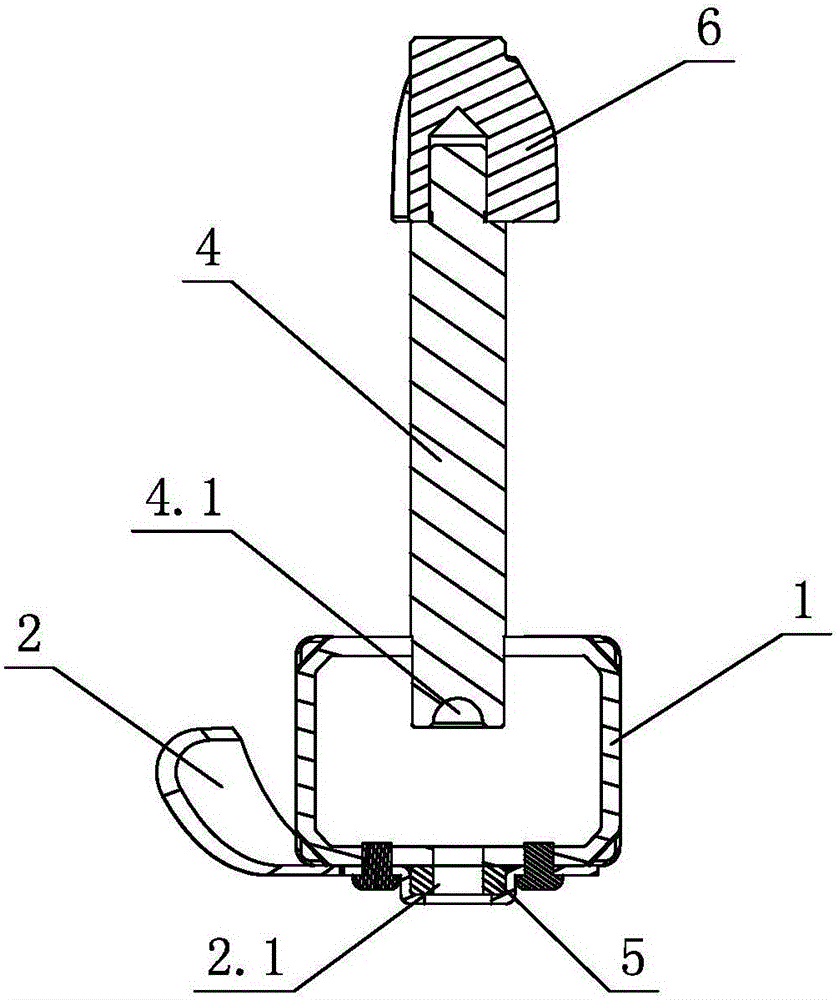

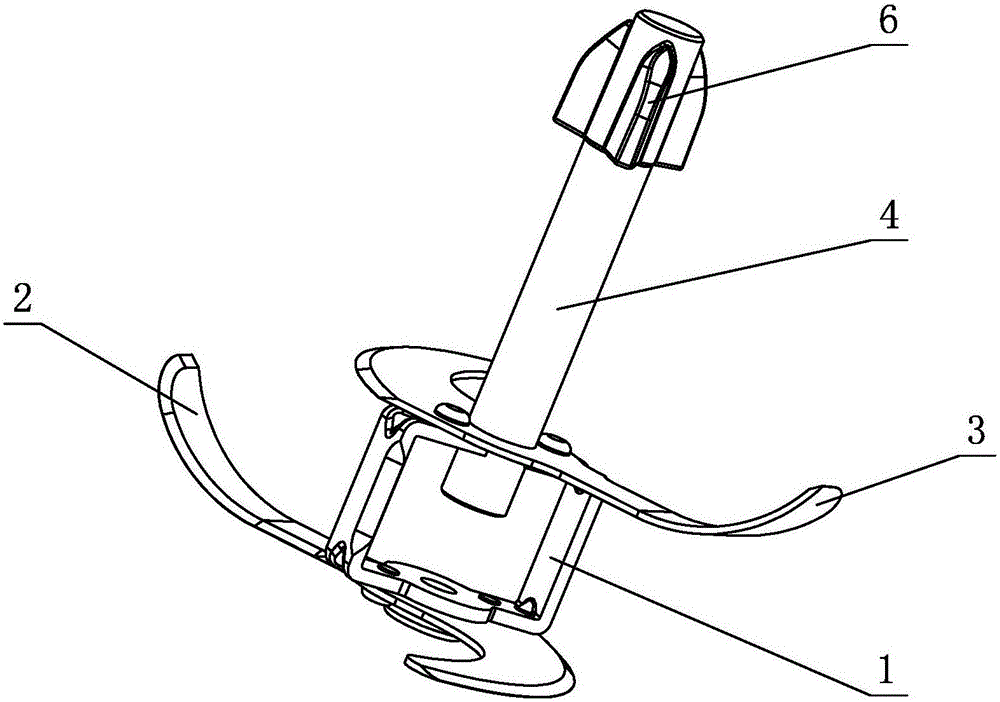

Garden watering and irrigating device

InactiveCN108308152AImprove drug spraying effectMeet Filtration NeedsRotary stirring mixersPV power plantsEngineeringSprayer

The invention discloses a garden watering and irrigating device which comprises a shell. A pump machine is fixedly mounted at the right end of an inner cavity of the shell, a rotating shaft is movablymounted at the lower end of the inner cavity of the shell, stirring blades are fixedly connected on the outer surface of the rotating shaft, and a clear water tank is fixedly connected at the left end of the top of the inner cavity of the shell. According to the device, a second supporting rod is fixedly connected at the right end of the top of a third supporting rod, sixth supporting rods and fourth supporting rods are sequentially and fixedly connected on the right side of an eighth supporting rod from top to bottom, adjusting requirements of people for horizontal positions, vertical positions, inclined angles and telescopic lengths of a steering sprayer are met through actions of a second bearing block, a sleeve, a screw hole, a fastening screw, a first electric telescopic rod, a thirdmovable joint, a second electric telescopic rod, a first movable joint, a third electric telescopic rod, a second movable joint and a fifth supporting rod, and great convenience is provided for watering and irrigating operation of people.

Owner:李元珍

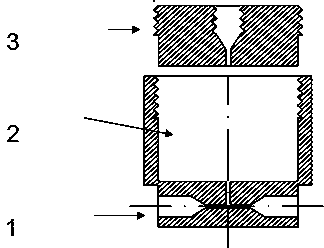

Split-flow convergent type mixer and mixing method

InactiveCN103949170AImprove the mixing effectImprove mixing efficiencyFlow mixersMixing methodsSteel tubeMixed approach

The invention discloses a split-flow convergent type mixer. A tank body of the split-flow convergent type mixer mainly comprises a T-junction, a mixing chamber and an outlet adapter, wherein the T-junction comprises two feeding channels which are in tight coupling with a stainless steel tube through a screw and a stainless steel edge ring; the other opening of the T-junction is connected to the mixing chamber; the mixing chamber comprises an inlet, a mixing chamber body, a thread and an exit hole; an inlet at one end of the mixing chamber is an outlet of the T-junction, and a thread at the other end of the mixing chamber is matched with a thread of the outlet adapter; and a baffle plate, a splitter plate, a baffle plate, a convergent plate and a baffle plate are alternatively arranged in the mixing chamber. Lots of turbulence zones and multiple mixture can be formed by adopting the design of a split-flow convergent runner, so that the mixing effect is improved; and the split-flow convergent type mixer has the advantages of high mixing efficiency, can be conveniently matched with various equipment for use and has the characteristics of convenience in use and wide application.

Owner:LIAOCHENG UNIV

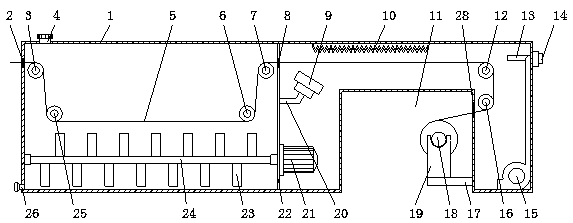

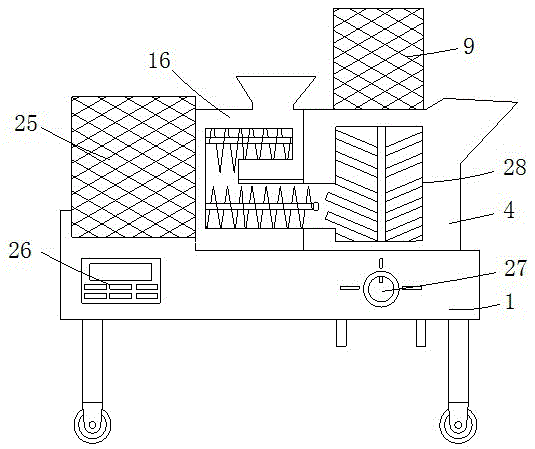

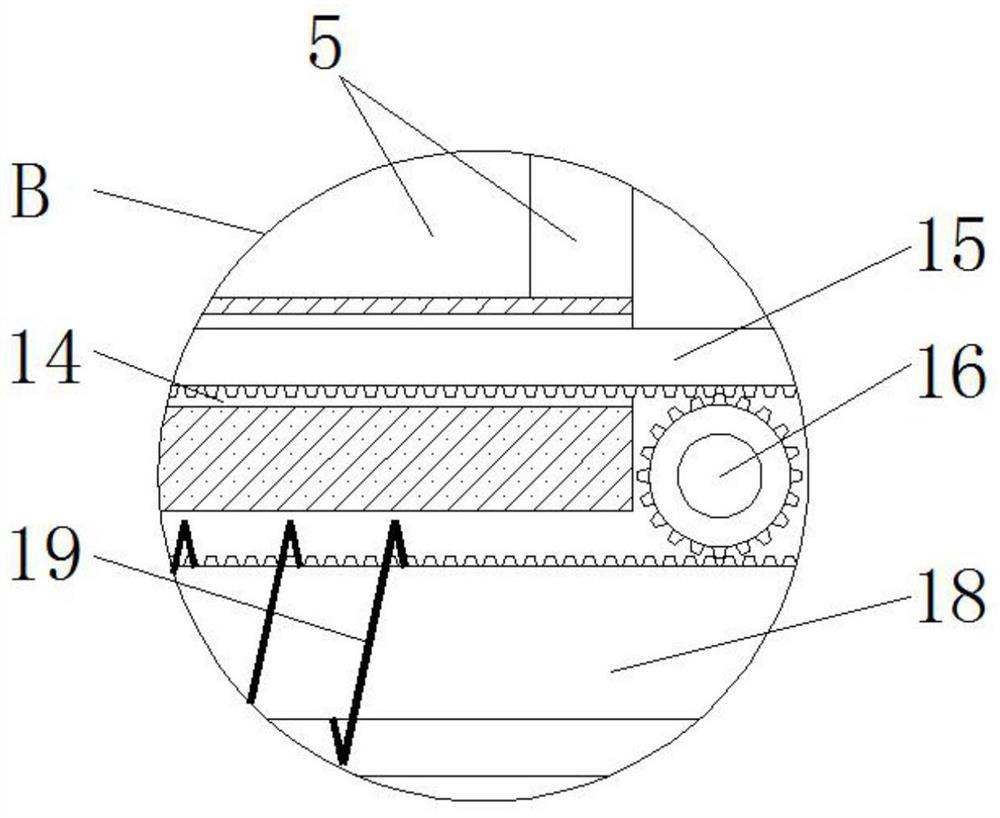

Textile-fabric printing and dyeing device

InactiveCN107904839AMeet drying needsMeet mixing needsTextile treatment containersTextile treatment machine arrangementsEngineeringDyeing

The invention discloses a textile fabric printing and dyeing device, which comprises a casing, and the inner cavity of the casing is sequentially provided with a first conveying roller, a second conveying roller, a third conveying roller, a fourth conveying roller, a partition plate, the fifth conveying roller and the sixth conveying roller, the upper end on the right side of the partition is fixedly connected with a hot air blower through the first support rod, the lower end on the right side of the partition is fixedly installed with a first motor, and the output of the first motor The shaft is fixedly connected with a stirring shaft, and the outer surface of the stirring shaft is fixedly connected with a stirring blade. In the present invention, a hot air blower is fixedly connected to the upper end of the right side of the partition through a first support rod, and a heating wire is fixedly connected to the right end of the top of the inner cavity of the casing, and through the function of the fan and the pipeline, it can satisfy people's requirements for the surface of the cloth after printing and dyeing. The need for drying solves the problem that the existing printing and dyeing devices only have a single printing and dyeing ability, which leads to low overall processing efficiency of fabrics and does not conform to the self-interest of the enterprise.

Owner:苏州旺谦纺织科技有限公司

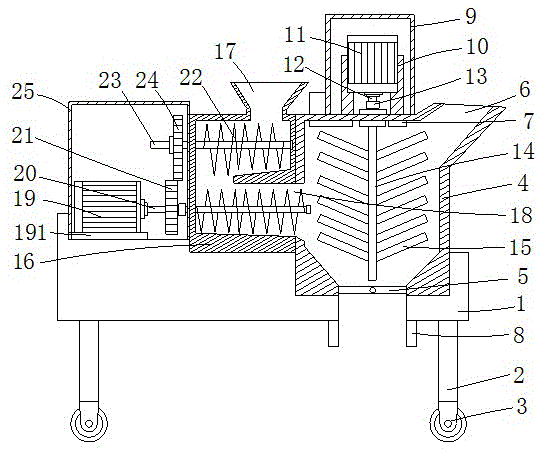

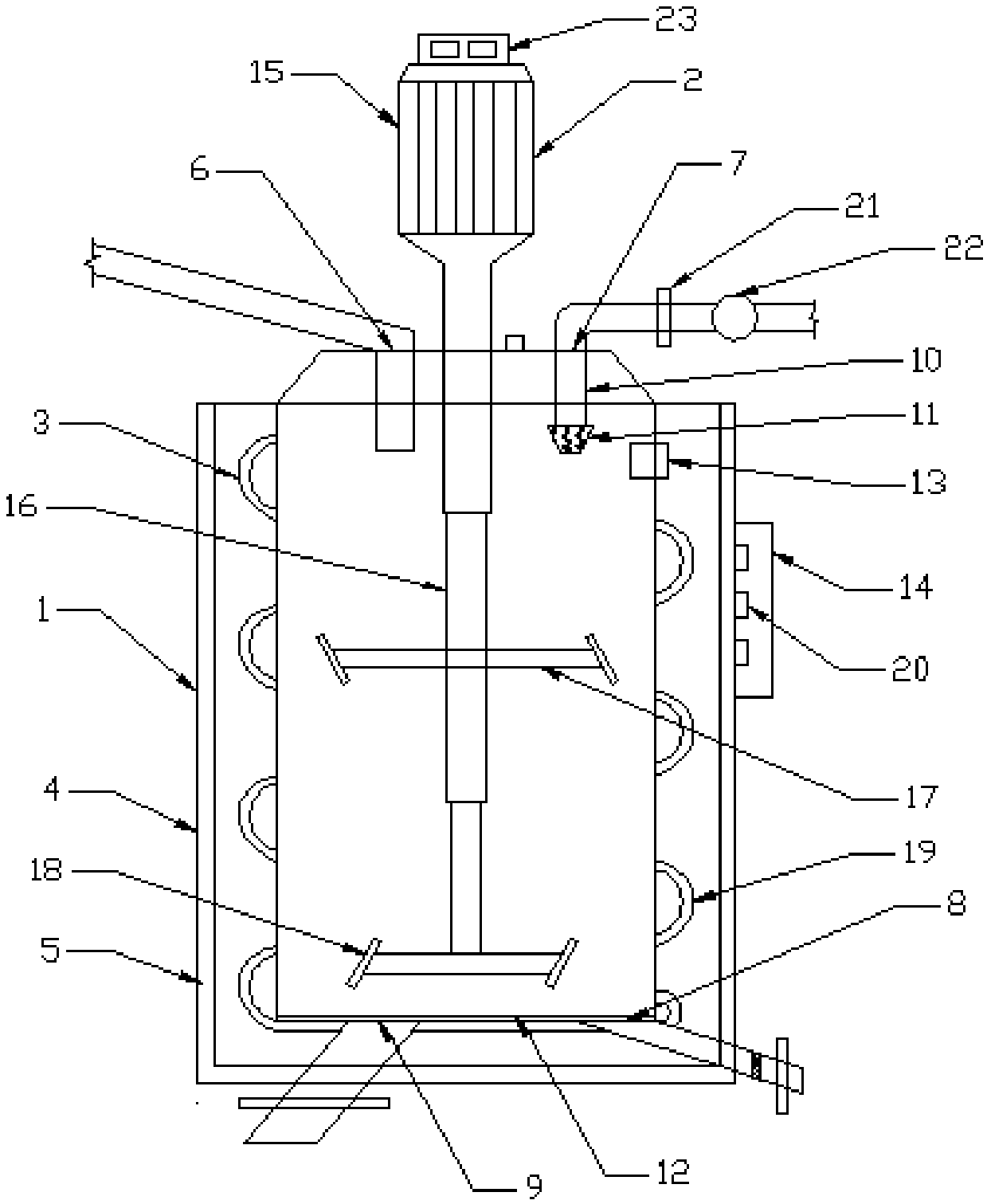

Stirring apparatus for food processing

InactiveCN106732122ASimple structureEasy to useTransportation and packagingRotary stirring mixersLow noiseImpeller

The invention discloses a stirring apparatus for food processing. The stirring apparatus comprises a housing, a stirring tank and a working chamber, wherein the top portion of the housing is respectively provided with the stirring tank, the working chamber and a noise reducing box from right to left, the middle on the top portion of the stirring tank is provided with a sound suction box, a speed regulating motor is arranged on the top portion of the middle of the supporting plate arranged on the bottom portion of the inner cavity of the sound suction box, a main shaft is arranged in the middle of the inner cavity of the stirring tank, and the outer periphery of the main shaft part positioned in the inner cavity of the stirring tank is symmetrically provided with stirring rods. According to the present invention, with the matching of the rotation blade wheels in the working chamber and the stirring rods in the stirring tank, the stirring requirements of different materials are met, the multiple-purpose-in-one-machine effect is achieved, and when the material outlet guide plate vertically arranged in the inner cavity of the stirring tank is opened, the material can be directly exported in the case of gravity, such that the condition that the stirring tank is clogged by the material during the exporting of the material can be avoided; and the stirring apparatus has advantages of practical and simple structure, low noise, and easy promotion application.

