Patents

Literature

42results about How to "Realize circulating stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

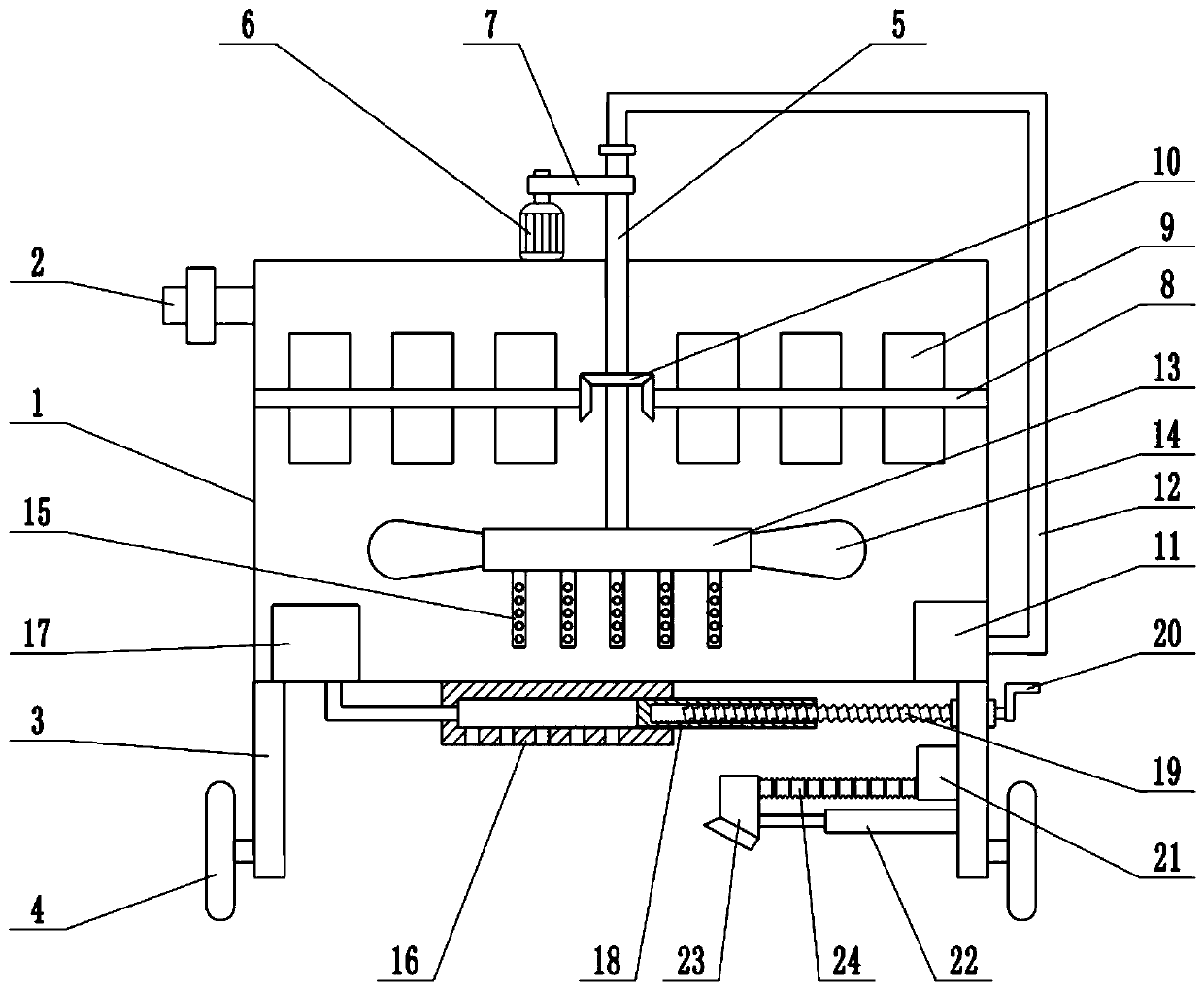

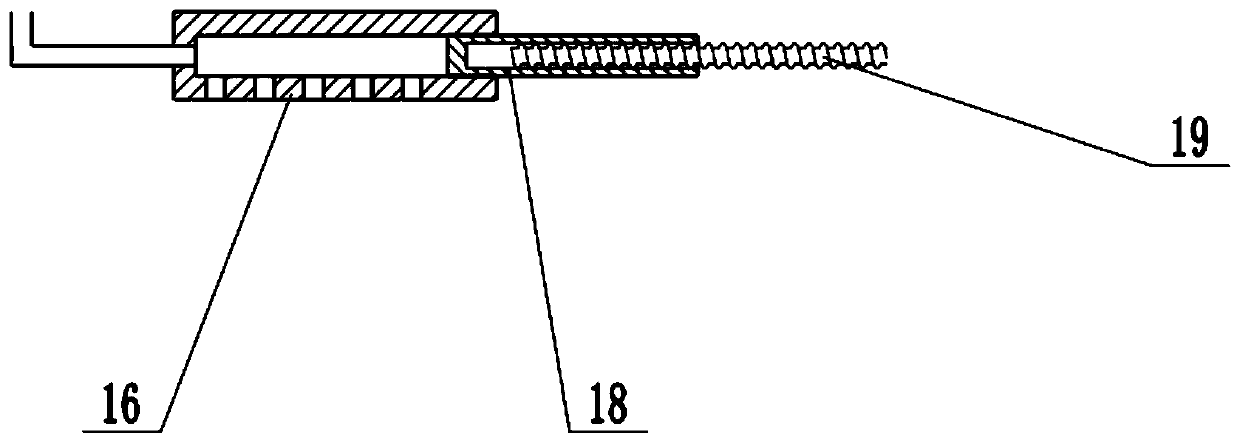

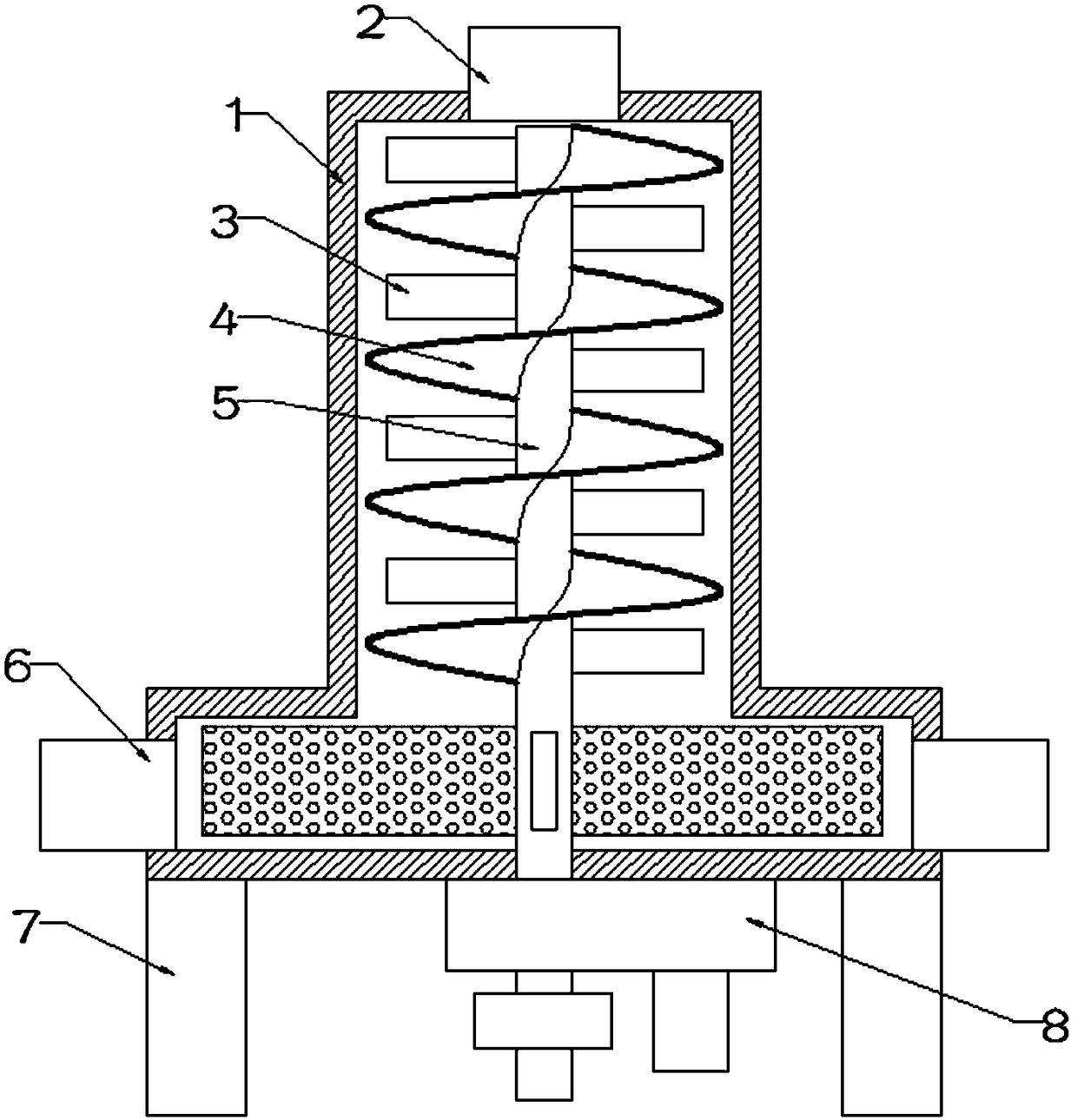

Dustproof efficient building mixing device

InactiveCN106426556AEasy to spray and settleEasy for secondary mixingDischarging apparatusMixing operation control apparatusMaterial balanceMechanical engineering

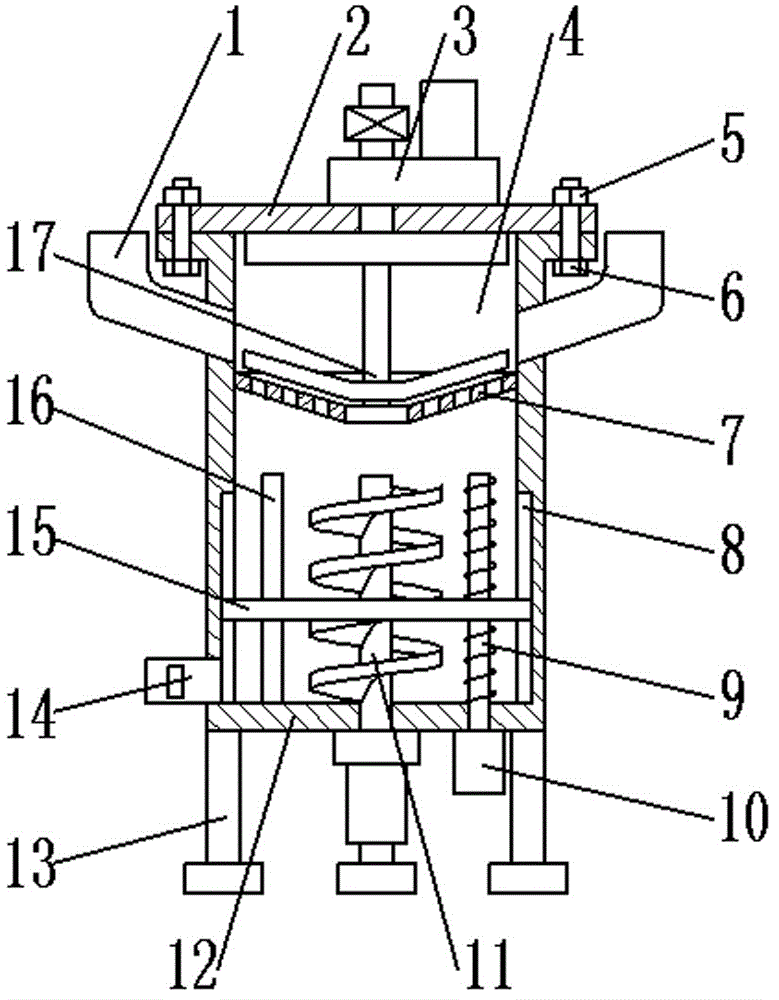

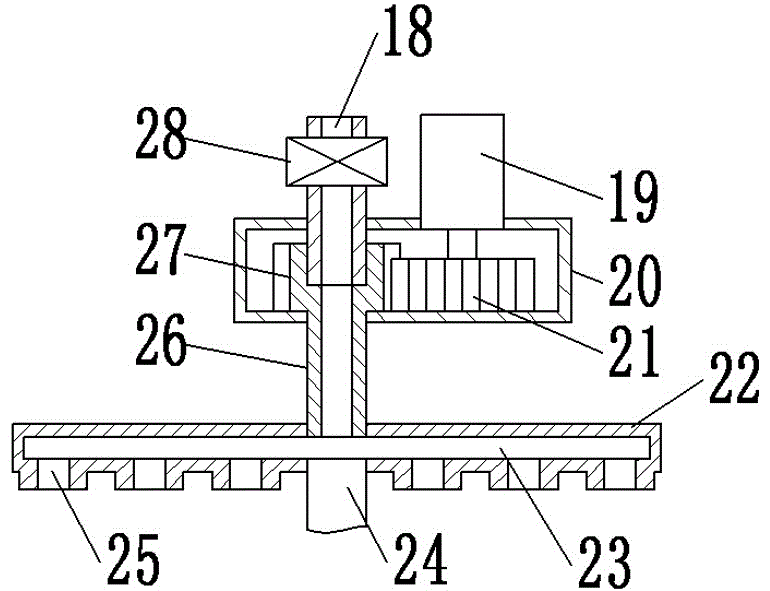

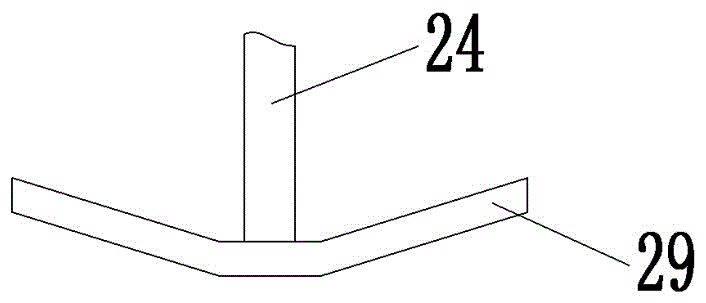

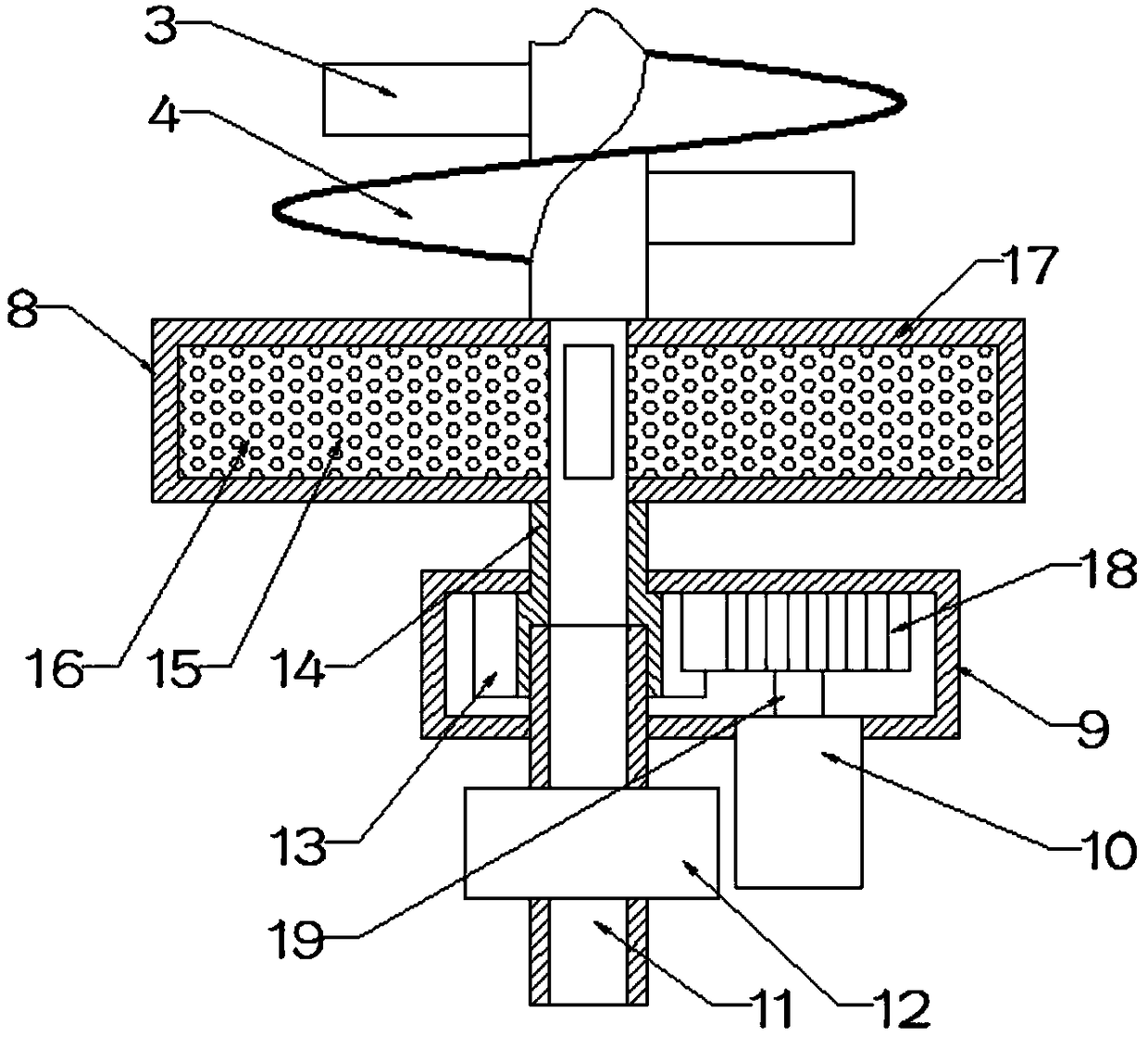

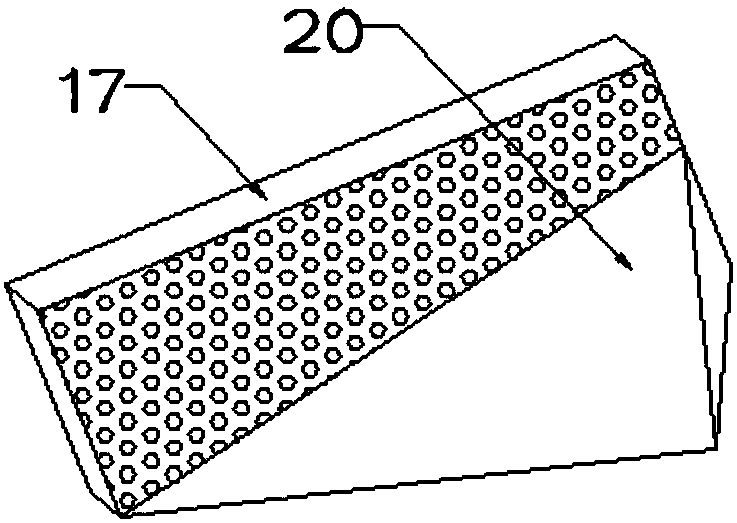

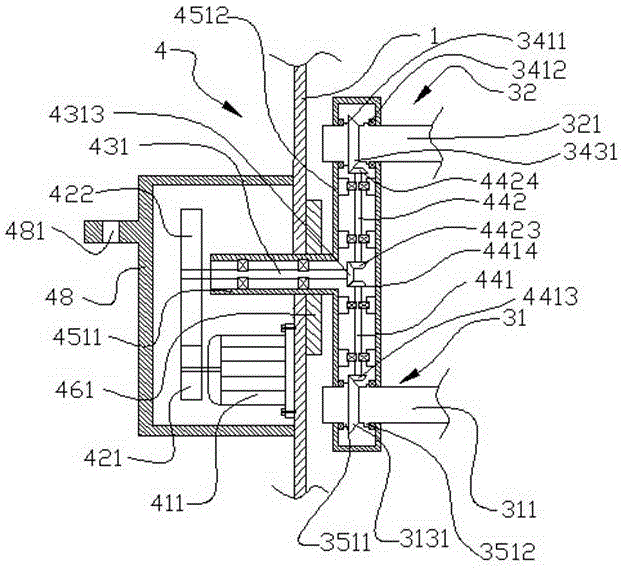

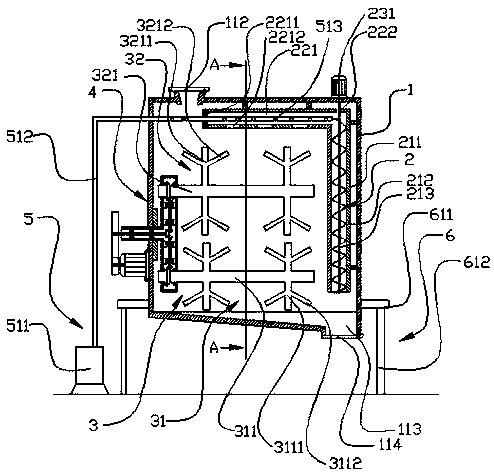

The invention provides a dustproof efficient building mixing device which comprises a tank. A mixing cavity is formed in the tank, an upper cover is arranged at an opening in the top of the tank, a dust falling device is arranged on the upper cover and comprises a driving box, a first motor, a water inlet pipe and a rotary spraying disk, a material guiding disk, a material balancing device, a spiral material rising device and a ring-shaped lifting plate are arranged in the mixing cavity, the material balancing device is arranged on the upper surface of the material guiding disk and comprises a material balancing rotation shaft and a material balancing plate, the spiral material rising device comprises a second motor, a rotating shaft and spiral mixing blades, sliders are arranged at two ends of one diameter of the ring-shaped lifting plate, and a spiral mixer mounting hole is formed in the middle of the ring-shaped lifting plate. Dust generated in the mixed process of building materials is sprayed and settled by the dust falling device and prevented from overflowing to pollute the environments, the materials are circularly mixed by a spiral mixer, and mixed quality of the materials is improved.

