Liquid-state selenium-enriched nutritional chelated fertilizer production equipment

A kind of production equipment and selenium-enriched technology, which is applied in the direction of liquid fertilizer, fertilizer mixture, feeding device, etc., can solve the problem of automatic adjustment and control of uneven mixing of raw materials, unstable quality of liquid selenium-enriched nutritional chelated fertilizer, and long chelation time, etc. problems, to achieve consistent product quality, facilitate large-scale production, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, further illustrate the present invention.

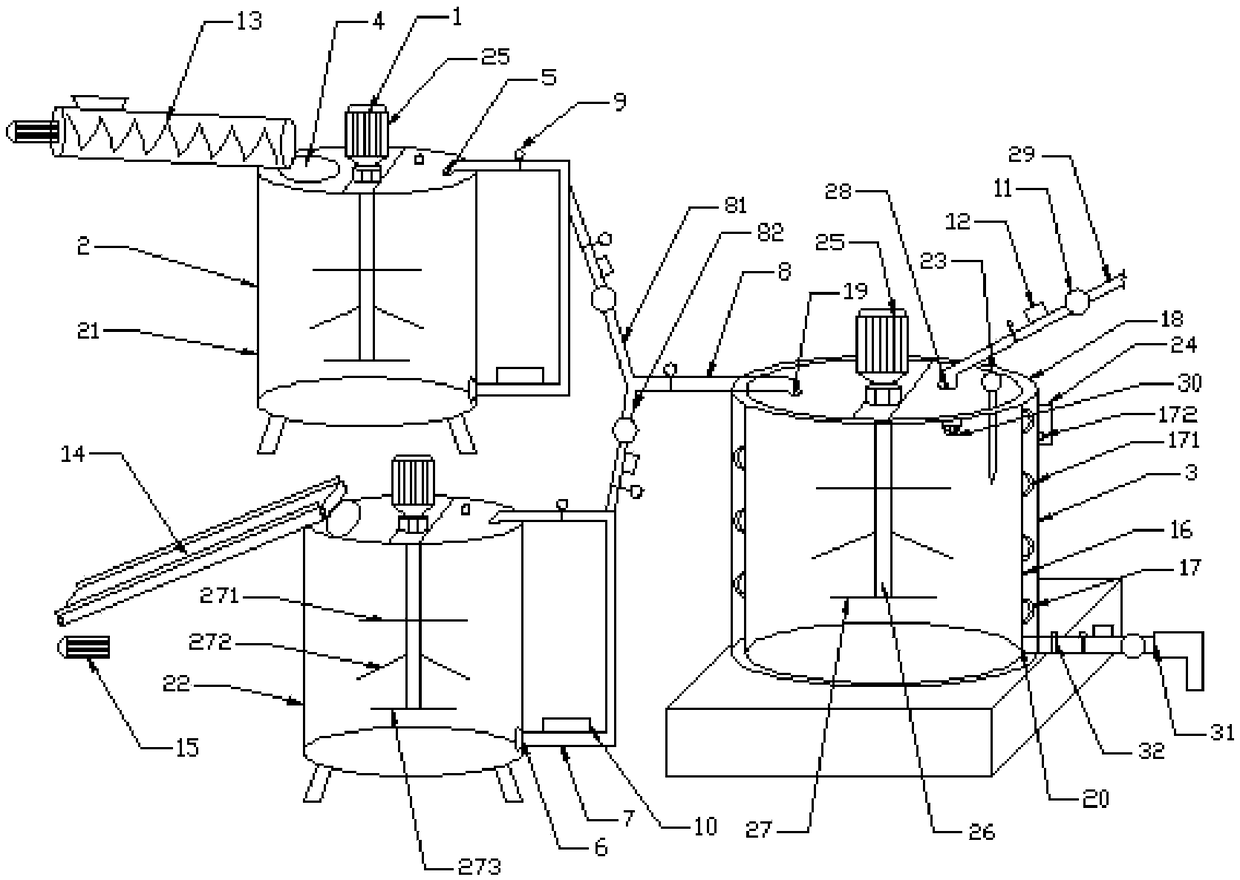

[0022] Such as figure 1 As shown, a liquid selenium-enriched nutritional chelating fertilizer production equipment includes a mixing drum 2 with a stirring device 1 and a chelating drum 3. The mixing drum 2 includes a first mixing drum 21 and a second mixing drum 22, the upper parts of the first mixing drum 21 and the second mixing drum 22 are provided with a feeding port 4 and a return port 5, and the lower part is provided with a discharge port 6, The discharge port 6 is connected to the return port 5 through the return pipe 7, and the return pipe 7 is also connected to the chelation cylinder 3 through the infusion pipe 8, and the electromagnetic valve 9 is arranged on the return pipe 7 and the infusion pipe 8, The return pipe 7 is also provided with a suction pump 10 . The first mixing drum 21 is connected to the chelating drum 3 through the first infusion tube 81 , and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com