Owner:蓝玉

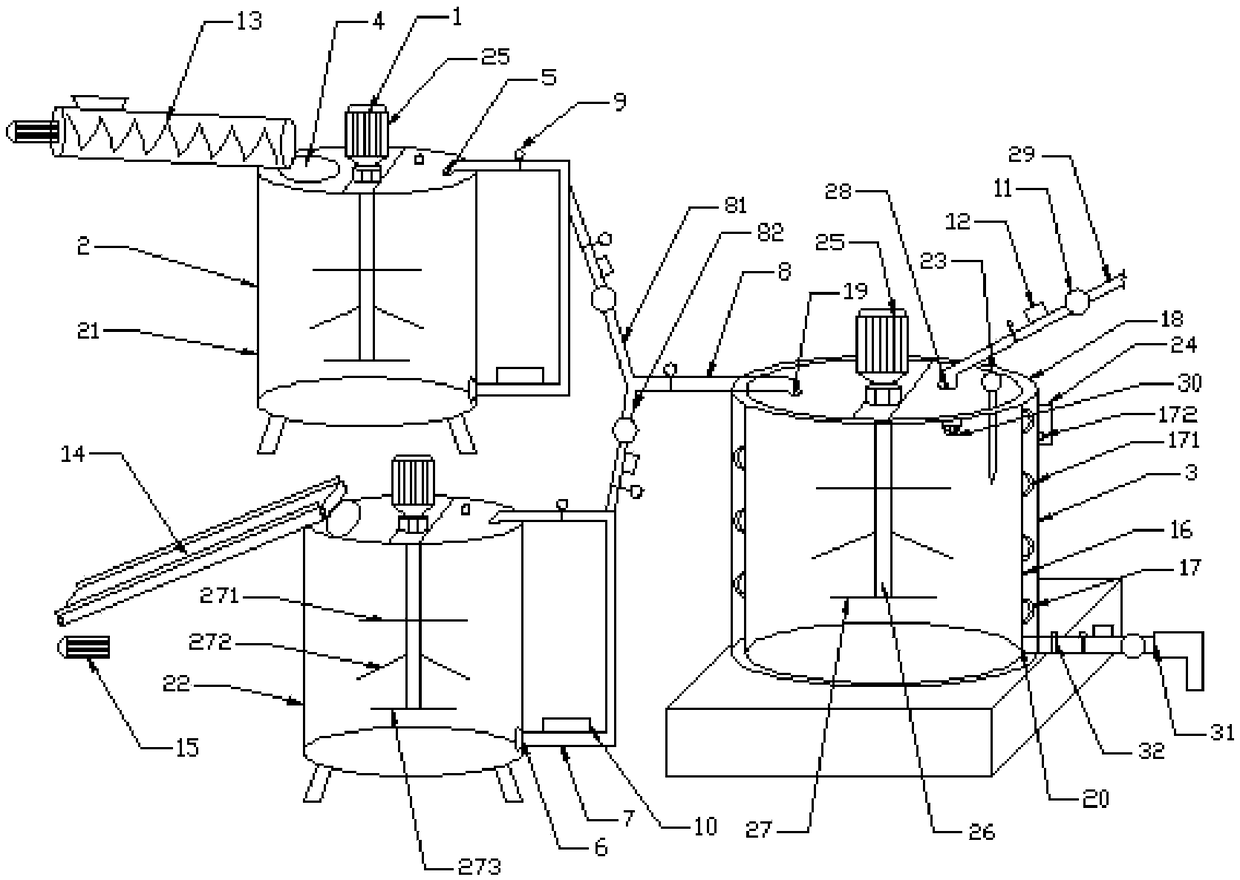

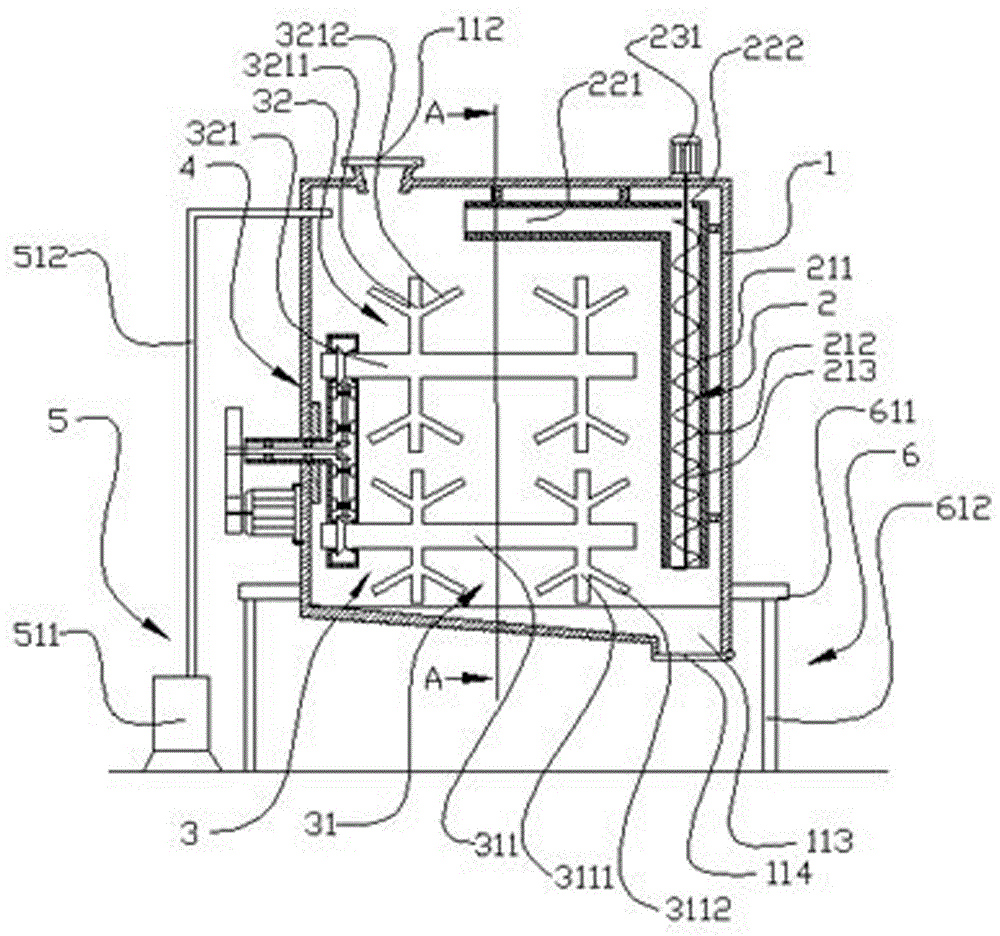

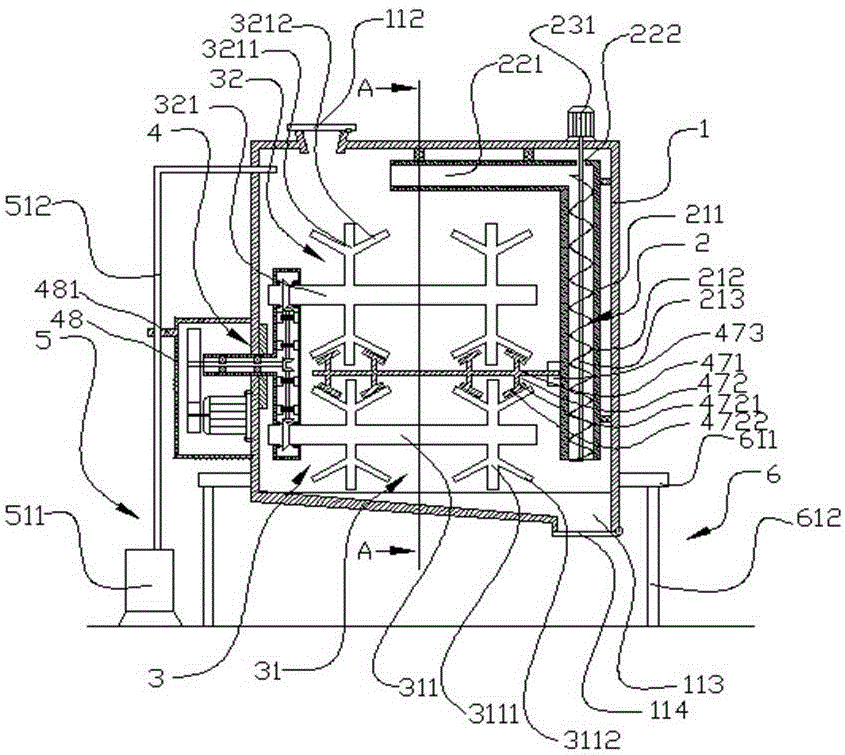

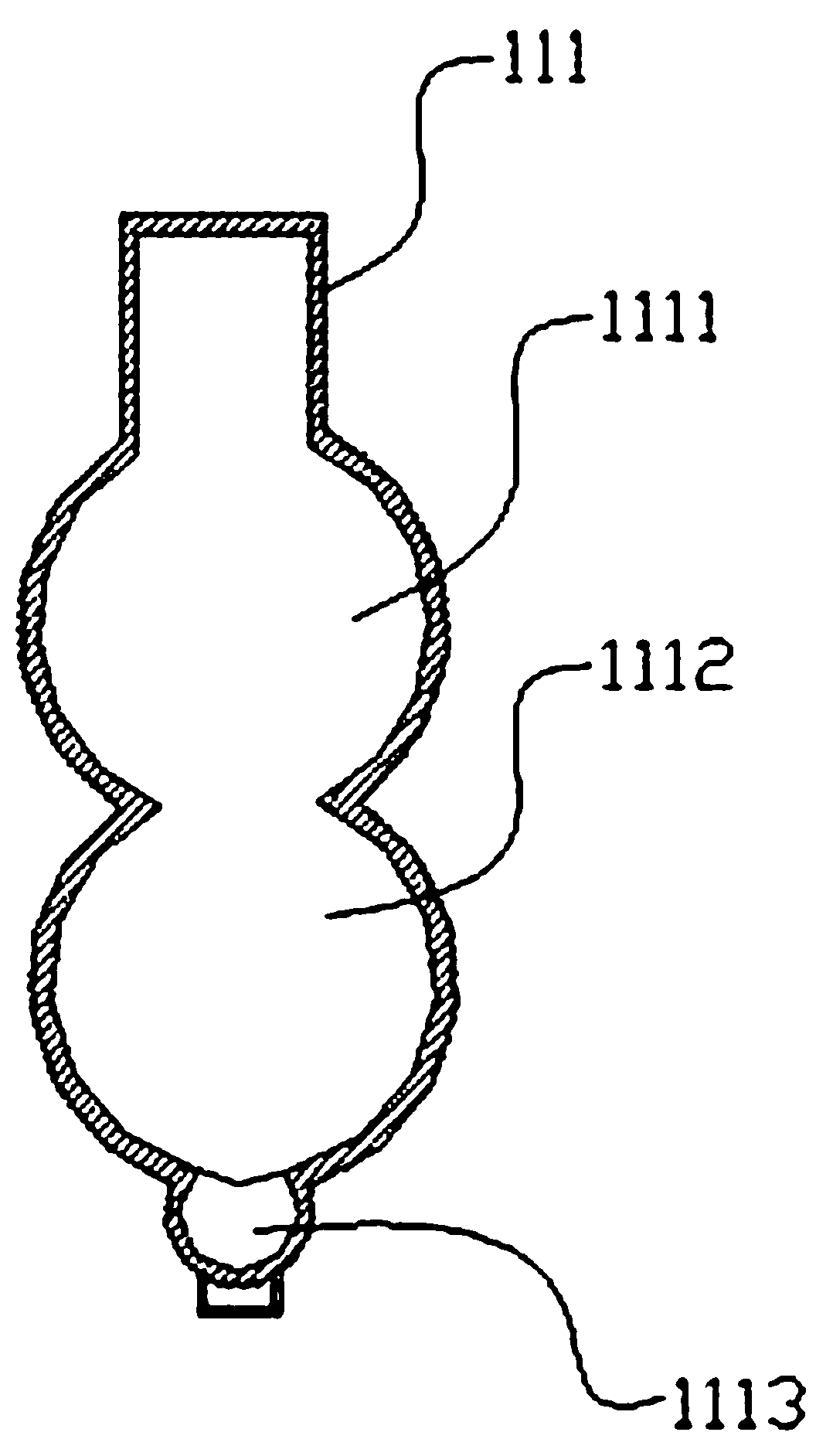

Liquid-state selenium-enriched nutritional chelated fertilizer production equipment

PendingCN108620014AGuaranteed stabilityImprove stabilityChemical/physical/physico-chemical stationary reactorsLiquid fertilisersFertilizerEngineering

The invention belongs to the field of fertilizer production device, and more specifically relates to a liquid-state selenium-enriched nutritional chelated fertilizer production equipment. The liquid-state selenium-enriched nutritional chelated fertilizer production equipment comprises a stirring barrel provided with a stirring device, and a chelating barrel; the upper part of the stirring barrel is provided with a feed inlet and a backflow port, and the lower part is provided with a feed outlet; the feed outlet is connected with the backflow port through a backflow pipe; the backflow pipe is connected with the chelating barrel through a liquid convey pipe; the backflow pipe and the liquid convey pipe are provided with solenoid valves; the backflow pipe is provided with a liquid suction pump; the chelating barrel comprises a barrel body, and a heating device and a housing arranged outside the barrel body; the upper part of the barrel body is provided with a liquid inlet, and the lower part is provided with a liquid outlet; a stirring device, a temperature sensor, and a controller are arranged in the barrel body; the stirring device, the heating device, and the temperature sensor arecommunicated with a controller circuit. The liquid-state selenium-enriched nutritional chelated fertilizer production equipment is capable of realizing automatic quantitative material charging, independent stirring and full uniform mixing based on material characteristics, controlling chelating temperature and time, and ensuring the stability of finished chelated fertilizer quality.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI +1

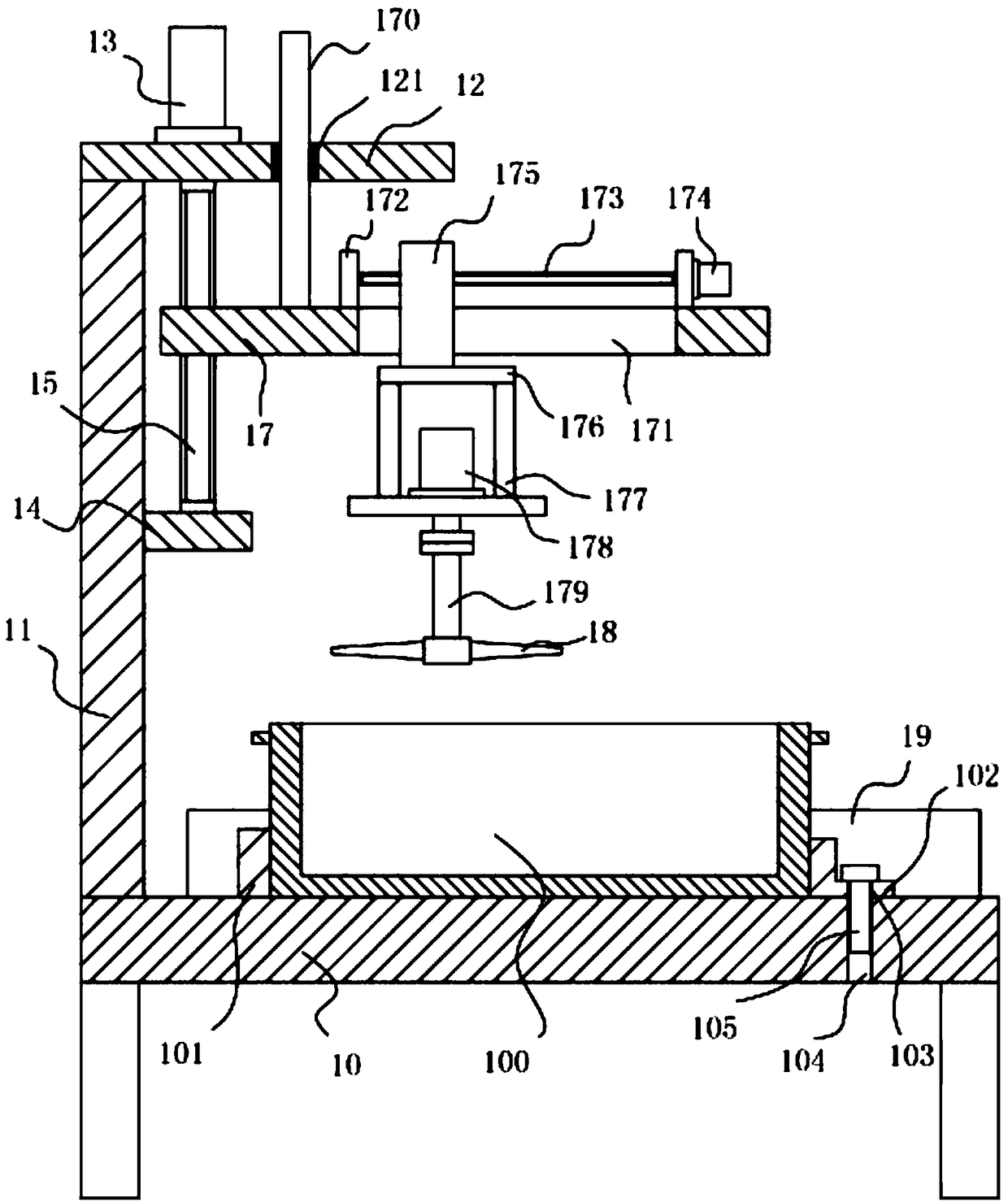

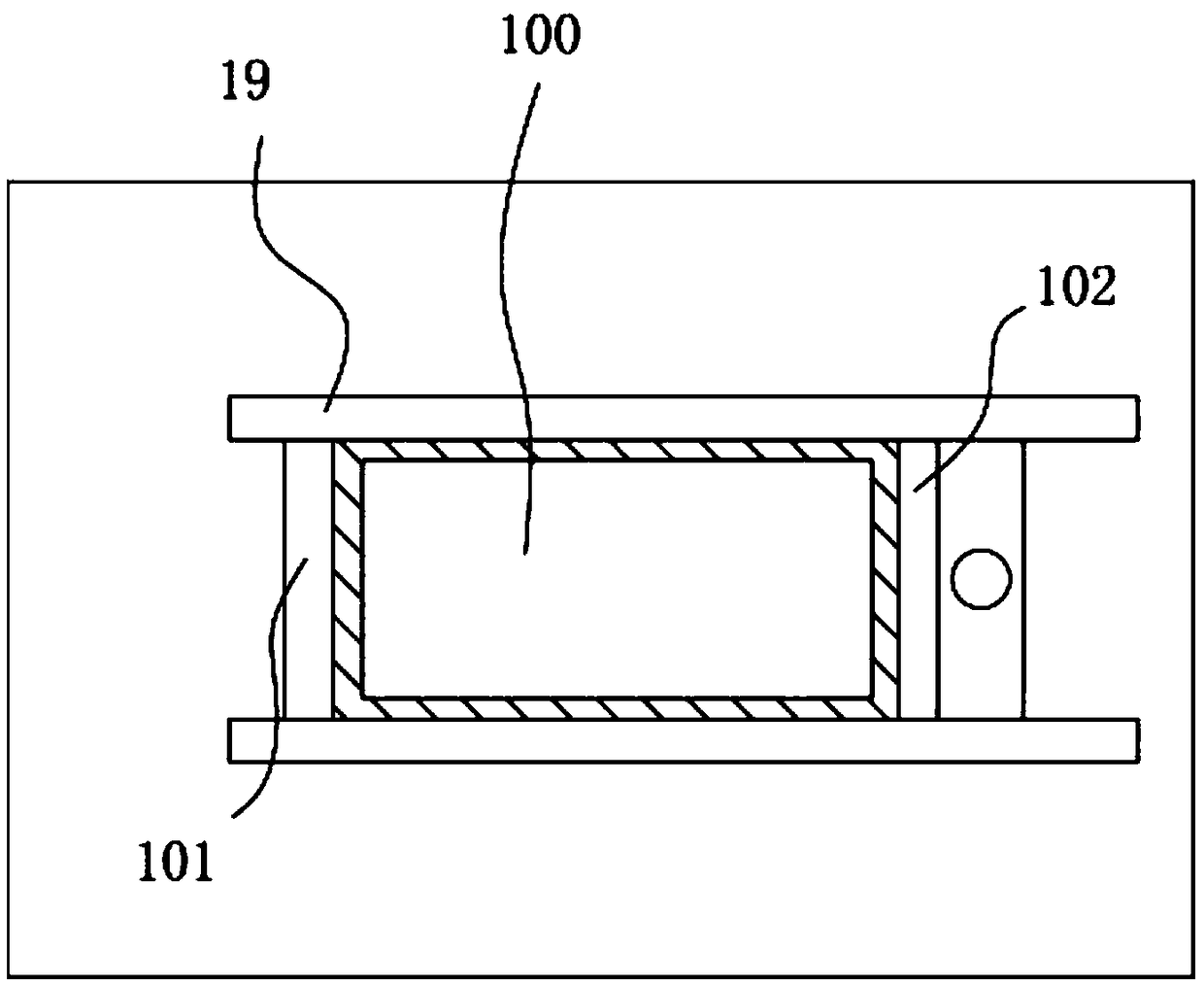

Color master batch processing stirring device and stirring method

The invention discloses a color master batch processing and stirring device and a stirring method, and relates to the technical field of color master batch stirring, the color master batch processing and stirring device comprises a stirring cylinder and a stirring mechanism, a feeding port is formed in the top end of the stirring cylinder, a feeding hopper is arranged at an opening of the feeding port, the stirring mechanism is arranged in the stirring cylinder, and the stirring mechanism is located under the feeding hopper; the stirring mechanism comprises a frustum-shaped material guiding seat, a first driving motor and an L-shaped transmission rod, the frustum-shaped material guiding seat is fixed in the stirring barrel through a supporting rod and located under the feeding hopper, a plurality of annular partition plates are fixedly arranged on the outer wall of the frustum-shaped material guiding seat, and discharging notches are formed in the radial side walls of the annular partition plates; the discharging notches of every two adjacent annular partition plates are distributed in a staggered mode. Color master batches to be stirred are fed into the stirring barrel through the feeding hopper, then the stirring barrel is used for conducting multi-stage rapid stirring operation on the color master batches, the stirring mechanism is small in load and short in time consumption, the color master batches are not prone to caking, and the stirring efficiency is improved.