Owner:姚旭

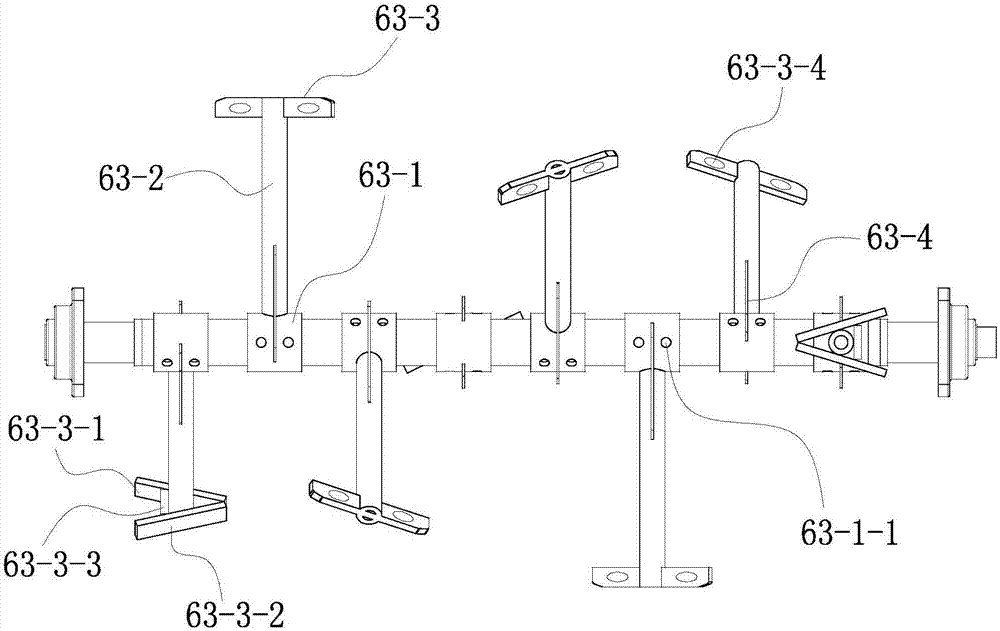

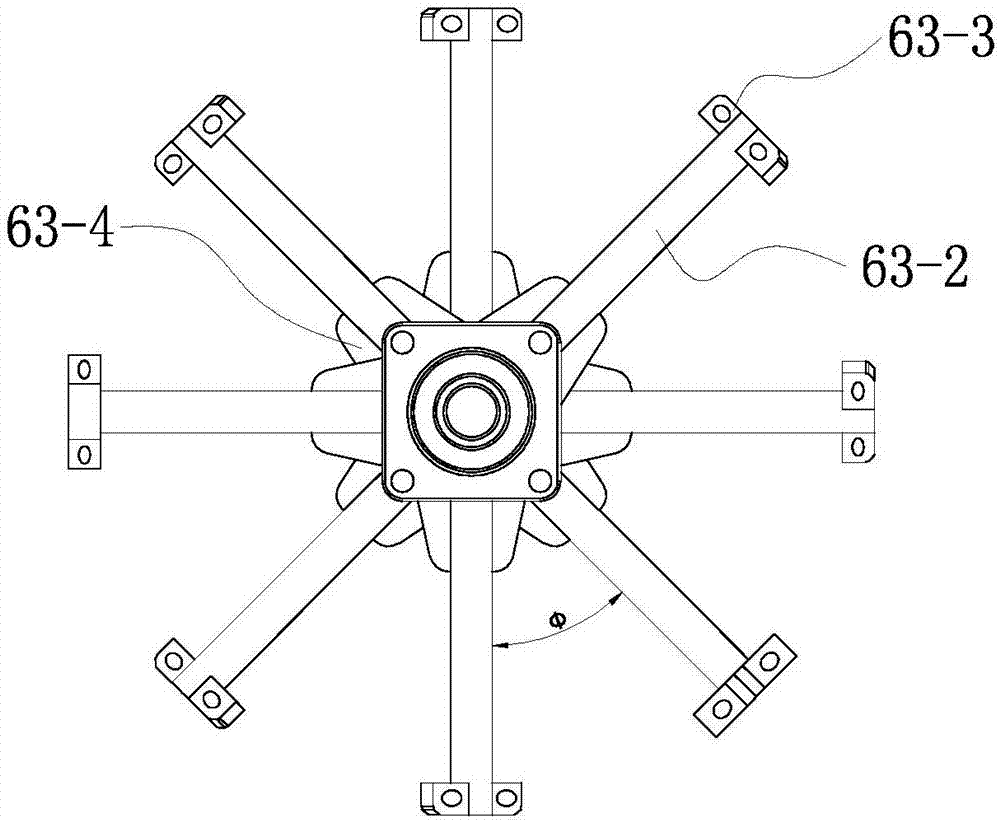

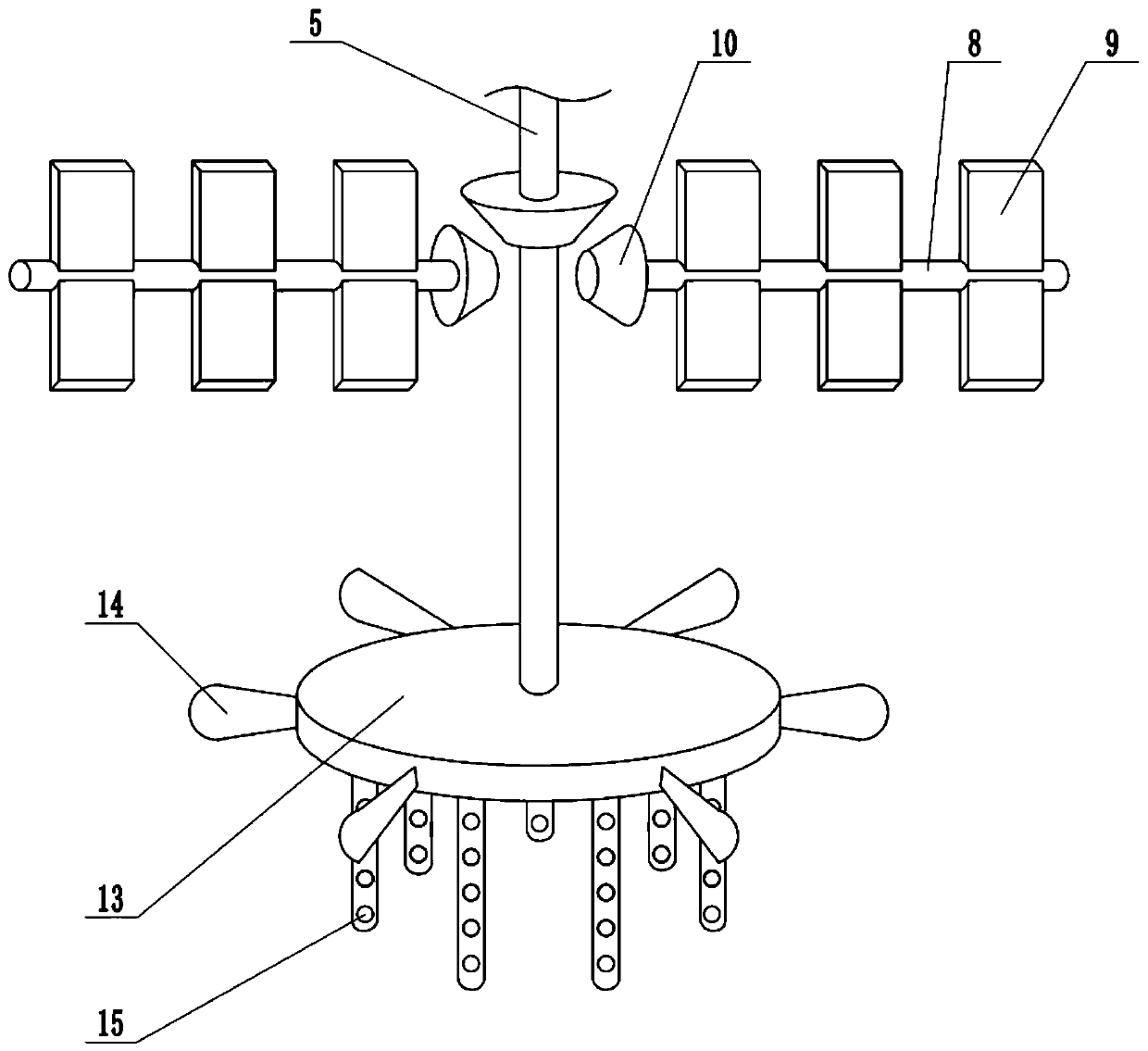

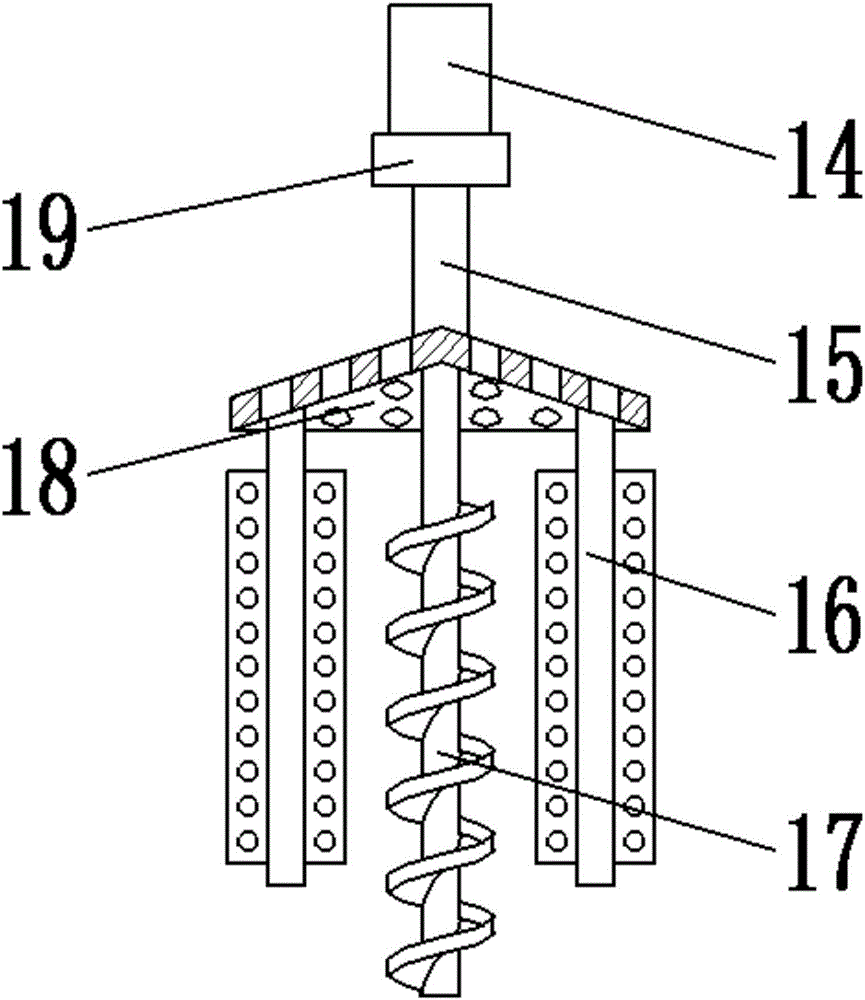

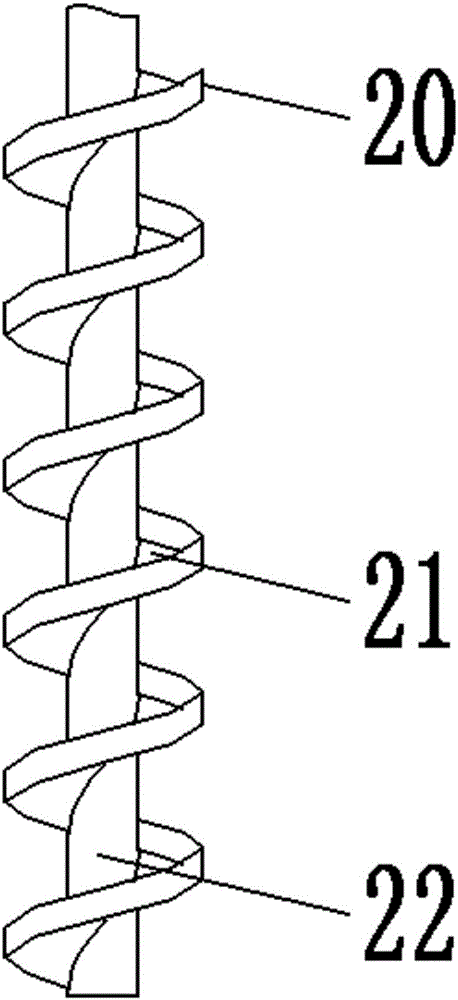

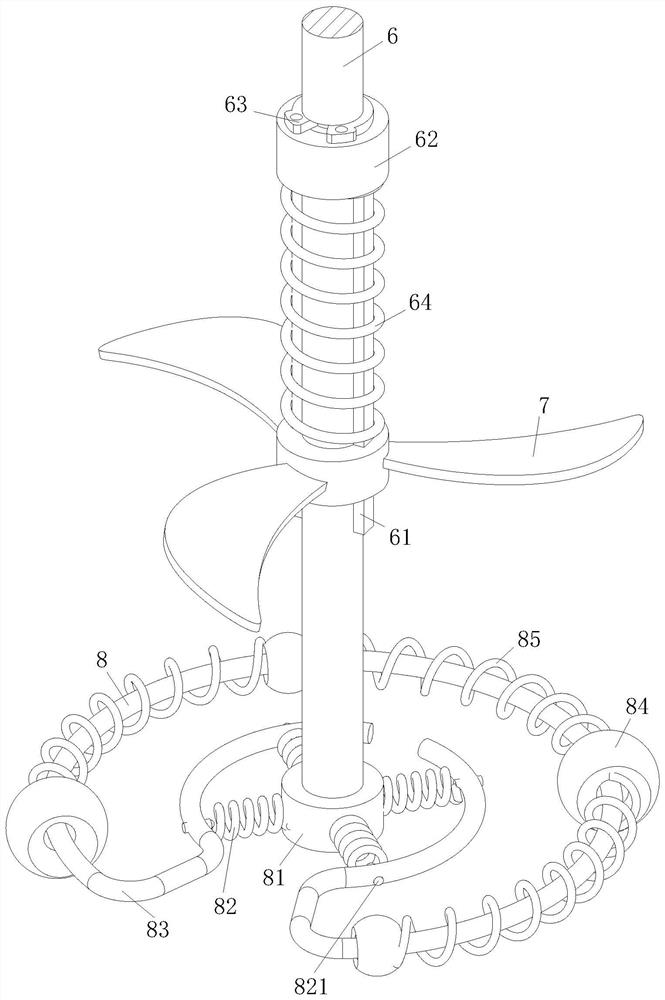

Stirring device of organic garbage microbial treater

PendingCN107029576AImprove stirring efficiencyAvoid offsetRotary stirring mixersTransportation and packagingDecompositionPulp and paper industry

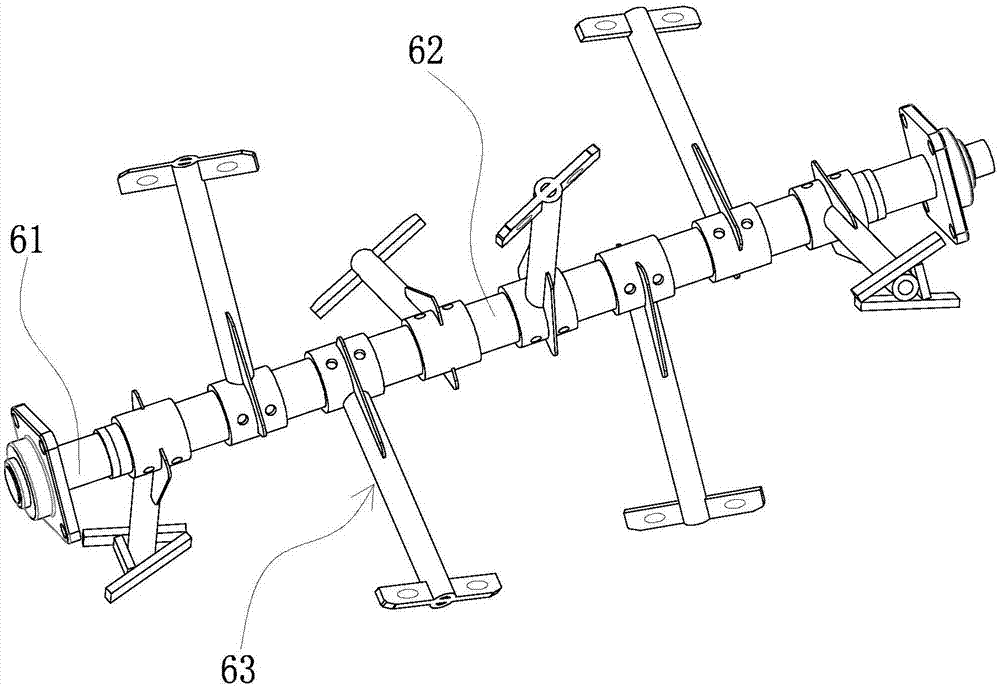

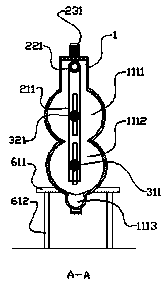

The invention relates to a stirring device of an organic garbage microbial treater. The stirring device comprises a spindle, a stirring shaft and multiple stirring blade mechanisms connected to the stirring shaft in a sleeving mode. The spindle is sleeved with the stirring shaft. Each stirring blade mechanism comprises a connecting pipe, a blade fixing rod and a blade. One end of each blade fixing rod is fixedly connected with the corresponding connecting pipe, and the other end of the blade fixing rod is used for fixing the corresponding blade. The stirring shaft is sleeved with the connecting pipes at equal intervals, and the adjacent blade fixing rods have the same inclination angle in the circumferential direction of the stirring shaft. According to the stirring device, the stirring blade mechanisms arranged on the stirring shaft at equal intervals are arranged, along with rotation of the stirring shaft, the blades are driven to decompose organic garbage in a decomposition cabin, and the stirring efficiency of the garbage is improved.

Owner:ZHEJIANG HUAQINGYUAN BIOTECH CO LTD

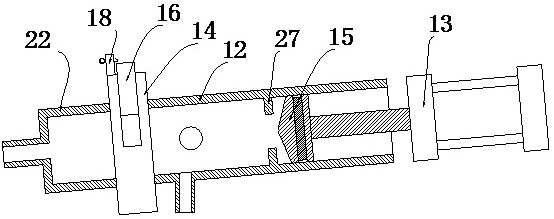

Marking device for road construction

InactiveCN110939048AEasy to adjustWell mixedFlow mixersRotary stirring mixersCrankElectric machinery

The invention relates to the field of road construction equipment. More particularly, the present invention relates to a marking device for road construction. The device comprises a box body, a support plate, rollers, a spraying plate and a booster pump, the suppor plate is mounted at the bottom of the box body; a hollow rotating shaft is mounted in the box body; a stirring shaft is mounted in thebox body; a rotary joint is mounted at the top end of the hollow rotating shaft; a circulating pump is mounted at the bottom of the box body; stirring discs are mounted at the lower end of the hollowrotating shaft; the lower surface of the box body is fixedly connected with a spraying plate; the booster pump is mounted at the bottom of the box body; the crank is rotated to drive the movable plate to move left and right in the spraying plate; depending on actual scribing requirements, in the marking process, the motor is started, the stirring plate is used for stirring upper-layer paint to enable the paint to be evenly mixed, the stirring blades and the stirring rod are used for stirring bottom-layer paint to enable the paint to be mixed more evenly, precipitation of the paint is prevented, and the circulating pump is used for achieving circulating stirring of the paint to enable the paint to be mixed more evenly.