Owner:安徽卡洛塑业科技有限公司

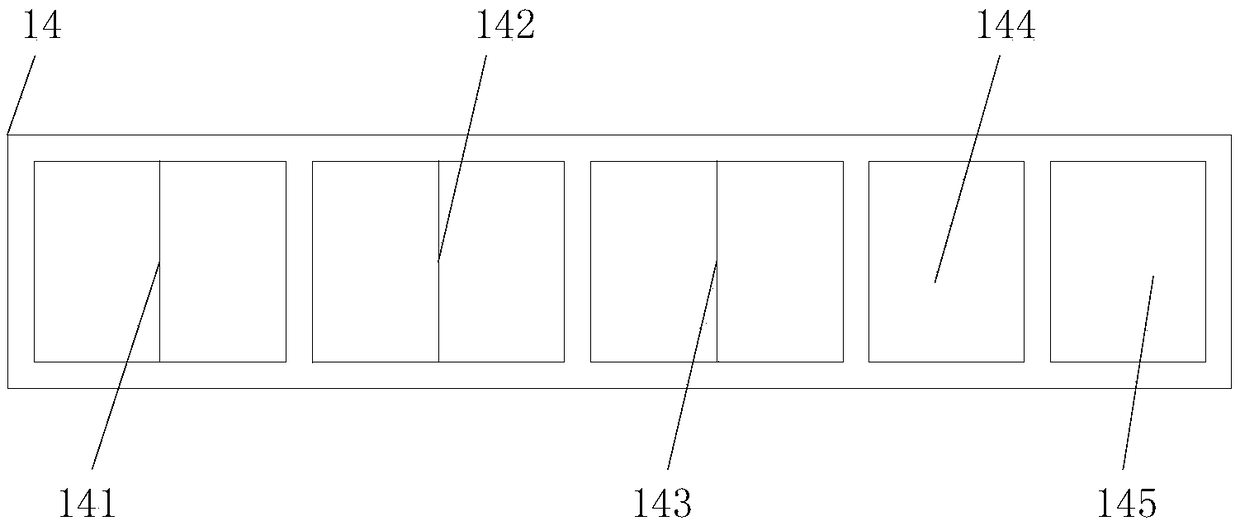

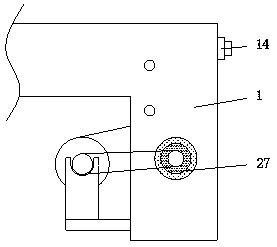

Mixing and stirring mechanism for long tank

InactiveCN108686548AMeet mixing needsImprove the mixing effectShaking/oscillating/vibrating mixersRotary stirring mixersEngineering

Owner:FOSHAN HAIYUE ZHIDA TECH CO LTD

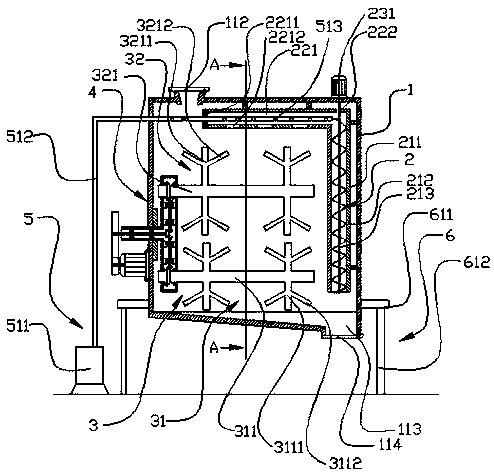

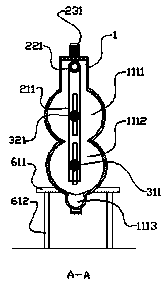

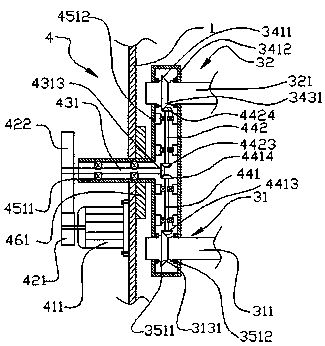

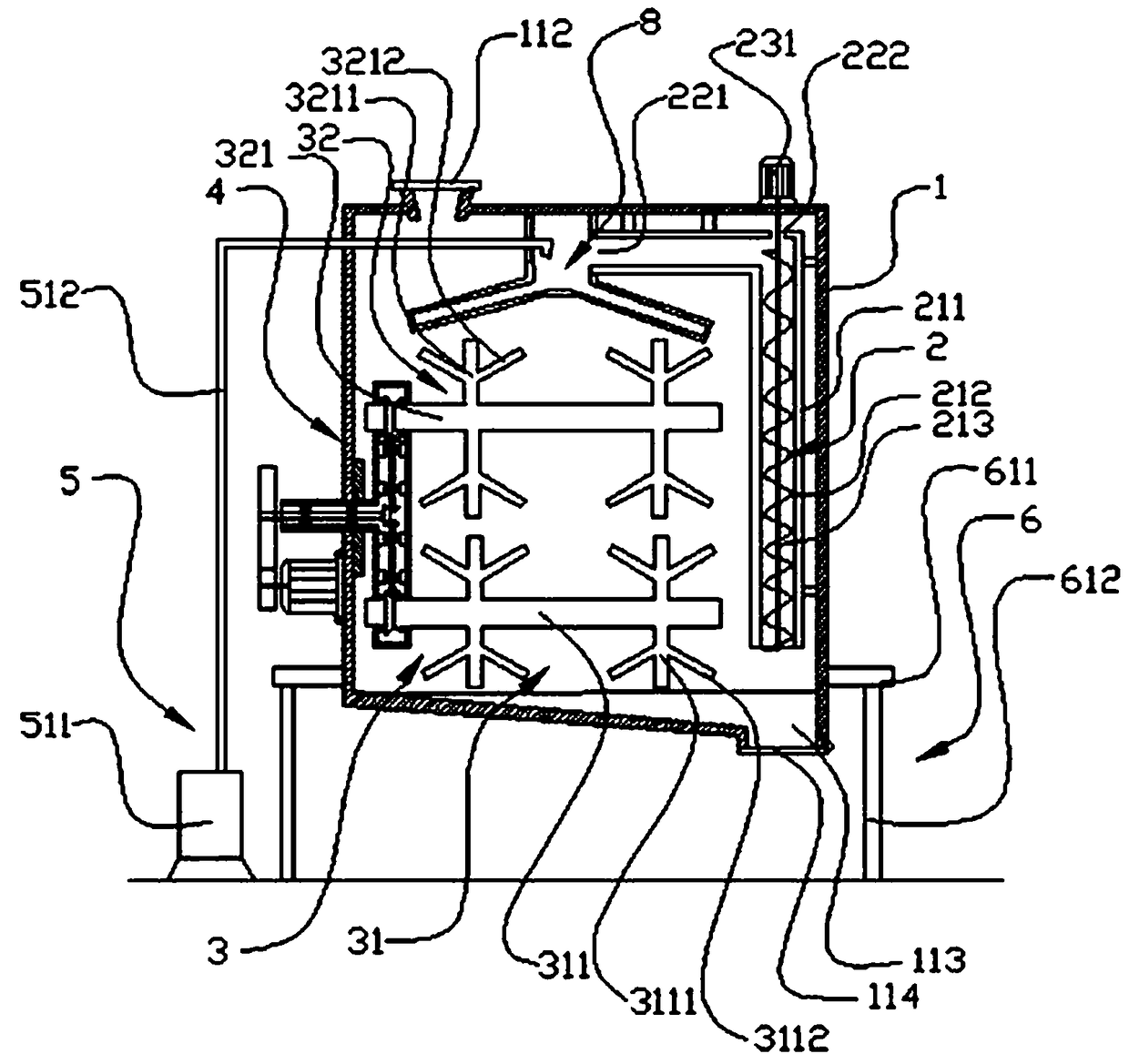

Stirring machine for buildings

InactiveCN106272965ARealize circulating stirringImprove the mixing effectDischarging apparatusCement mixing apparatusEngineering

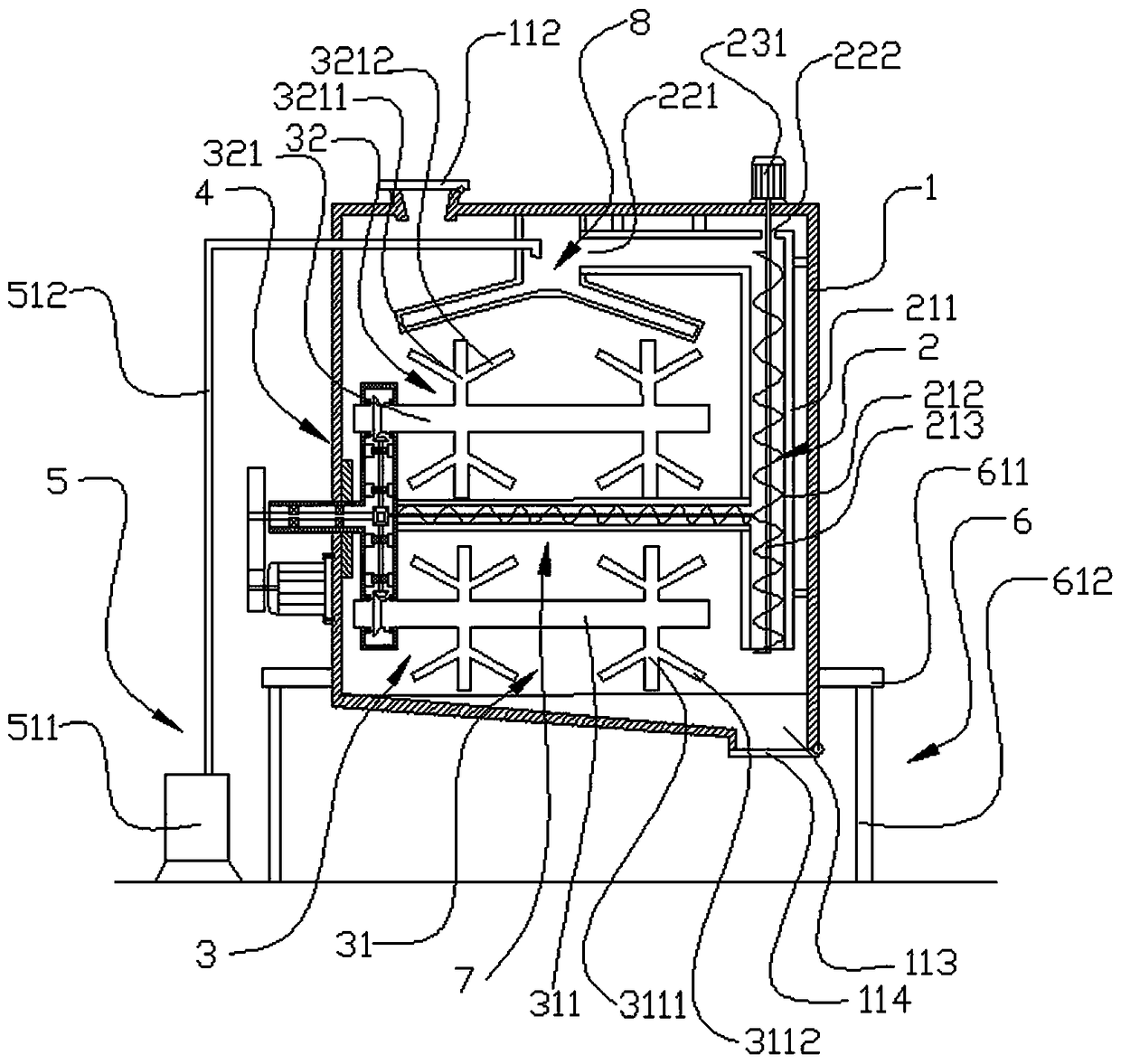

The invention discloses a stirring machine for buildings. The stirring machine comprises a shell, a vertical material guiding assembly, a stirring shaft assembly, a driving mechanism, a water inlet mechanism and a bearing mechanism, wherein materials enter the shell from a feed inlet in the shell; water enters the shell from the water inlet mechanism; stirring is achieved under the action of stirring shafts; the stirring shafts are driven through the driving mechanism; and materials at the bottom can be guided to the upper part to be fully stirred under the action of the vertical material guiding assembly, the stirring effect is improved, the segregation phenomenon of materials during the stirring process can be prevented, and after stirring, a discharge hole performs discharge. According to the stirring machine, stirring dead spaces in a traditional device are eliminated, the stirring effect is improved, and the stirring machine is suitable for wide application in the field of stirring.

Owner:晟唐伟业建设集团有限公司

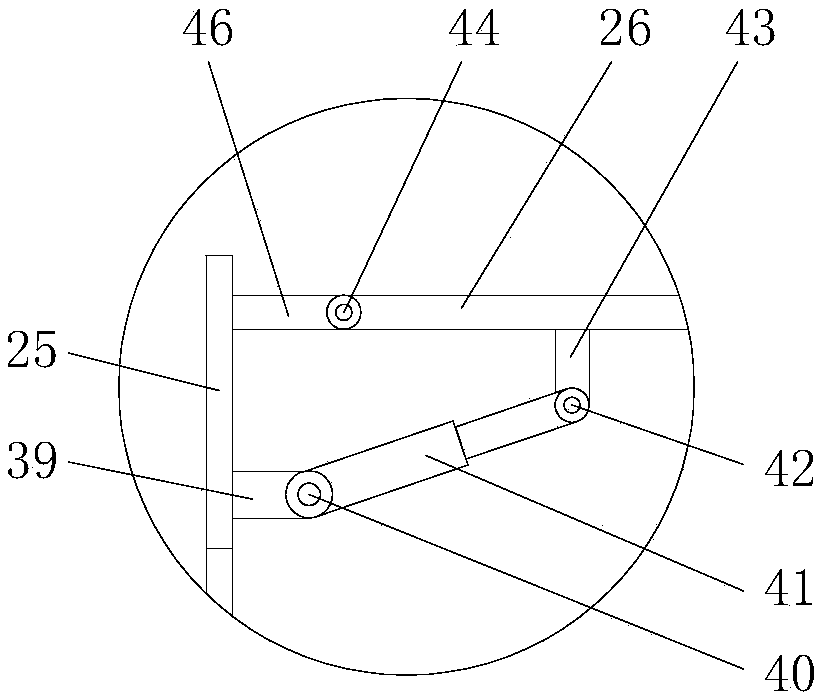

Stirring device

InactiveCN113019190AReduce angleMeet mixing needsRotary stirring mixersTransportation and packagingEngineeringCentrifugal force

The invention belongs to the technical field of fluid stirring, and discloses a stirring device which comprises a tank body, a middle shaft and a stirring piece, a driving piece is arranged on the tank body, the middle shaft is located in the tank body, one end of the middle shaft is connected to the output end of the driving piece, and the driving piece can drive the middle shaft to rotate around the axis of the middle shaft; The stirring part comprises a plurality of blades, one end of the blades is hinged to the middle shaft, a plurality of blades are evenly distributed around the circumference of the middle shaft, and when the middle shaft rotates, the blades can be driven to rotate into a plane perpendicular to the middle shaft. The included angle between the blades and the middle shaft can be adjusted to be small or even overlapped, and the blades are not influenced by the length of the blades when entering through the tank opening of the tank body, so that the blades can be set to be large in size, and the driving piece drives the middle shaft to rotate when stirring is needed; under the effect of rotating centrifugal force, the blades rotate into the plane perpendicular to the middle shaft from the free drooping state, the blades with the large size can be unfolded to fully stir the coating, and the stirring device is suitable for stirring the coating with the high solid content and the high viscosity.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