Owner:王敏帆

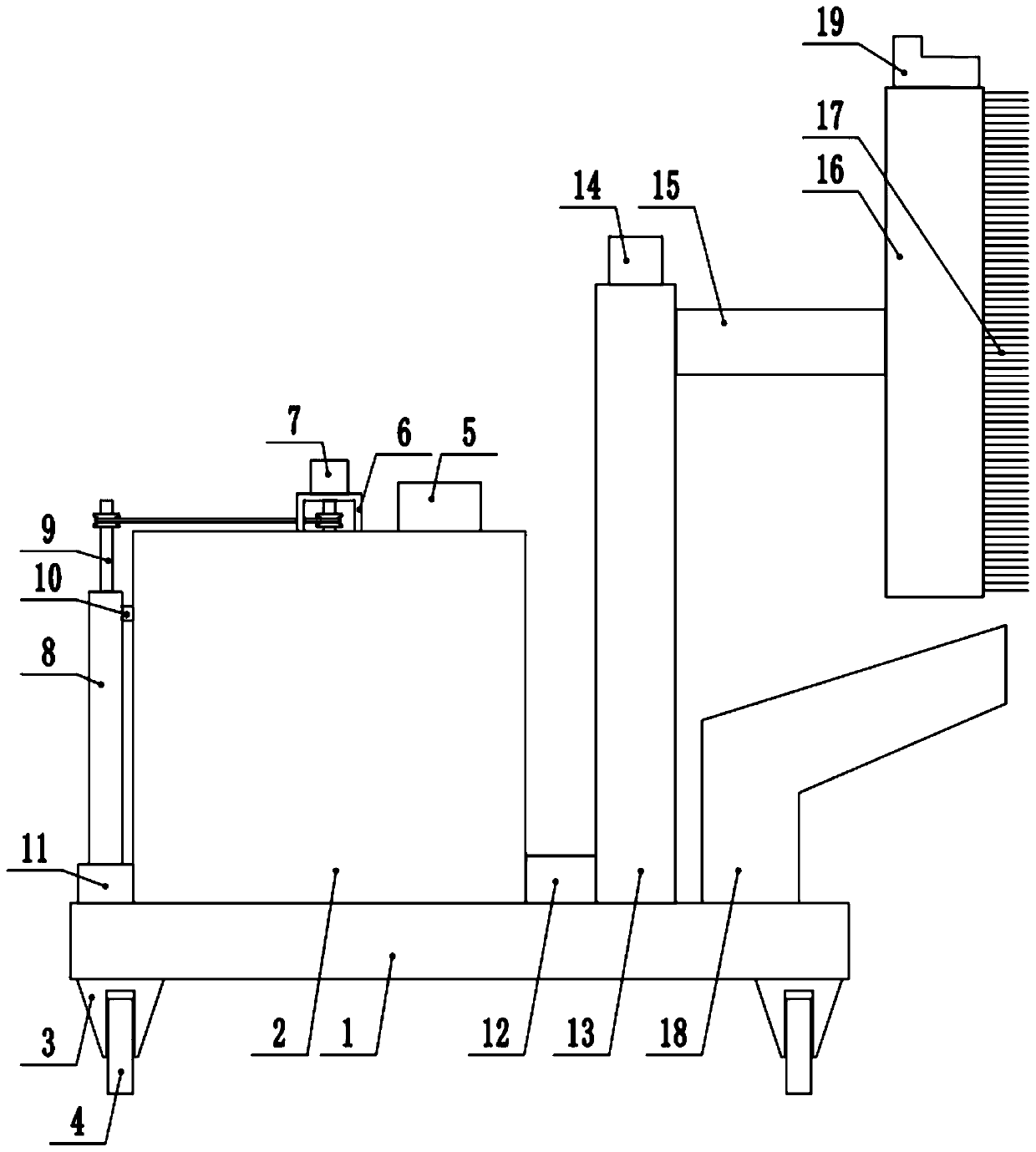

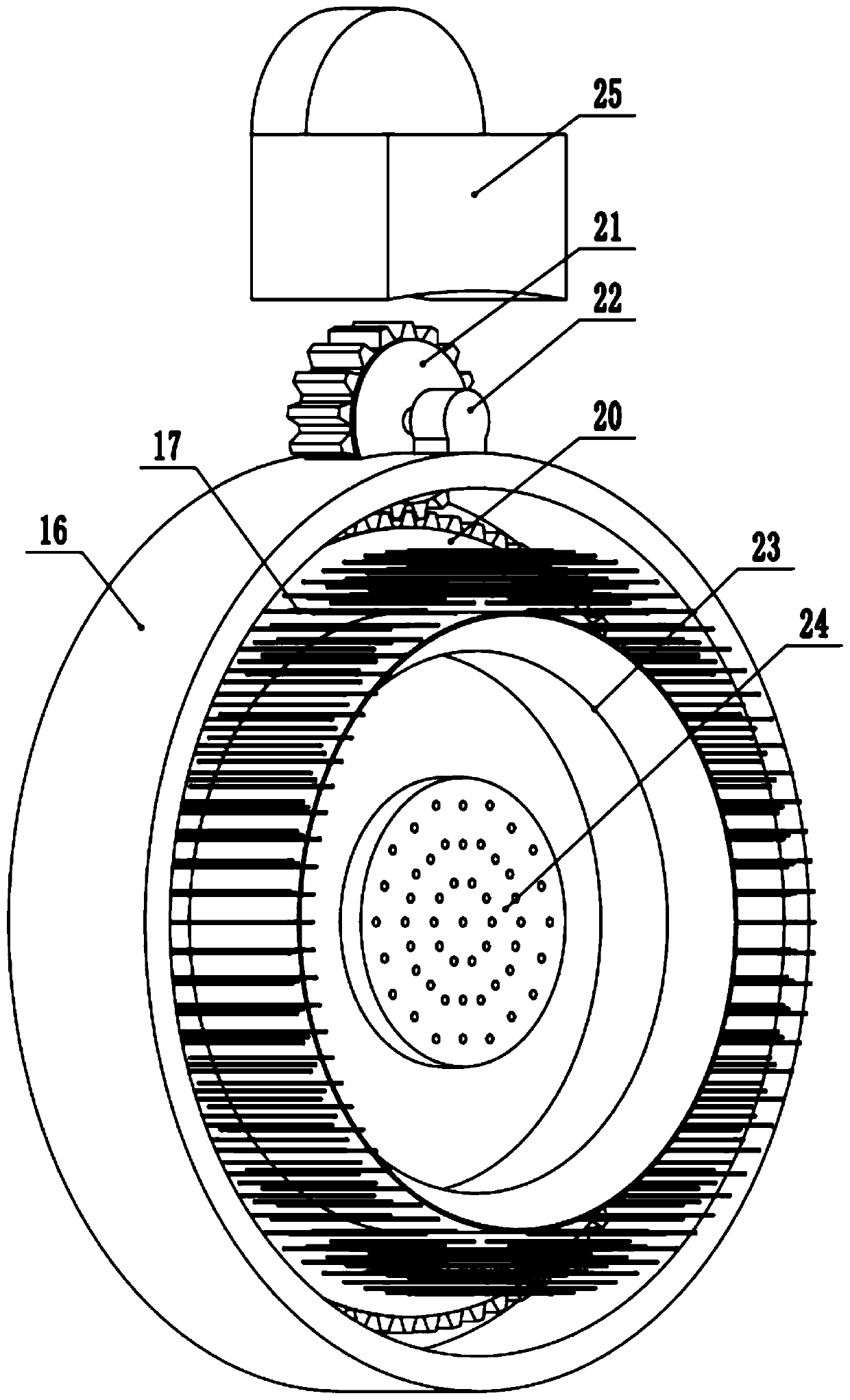

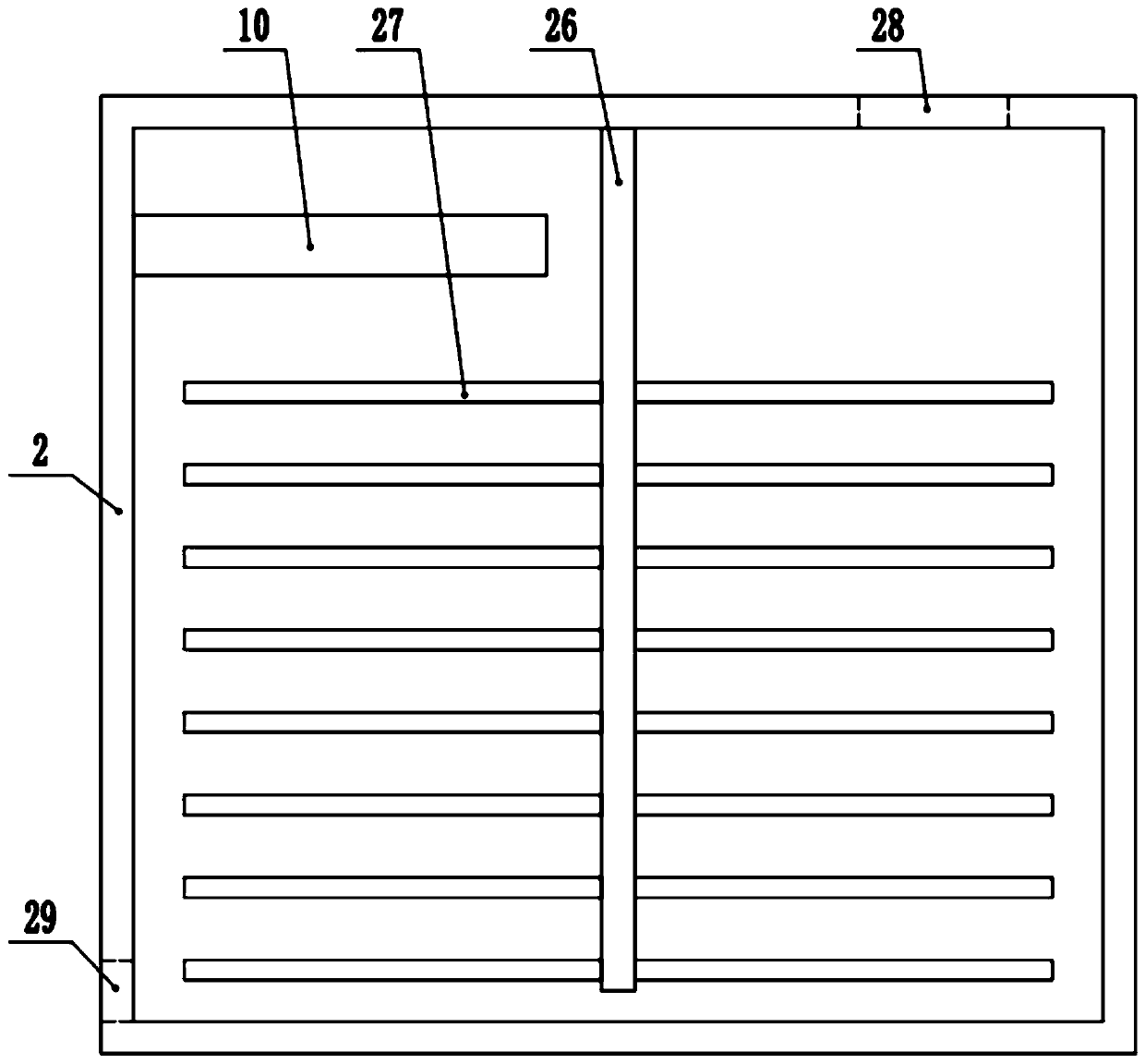

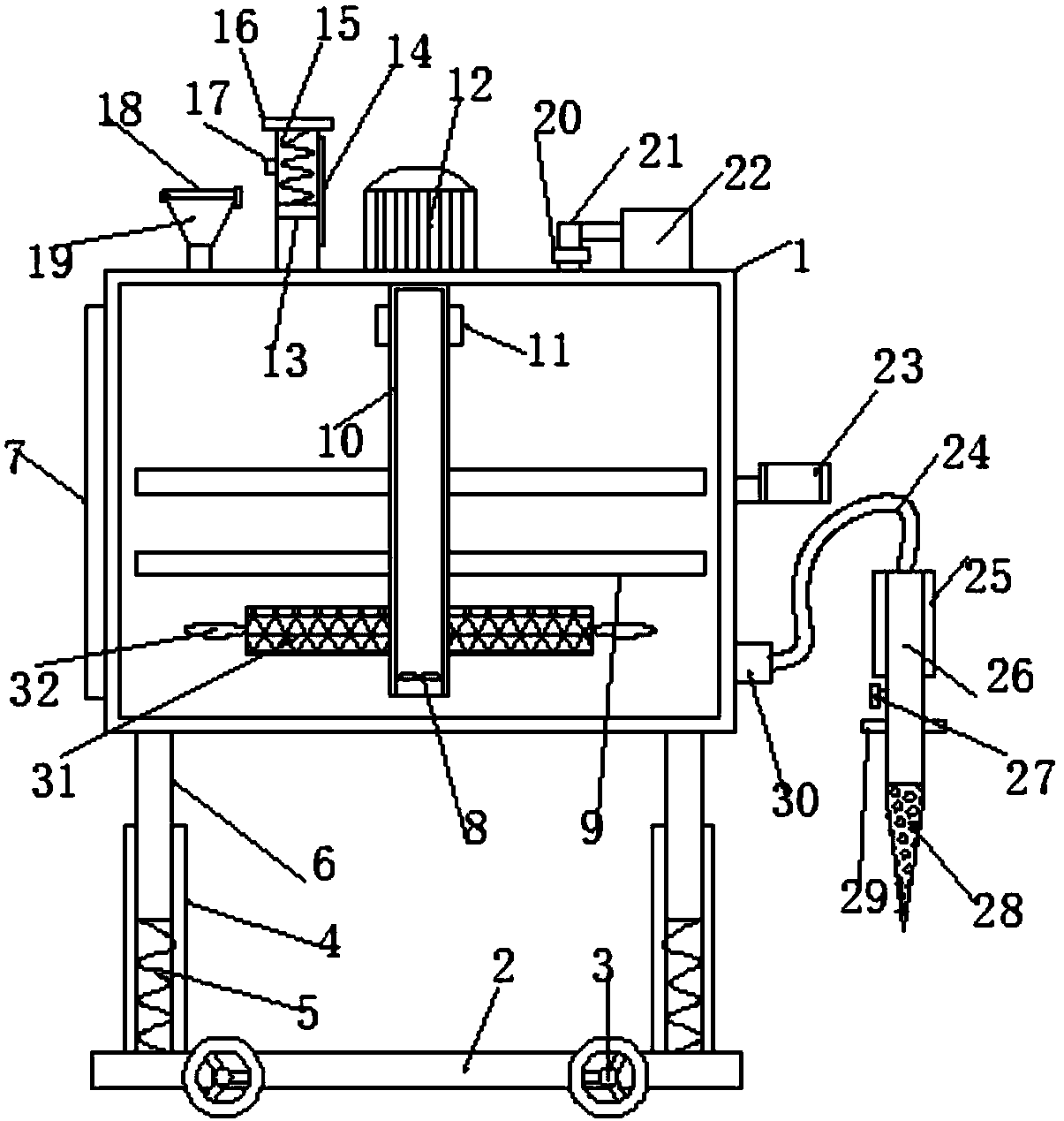

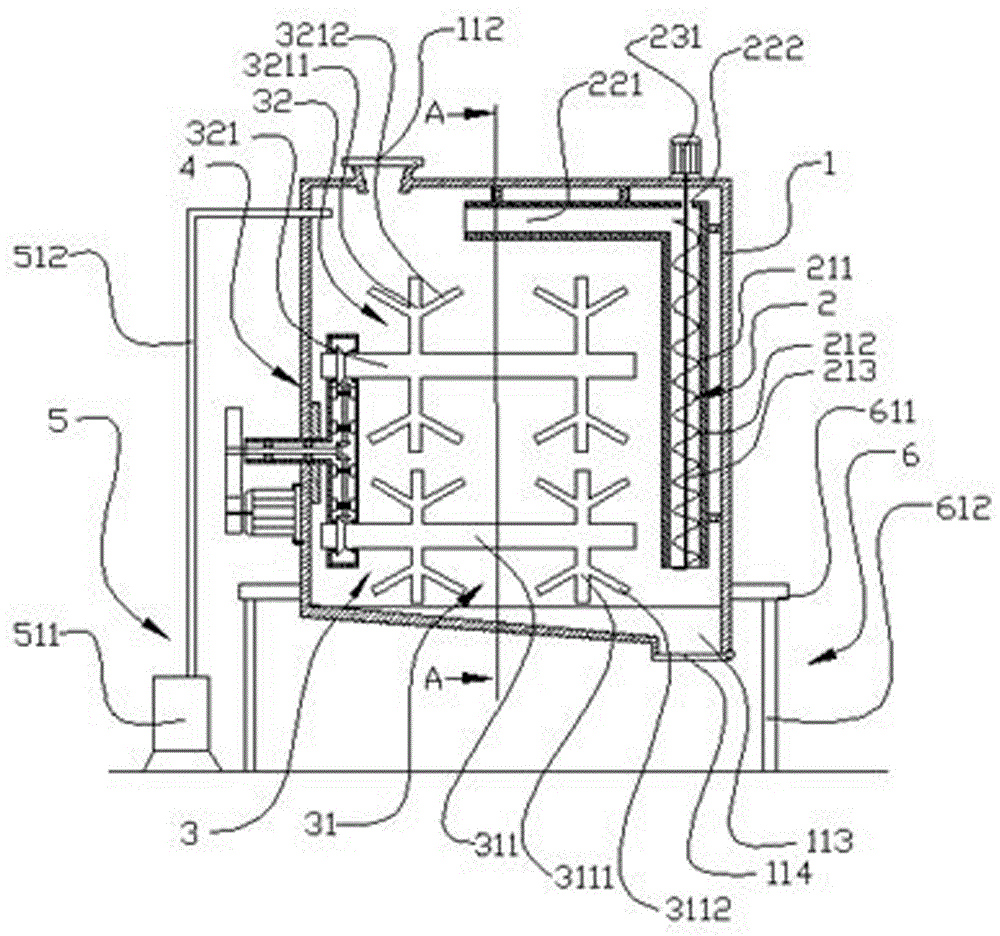

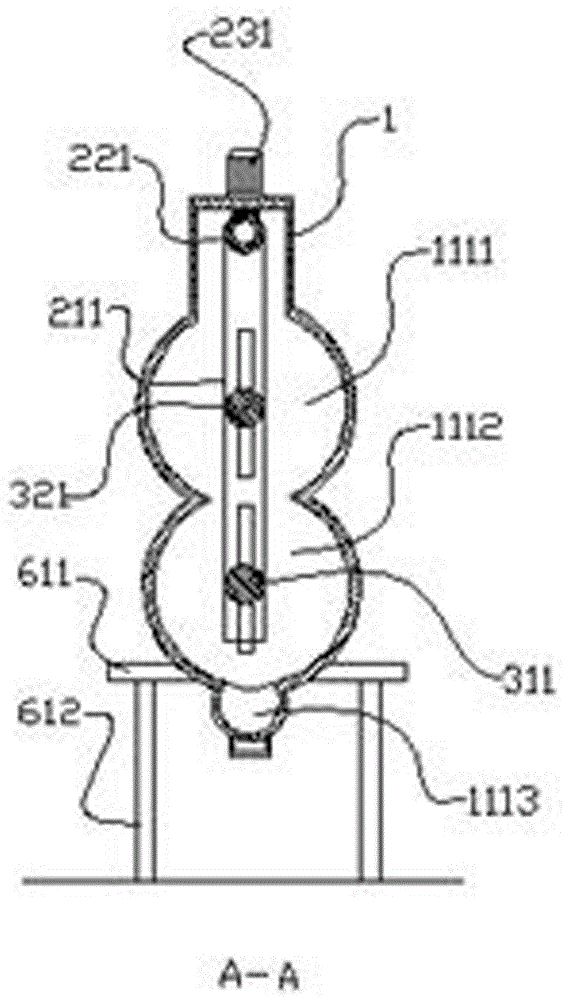

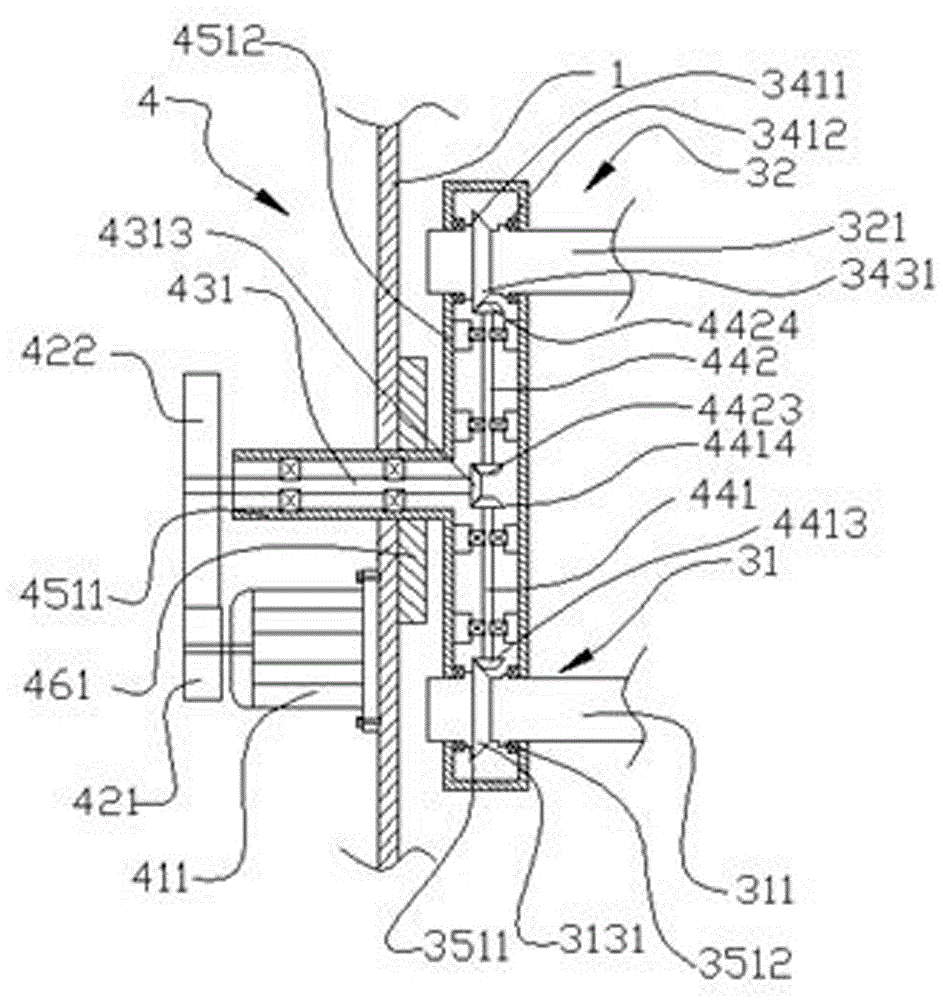

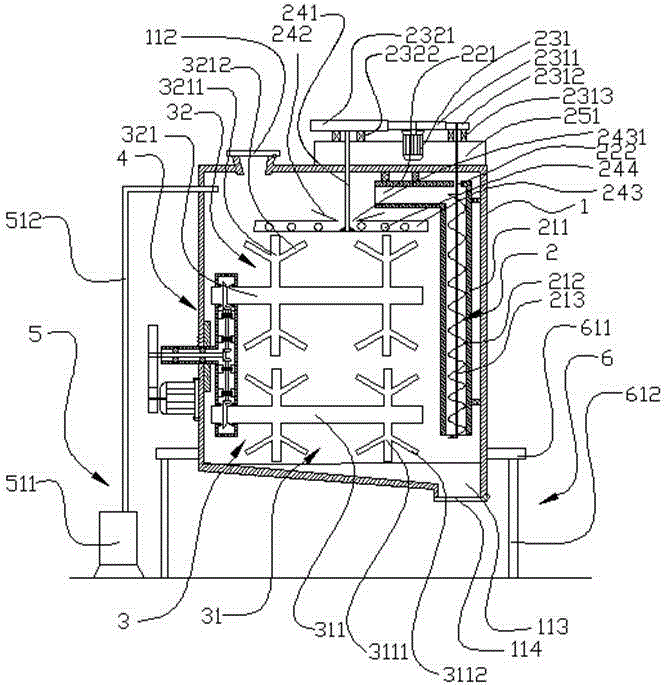

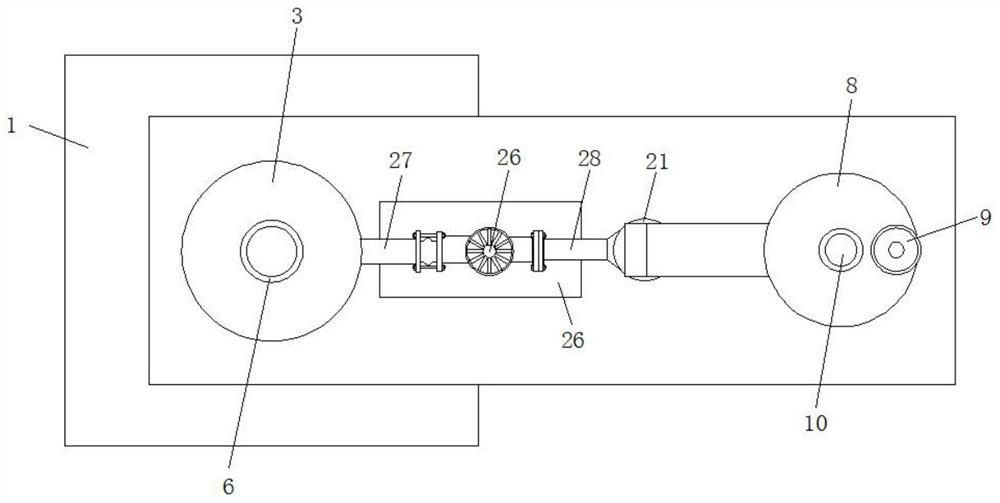

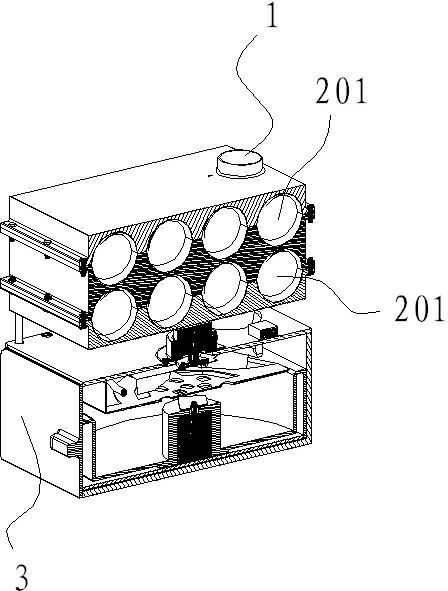

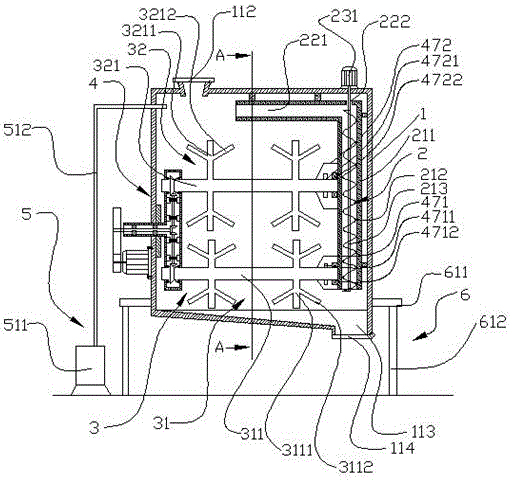

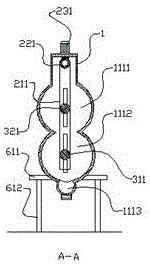

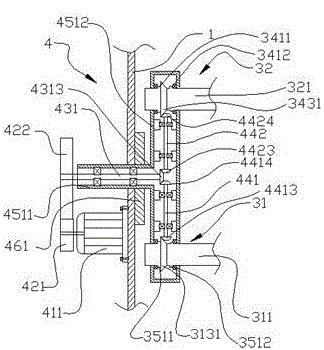

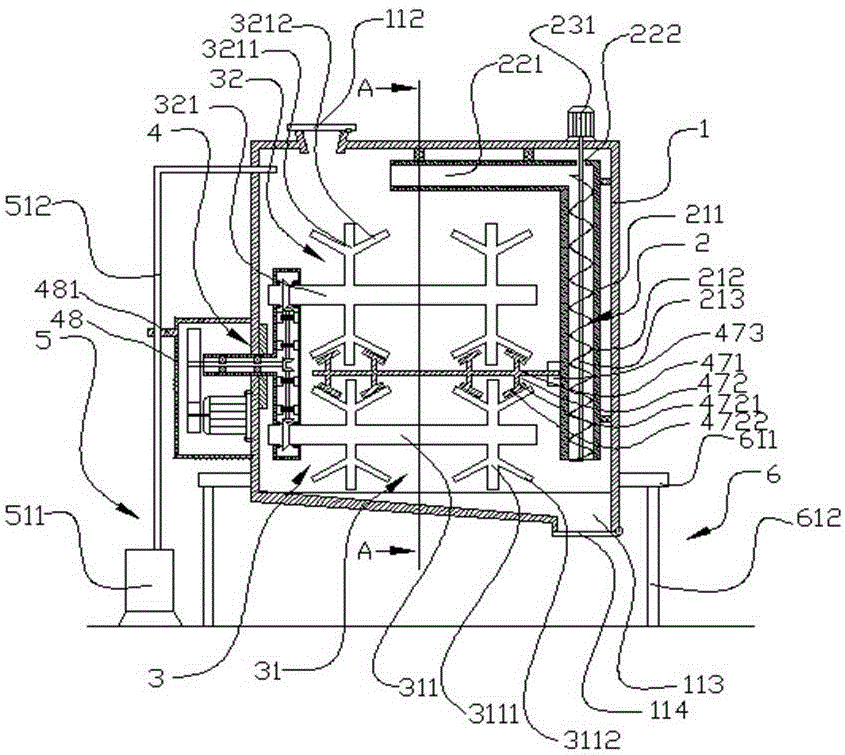

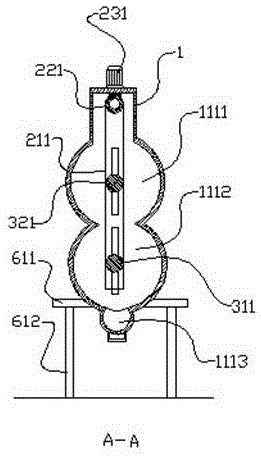

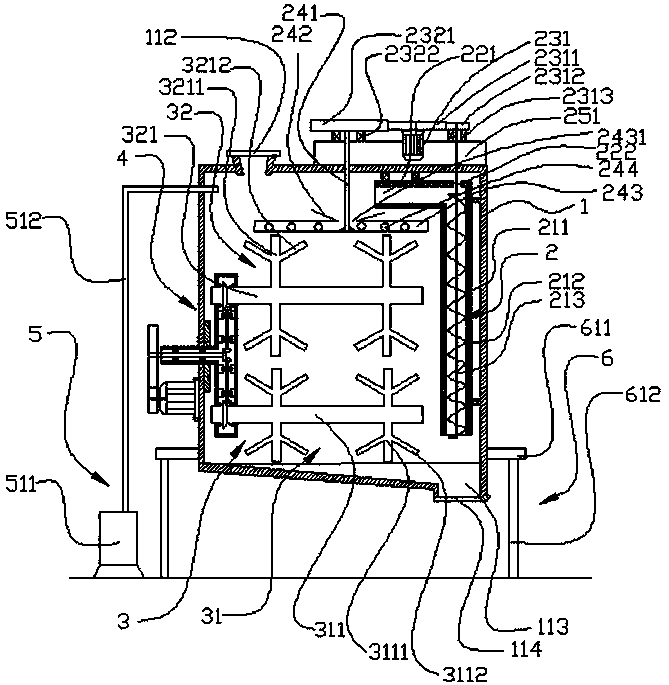

Wall face coating spraying equipment for building decoration

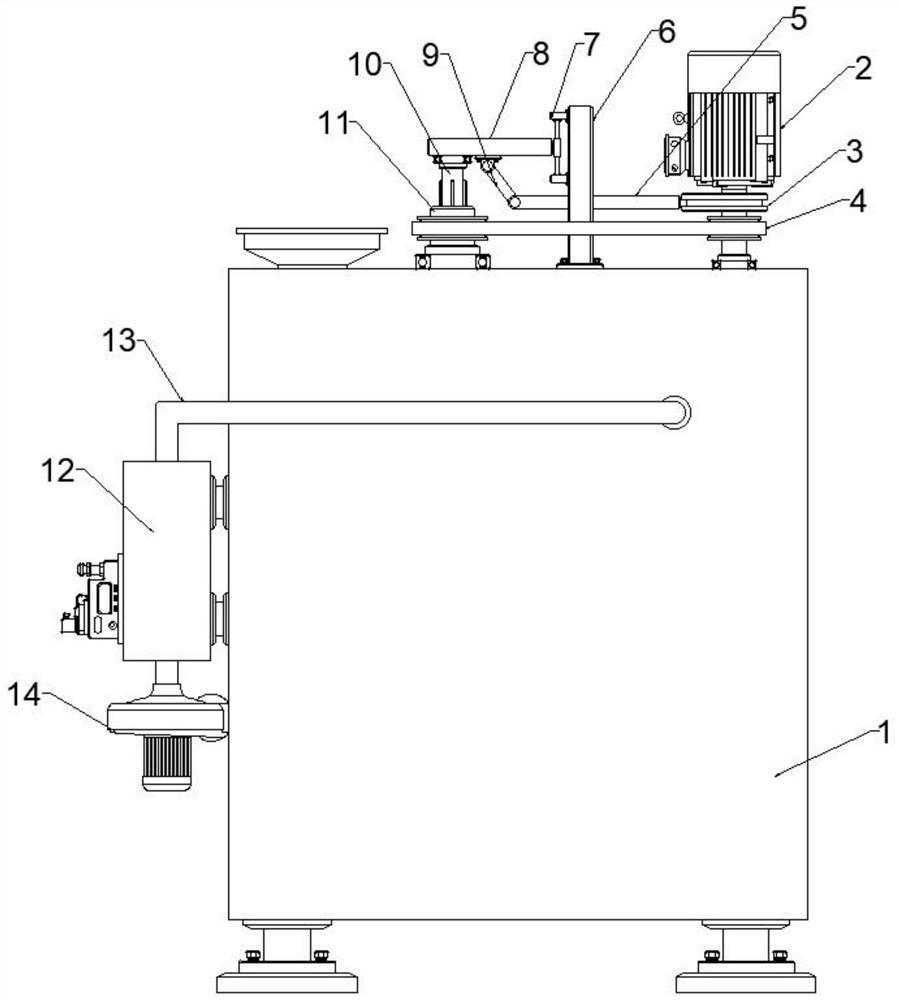

ActiveCN111335596ARealize circulating stirringStir wellBuilding constructionsDust controlStructural engineering

The invention discloses wall face coating spraying equipment for building decoration, and relates to the field of building decoration. A base is included. The top of the base is fixedly provided witha mixing box. An elevating device is arranged on one side of the mixing box. A conveying pump is fixedly connected between the elevating device and the mixing box. The elevating device is connected with a connecting column. The connecting column is fixedly connected with an outer stop