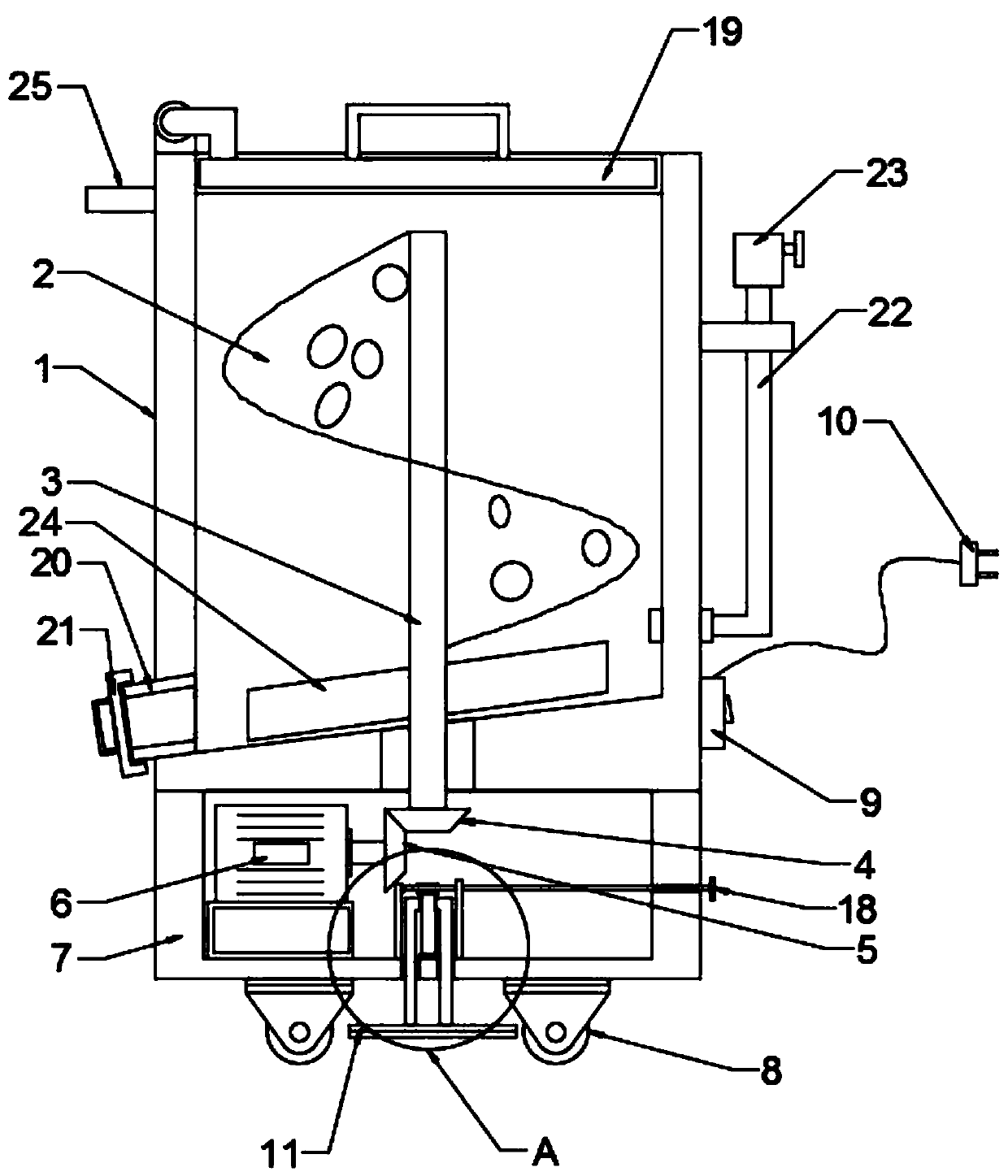

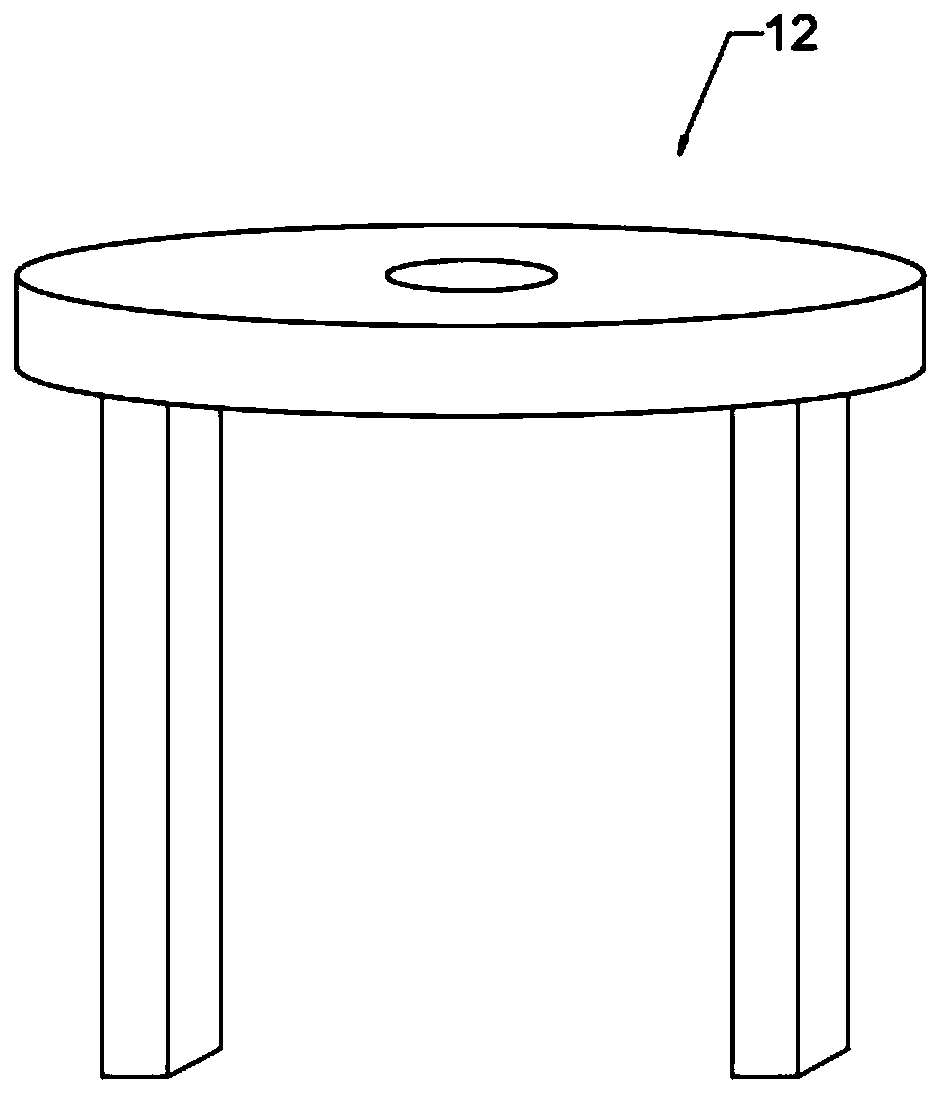

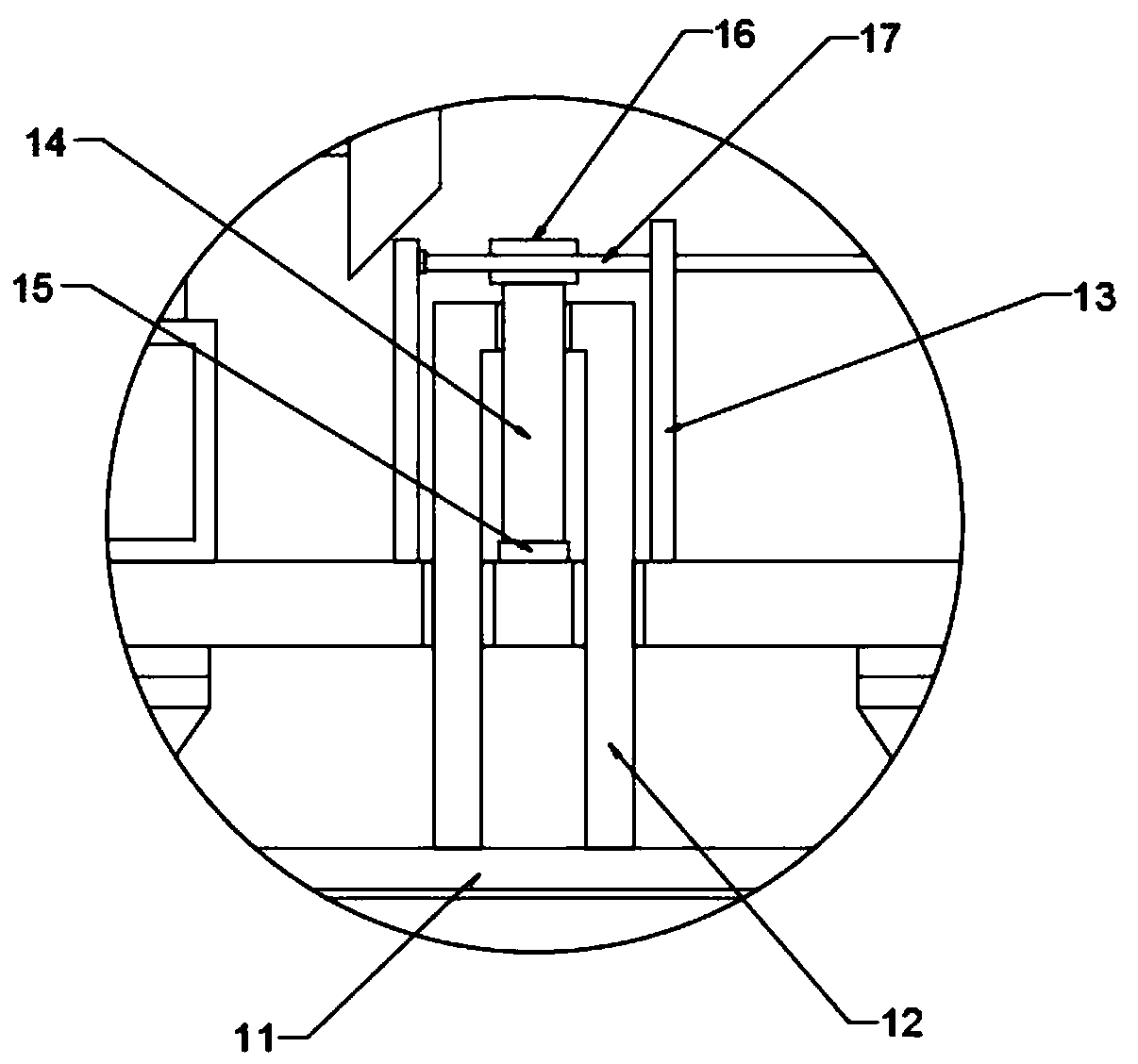

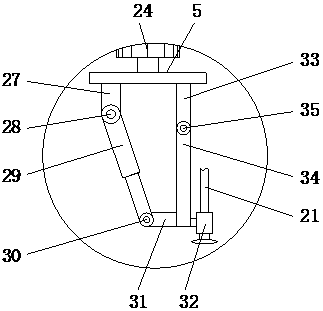

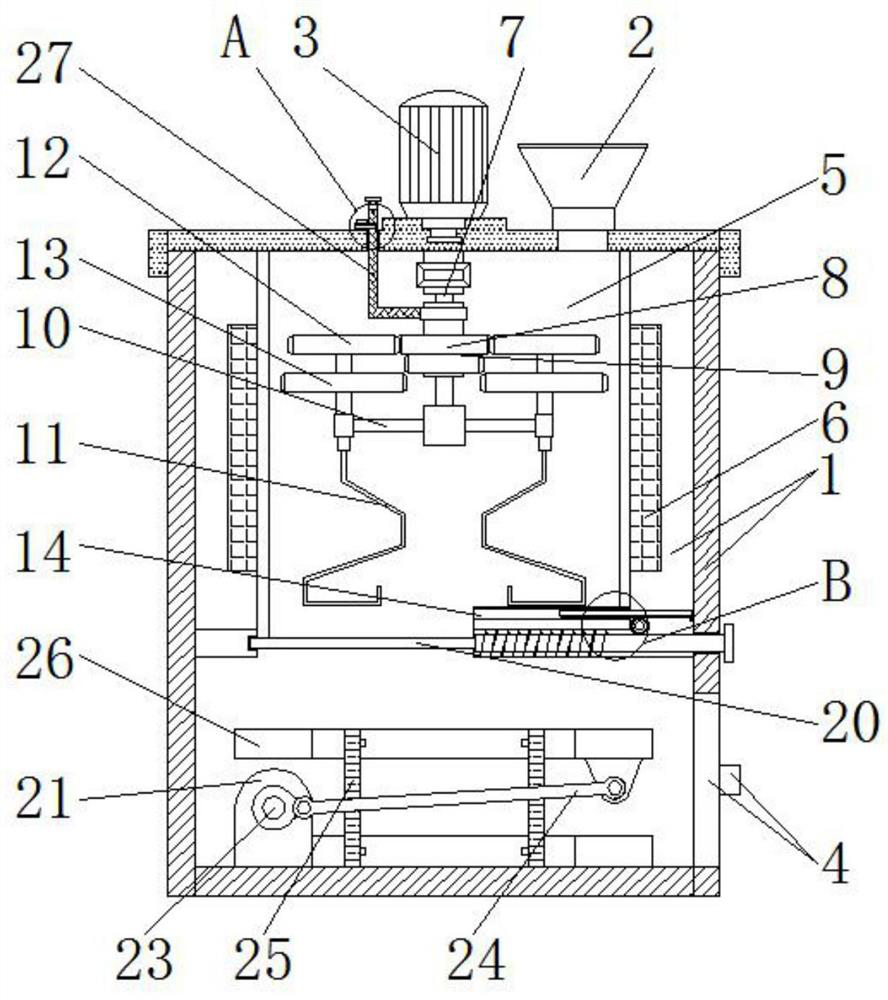

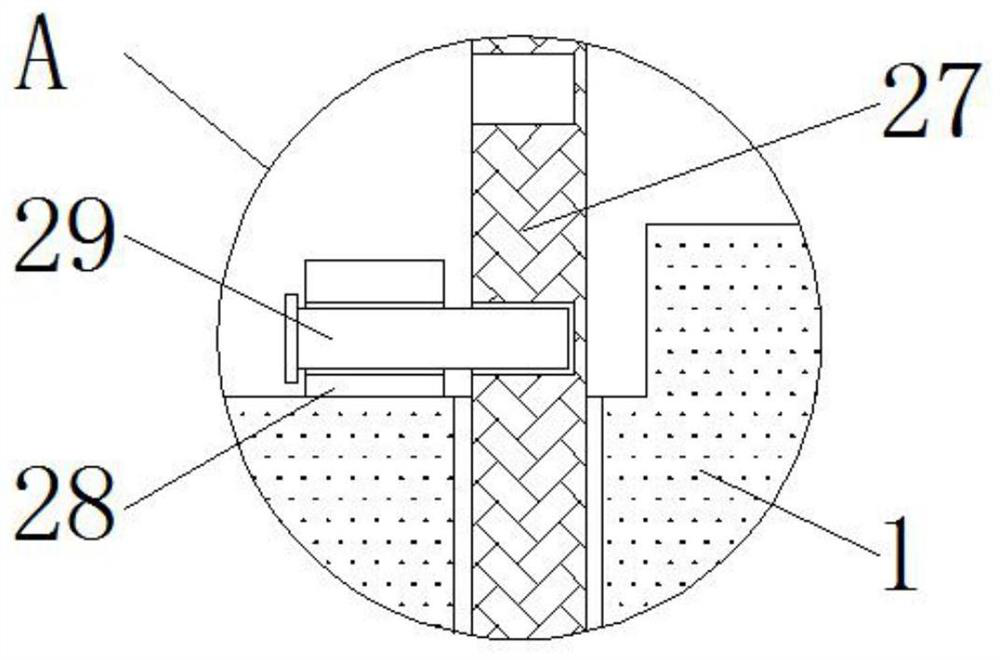

Indoor concrete stirring device for building decoration

ActiveCN110757650AGood stabilityReduce vibrationDischarging apparatusCement mixing apparatusRubber matStructural engineering

The invention discloses an indoor concrete stirring device for building decoration. The indoor concrete stirring device comprises a stirring barrel, wherein a movable seat is fixedly connected below the stirring barrel; rollers which are distributed in the peripheral direction are arranged below the movable seat; and a liftable abutting plate is arranged between the rollers. According to the indoor concrete stirring device disclosed by the invention, the abutting plate, a lifting frame, a guide barrel, a lead screw, a worm gear and worm and a regulating wheel are arranged, so that when the stirring device works, the movable seat has relatively good stability, vibration of the stirring device is reduced, and stirring quality is guaranteed; a rubber pad is arranged on the lower end surface of the abutting plate, so that vibration noise is reduced, and therefore, the indoor concrete stirring device is suitable for construction of a home decoration environment; and the movable seat, a pushing handle and the stirring barrel are arranged, so that the stirring device is conveniently moved, and therefore, small-batch multi-frequency concrete stirring needs in a decoration process are met.

Owner:博兴兴博城建投资集团有限公司

Chemical spraying device

InactiveCN108380412AReduce pollutionMeet mixing needsLiquid spraying apparatusPolypropyleneCompound (substance)

The invention discloses a chemical spraying device which comprises a support seat. A filter tank is fixedly connected to the left end of the bottom part of the support seat; a polypropylene filter screen layer, a particle filter screen layer and a sponge filter layer are sequentially and fixedly connected into an inner cavity of the filter tank from top to bottom; and a reflowing hole is formed between the left end of the top part of the filter tank and the left end of the bottom part of a reflowing tank. According to the chemical spraying device provided by the invention, a first slider is slidably connected to the outer surface of a first sliding seat, a second slider is slidably connected to the outer surface of a second sliding seat, a first electric telescopic rod is fixedly connectedto the bottom part of the second slider, a second support rod and a fifth support rod are sequentially and fixedly connected to the bottom part of a first support rod from left to right, and throughthe action of a first movable joint, a second electric telescopic rod, a second movable joint, a third support rod, a third movable joint, a fourth support rod and a steering motor, the demand on all-dimensionally spraying a chemical product without a dead corner can be met, and great convenience is brought for the use by people.

Owner:李丽倩

Concrete mixer

ActiveCN106182419ARealize circulating stirringImprove the mixing effectCement mixing apparatusLiquid ingredients supply apparatusMixing effectMechanical engineering

The invention discloses a concrete mixer. The concrete mixer comprises a shell, a vertical leading assembly, a mixing shaft assembly, a driving mechanism, a water feeding mechanism and a bearing mechanism; a material enters the shell through a feed port in the shell; water enters the shell from the water feeding mechanism; the mixing is realized under an effect of a mixing shaft; the mixing shaft is driven by the driving mechanism; the material at the bottom can be leaded to the upper part for fully mixing under an effect of the vertical leading assembly to promote a mixing effect and to prevent segregation phenomenon in the material mixing process; and the material is unloaded from a discharge port after mixing. The concrete mixer eliminates mixing dead angles in a traditional device, improves the mixing effect, and is suitable for wide application in the mixing field.

Owner:扬州扬工机械有限公司

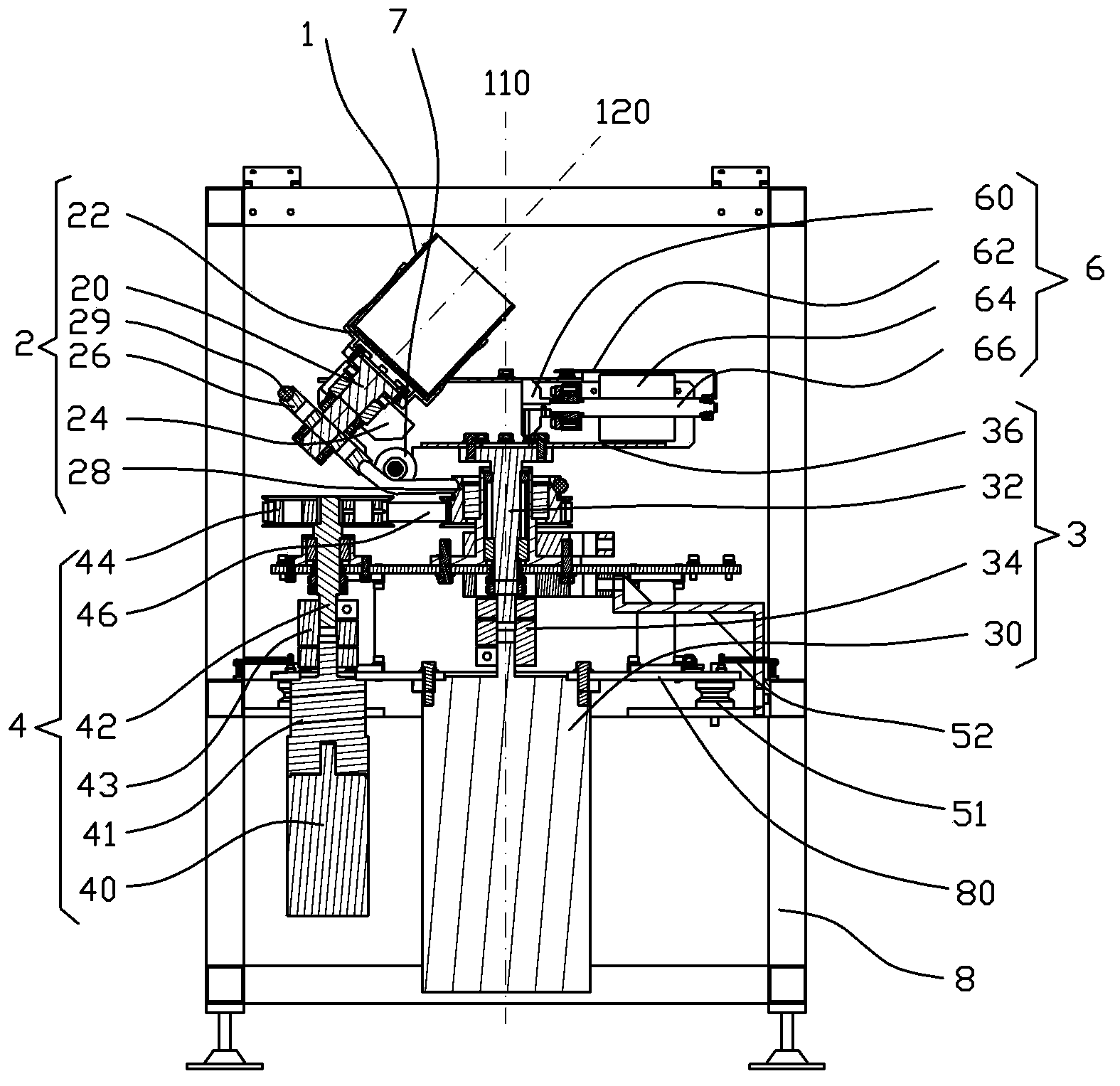

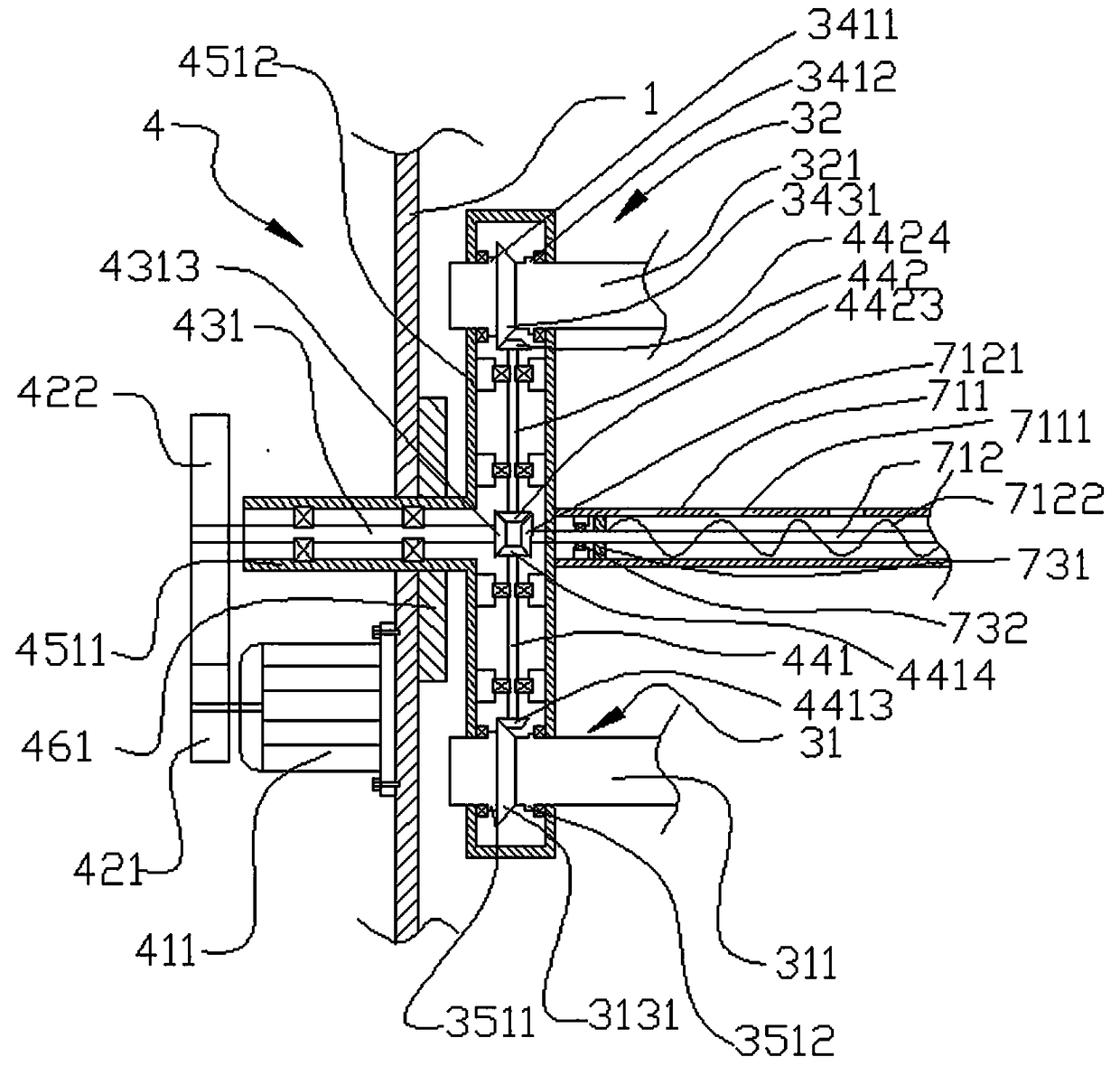

Autoroatation and revolution combined blender

The invention discloses an autoroatation and revolution combined blender. The autoroatation and revolution combined blender comprises a revolution system, an autoroatation system, a material barrel and a speed ratio regulating system, wherein the revolution system comprises a first motor, a revolution shaft and a rotating bottom plate fixed at the top end of the revolution shaft; the autoroatation system comprises an autoroatation shaft, a bearing disc, an autoroatation driven wheel, an autoroatation driving wheel and an autoroatation belt; the autoroatation shaft is arranged on the side edge of the rotating bottom plate through an autoroatation shaft fixed base, the bearing disc is fixed at the top end of the autoroatation shaft, the autoroatation driven wheel is fixed at the bottom end of the autoroatation shaft, the revolution shaft is sleeved with the autoroatation driving wheel which is driven to rotate through the revolution shaft, and the autoroatation belt is wound between the autoroatation driving wheel and the autoroatation driven wheel; the material barrel is arranged on the bearing disc; the speed ratio regulating system comprises a second motor, a regulating rotating shaft, a regulating belt wheel fixed on the regulating rotating shaft and a regulating belt wound between the regulating belt wheel and the autoroatation driving wheel. The invention also discloses an autoroatation and revolution speed ratio regulating method based on the blender. The autoroatation and revolution combined blender provided by the invention has the advantages that the rotating speed and steering of the second motor are regulated, and different applied forces can be acted on the autoroatation driving wheel, so that the autoroatation rotating speed of the autoroatation system is regulated.