cover. A dust removal device and a spraying device are arranged in the outer stop cover. A stirring mechanism is arranged in the mixing box. An outer circulating mixing mechanism is arranged at the outer portion of the mixing box. Through the arrangement of the stirring mechanism and the outer circulating mixingmechanism, coating circulating type stirring can be achieved, coating stirring is sufficient and rapid, and the stirring effect is good; through the arrangement of the dust removal device, brushing type dust removal can be conducted on the wall face before spraying, dust on the wall face is removed, a coating can be well combined with the wall face during later spraying; and through the arrangement of the spraying device, uniform spraying can be conducted on the wall face, and the wall face spraying effect is good.

Owner:浙江纳川纸业有限公司

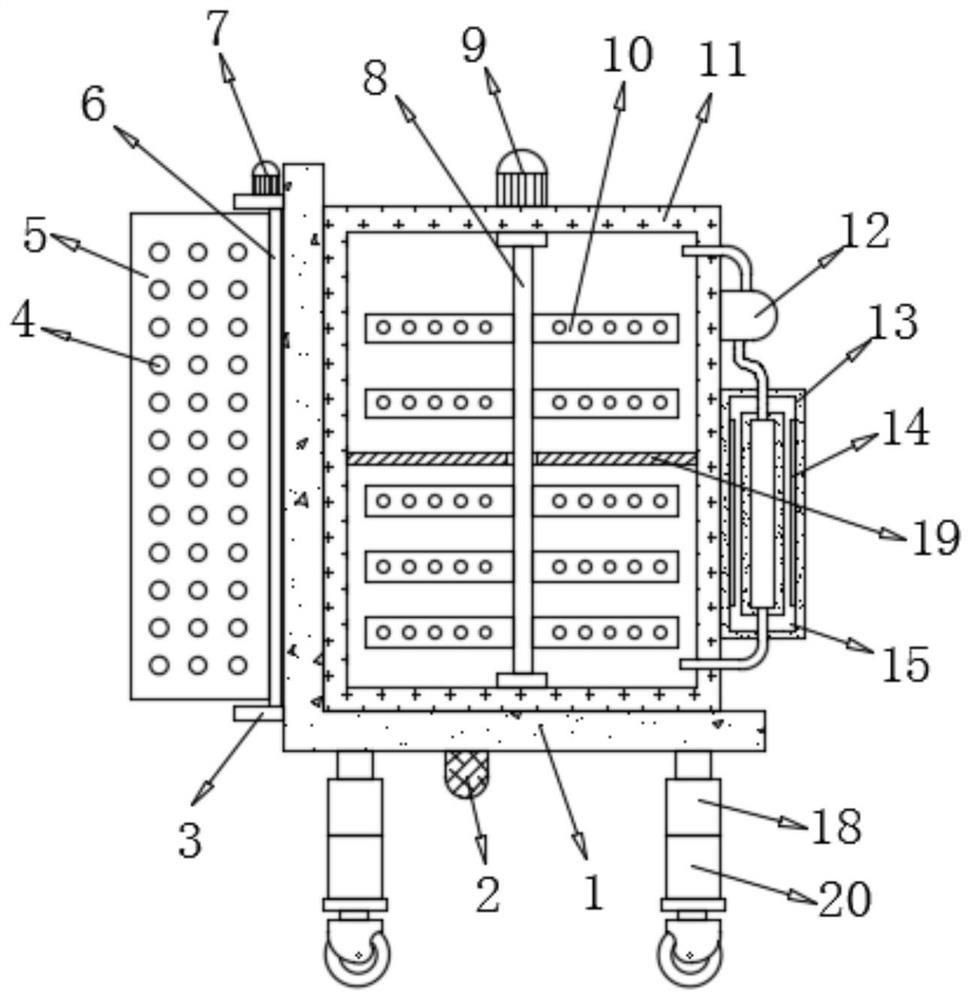

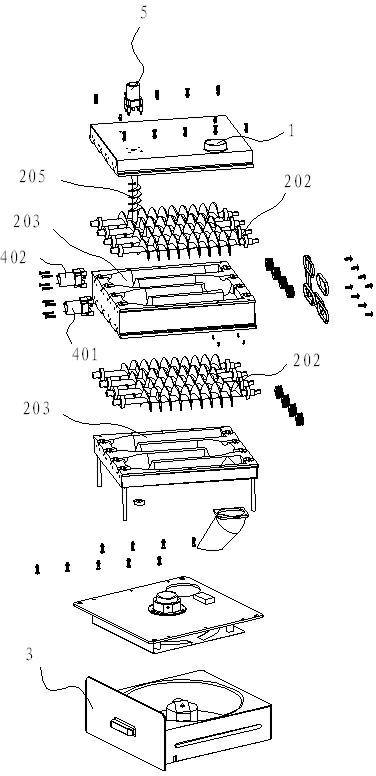

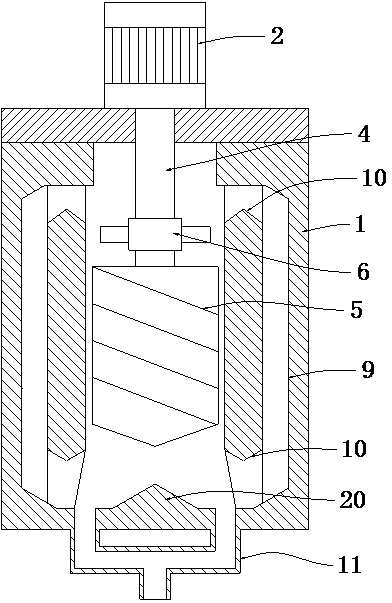

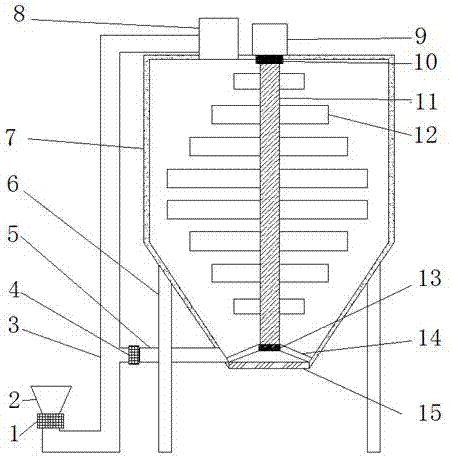

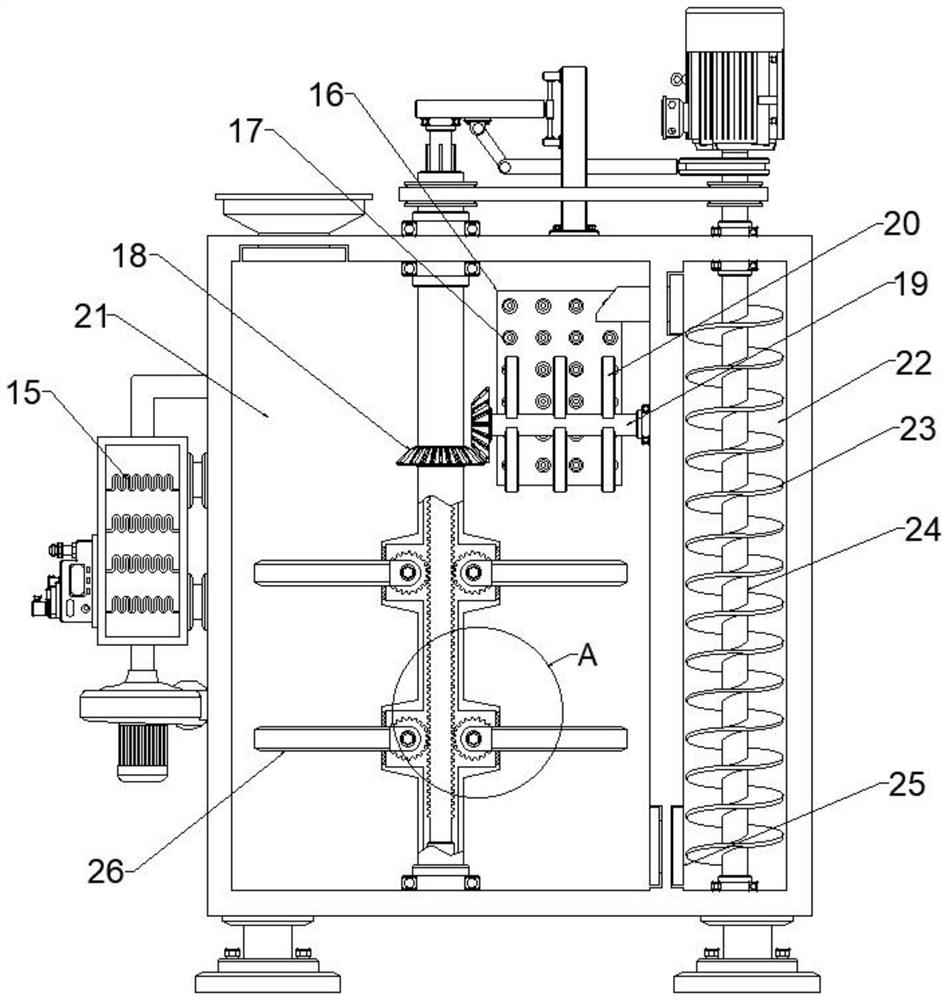

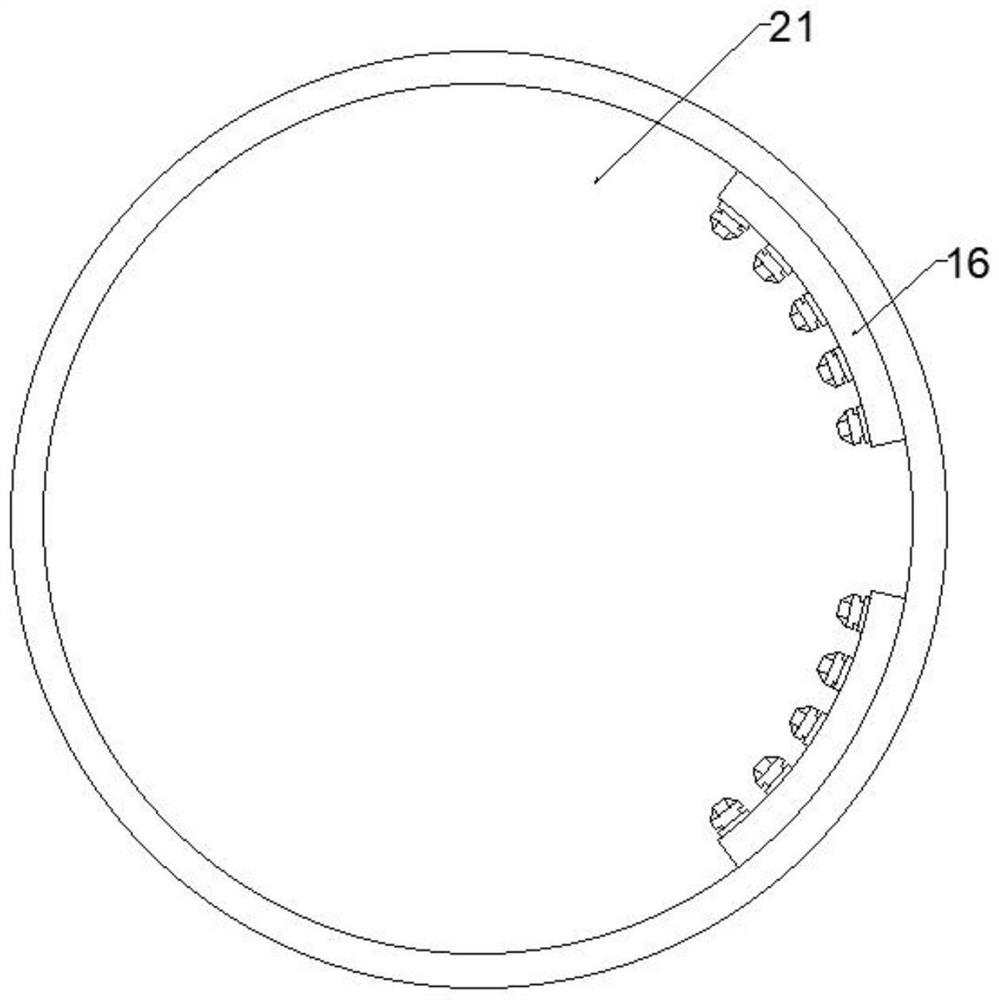

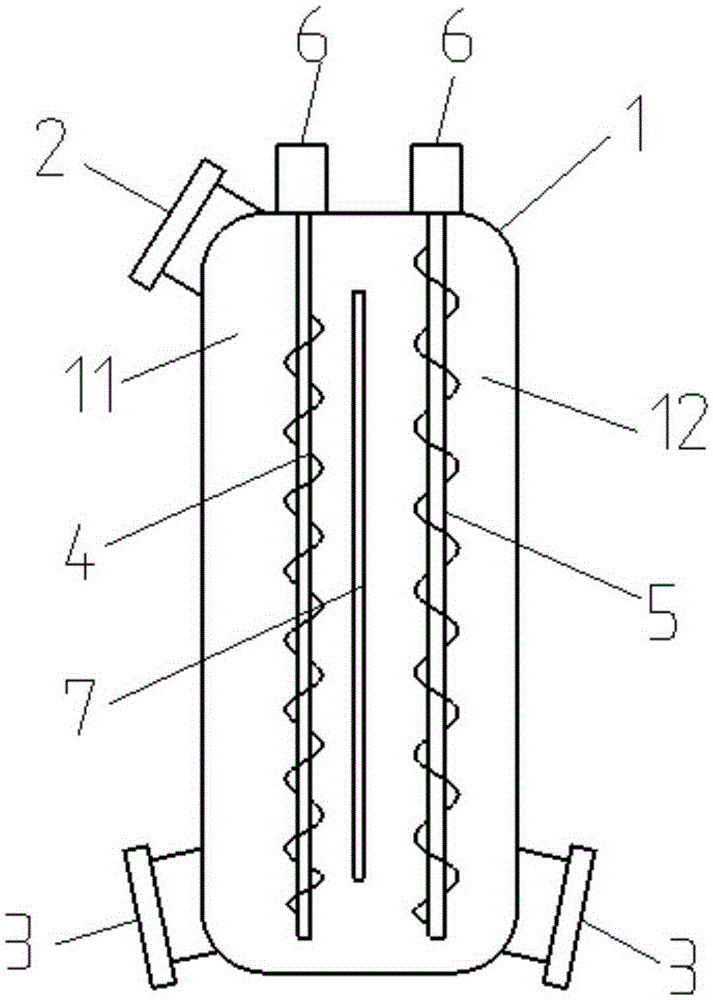

Efficient material stirring and mixing device used in pharmaceutical workshop

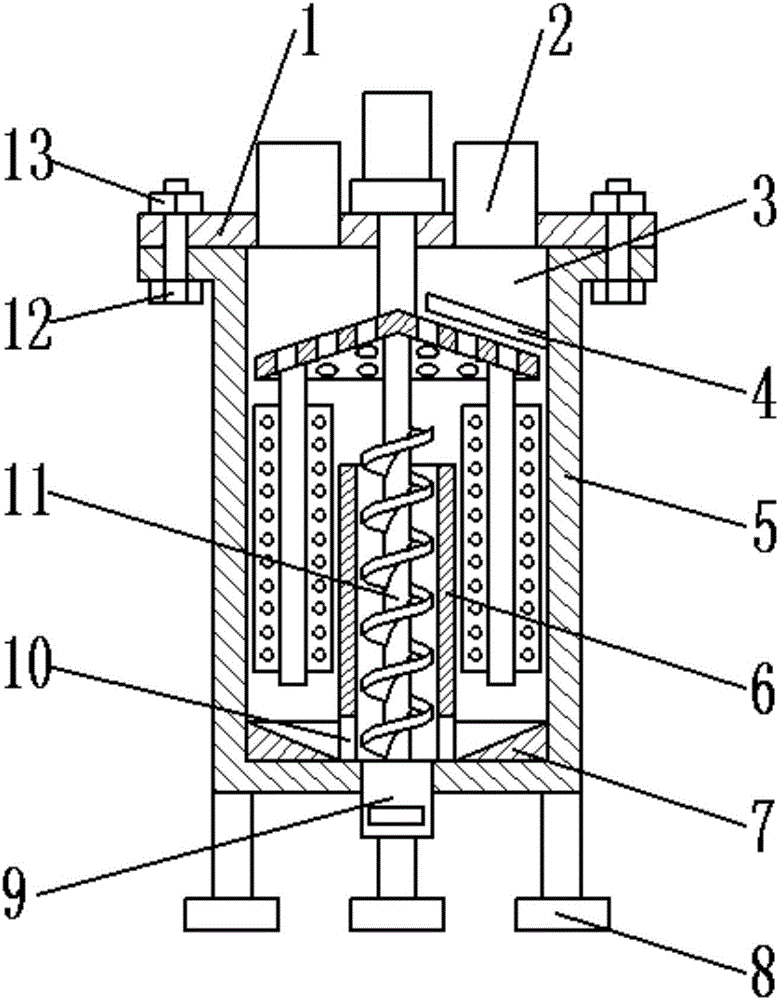

InactiveCN106732001AEasy to crushImprove mix qualityRotary stirring mixersTransportation and packagingEngineering