Owner:SHENNAN CIRCUITS

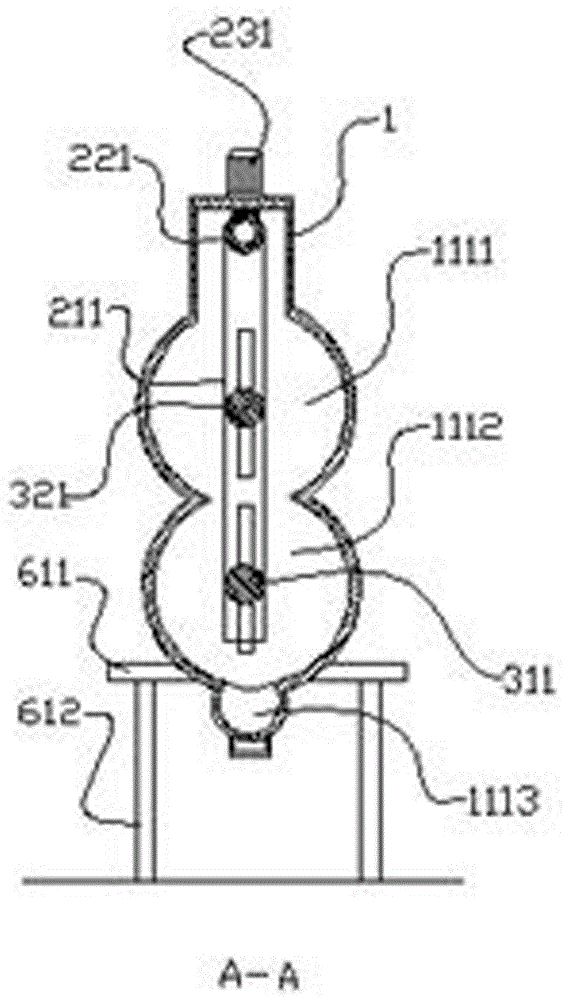

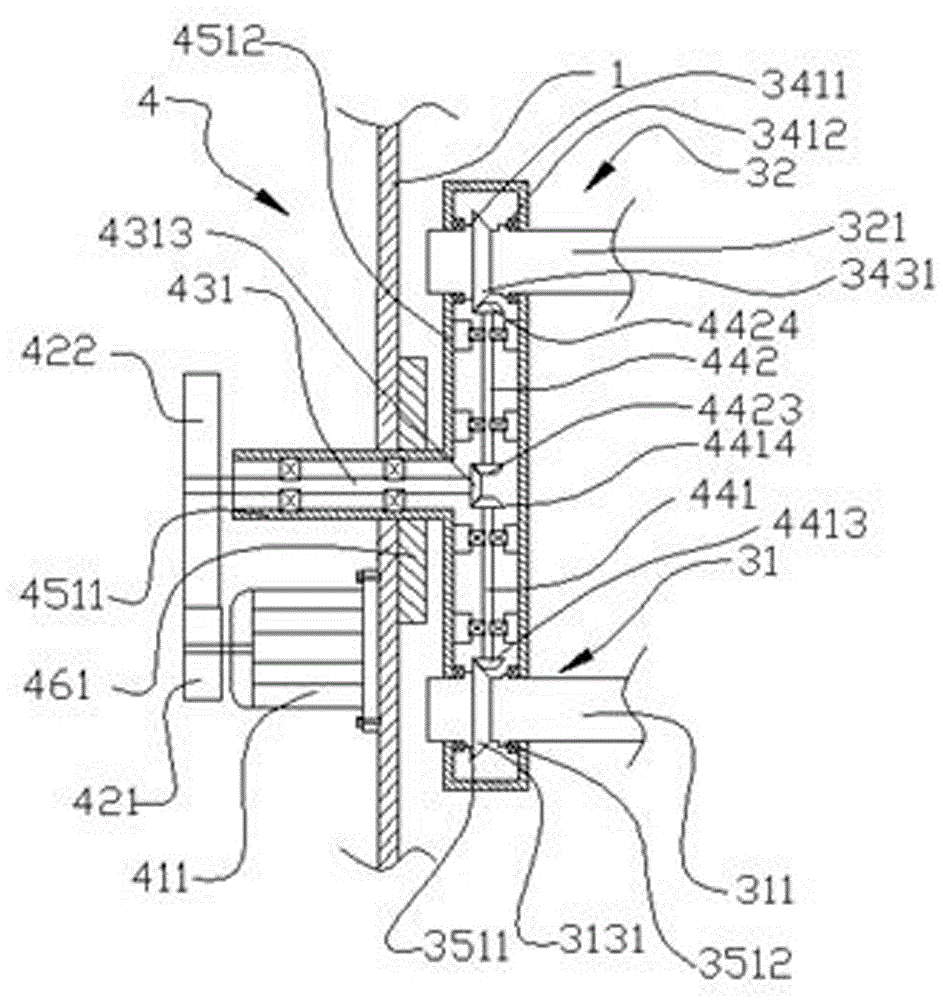

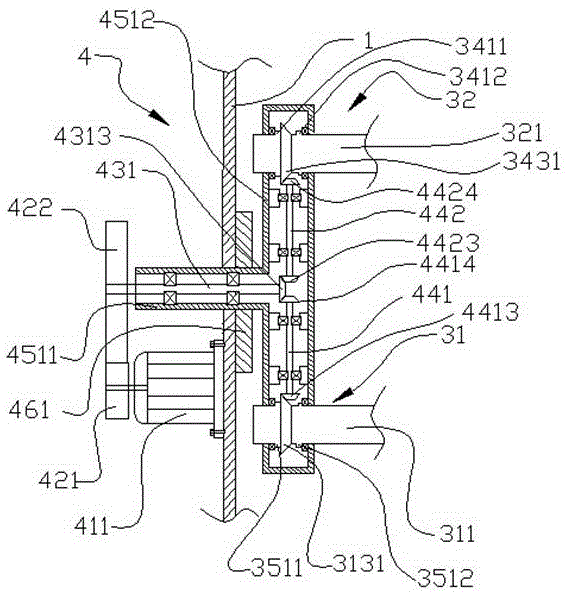

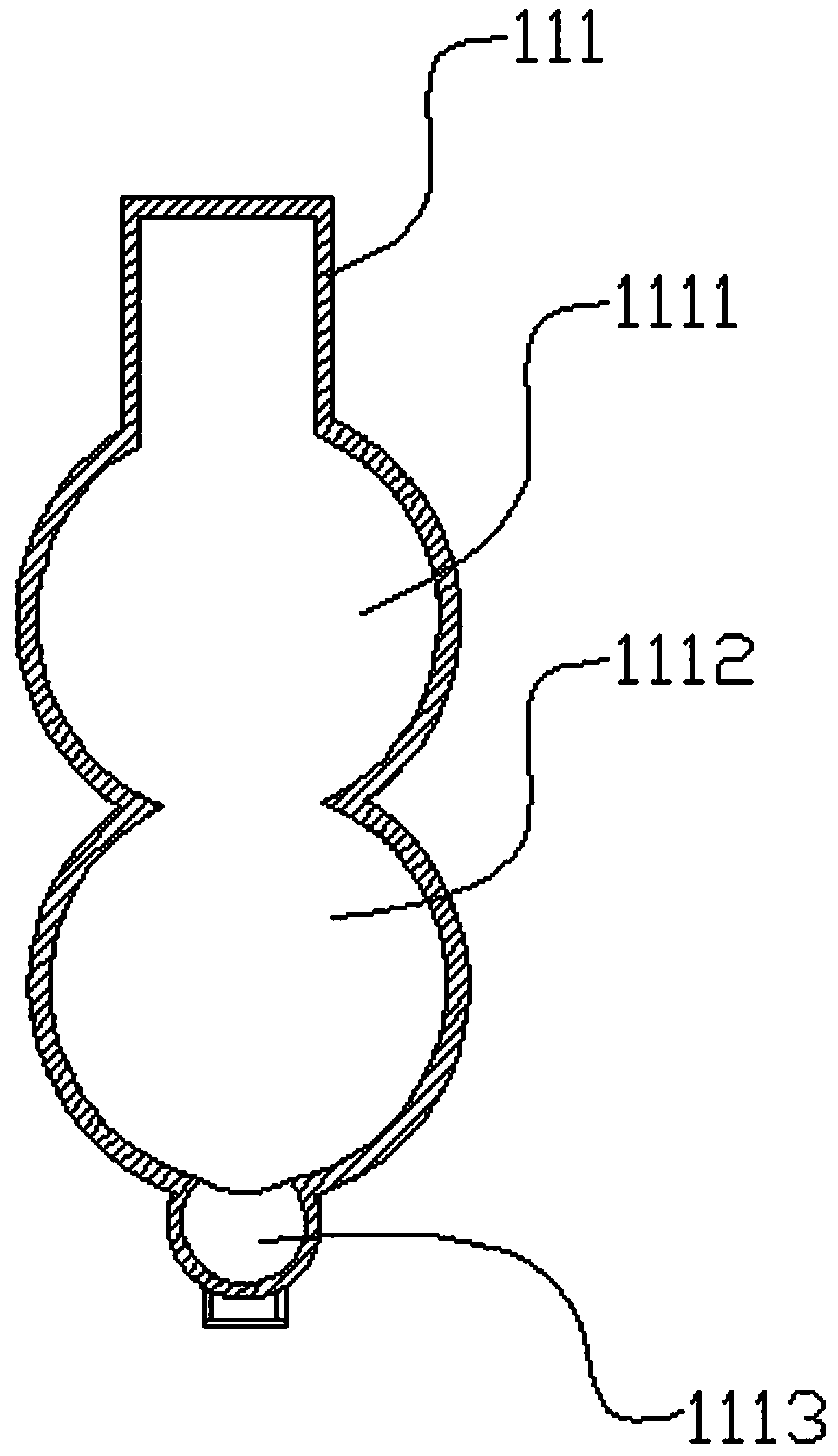

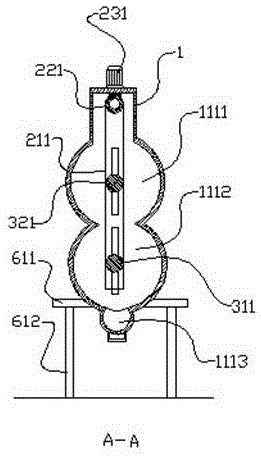

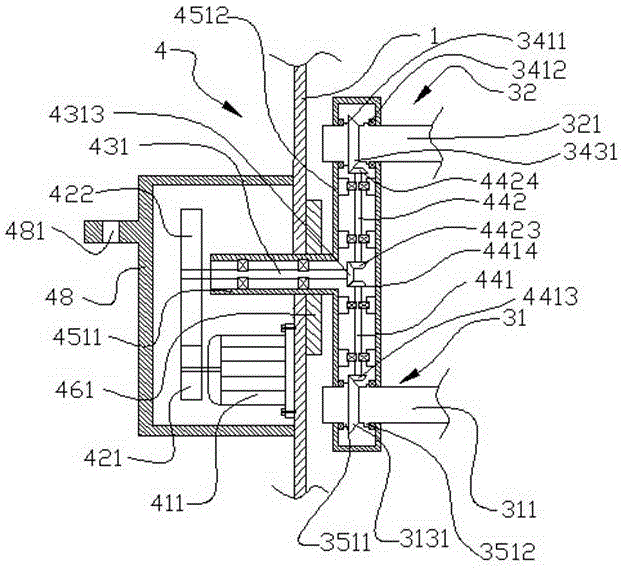

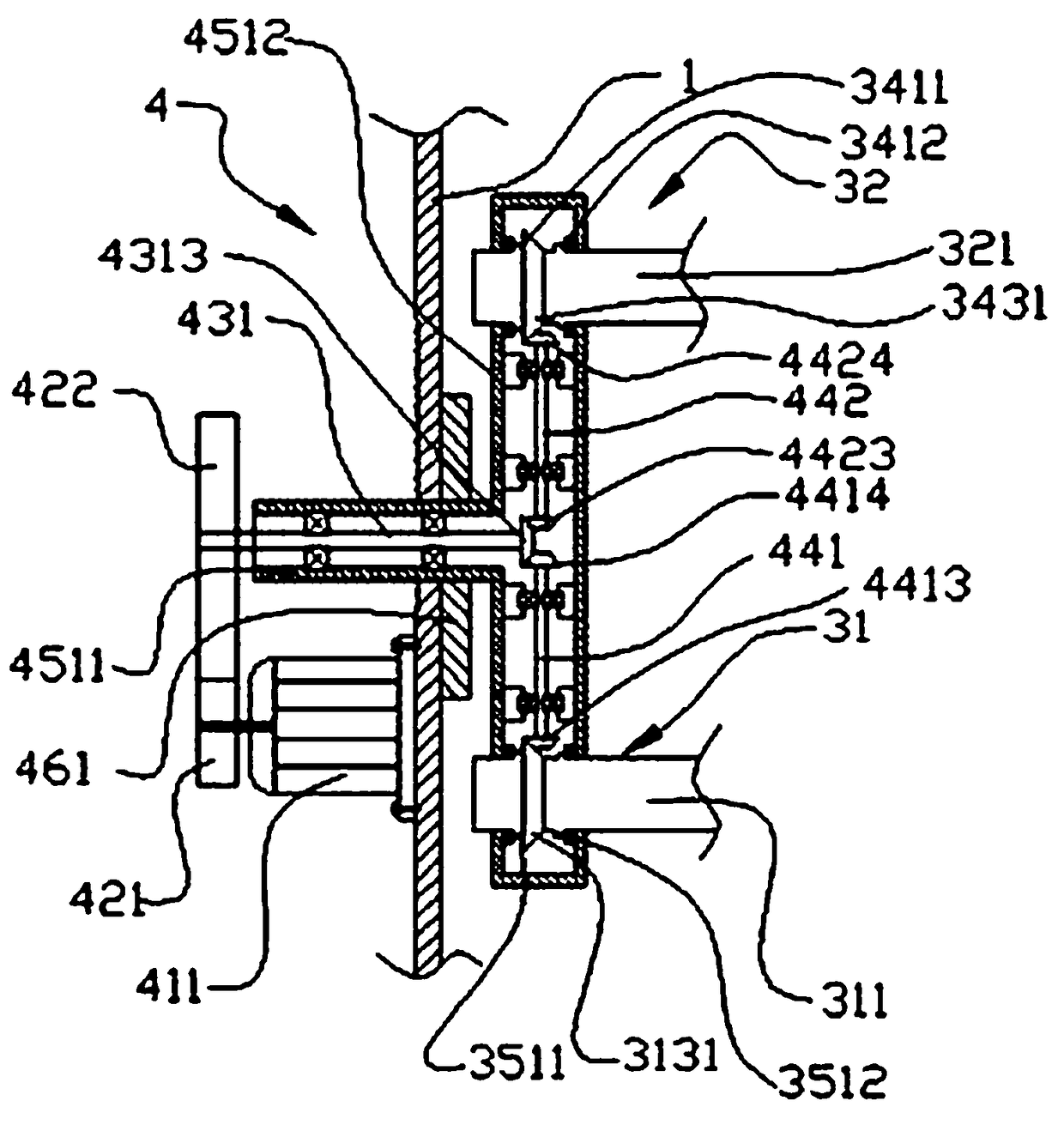

Top-insertion type short-cantilever stator-rotor stirring device

The invention relates to a top-insertion type short-cantilever stator-rotor stirring device comprising a rotation shaft, a bearing seat, a bearing gland, an emulsification support, a rotor, a stator, a sleeve, and an inducer. The bearing seat is connected with the emulsification support. The rotation shaft penetrates through the bearing seat and the emulsification support, and is arranged in the bearing seat through a bearing. The rotor is arranged on the rotation shaft. The stator is positioned on the outer side of the rotor and is connected with the lower end of the emulsification support. A connection plate is arranged on the upper end of the sleeve. The sleeve is sleeved on the outer side of the rotation shaft below the stator, and is connected with the bottom end of the stator through the connection plate. The inducer is arranged on the rotation shaft, and is positioned in the sleeve. The bearing gland penetrates through the rotation shaft, and is arranged between the bearing seat and the emulsification support. According to the invention, cantilever length is greatly shortened, system stiffness is improved, and resonance frequencies of various stages are improved, such that higher rotation speed and lower space between the stator and the rotor are realized. High-quality and high-efficiency mixing of the materials is realized, and equipment reliability can be improved.

Owner:LIUZHOU HUT CHEM MACHINERY

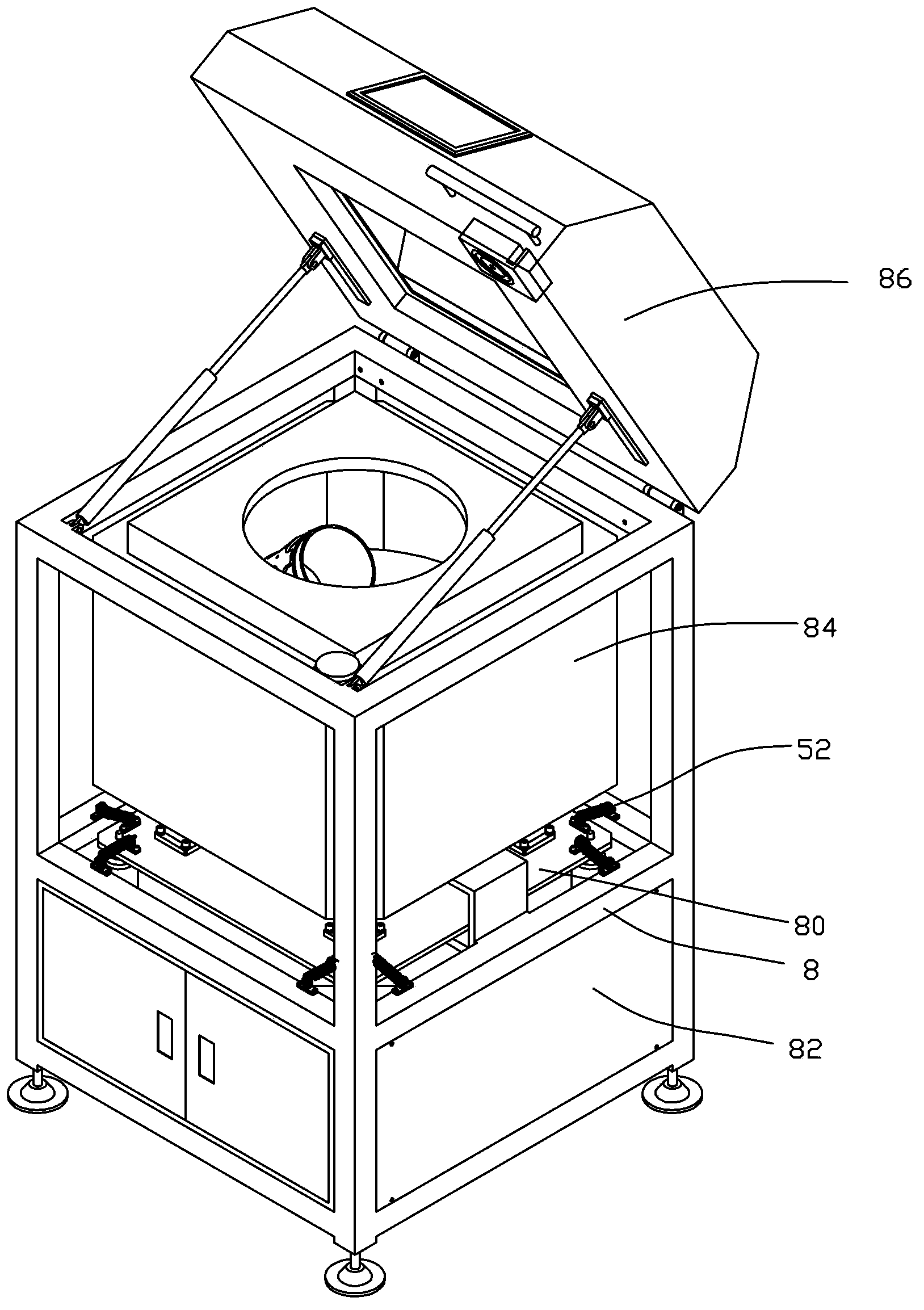

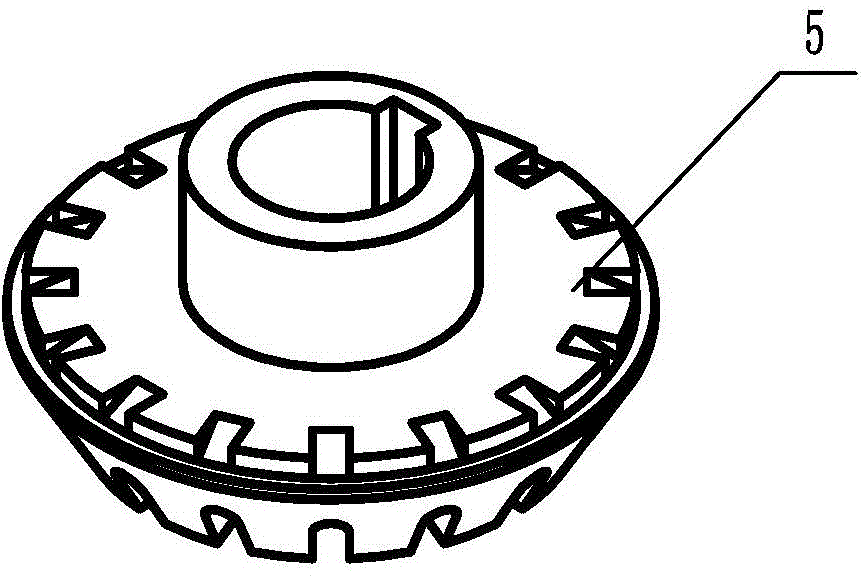

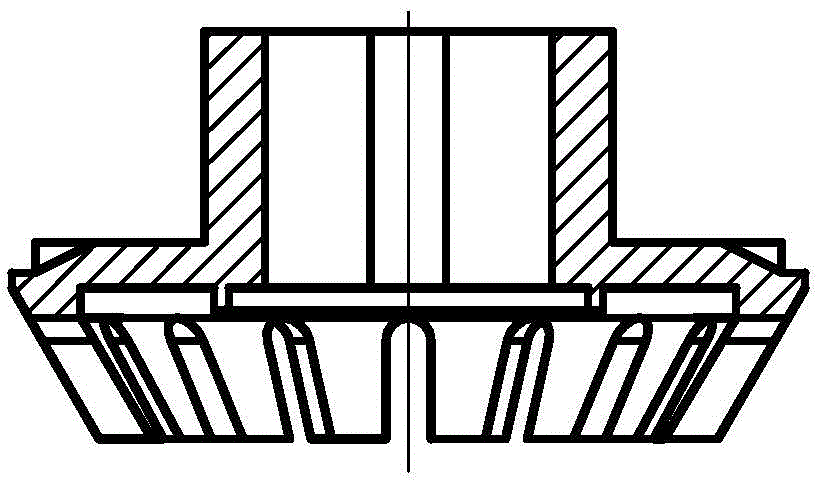

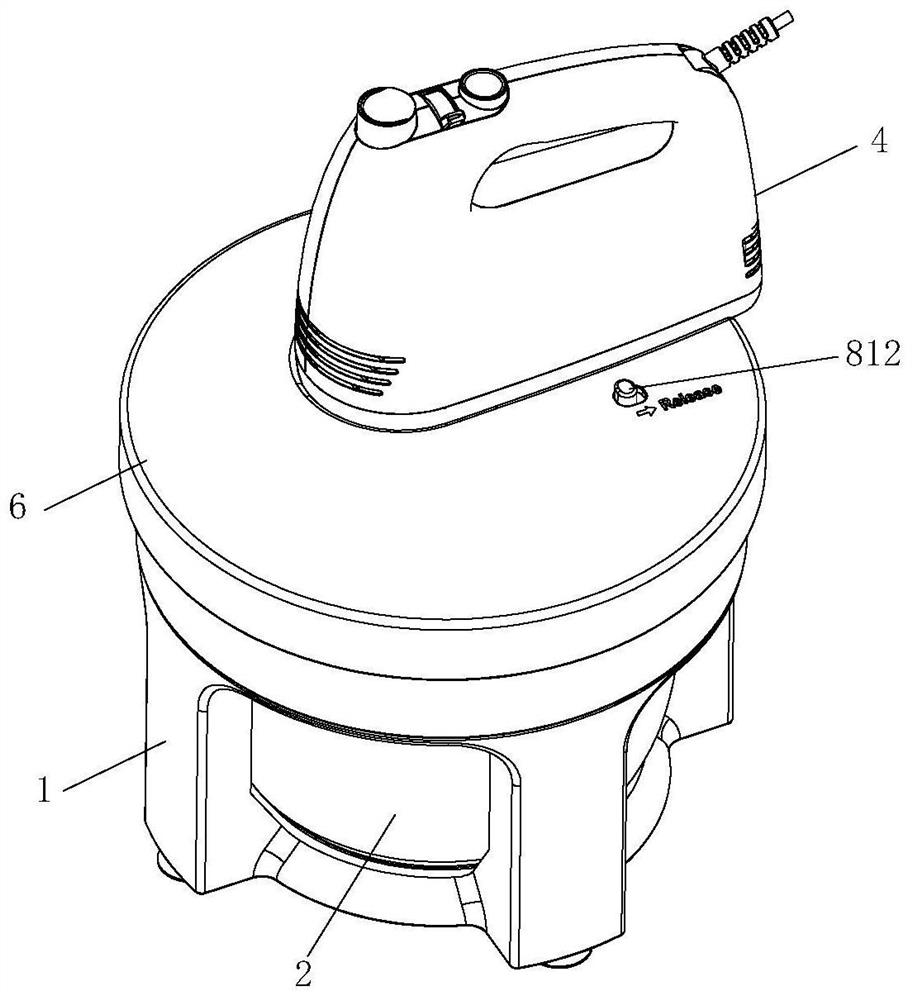

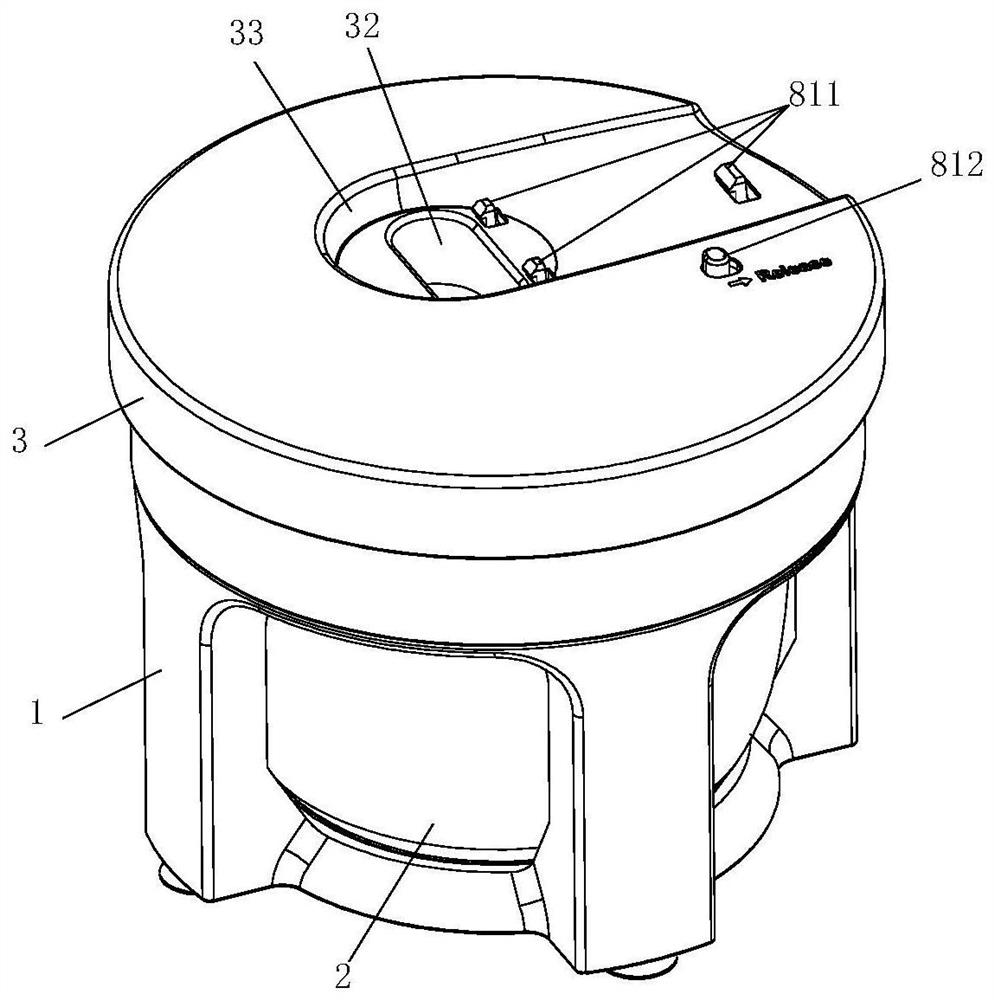

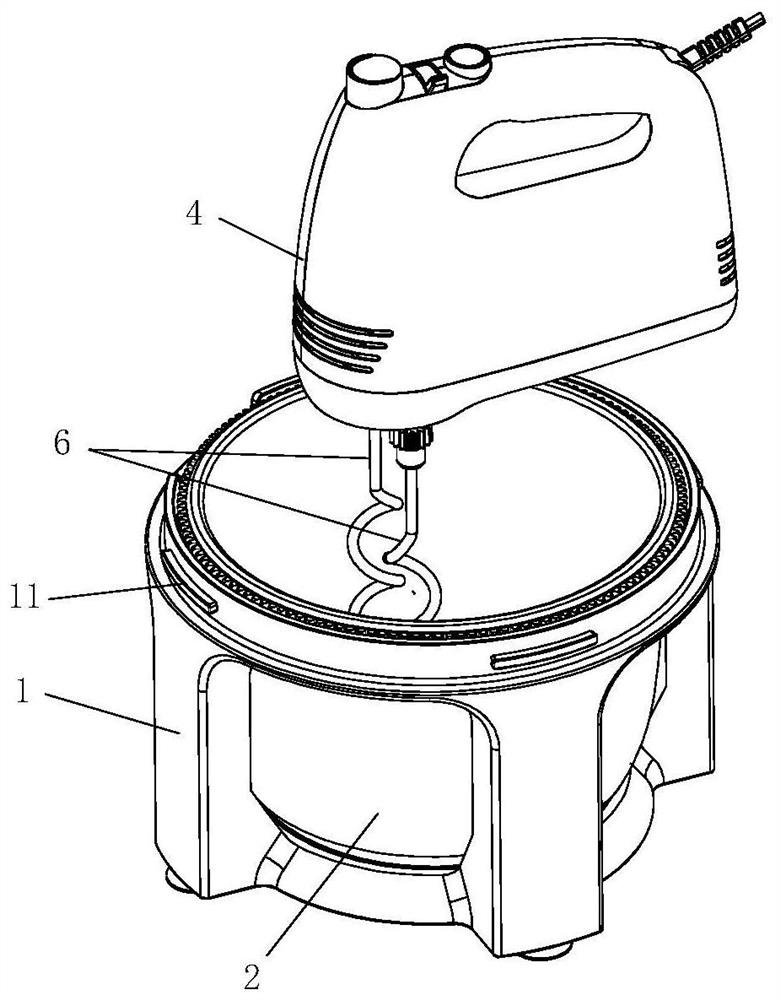

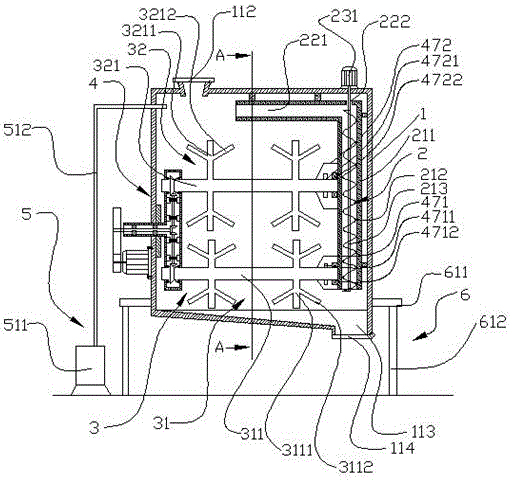

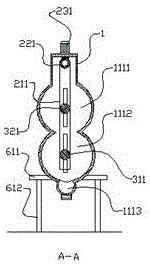

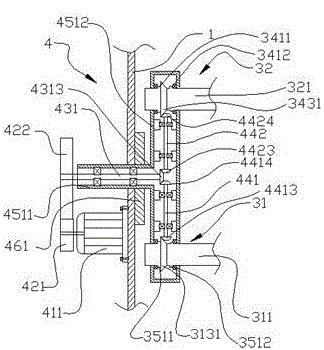

Stirring machine

PendingCN111973014AGuaranteed uptimeEasy to operateKitchen equipmentFood materialMechanical engineering

The invention relates to a stirrer. The stirrer comprises a base, a stirring bowl, a bowl cover and a main machine. The stirring bowl is mounted in the base; the bowl cover is detachably connected with the top of the base, and a first transmission mechanism is arranged in the bowl cover; the main machine is detachably mounted on the bowl cover; and a driving mechanism is arranged in the main machine, the driving mechanism is connected with a stirring mechanism, the stirring mechanism can penetrate through the bowl cover to extend into the stirring bowl, a first transmission mechanism is arranged in the bowl cover, and the stirring mechanism is in transmission connection with the stirring bowl through the first transmission mechanism so as to drive the stirring bowl to rotate together whenthe driving mechanism drives the stirring mechanism to rotate and stir. The stirring mechanism is driven by the driving mechanism to rotate and stir, and meanwhile, the stirring bowl can be driven torotate together, so that the stirring efficiency and the stirring effect are effectively improved, stable operation of the stirring bowl can be guaranteed, food materials are prevented from splashingduring stirring, and the service life of the stirrer is prolonged; and in addition, all parts of the stirrer are convenient to disassemble and assemble, the size of the whole machine is small, and cost can be reduced.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Stirring machine for construction

ActiveCN106182420ARealize circulating stirringImprove the mixing effectCement mixing apparatusLiquid ingredients supply apparatusArchitectural engineering

The invention discloses a stirring machine for construction. The stirring machine for construction comprises a shell, a vertical guiding assembly, a stirring shaft assembly, a driving mechanism, a water inlet mechanism and a carrying mechanism. Materials enter the shell through a feeding port in the shell. Water enters the shell from the water inlet mechanism. Stirring is achieved under the action of stirring shafts. The stirring shafts are driven by the driving mechanism. The materials at the bottom can be guided to the upper portion to be fully stirred under the action of the vertical guiding mechanism, so that the stirring effect is improved, the separation phenomenon of the materials in the stirring process can be prevented, and discharging is conducted through a discharging port after stirring is completed. By the adoption of the stirring machine for construction, stirring dead angles existing when a traditional device is used are eliminated, and the stirring effect is improved. The stirring machine for construction is suitable for being widely applied in the stirring field.

Owner:江苏力连重工机械有限公司

mixer for construction

ActiveCN106272964BInhibition of segregationStir wellMixing operation control apparatusCement mixing apparatusEngineeringBuilding construction

The invention discloses a building mixer. The building mixer comprises a shell, a vertical leading assembly, a stirring shaft assembly, a driving mechanism, a water feeding mechanism and a bearing mechanism; materials enter the shell through a feed port in the shell; water enters the shell from the water feeding mechanism; the stirring is realized under the effect of the stirring shaft; the stirring shaft is driven by the driving mechanism; and the materials can be leaded therein for fully stirring under the effects of the vertical leading mechanism and a middle feeding structure, so that the stirring effect is promoted, the segregation phenomenon in the material stirring process can be prevented, and the materials are unloaded by a discharge port after the stirring is finished. The building mixer eliminates the stirring dead angles in a traditional device, improves the stirring effect, and is suitable for wide application in the field of stirring.