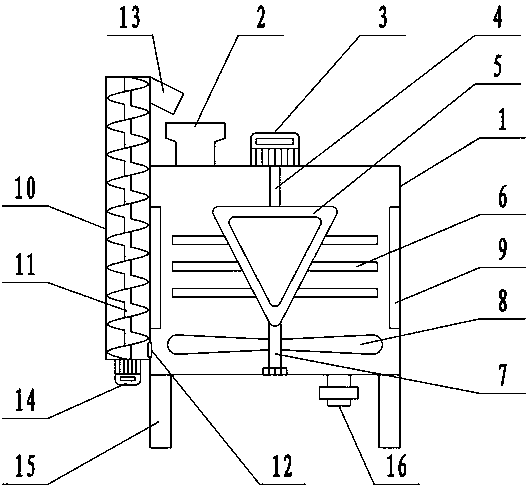

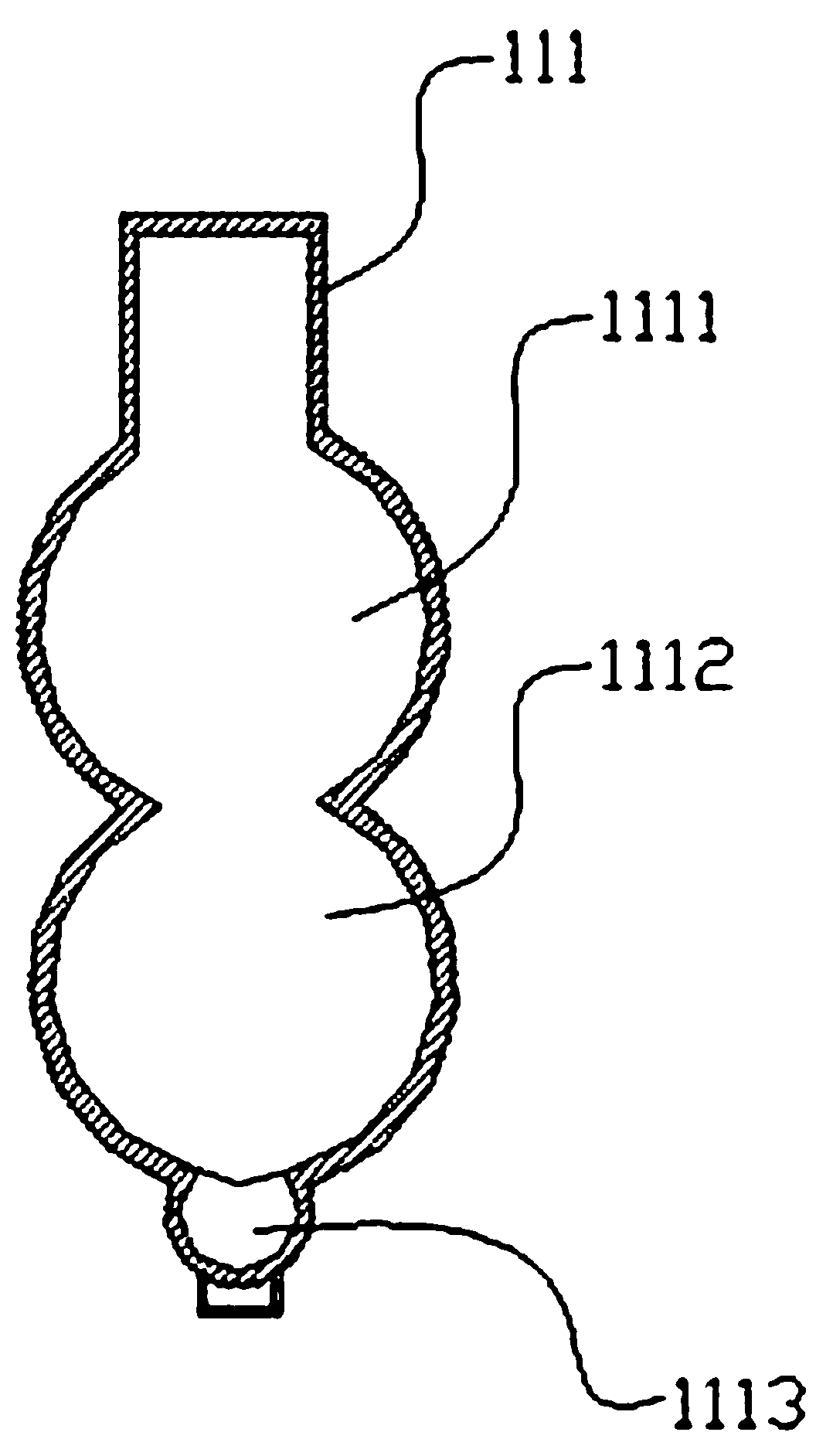

The invention provides an efficient material stirring and mixing device used in a pharmaceutical workshop. The efficient material stirring and mixing device comprises a tank body and an upper cover. A mixing cavity is formed in the tank body. The upper cover is provided with a feeding device. The feeding device consists of a crushing tank, a crushing motor, a crushing rotation shaft a fixed blade and a rotary blade. A stirring device is arranged in the mixing cavity. The stirring device consists of a rotary motor, a rotary shaft, a material uniformizing disc, a material lifter and a stirrer. The material lifter consists of a material lifting shaft and spiral material lifting blades. A material lifting tank is arranged on the outer side of the material lifter. The stirrer consists of a stirring shaft and stirring blades. A material guiding disc is arranged at the bottom of the tank body, and a material discharging pipe is arranged in the middle of the bottom surface. The efficient material stirring and mixing device crushes agglomerated materials through the feeding device to facilitate improvement of material stirring and mixing quality, and stirs and mixes materials in the tank body through the stirring device to facilitate improvement of the material stirring and mixing quality, the material blanking area is increased and mixing is promoted by arranging the material uniformizing disc.

Owner:河南微服网络科技有限公司

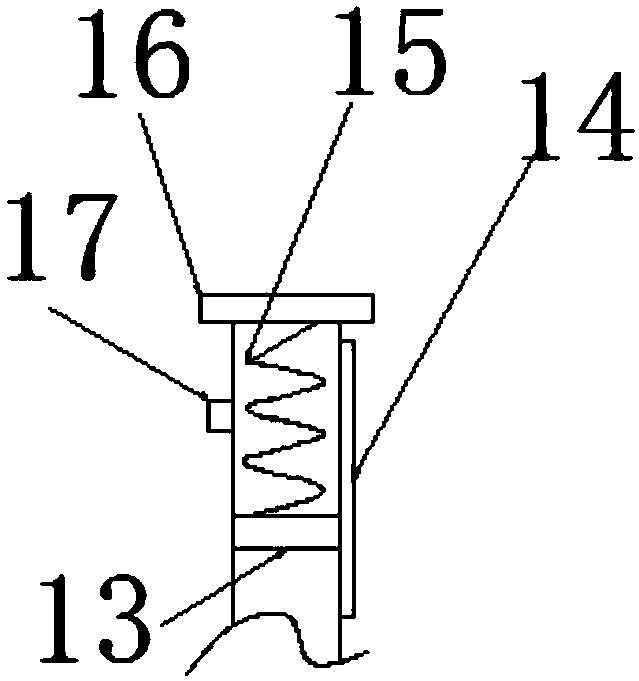

Watering device capable of realizing blind angle-free stirring

InactiveCN108159943AEasy to carryGood shock resistanceManure treatmentRoot feedersDrive motorHigh pressure

The invention discloses a watering device capable of realizing blind angle-free stirring. The watering device comprises a processing box and a pedestal; the pedestal is arranged on the lower part of the processing box; a driving motor is arranged on the upper end of the processing box; an output shaft of the driving motor is provided with a stirring shaft; a flow guide internal chamber is arrangedin the stirring shaft; the lower end of the flow guide internal chamber is provided with a through hole; a No.1 material pushing blade is arranged at an lower end opening of the flow guide internal chamber; the two sides of the upper end of the stirring shaft are symmetrically provided with overflow holes; stirring rods are arranged on the left side and the right side of the stirring shaft symmetrically. The watering device is convenient for transportation; the vibration resistance is excellent; material mixing effect is improved greatly; it is convenient to insert the watering device into soil for pouring; the watering device is provided with a pressure limiting mechanism to avoid over high pressure in the processing box, so that it is beneficial for prolonging of service life.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

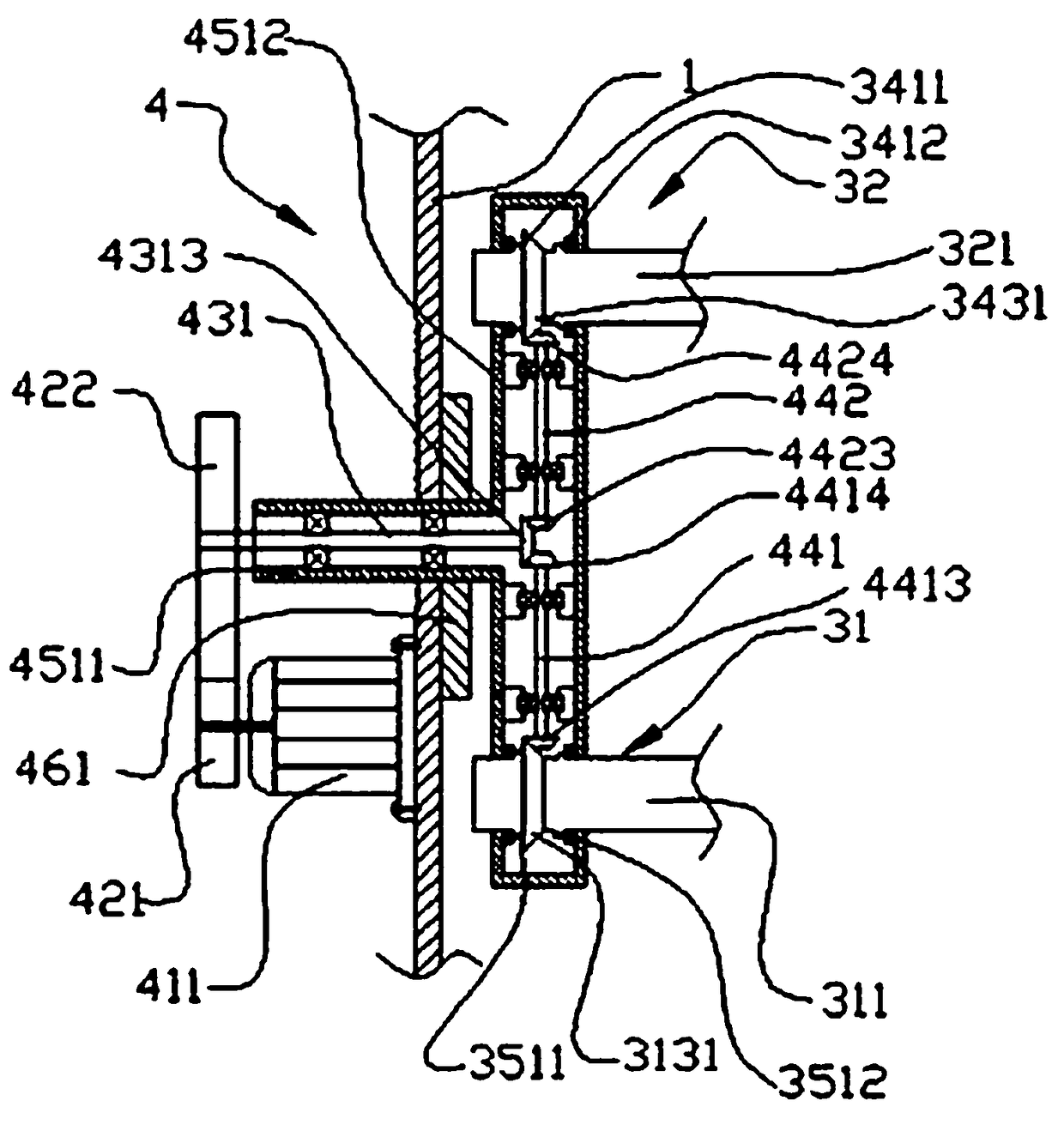

Stirring machine for buildings

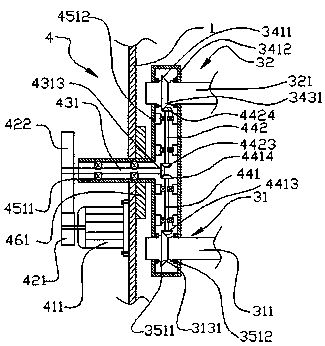

InactiveCN106272965ARealize circulating stirringImprove the mixing effectDischarging apparatusCement mixing apparatusEngineering

The invention discloses a stirring machine for buildings. The stirring machine comprises a shell, a vertical material guiding assembly, a stirring shaft assembly, a driving mechanism, a water inlet mechanism and a bearing mechanism, wherein materials enter the shell from a feed inlet in the shell; water enters the shell from the water inlet mechanism; stirring is achieved under the action of stirring shafts; the stirring shafts are driven through the driving mechanism; and materials at the bottom can be guided to the upper part to be fully stirred under the action of the vertical material guiding assembly, the stirring effect is improved, the segregation phenomenon of materials during the stirring process can be prevented, and after stirring, a discharge hole performs discharge. According to the stirring machine, stirring dead spaces in a traditional device are eliminated, the stirring effect is improved, and the stirring machine is suitable for wide application in the field of stirring.

Owner:晟唐伟业建设集团有限公司

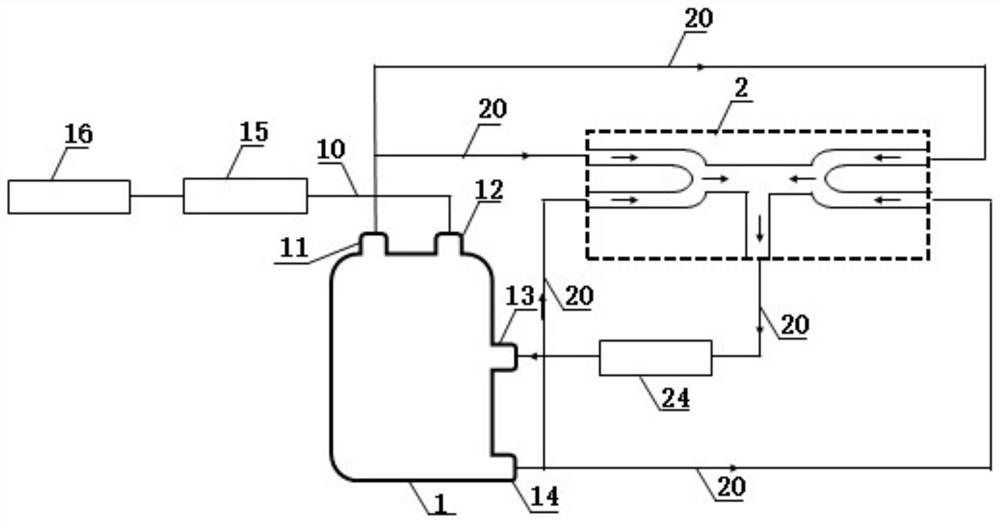

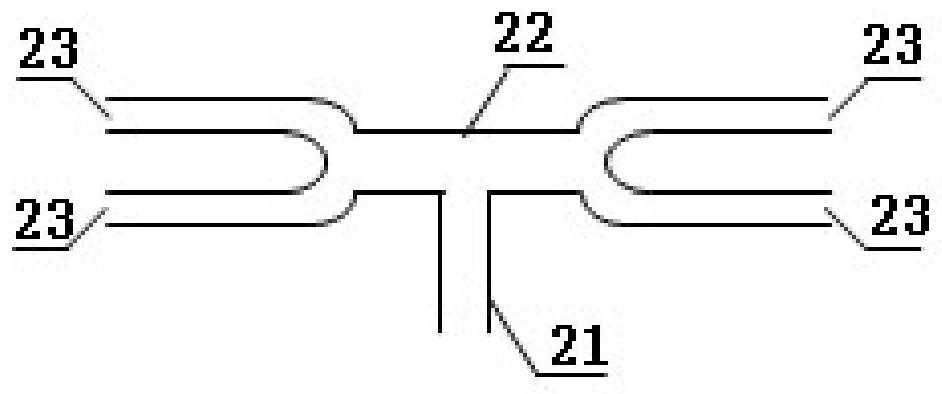

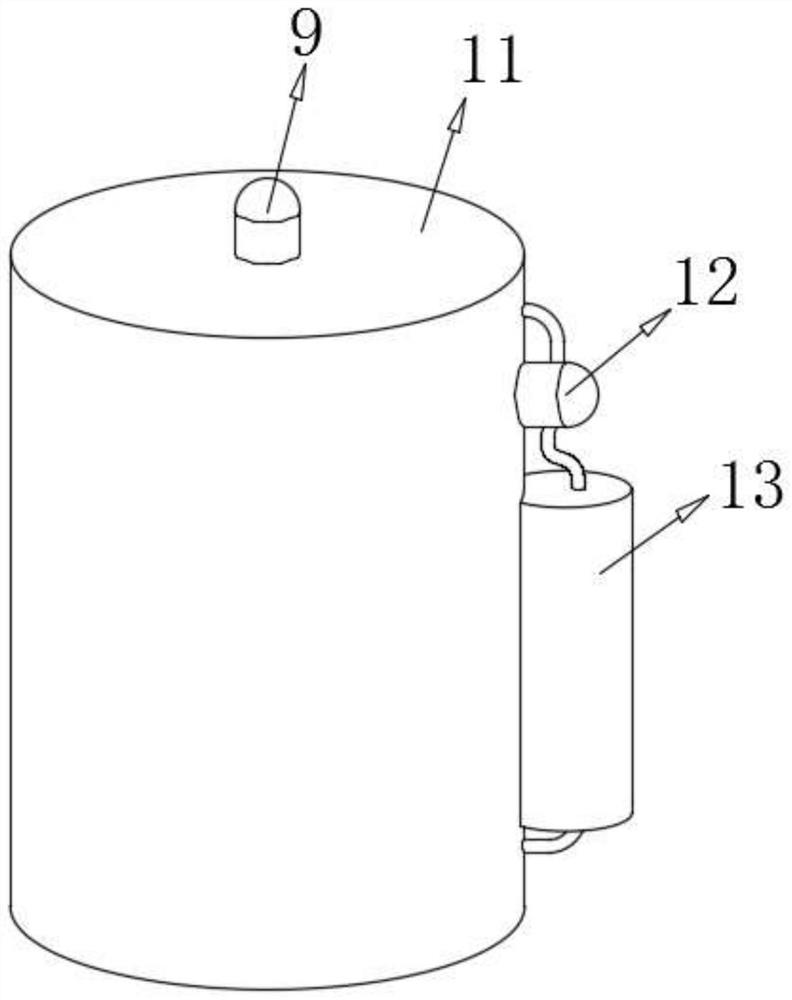

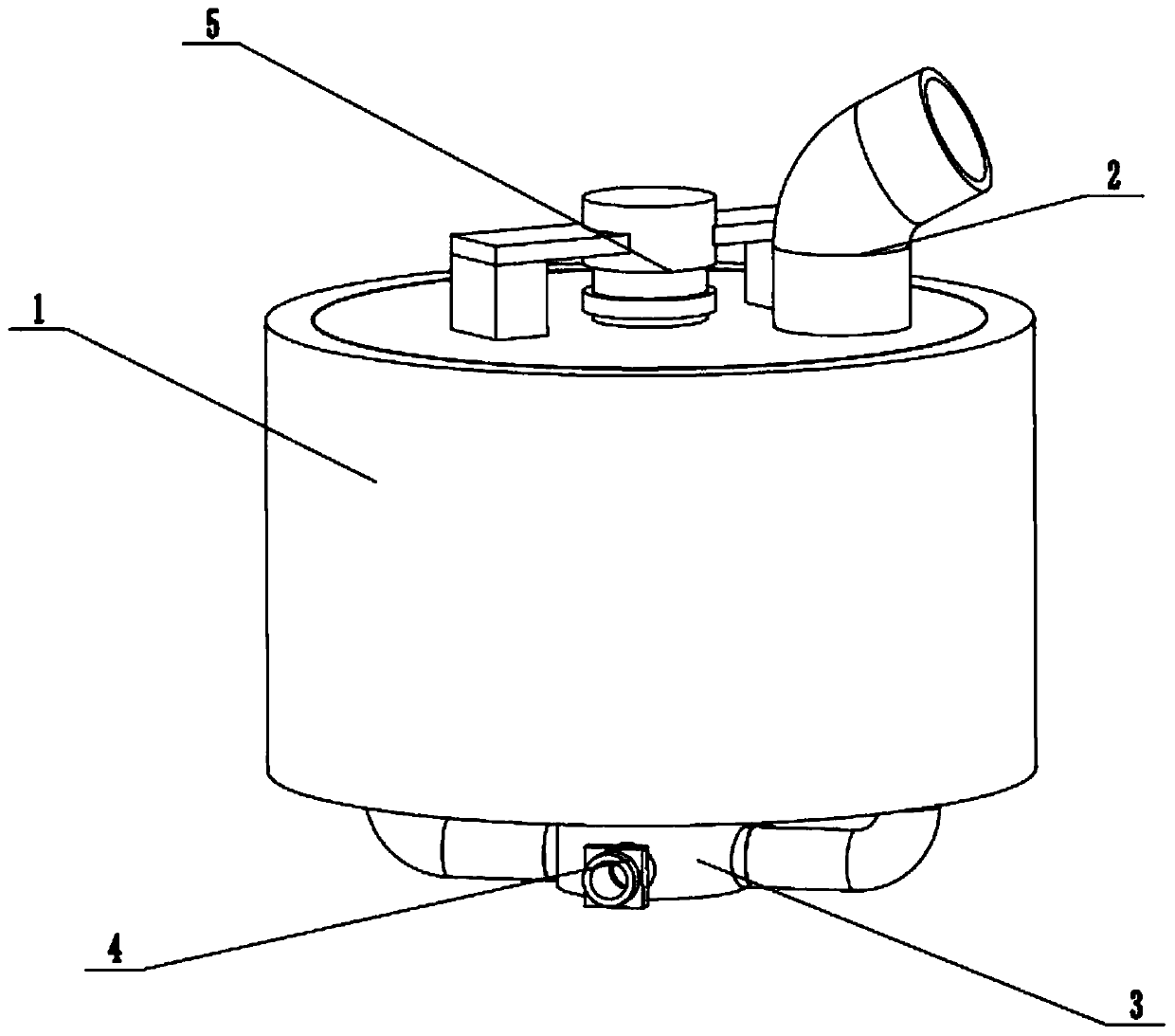

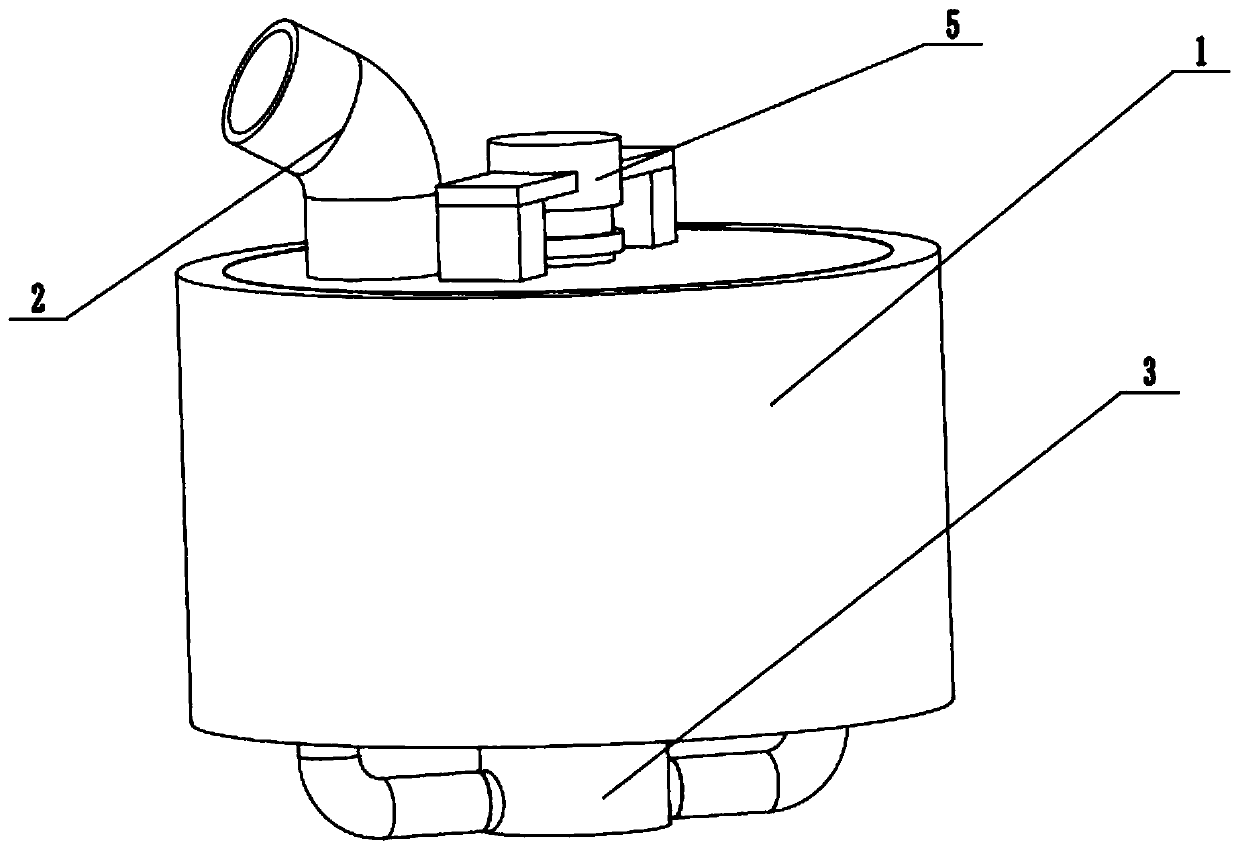

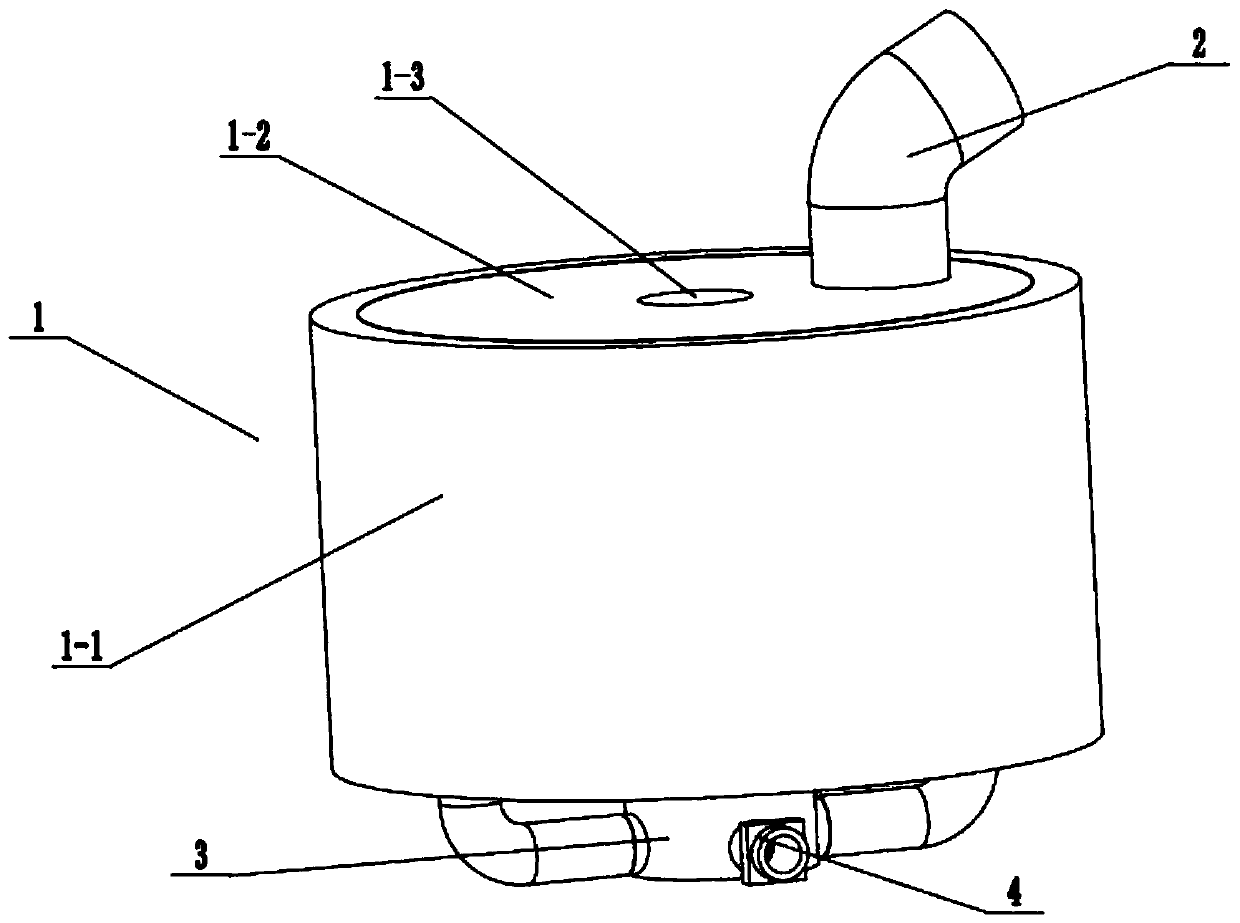

Gas mixing system of heptafluoroisobutyronitrile

PendingCN112791613ARealize circulating stirringWell mixedFlow mixersTransportation and packagingThermodynamicsEngineering

The invention provides a gas mixing system of heptafluoroisobutyronitrile, and the gas mixing system comprises a gas mixing tank and is characterized in that the gas mixing tank is connected with a gas circulating mixing pipeline with a mixer and a gas detection pipeline; the gas circulating mixing pipeline enters the mixer from the top and the bottom of the gas mixing tank at the same time and then returns from the middle of the gas mixing tank through the circulating pump, so the gas is circularly stirred, the operation is simple and convenient, and uniform mixing of heptafluoroisobutyronitrile mixed gas can be well realized. Meanwhile, the gas mixing system provided by the invention can intuitively observe the mixing condition of the gas and judge the mixing end point of the heptafluoroisobutyronitrile mixed gas by detecting the gas in the gas mixing tank 1 in real time, so the mixing efficiency is greatly improved, and the time is saved.

Owner:CHEM & CHEM ENG GUANGDONG LAB +1

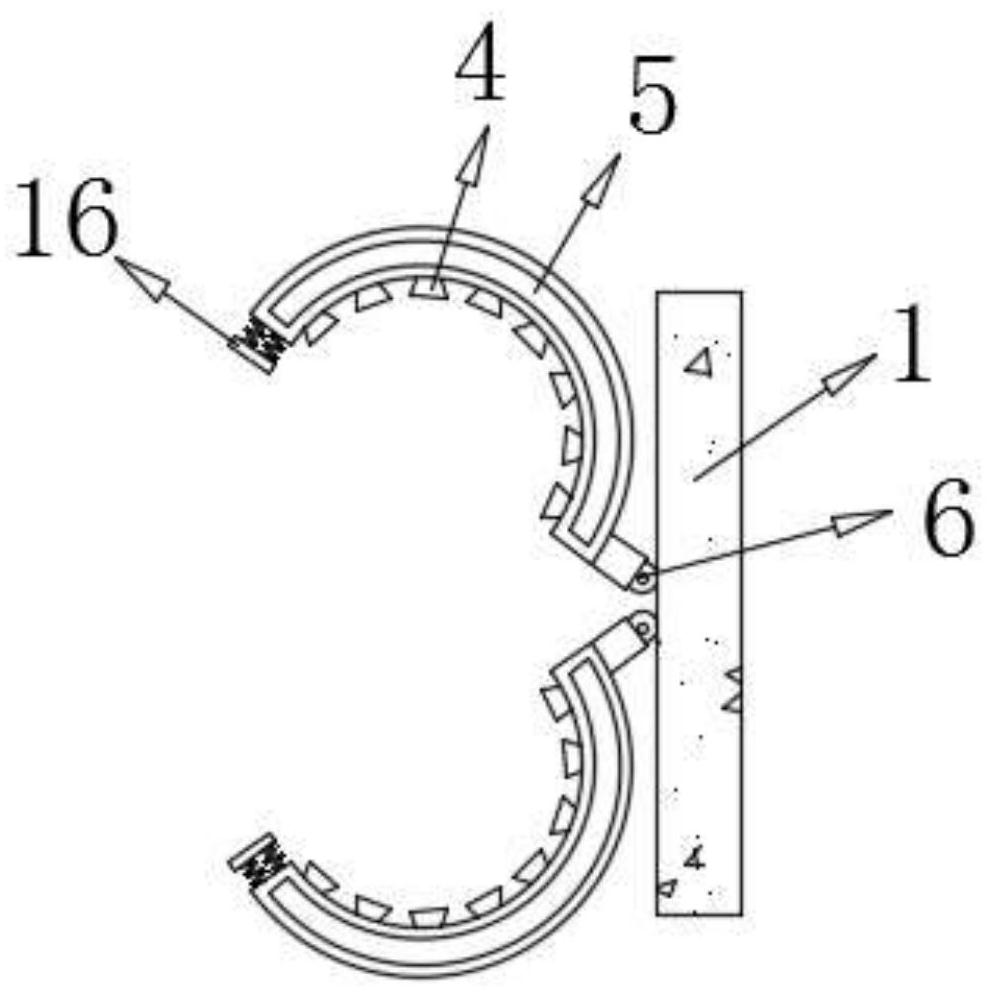

Tree trunk whitewashing device for garden

InactiveCN112452594AWhite evenlyPrevent mis-sprayingLiquid spraying apparatusPlant protectionTree trunkAgricultural engineering

The invention discloses a tree trunk whitewashing device for a garden. The tree trunk whitewashing device comprises a movable seat with an L-shaped cross section, wherein the top of the movable seat is connected with a material storage barrel through a bolt; the bottom of the movable seat is connected with a first conveying pump through a bolt; a stirring mechanism is arranged in the material storage barrel; the top and the bottom of one side of the movable seat are connected with mounting plates correspondingly through bolts; and one side of one mounting plate is connected with a rotary motorthrough bolts. According to the tree trunk whitewashing device disclosed by the invention, a stirring motor drives a rotary rod and a stirring paddle to stir and uniformly mix a whitewashing agent; the movable seat is pushed to move so that a tree trunk is located between two movable plates; the rotary motor drives the two movable plates to rotate around a rotary shaft and cover an outer wall ofthe tree trunk in a buckling manner; the first conveying pump is used for pumping the whitewashing agent in the material storage barrel into the movable plates and spraying the whitewashing agent through a spraying nozzle to uniformly whitewash the tree trunk; and the tree trunk whitewashing device is convenient and efficient, and the circumstance that the whitewashing agent is sprayed onto clothes by mistake in a spraying process is avoided.

Owner:薛晶

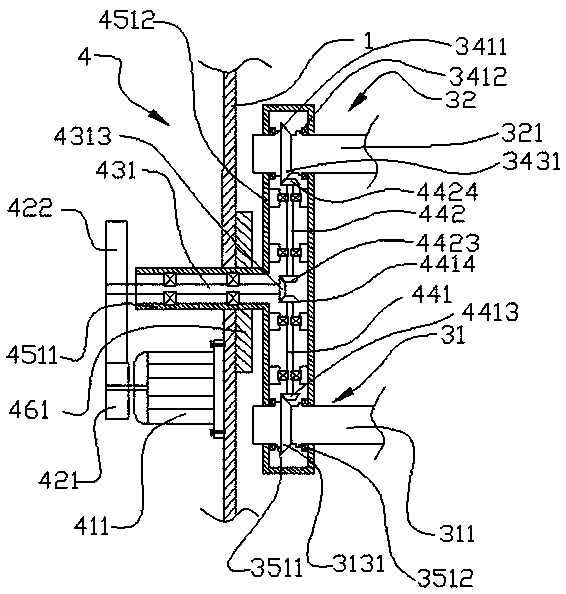

Concrete mixer

ActiveCN106182419ARealize circulating stirringImprove the mixing effectCement mixing apparatusLiquid ingredients supply apparatusMixing effectMechanical engineering

The invention discloses a concrete mixer. The concrete mixer comprises a shell, a vertical leading assembly, a mixing shaft assembly, a driving mechanism, a water feeding mechanism and a bearing mechanism; a material enters the shell through a feed port in the shell; water enters the shell from the water feeding mechanism; the mixing is realized under an effect of a mixing shaft; the mixing shaft is driven by the driving mechanism; the material at the bottom can be leaded to the upper part for fully mixing under an effect of the vertical leading assembly to promote a mixing effect and to prevent segregation phenomenon in the material mixing process; and the material is unloaded from a discharge port after mixing. The concrete mixer eliminates mixing dead angles in a traditional device, improves the mixing effect, and is suitable for wide application in the mixing field.