Owner:中磐建设集团有限公司

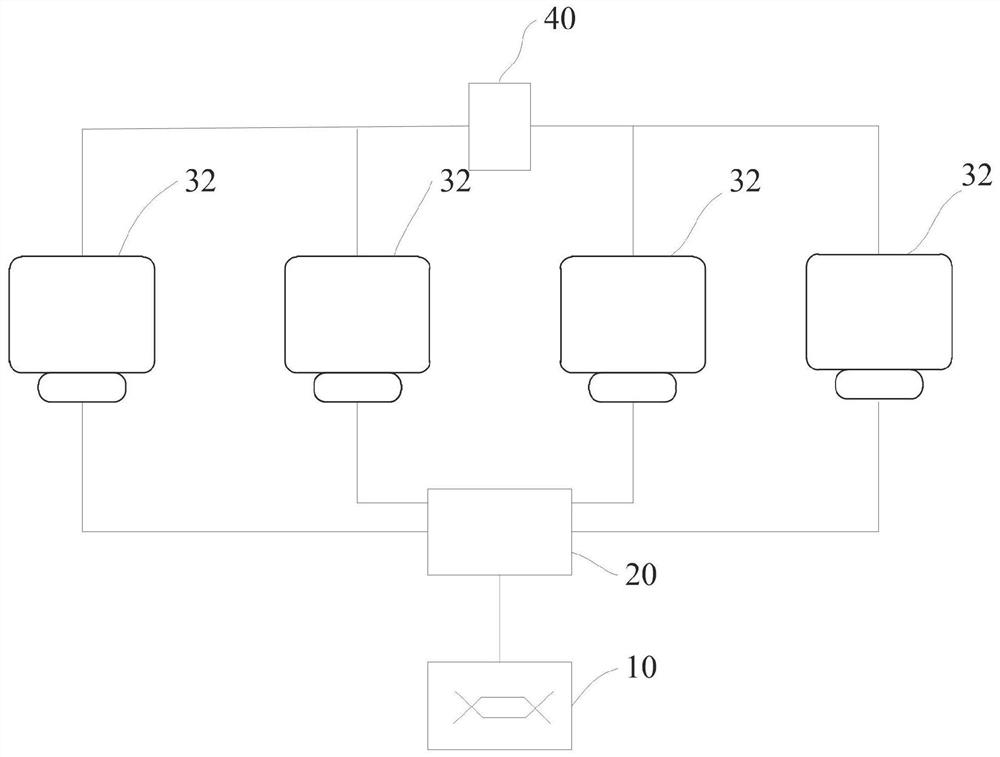

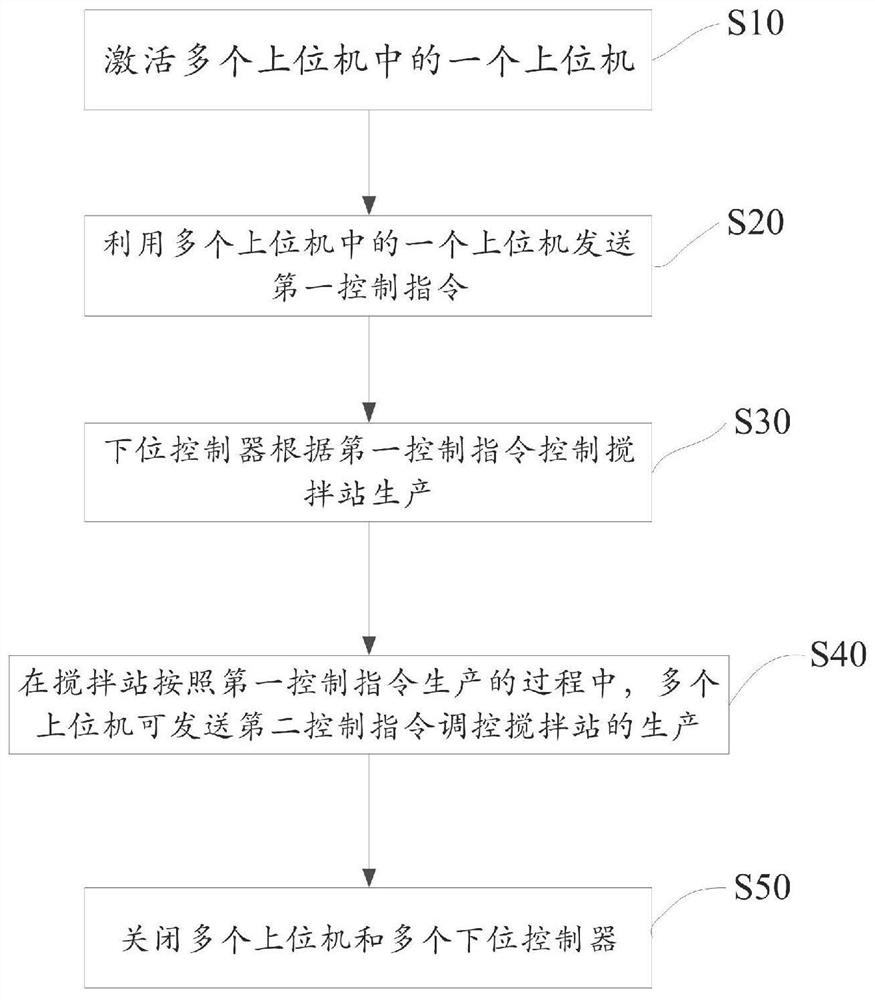

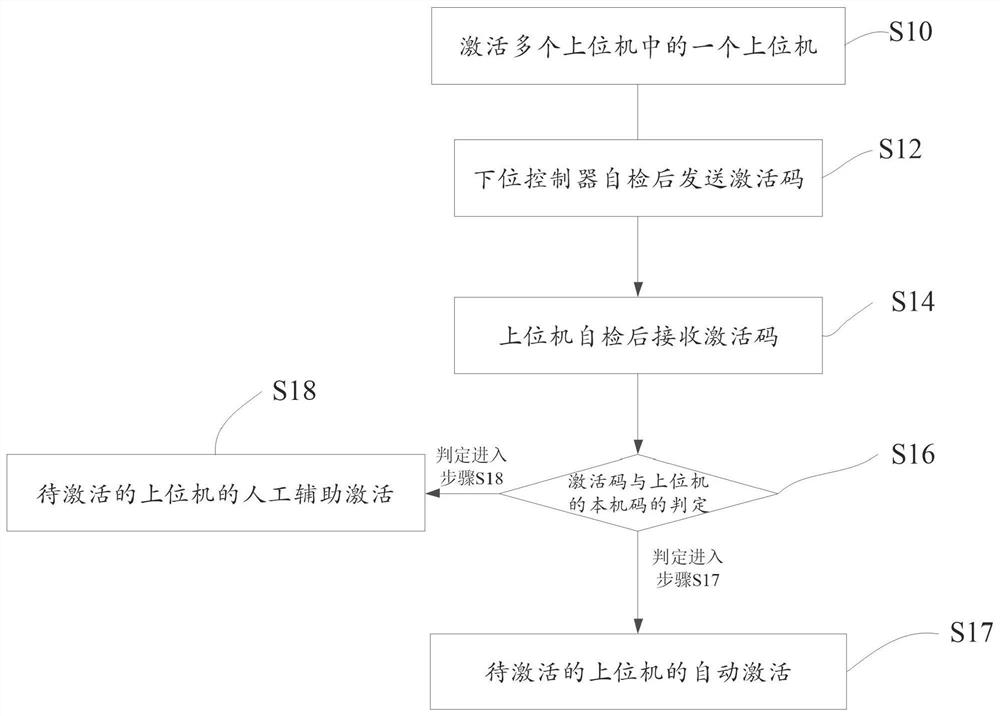

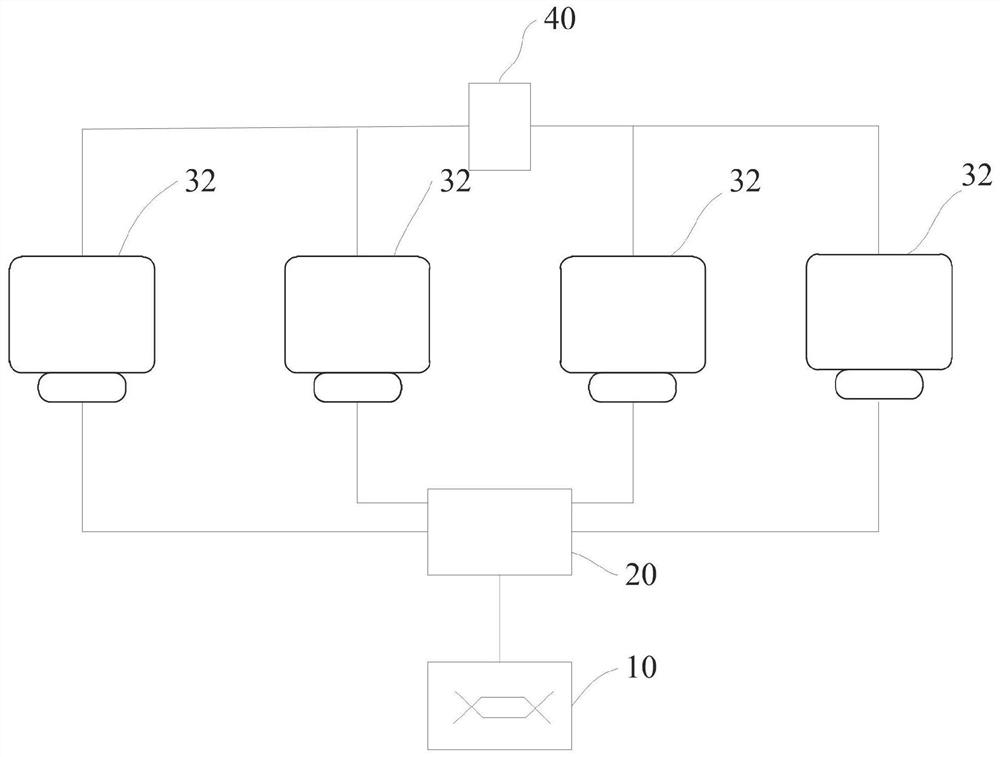

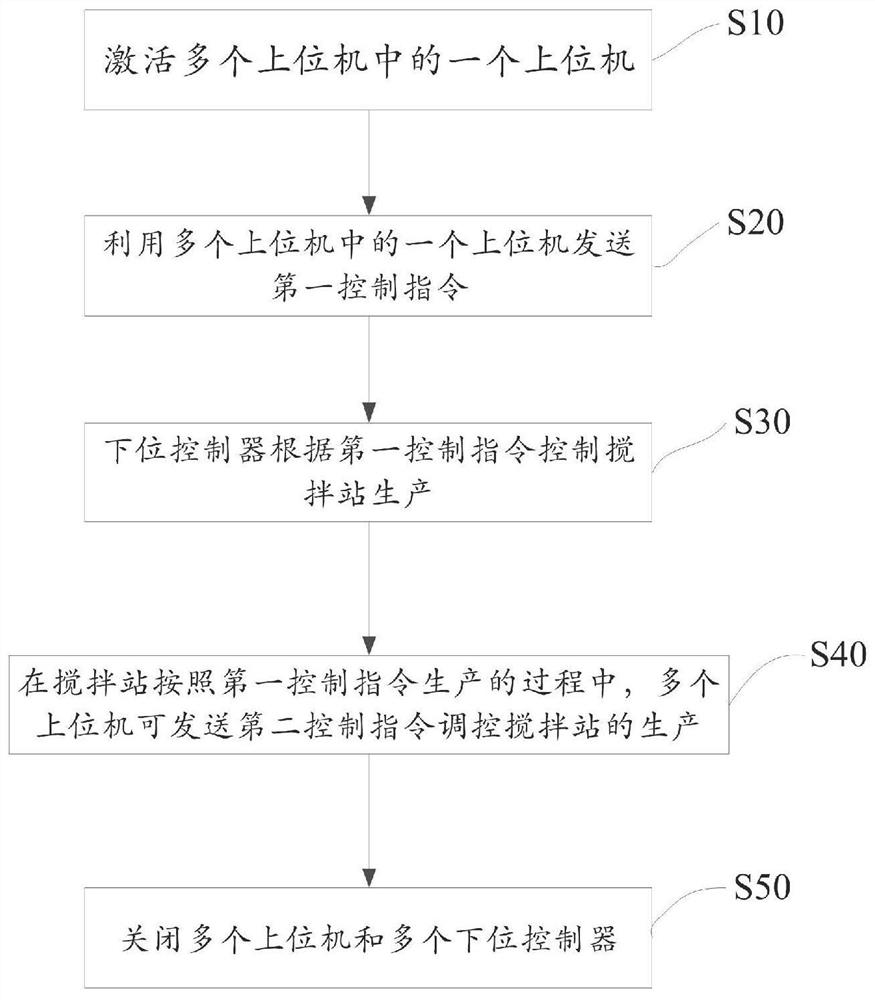

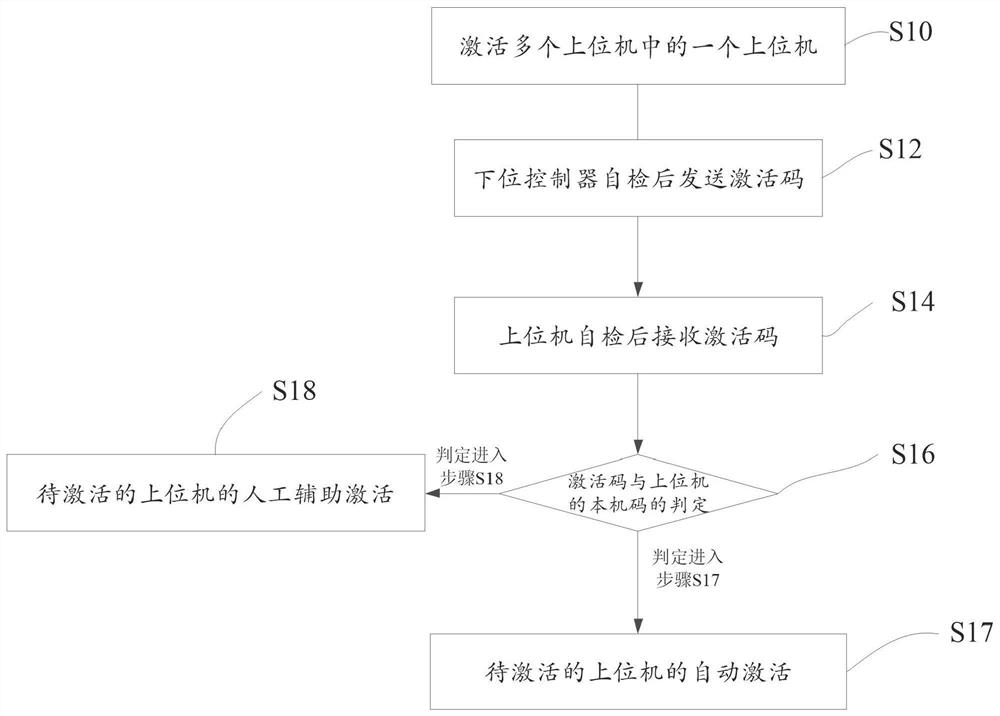

Control system and control method

ActiveCN112034798AIncrease productivityAvoid problems with more restrictive controlsTotal factory controlProgramme total factory controlControl systemControl engineering

The invention provides a control system and a control method. The control system comprises a mixing station, a lower controller which is connected with the mixing station, and an upper control devicewhich is connected with the lower controller, and comprises a plurality of upper computers. According to the technical scheme, the lower controller can control the mixing station to produce accordingto the first instruction and the second instruction so as to complete the on-site mixing production task, so that the plurality of upper computers can control the mixing station to produce by controlling the lower controller, and the one-station multi-control control function of the control system is realized, namely, a plurality of upper computers control one mixing station to produce.

Owner:SANY AUTOMOBILE MFG CO LTD

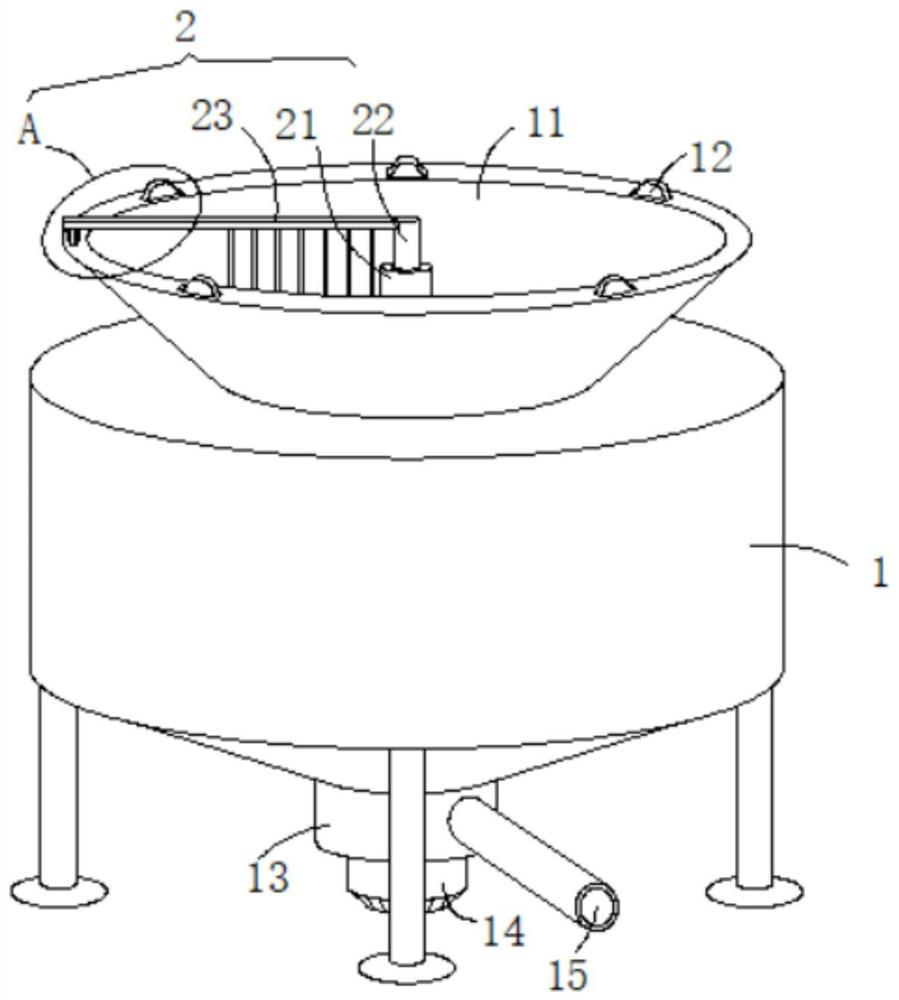

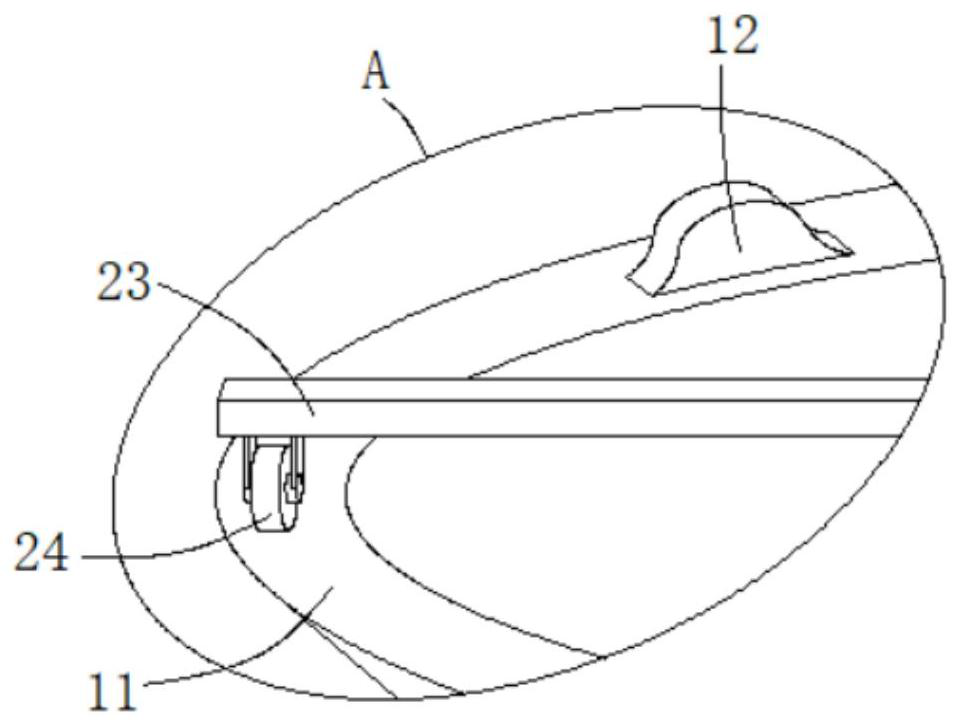

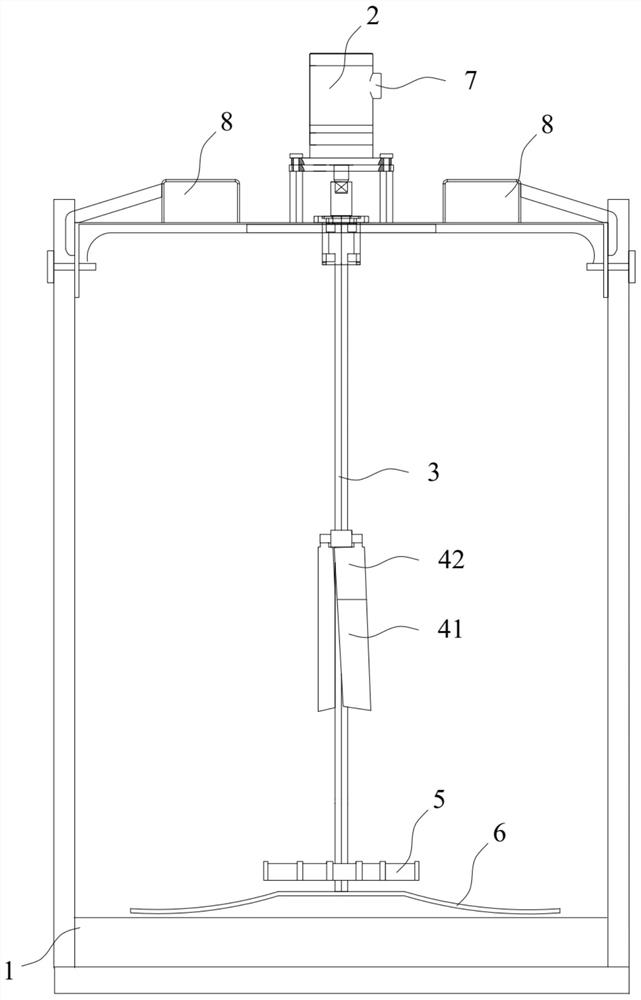

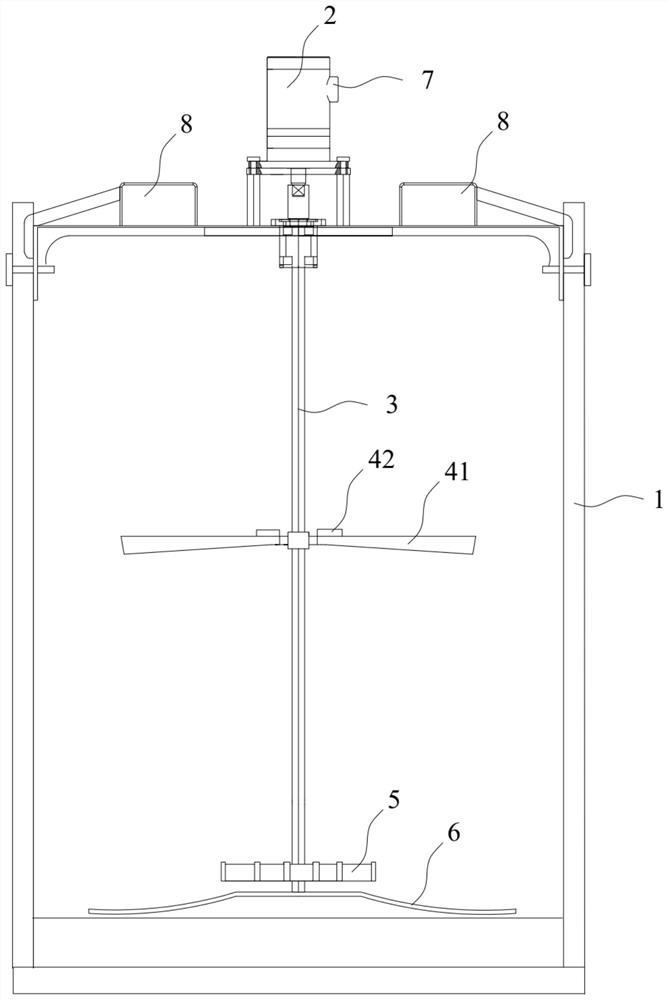

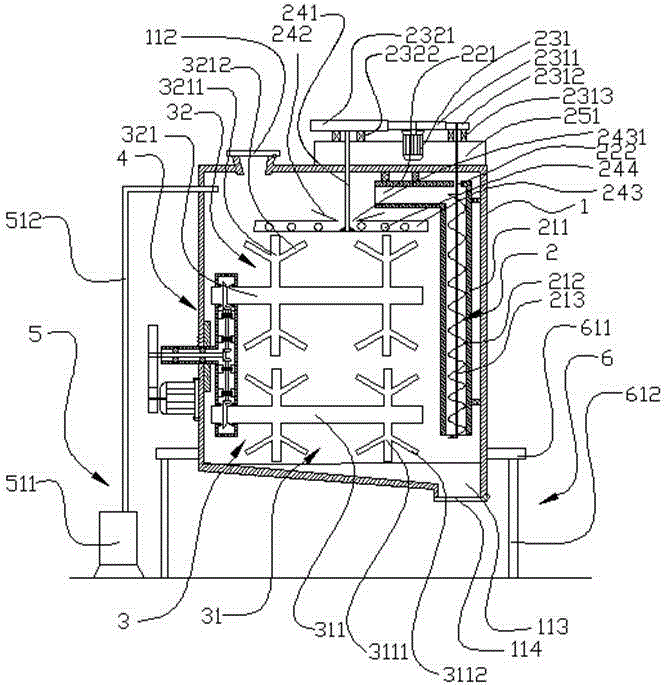

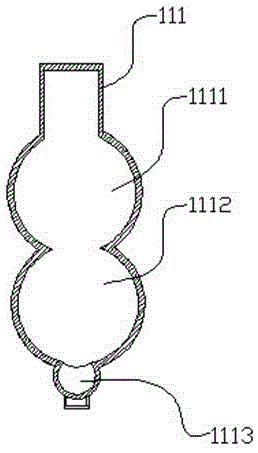

Liquid-state selenium-enriched nutritional chelated fertilizer reaction vessel

PendingCN108620015ATemperature controlGuaranteed stabilityChemical/physical/physico-chemical stationary reactorsLiquid fertilisersBiochemical engineeringLiquid state

The invention belongs to the field of fertilizer production device, and more specifically relates to a liquid-state selenium-enriched nutritional chelated fertilizer reaction vessel. The liquid-stateselenium-enriched nutritional chelated fertilizer reaction vessel comprises a tank body, a stirring device arranged in the tank body, and a heating device and a housing arranged outside the tank body;the upper part of the tank body is provided with a feed inlet and a water inlet; the lower part of the tank body is provided with a feed outlet and a sewage draining exit; the liquid-state selenium-enriched nutritional chelated fertilizer reaction vessel also comprises a temperature sensor and a controller; the temperature sensor is arranged on the upper part of the internal side of the tank body; the temperature sensor is communicated with a controller circuit arranged outside the housing; a display screen is arranged on the controller; the heating device is communicated with the controllercircuit; the stirring device comprises a multistage speed regulation motor, a stirring shaft, stirring blades, and a stirring controller. In applications of the liquid-state selenium-enriched nutritional chelated fertilizer reaction vessel, it is possible to realize automatic adjusting of opening and closing of the heating device based on the real time temperature in the tank body, realizing preferable control on the temperature in the tank body, ensuring chelating environment stability; the stirring controller is used for automatic adjusting the stirring speed and stirring time of the stirring device, so that product full chelating is realized, layering is avoided, and the stability and homogeneity of the quality of obtained liquid-state selenium-enriched nutritional chelated fertilizer are ensured.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI +1

Building mixer

ActiveCN106272966ARealize circulating stirringImprove the mixing effectCement mixing apparatusArchitectural engineering

The invention discloses a building mixer. The building mixer comprises a shell, a vertical leading assembly, a stirring shaft assembly, a driving mechanism, a water feeding mechanism and a bearing mechanism; a material enters the shell through a feed port in the shell, and water enters the shell from the water feeding mechanism to realize stirring under the effect of a stirring shaft; the stirring shaft is driven by the driving mechanism; and the material at the bottom can be leaded to the upper part under the effect of the vertical leading mechanism for full stirring to enhance the stirring effect and to prevent the segregation phenomenon in the material stirring process, and is unloaded by a discharge port after stirring. The building mixer eliminates the stirring dead angles in a traditional device, improves the stirring effect, and is suitable for wide application in the stirring field.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

Aluminum powder mixing method

ActiveCN111136259AFully distributedEvenly distributedTransportation and packagingMetal-working apparatusMetallurgyAluminium powder

The invention provides an aluminum powder mixing method. The aluminum powder mixing method comprises the following steps of first, obtaining raw materials: selecting skeleton aluminum powder and graded aluminum powder as the raw materials; second, premixing: uniformly stirring the raw materials containing the skeleton aluminum and the graded aluminum powder in the first step in a conical mixer toobtain pre-mixed aluminum powder; and third, mixing: uniformly stirring a certain amount of aluminum powder taken out from the pre-mixed aluminum powder obtained in the second step to obtain the target product. A variety of aluminum powders with the same specifications are taken as the raw materials, the appropriate ratio is selected according to different needs, and mixing is performed accordingto a specific mixing process (the combination of obtaining raw materials, premixing, and mixing, and even remixing), and after multiple cross-mixing treatments, graded aluminum powder particles can befully and evenly distributed between skeleton aluminum powder particles to achieve full filling, so that the particle size fluctuations of the final aluminum powder product batches do not exceed eight per thousand, and the tap density is as high as 1.65g / cm<3>.