Owner:扬州扬工机械有限公司

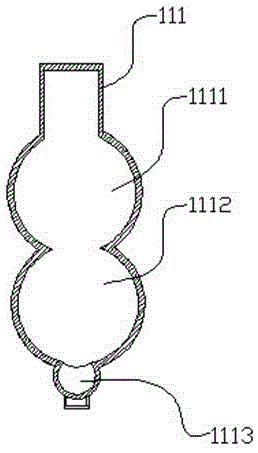

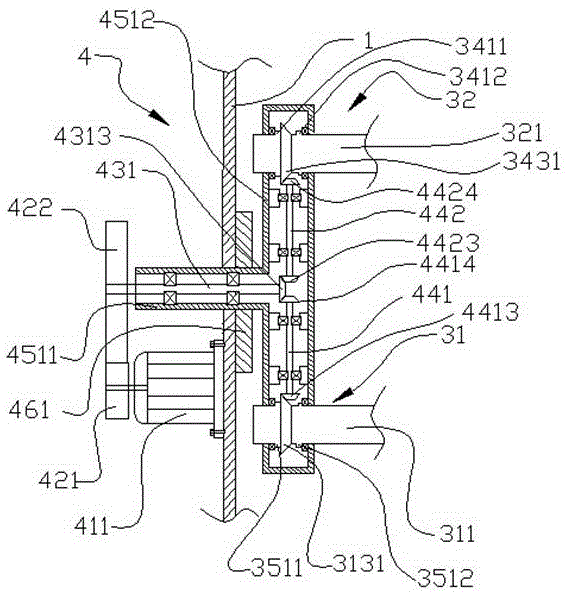

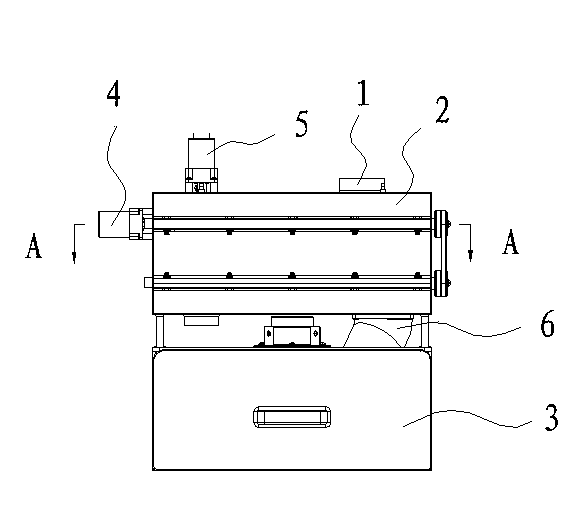

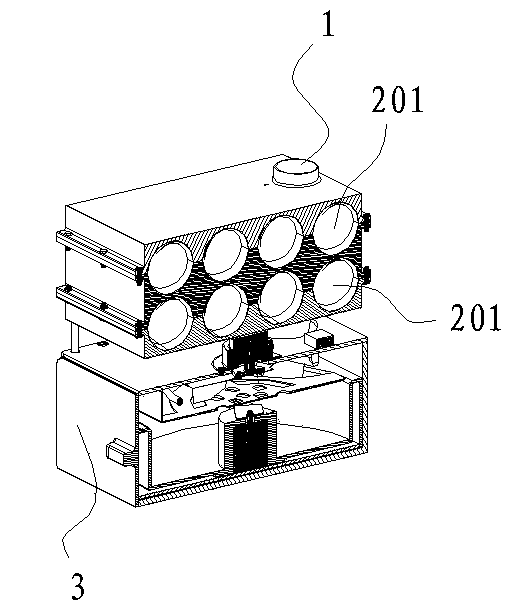

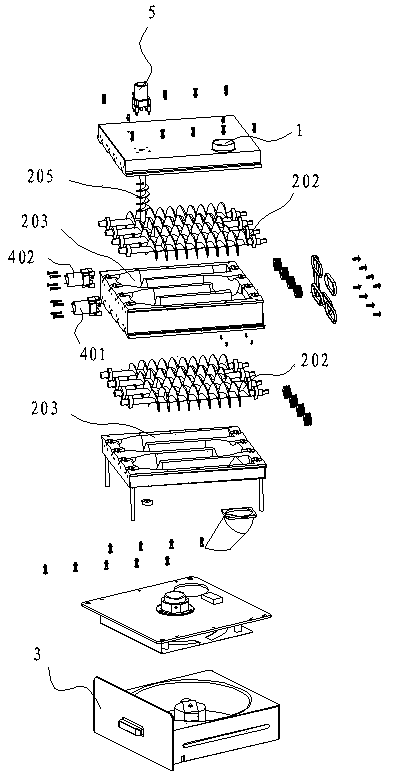

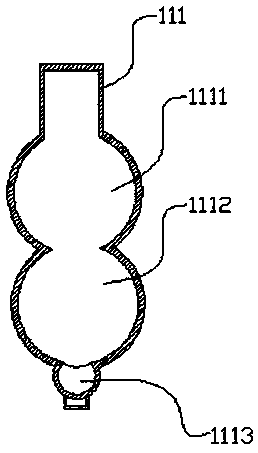

Magnetic ferrite core forming equipment feeding device

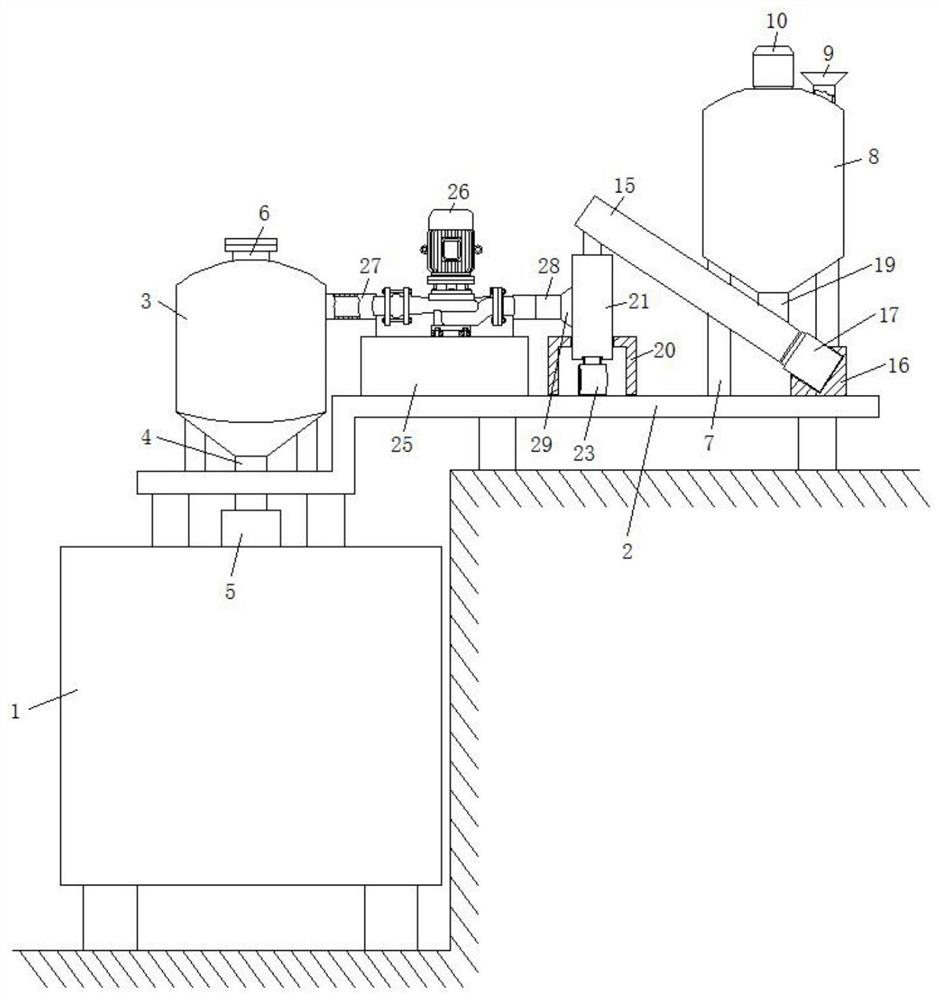

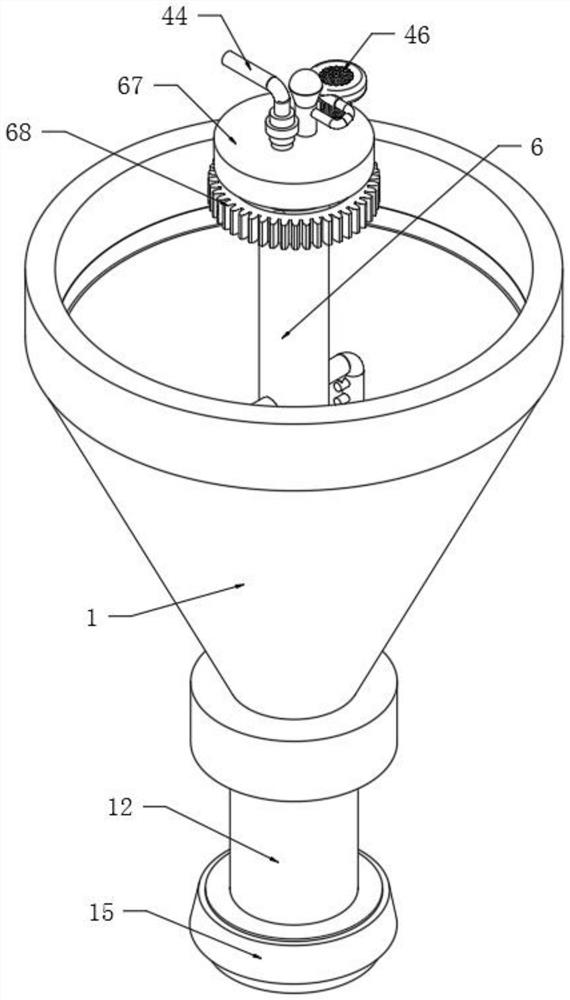

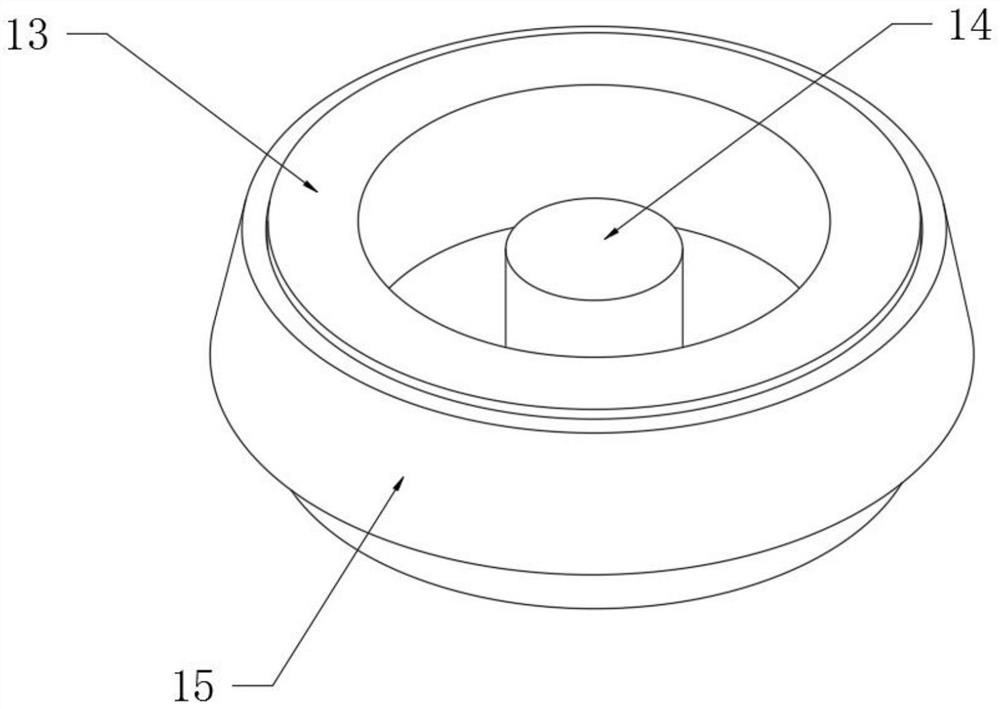

ActiveCN111891666AReasonable designGood quality powderRotary stirring mixersBulk conveyorsMagnetic coreStructural engineering

The invention discloses a magnetic ferrite core forming equipment feeding device. The magnetic ferrite core forming equipment feeding device comprises a forming equipment body, a material injection pipe is fixed to the feeding end of the forming equipment body, a mounting frame is arranged at the upper end of the forming equipment body, a cyclone collector is fixed to one side of the top face of the mounting frame, a feeding pipe is fixed to the output end of the cyclone collector, the lower end of the feeding pipe is arranged in the material injection pipe, an exhaust pipe is further fixed tothe top of the cyclone collector, a supporting base is further fixed to the other side of the top face of the mounting frame, a storage barrel is fixed to the top of the supporting base through screws, a feeding hopper is connected to one side of the upper end of the storage barrel in a penetrating mode, and a first servo motor is further fixed to the center of the top face of the storage barrelthrough screws. The device is reasonable in design, the loading operation of ferrite core forming is realized by adopting a negative pressure adsorption mode, the powder quality is good, the influenceof caking in the powder on the production quality of the ferrite core is avoided, and the preparation quality of the ferrite core is well ensured.

Owner:天长市烁源磁电有限公司

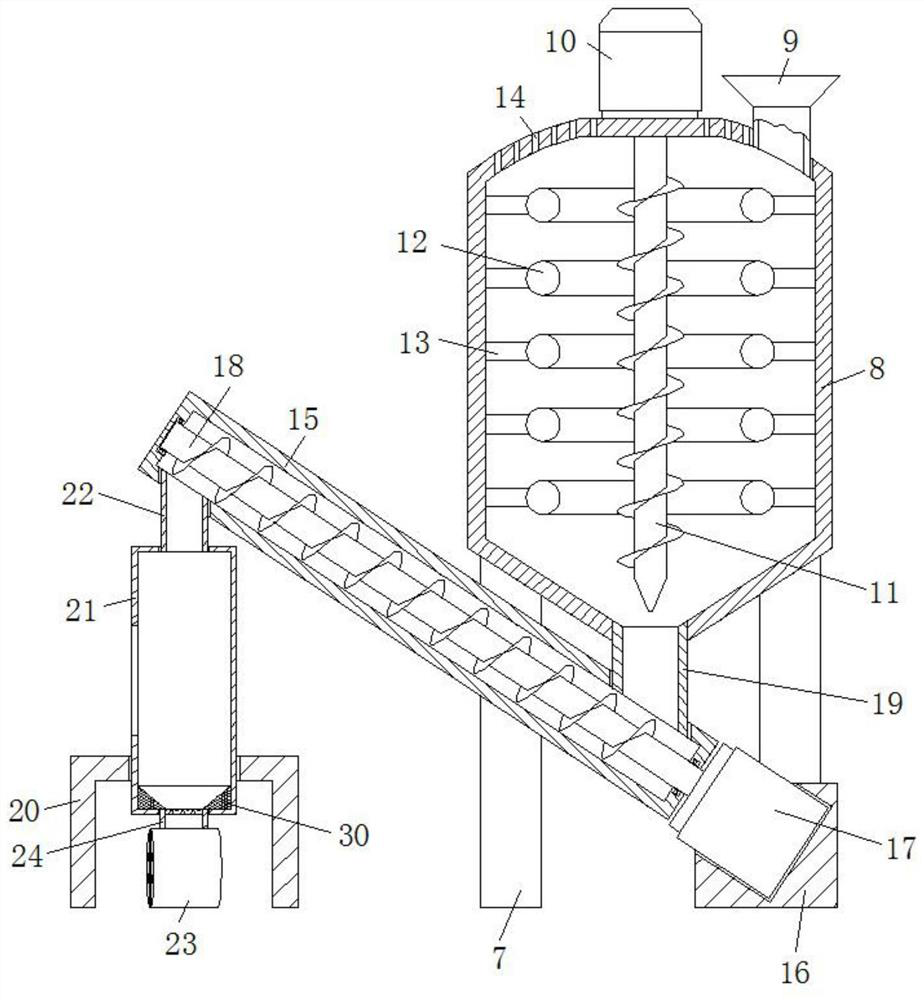

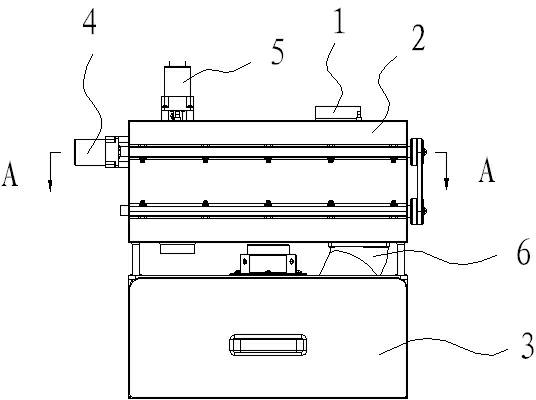

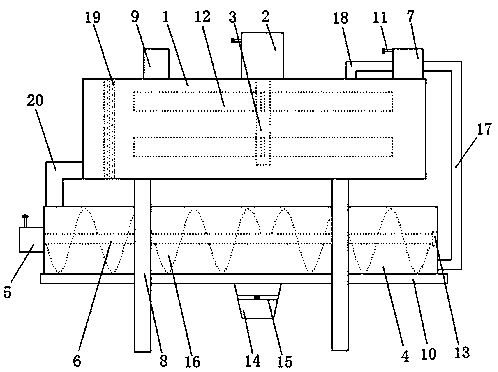

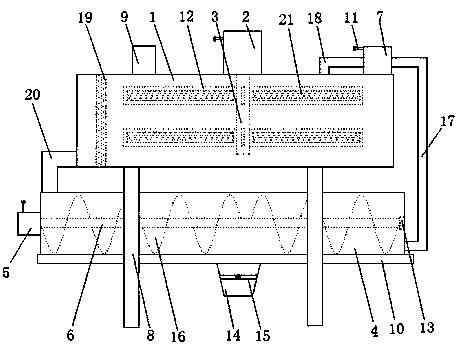

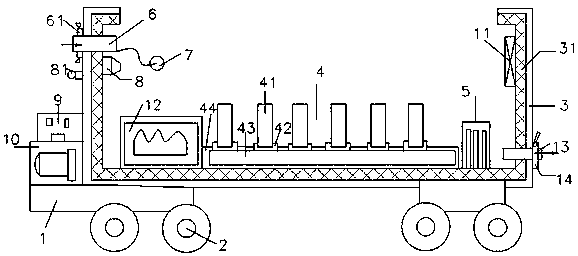

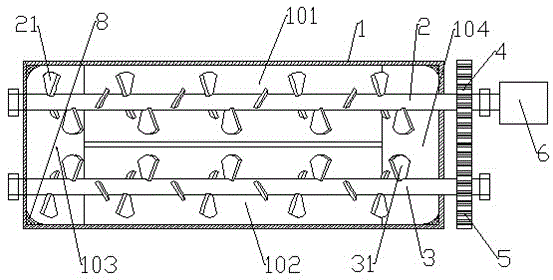

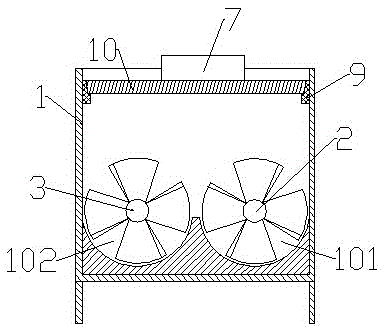

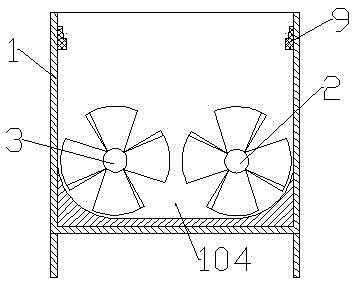

Repeated lifting and stirring air drying device for feed raw materials

InactiveCN108224993AExpand the spraying areaEasy to exportFeeding-stuffDrying gas arrangementsEngineeringCentrifugal force

The invention provides a repeated lifting and stirring air drying device for feed raw materials, and belongs to the technical field of feed drying. The air drying device comprises a box body, supporting legs and a stirring air drying device, wherein a feeding pipe is arranged on the box body. According to the air drying device, a stirring air drying device body is arranged, hot air is blown into an air inlet pipe through a hot air blower, the hot air passes through a second gear, a rotating rod and flow passages arranged in an air distribution plate to spray out of nozzles uniformly distributed on the surface of the air distribution plate, so that the spraying area of the hot air is enlarged, full contact with the feed raw materials is facilitated, and the drying quality is improved; and the rotating rod is driven to rotate through a rotating motor and a transmission box, the rotating rod drives spiral lifting blades to rotate, the feed raw materials at the bottom part of a box body are lifted upwards, meanwhile, stirring blades among the spiral lifting blades are used for carrying out stirring treatment on the feed raw materials, the lifted materials fall back to the bottom part of the box body under the action of centrifugal force, so that circulating stirring of the feed raw materials is realized, and the drying quality of the feed raw materials is improved.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Fermentation treatment device for organic waste

ActiveCN102627480ACompact structureEasy to storeClimate change adaptationOrganic fertilisersLitterFermentation

The invention discloses a fermentation treatment device for organic wastes. The fermentation treatment device comprises a fermentation treatment chamber with a feed inlet, and a drying and storage chamber which is communicated with the discharge outlet of the fermentation treatment chamber. The fermentation treatment chamber comprises a plurality of horizontally and abreast arranged straight round pipes. An agitating screw which is driven by a motor is arranged in each round pipe. The adjacent end parts of the abreast round pipes are serially connected to form a zigzag connected run-through fermentation treatment pipe chamber. The initial end of the fermentation treatment pipe chamber is communicated with the feed inlet and the terminal end of the fermentation treatment pipe chamber is communicated with the discharge outlet. The organic wastes and zymophyte are fed through the feed inlet to enter from the initial end of the fermentation treatment pipe chamber. The organic wastes and the zymophyte in the fermentation treatment pipe chamber are fully fermented under the agitation of the agitating screws, then enter the drying and storage chamber through the discharge outlet and are dried. The fermentation treatment device is suitable for places such as families, restaurants and hotels and can purify and treat the organic wastes into fertilizers capable of being used by plants. The treated fertilizers are convenient to store and do not have peculiar smells.

Owner:YUHUAN SENDOE SANITARYWARE

Stirring machine for construction

ActiveCN106182420ARealize circulating stirringImprove the mixing effectCement mixing apparatusLiquid ingredients supply apparatusArchitectural engineering

The invention discloses a stirring machine for construction. The stirring machine for construction comprises a shell, a vertical guiding assembly, a stirring shaft assembly, a driving mechanism, a water inlet mechanism and a carrying mechanism. Materials enter the shell through a feeding port in the shell. Water enters the shell from the water inlet mechanism. Stirring is achieved under the action of stirring shafts. The stirring shafts are driven by the driving mechanism. The materials at the bottom can be guided to the upper portion to be fully stirred under the action of the vertical guiding mechanism, so that the stirring effect is improved, the separation phenomenon of the materials in the stirring process can be prevented, and discharging is conducted through a discharging port after stirring is completed. By the adoption of the stirring machine for construction, stirring dead angles existing when a traditional device is used are eliminated, and the stirring effect is improved. The stirring machine for construction is suitable for being widely applied in the stirring field.

Owner:江苏力连重工机械有限公司

Circular-type mixing device suitable for paint production

InactiveCN108970440AImprove mixing efficiency and mixing qualityImprove mix qualityFlow mixersRotary stirring mixersEngineeringMixing chamber

The invention discloses a circular-type mixing device suitable for paint production. The circular-type mixing device comprises a first mixing chamber, a first motor, a first transmission shaft, a second mixing chamber, a second motor, a second transmission shaft and an infusion pump. The first mixing chamber is installed on a bracket. The first motor is installed on the first mixing chamber. The first transmission shaft is installed in the first mixing chamber. The second mixing chamber is installed on a base plate. The second motor is installed on the outer wall of the second mixing chamber.One end of the second transmission shaft is installed in a bearing. The circular-type mixing device is capable of enabling the infusion pump to be connected with the second mixing chamber and the first mixing chamber through a liquid inlet pipe and an infusion pipe, enabling paint in the second mixing chamber to enter the infusion pump through the liquid inlet pipe, and entering the first mixing chamber through the infusion pipe, enabling the paint to be circularly flowed in the first mixing chamber, the second mixing chamber and the infusion pump, realizing circular stirring to the paint, andimproving mixing efficiency of the paint.

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

A paint processing mixing and stirring device

ActiveCN109012261BWell mixedQuality improvementFlow mixersTransportation and packagingRotational axisElectric machinery

The invention discloses a mixing and stirring device for paint processing, which comprises a tank body and a deceleration motor placed on the top of the tank body. A control switch is arranged on the surface of the tank body, and a rotating shaft is provided at the end of the output shaft of the deceleration motor. The shaft is placed inside the tank, the end of the rotating shaft is provided with a pusher stirring head, the middle of the rotating shaft is provided with a connecting block, the outer side of the connecting block is surrounded by a number of stirring blades, and the outer side of the cylindrical tank is provided with two second One through hole, the invention can drive the rotating shaft to rotate through the geared motor, and can drive the pushing material mixing head and the mixing blade to rotate through the rotating shaft, and can not only mix and stir the raw materials through the pushing material stirring head, but also squeeze the raw materials downward Pushing makes the raw materials flow inside the tank, and then moves down from the position near the top of the tank again to realize circular stirring, improve the stirring effect, and make the raw materials fully mixed.

Owner:南通立方新材料科技有限公司

Efficient chloroacetate material stirring device

InactiveCN107159047AImprove stirring efficiencyImprove mix qualityTransportation and packagingMixersEngineeringGround level

The invention discloses an efficient chloroacetate material stirring device which comprises a stirring tank. The bottom of the stirring tank is of an opening structure, a bin gate is connected with the bottom of the stirring tank by a hinge, a rotary shaft support is welded on the inner wall of the bottom of the stirring tank and is of an X-shaped structure, a bearing block is welded in the center of the rotary shaft support, a second bearing is nested in the inner wall of the bearing block, and an opening is formed in the central point of the top of the stirring tank. The efficient chloroacetate material stirring device has the advantages that stirring blades with uneven lengths are mounted in an inner cavity of the stirring tank, and accordingly the stirring efficiency and stirring quality of chloroacetate in the stirring tank can be improved; a discharge pipe is additionally arranged at the bottom of the stirring tank and is connected with a vacuum feeding machine, and accordingly the chloroacetate at the bottom of the stirring tank can be fed into the top of the stirring tank again via the discharge pipe and can be circularly stirred; a feed hopper is mounted on the ground, accordingly, materials can be conveniently fed by employees, and labor can be saved.

Owner:YANCHENG GUOZHONG CHEM CO LTD

Building mixer

ActiveCN106272966ARealize circulating stirringImprove the mixing effectCement mixing apparatusArchitectural engineering

The invention discloses a building mixer. The building mixer comprises a shell, a vertical leading assembly, a stirring shaft assembly, a driving mechanism, a water feeding mechanism and a bearing mechanism; a material enters the shell through a feed port in the shell, and water enters the shell from the water feeding mechanism to realize stirring under the effect of a stirring shaft; the stirring shaft is driven by the driving mechanism; and the material at the bottom can be leaded to the upper part under the effect of the vertical leading mechanism for full stirring to enhance the stirring effect and to prevent the segregation phenomenon in the material stirring process, and is unloaded by a discharge port after stirring. The building mixer eliminates the stirring dead angles in a traditional device, improves the stirring effect, and is suitable for wide application in the stirring field.

Owner:THE SECOND CONSTR ENG CO LTD CCSEB

Self-cycle asphalt agitating equipment

InactiveCN108311055AStir wellRealize circulating stirringFlow mixersTransportation and packagingBiochemical engineeringAsphalt

The invention discloses self-cycle asphalt agitating equipment. The self-cycle asphalt agitating equipment comprises a tank body, a material feed port, an agitating motor, agitating rods, support legsand a material discharge tube, wherein the top of the tank body is fixedly connected with the material feed port, the upper surface of the tank body is fixedly connected with the agitating motor, a shaft stretch end of the agitating motor is fixedly connected with an agitating frame, the left and right of the agitating frame are fixedly connected with a plurality of agitating rods separately, theinner wall of the tank body is fixedly connected with a plurality of electric heating boards, and the left side wall of the tank body is fixedly connected with a cycle cylinder. In the agitating process, the electric heating board heats and melts the asphalt, so that the asphalt can be agitated conveniently; due to arrangement of the agitating frame in an inverted triangular shape, the agitatingscope is increased and the agitating effect is better; agitating blades agitate bottom asphalt to overturn upward, thereby further improving agitating effect; the cycle cylinder enables the asphalt tobe agitated circularly, thereby improving a agitating effect and making the asphalt be agitated more thoroughly.

Owner:云和县东泽阀门有限公司

Anti-caking organic fertilizer mixing and drying integrated equipment

InactiveCN112595058AImprove the mixing effectRealize circulating stirringDrying gas arrangementsDrying machines with non-progressive movementsDrive shaftElectric machine

The invention relates to anti-caking organic fertilizer mixing and drying integrated equipment, comprising a shell. The inner side of the shell is divided into a mixing cavity and a lifting cavity through a partition plate; the mixing cavity and the lifting cavity communicate through a through hole formed in the partition plate and a discharge pipe; a lifting assembly is arranged on the inner sideof the lifting cavity; the lifting assembly is connected with an output shaft of a motor installed on the shell; a hollow driving shaft is rotatably installed on the inner side of the mixing cavity;the hollow driving shaft is rotatably connected with the output shaft of the motor through a transmission belt; a plurality of protruding cavities are formed in the hollow driving shaft; second stirring rods are rotatably installed on the protruding cavities; and a scattering assembly is further rotatably installed at the position, located at a discharge port of the discharge pipe, in the mixing cavity and rotatably connected with the hollow driving shaft. When an organic fertilizer is discharged from the discharge pipe, the organic fertilizer is scattered through the scattering assembly, so that the caking phenomenon of the organic fertilizer in the mixing process is effectively prevented.