Owner:深圳立专信息科技有限公司

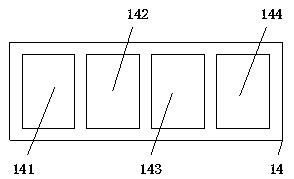

Fixation equipment convenient to screening for Huangkui tea processing

PendingCN112273448AImprove the quality of finishingEasy to filterSievingPre-extraction tea treatmentDrive motorEngineering

The invention discloses fixation equipment convenient to screening for Huangkui tea processing. The equipment comprises a device main body, a driving motor and a double-head motor, a blanking openingis fixedly connected to the upper surface of the device main body, the driving motor is fixedly mounted on the upper surface of the device main body, a discharging opening is formed in one side of thelower end of the device main body, a heating barrel and a material collecting block are installed in the device body, meanwhile, the upper end of the heating barrel is connected with the upper end ofthe device main body, the lower end of the driving motor is connected with an output shaft, and the outer surface of the output shaft is connected with a first connecting gear and a second connectinggear in a sleeved mode. According to the fixation equipment convenient to screening for Huangkui tea processing, a connecting block drives a connecting shaft to rotate, then the connecting shaft drives a screen to move, the connecting block is fixedly connected with the connecting shaft, the length of the screen is equal to that of the material collecting block, screen holes are distributed in the screen at equal intervals, and the screen conveniently screens the Huangkui tea through swinging.

Owner:安徽宏云制茶有限公司

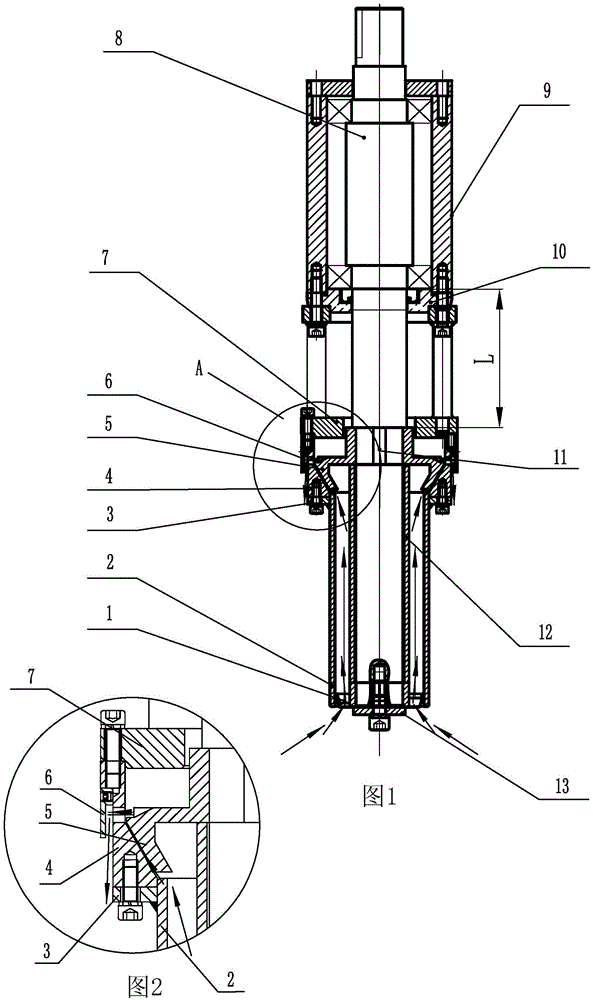

A mixing knife assembly

A stirring knife assembly at least comprises a knife bracket and a stirring shaft; the knife bracket is of a framework structure and is fixedly provided with at least one blade; the stirring shaft is fixedly connected with the knife bracket. The lower part of the knife bracket is provided with a first blade, and the upper part of the knife bracket can be provided with a second blade or can be not provided with the blade; the stirring shaft is not provided with a blade or is provided with at least one blade; the mode of blade arrangement on the knife bracket can be combined randomly with the mod of blade arrangement on the stirring shaft. Because the blade is connected with the stirring shaft through a non-injection molding mode, the defects brought by the injection molding process are avoided, the shape and the number of the blades have no limitation, and the blade arranged positions are relatively flexible; and moreover, the blade bracket adopts the framework structure, the braking structure is simplified, at the same time, a deep hole structure, which is matched with a positioning shaft of a stirrer, of a stirring shaft of a traditional stirring knife assembly is avoided, moreover, enough space is left for food to pass through, food is avoided from remaining in the deep hole structure, no cleaning dead angle exist, cleaning becomes easy, and the practicability is high.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

mixer for construction

InactiveCN106217643BRealize circulating stirringImprove the mixing effectDischarging apparatusMixing operation control apparatusEngineeringBuilding construction

The invention discloses a blender for a building. The blender comprises a shell, a vertical material guide assembly, a blending shaft assembly, a drive mechanism, a water inlet mechanism and a bearing mechanism; materials enter the shell through a feeding opening in the shell, water enters the shell from a water inlet shell, under the effect of a blending shaft, blending is achieved, the blending shaft is driven by the drive mechanism, the bottom materials can be guided to the upper portion under the action of the vertical material guiding mechanism to be fully blended, the blending effect is improved, the segregation phenomenon in the material blending process can be prevented, and after blending, the materials are discharged out of a discharging opening. Stirring dead angles existing in a traditional device can be removed, the blending effect is improved, and the blender is suitable for being widely applied in the blending field.

Owner:高聪聪

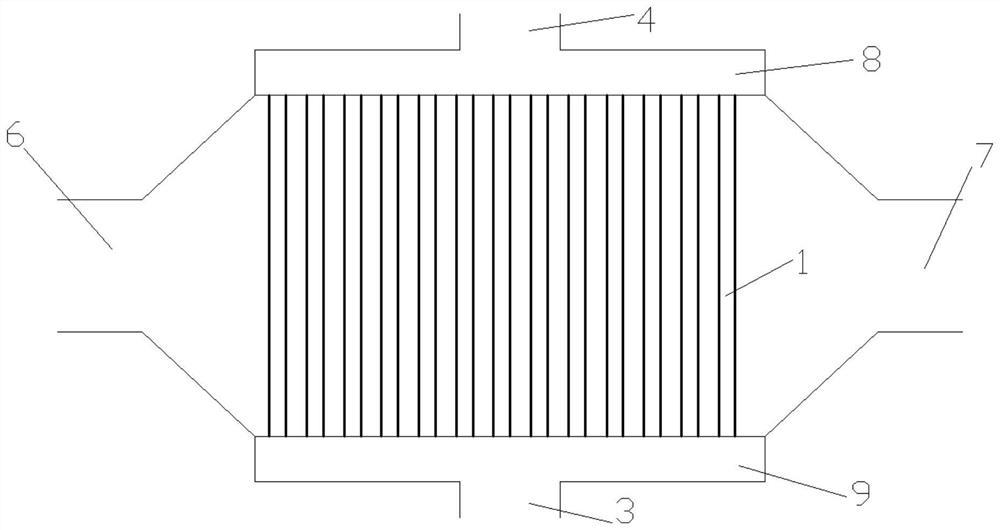

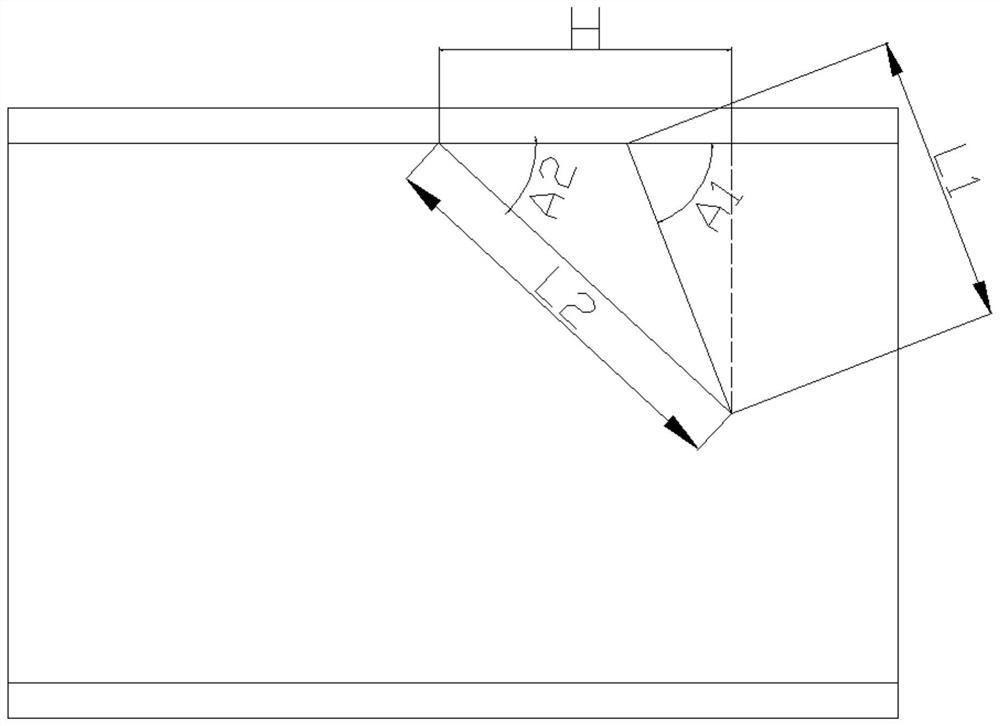

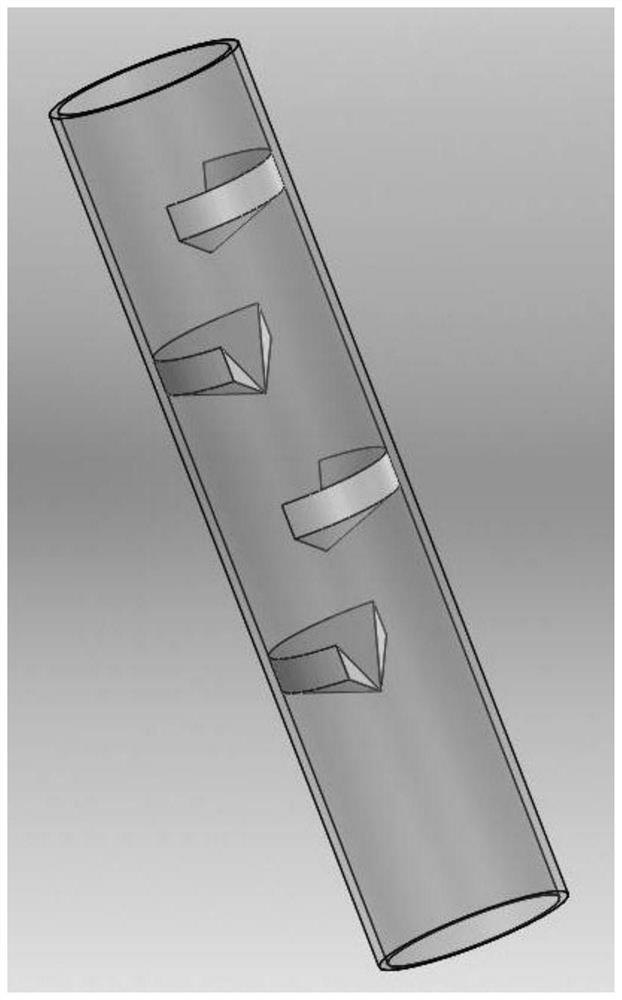

Linear temperature-equalizing flow-guide shell-and-tube heat exchanger

InactiveCN113624037ALow costSmall sizeHeat exchanger casingsStationary tubular conduit assembliesEngineeringMechanical engineering

The invention provides a shell-and-tube heat exchanger with optimized structures. Drainage plates extending from the inner wall of an outlet pipe to the center of the outlet pipe are arranged in the outlet pipe, the drainage plates comprise first linear walls and second linear walls which extend from the inner wall, the acute angles between the second linear walls and the inner wall are A1, in a gas flow direction, the multiple drainage plates are arranged on the inner wall of the outlet pipe, and the included angles A1 become larger and larger in the gas flow direction. According to the novel shell-and-tube heat exchanger provided by the invention, the included angles are set to be larger and larger so that the size can be reduced, the flow resistance can be reduced, and a temperature equalizing effect can be basically the same on the aspects of resistance reduction and material cost saving.

Owner:STATE GRID SHANDONG ENERGY SAVING SERVICE

Control system and control method

ActiveCN112034798BIncrease productivityAvoid problems with more restrictive controlsTotal factory controlProgramme total factory controlMachine controlControl system

The invention provides a control system and a control method. The control system includes: a mixing station; a lower controller connected to the mixing station; an upper control device connected to the lower controller, and the upper control device includes multiple PC. In the technical solution of the present invention, the lower controller can control the production of the mixing station according to the first instruction and the second instruction, so as to complete the on-site mixing production task, so that multiple upper computers can control the production of the mixing station by controlling the lower controller, thereby The control function of one station and multiple controls of the control system is realized, that is, multiple upper computers control the production of one mixing station.

Owner:SANY AUTOMOBILE MFG CO LTD

mixer for construction

ActiveCN106182418BRealize circulating stirringImprove the mixing effectCement mixing apparatusLiquid ingredients supply apparatusArchitectural engineeringBuilding construction

The invention discloses a stirring machine for construction. The stirring machine for construction comprises a shell, a vertical guiding assembly, stirring shaft assemblies, a driving mechanism, a water inlet mechanism and a bearing mechanism. Materials enter the shell through a feeding port in the shell. Water enters the shell from the water inlet mechanism. Stirring is achieved under the action of stirring shafts, the stirring shafts are driven by the driving mechanism, the materials at the bottom can be guided to the upper portion under the action of the vertical guiding assembly so as to be fully stirred, the stirring effect is improved, the segregation phenomenon in the material stirring process can be prevented, and discharging is conducted through a discharging port after stirring is completed. By the adoption of the stirring machine for construction, stirring dead angles exist when a traditional device is adopted are eliminated, and the stirring effect is improved; and the stirring machine for construction is suitable for being widely applied to the stirring field.

Owner:FUJIAN JINDING CONSTR DEV CO LTD

Efficient reverse type flue gas mixer

InactiveCN109876719ACompact designEasy to installFlow mixersDispersed particle separationFlue gasEngineering

The invention relates to the technical field of environmental protection, and particularly discloses an efficient reverse type flue gas mixer which comprises a plurality of grids of reaction spaces, and spray heads connected with an air inlet pipe are arranged in the reaction spaces; each spray head comprises a cone shell and an inner cone, and an air outlet is formed in a gap between each cone shell and the corresponding inner cone; the lower end of the air inlet pipe and the cone shells are fixedly connected with the reaction spaces through supports, and the inner cones are connected with the cone shells through connecting plates. The invention has the advantages that the mixer can be applied to flues of various types and shapes and equipment needing flue gas mixing, the problem of mixing dead angles can be well solved by adopting a multi-grid design style, the mixing effect with flue gas can be improved by adopting a reverse blowing mode, and the resistance of the flue gas can be reduced by adopting a special conical nozzle design style.

Owner:周涛

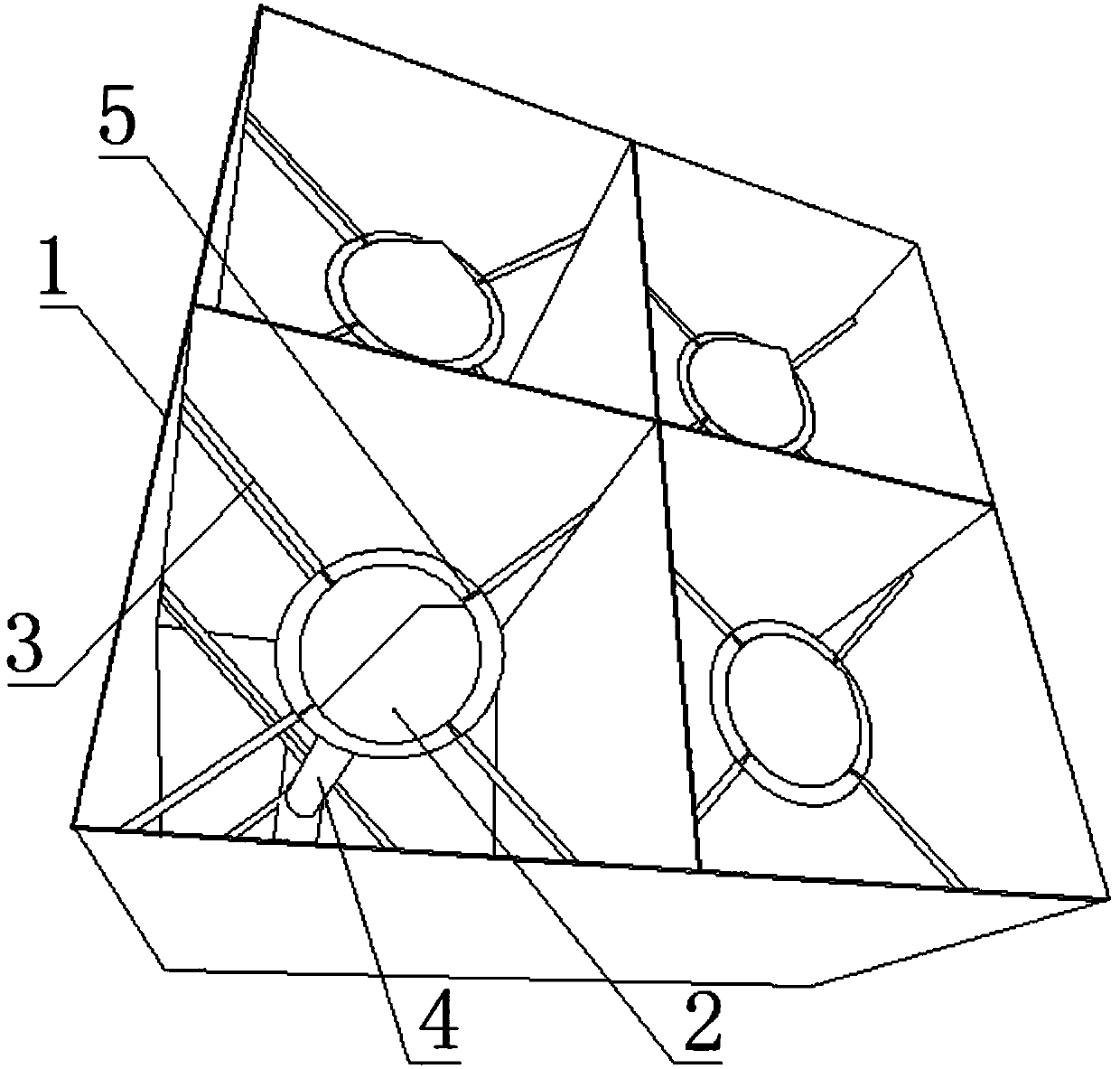

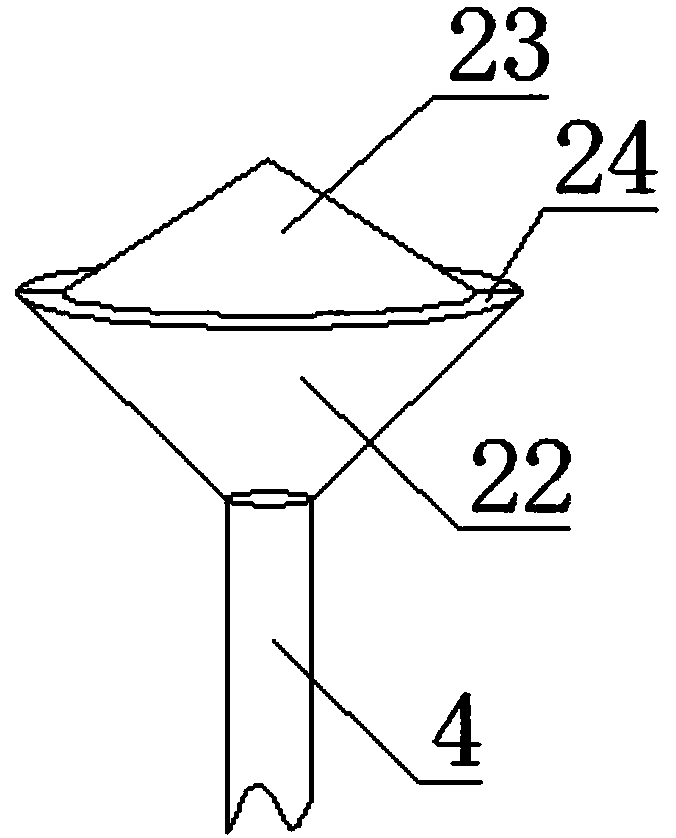

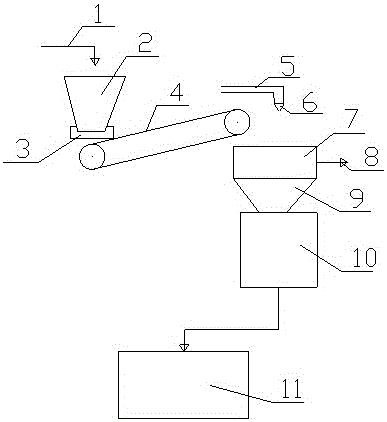

Ore supply system used for preparation of phosphoric acid from fine ores

The invention provides an ore supply system used for preparation of phosphoric acid from fine ores. The system is composed of a fine phosphate ore pipeline (1), a hopper (2), a disk feeder (3), a conveyer (4), a sewage pipe (5), a flushing screen (6), a drum screen (7), a tailing outlet (8), a chute (9), a pulp stirring tank (10) and a pulp storage tank (11). The ore supply system used for preparation of phosphoric acid from fine ores omits the energy consumption cost of milling of a ball mill, has a simple structure, and also uses sewage generated in industries.

Owner:ANHUI NEW ZHONGYUAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com