Owner:安乡县守安鸭业农民专业合作社

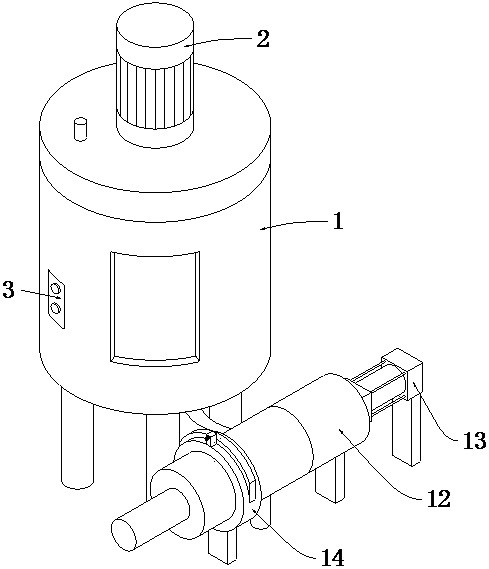

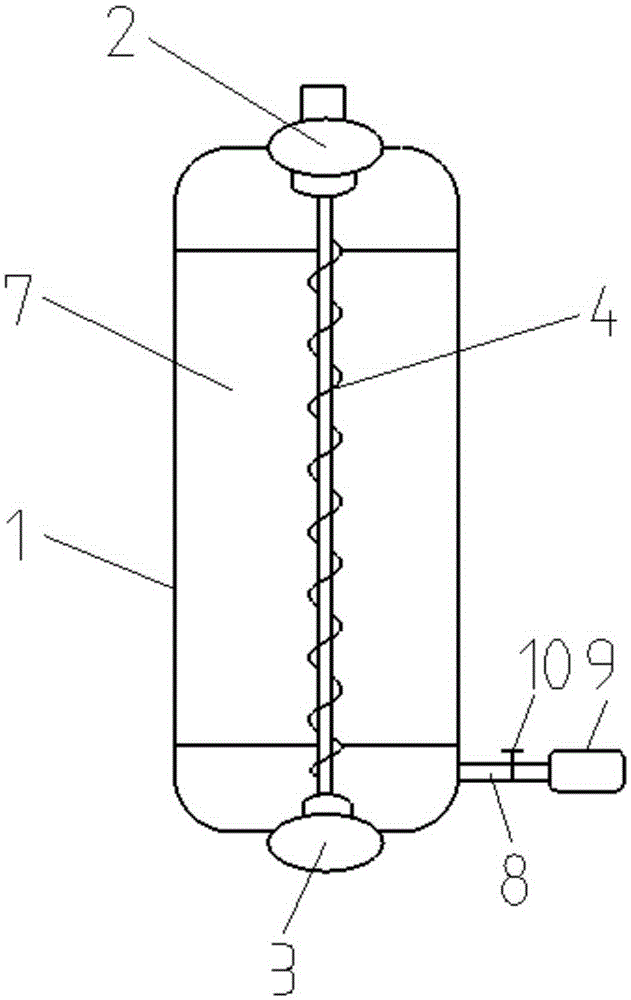

Lubricating oil circulating type coupled disperser

InactiveCN110711509ARealize circulating stirringEvenly mixedFlow mixersRotary stirring mixersThermodynamicsVALVE PORT

The invention relates to the field of dispersing and stirring and particularly relates to a lubricating oil circulating type coupled disperser. The coupled disperser comprises a lubricating oil dispersing box body, an oil feeding pipe, a circulating box body, a recovery pipe with a valve, a dispersing driver and a circulating driver, wherein the oil feeding pipe is fixedly connected and communicated with the eccentric part of the upper end of the lubricating oil dispersing box body; the middle end of the circulating box body is fixedly connected to the center of the lower end of the lubricating oil dispersing box body; the circulating box body communicates with the lubricating oil dispersing box body; the recovery pipe with a valve is fixedly connected and communicated with the lower sideof the rear end of the circulating box body; the upper end of the dispersing driver is fixedly connected to the upper end of the lubricating oil dispersing box body. The coupled disperser has the beneficial effects that automatic stirring and circulation can be achieved, circulation stirring of lubricating oil is achieved, the phenomenon of uneven stirring or layered stirring of the lubricating oil in the use and transportation process is avoided, the stirring efficiency is high, the occupied space is small, the manufacturing cost is low, and application and popularization are facilitated.

Owner:郝秀娥

Thermostatic water tank special for cooling of wax pattern

The invention relates to a thermostatic water tank special for cooling of a wax pattern, comprising a support frame, wherein a mountable pulley is arranged at the bottom of the support frame, a watertank is arranged on the pulley, a skid resistant layer is wrapped inside the water tank, a heating device and a cooler are arranged at the bottom of the water tank, the heating device is connected with a reflux device, a water inlet pipe is arranged at the 1 / 3 position of a distance from the water tank to the top, a distribution valve is arranged on the water inlet pipe, the water inlet pipe is connected with a floating ball, the floating ball is connected with an infrared sensor, the infrared sensor is connected with an alarm, the alarm is connected with a controller, the controller is located on a motor outside the water tank, the controller is connected with a temperature sensor on the inner wall of the water tank, a water outlet pipe is arranged at the bottom of the water tank and is fixed by a pass stop valve. The thermostatic water tank is simple in structure, and wide in application scope, and can increase the accuracy; the skid resistant layer can reduce friction, reduce the injury tolerance of a workpiece, and save cost; the reflux device can realize cyclic stirring of water flow, so as to ensure the uniform temperature of the water flow; acceleration is rapid, used time is short, and the working efficiency can be improved.

Owner:MAANSHAN ZHONGTIAN MACHINERY INSTALLED

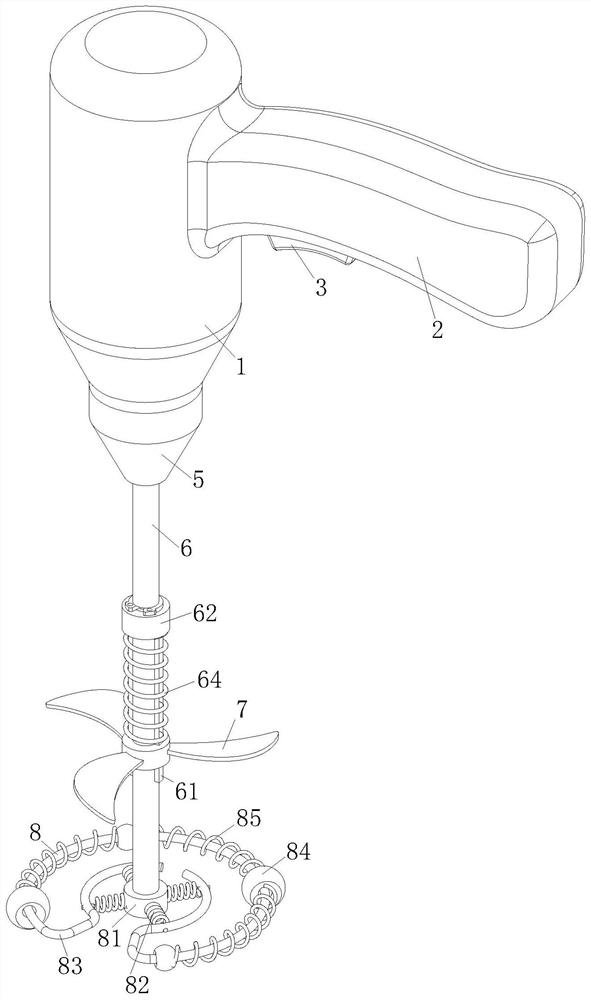

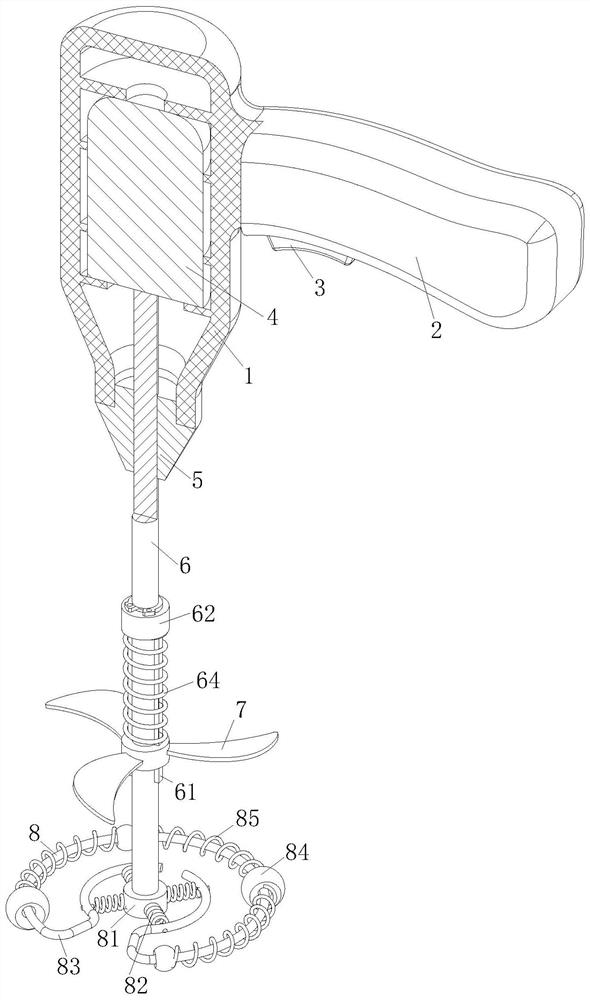

Handheld liquid stirrer based on impact stirring

ActiveCN111744409AEasy to useIncrease spacingTransportation and packagingMixer accessoriesElectric machineryHand held

The invention belongs to the technical field of stirring devices, and relates to a handheld liquid stirrer based on impact stirring. The stirrer comprises a shell, a handle, a speed regulating switch,a motor, a support sleeve, a rotating shaft, fan blades and a stirring part. The fan blades in the middle of the rotating shaft and the stirring part at the end of the rotating shaft are driven to rotate at the same time through the rotating shaft; in the process, the fan blades convey liquid to be stirred along the stirring part below the axial direction, so that and the liquid to be stirred isstirred and mixed by the rotating stirring part; in the stirring process, the liquid to be stirred above the fan blades is conveyed downwards by the fan blades, so that the liquid to be stirred at thebottom of a vessel for containing the liquid to be stirred is gathered, the liquid to be stirred is conveyed upwards from the periphery of the vessel, the liquid to be stirred around the fan blades is supplemented to the middles of the fan blades; the liquid to be stirred in the vessel is circularly stirred; and the stirring uniformity is guaranteed. The liquid to be stirred is stirred through the stirring part in a flowing process, so that stirring efficiency is improved.

Owner:重庆万盛川东化工有限公司

Fermentation treatment device for organic waste

ActiveCN102627480BCompact structureEasy to storeClimate change adaptationOrganic fertilisersLitterFermentation

The invention discloses a fermentation treatment device for organic wastes. The fermentation treatment device comprises a fermentation treatment chamber with a feed inlet, and a drying and storage chamber which is communicated with the discharge outlet of the fermentation treatment chamber. The fermentation treatment chamber comprises a plurality of horizontally and abreast arranged straight round pipes. An agitating screw which is driven by a motor is arranged in each round pipe. The adjacent end parts of the abreast round pipes are serially connected to form a zigzag connected run-through fermentation treatment pipe chamber. The initial end of the fermentation treatment pipe chamber is communicated with the feed inlet and the terminal end of the fermentation treatment pipe chamber is communicated with the discharge outlet. The organic wastes and zymophyte are fed through the feed inlet to enter from the initial end of the fermentation treatment pipe chamber. The organic wastes and the zymophyte in the fermentation treatment pipe chamber are fully fermented under the agitation of the agitating screws, then enter the drying and storage chamber through the discharge outlet and are dried. The fermentation treatment device is suitable for places such as families, restaurants and hotels and can purify and treat the organic wastes into fertilizers capable of being used by plants. The treated fertilizers are convenient to store and do not have peculiar smells.

Owner:YUHUAN SENDOE SANITARYWARE

mixer for construction

InactiveCN106217643BRealize circulating stirringImprove the mixing effectDischarging apparatusMixing operation control apparatusEngineeringBuilding construction

The invention discloses a blender for a building. The blender comprises a shell, a vertical material guide assembly, a blending shaft assembly, a drive mechanism, a water inlet mechanism and a bearing mechanism; materials enter the shell through a feeding opening in the shell, water enters the shell from a water inlet shell, under the effect of a blending shaft, blending is achieved, the blending shaft is driven by the drive mechanism, the bottom materials can be guided to the upper portion under the action of the vertical material guiding mechanism to be fully blended, the blending effect is improved, the segregation phenomenon in the material blending process can be prevented, and after blending, the materials are discharged out of a discharging opening. Stirring dead angles existing in a traditional device can be removed, the blending effect is improved, and the blender is suitable for being widely applied in the blending field.

Owner:高聪聪

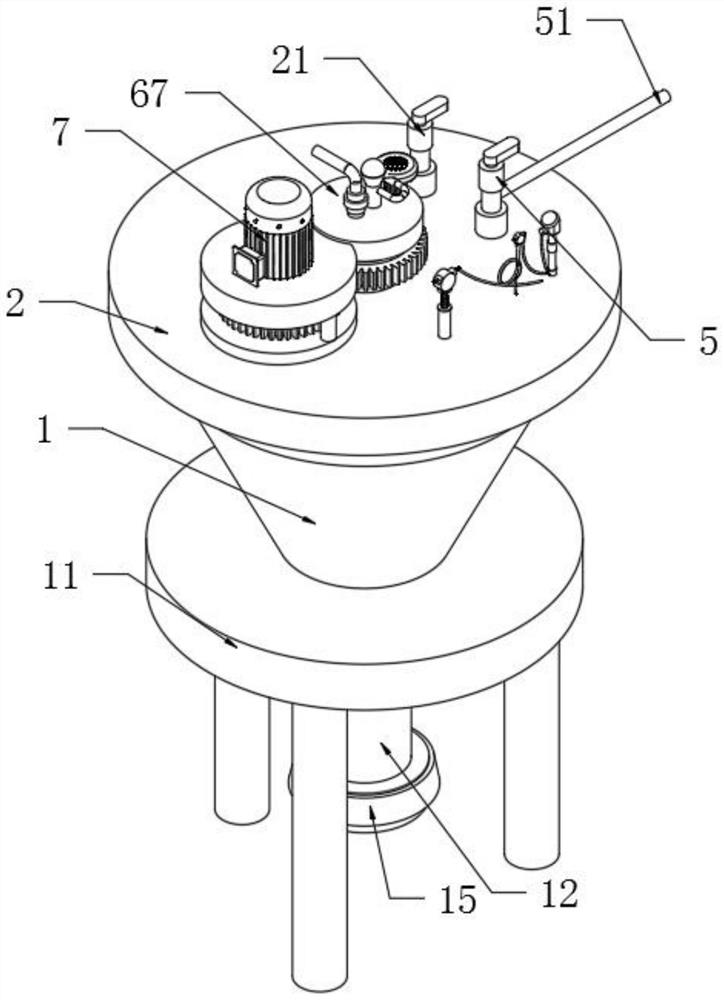

Method and equipment for preparing straw protein through secondary fermentation of rhizopus oligosporus

PendingCN114230412AIncrease contentSmall structureBio-organic fraction processingBioloigcal waste fertilisersBiotechnologyRhizopus

The invention belongs to the technical field of fertilizer production, and particularly relates to equipment for a preparation method of rhizopus oligosporus secondary fermentation straw protein.The equipment comprises a fermentation tank, the outer surface of the fermentation tank is fixedly connected with a supporting frame, the fermentation tank is of a conical structure, the lower surface of the fermentation tank is fixedly communicated with a discharging pipe, and the upper surface of the fermentation tank is connected with a sealing cover in a covering mode; a stirring device is arranged in the fermentation tank and comprises an arc-shaped stirring pipe, the outer surface of the arc-shaped stirring pipe is attached to the inner wall of the fermentation tank, and materials in the fermentation tank are uniformly stirred. According to the preparation method and equipment of the rhizopus oligosporus secondary fermentation straw protein, the auger stirring rod rotates along with rotation of the main stirring pipe, the auger stirring rod can drive materials in the discharging pipe to stir up and down, so that the materials are uniformly stirred, and when the cover body is taken down, the auger stirring rod rotates to stir the materials in the discharging pipe up and down, so that the materials are uniformly stirred. And the fermented materials can be conveyed out from the discharge pipe, so that the fermentation efficiency of the materials in the fermentation tank is improved.

Owner:嘉兴上柒寸生物科技有限公司

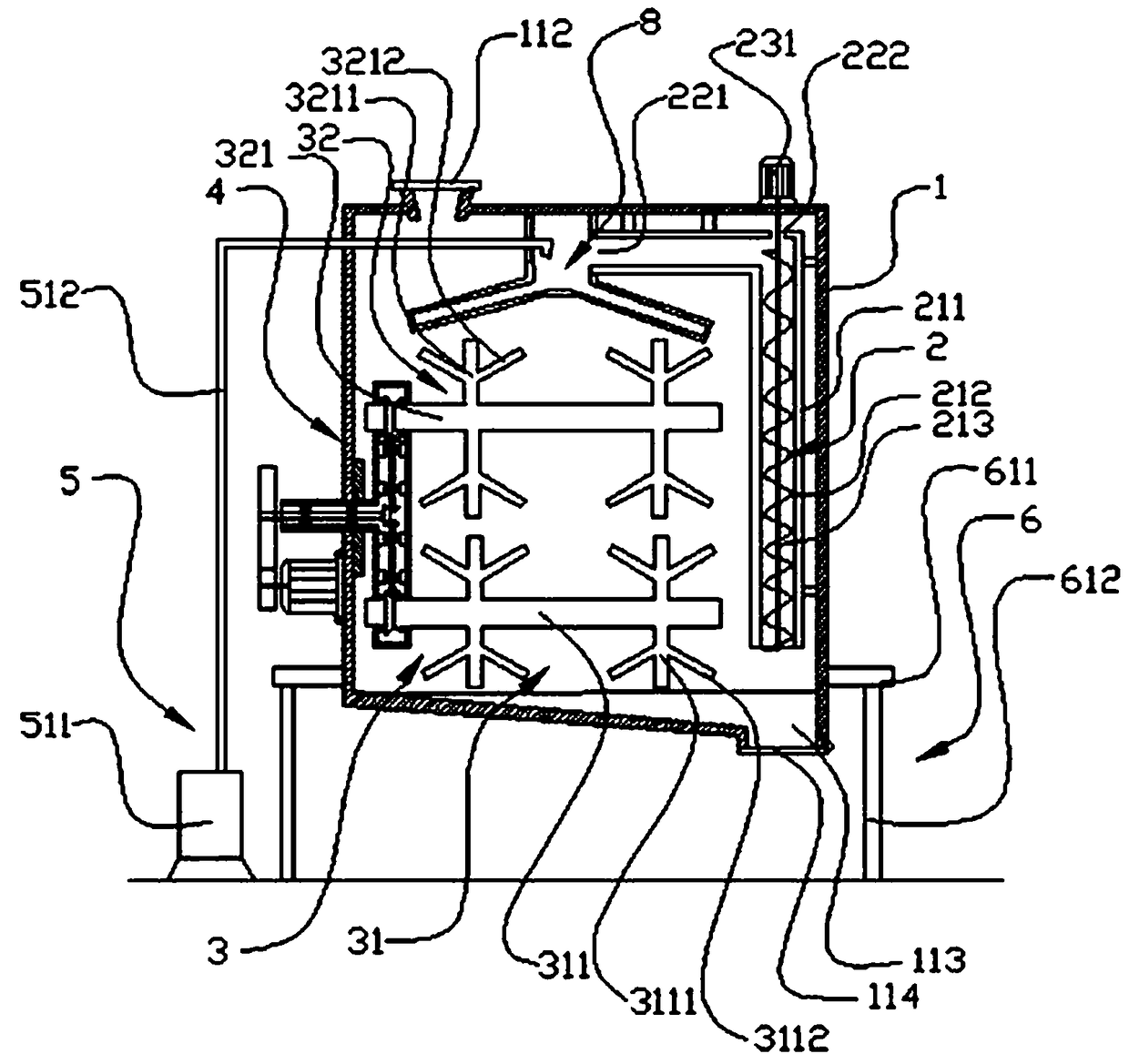

Organic Fermentation Stirring Device

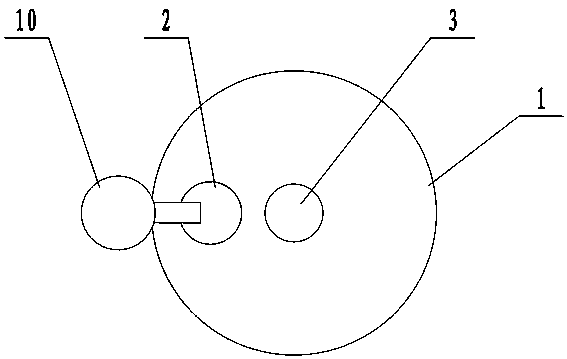

ActiveCN104694373BImprove the bactericidal effectFast filtrationBioreactor/fermenter combinationsBiological substance pretreatmentsMicrowaveHelical blade

The invention relates to a mixing device, in particular to a fermenting and mixing device for organic matters. A mixing tan is provided with a microwave heater, the two ends of the mixing tank are respectively a front recirculation zone and a rear recirculation zone, a main mixing area and a secondary mixing area are divided between the front recirculation zone and the rear recirculation zone, a main mixing shaft and a secondary mixing shaft are arranged in parallel and are provided with homodromous helical blades and blades at the front end of the mixing shaft and blades at the rear end of the secondary mixing shaft are opposite to the helical directions of other blades; the main mixing shaft is connected with a driving gear, the secondary mixing shaft is connected with a driven gear, and the driving gear and the driven gear are a pair of mutually engaged synchronous gears. The organic matters are pushed to the front recirculation zone by the main mixing shaft in the main mixing area, enter the secondary mixing area from the front recirculation zone, and then are pushed to the rear recirculation zone through the secondary mixing shaft; in the rear recirculation zone, the organic matters enter the main mixing area again, and are circularly mixed in the mixing tank, and then are sufficiently mixed to improve the fermenting efficiency.

Owner:JIANGSU SHEN LI ECOLOGICAL AGRI TECHCO LTD

Tower-type organic fertilizer stirring generator

InactiveCN105272434AGood fertilizer effectImprove fermentation qualityBio-organic fraction processingOrganic fertiliser preparationPulp and paper industryOrganic fertilizer

The invention provides a tower-type organic fertilizer stirring generator. The tower-type organic fertilizer stirring generator comprises a circulating and stirring mechanism, the circulating and stirring mechanism comprises a first auger and a second auger opposite in rotating direction, and the first auger and the second auger are arranged in a tower body in the height direction of the tower body. When the stirring generator is used, organic fertilizer raw materials prepared by a certain ratio are fed into the tower body through a fertilizer inlet and are made to ferment naturally, the compost raw materials are circulated and stirred in the limited environment in an inner cavity of the tower body through the two augers opposite in rotating direction, an air inlet pipe is matched to supplement oxygen so that the compost raw materials in the tower body can make full contact with oxygen, the fermentation quality of the organic compost raw materials is effectively improved, and the organic fertilizer finished product with better fertilizer efficiency can be obtained.

Owner:TIANJIN BASICGREEN BIOTECH

mixer for construction

ActiveCN106182418BRealize circulating stirringImprove the mixing effectCement mixing apparatusLiquid ingredients supply apparatusArchitectural engineeringBuilding construction

The invention discloses a stirring machine for construction. The stirring machine for construction comprises a shell, a vertical guiding assembly, stirring shaft assemblies, a driving mechanism, a water inlet mechanism and a bearing mechanism. Materials enter the shell through a feeding port in the shell. Water enters the shell from the water inlet mechanism. Stirring is achieved under the action of stirring shafts, the stirring shafts are driven by the driving mechanism, the materials at the bottom can be guided to the upper portion under the action of the vertical guiding assembly so as to be fully stirred, the stirring effect is improved, the segregation phenomenon in the material stirring process can be prevented, and discharging is conducted through a discharging port after stirring is completed. By the adoption of the stirring machine for construction, stirring dead angles exist when a traditional device is adopted are eliminated, and the stirring effect is improved; and the stirring machine for construction is suitable for being widely applied to the stirring field.

Owner:FUJIAN JINDING CONSTR DEV CO LTD

Concrete mixer

ActiveCN106182419BRealize circulating stirringImprove the mixing effectCement mixing apparatusLiquid ingredients supply apparatusEngineeringMixing effect

The invention discloses a concrete mixer. The concrete mixer comprises a shell, a vertical leading assembly, a mixing shaft assembly, a driving mechanism, a water feeding mechanism and a bearing mechanism; a material enters the shell through a feed port in the shell; water enters the shell from the water feeding mechanism; the mixing is realized under an effect of a mixing shaft; the mixing shaft is driven by the driving mechanism; the material at the bottom can be leaded to the upper part for fully mixing under an effect of the vertical leading assembly to promote a mixing effect and to prevent segregation phenomenon in the material mixing process; and the material is unloaded from a discharge port after mixing. The concrete mixer eliminates mixing dead angles in a traditional device, improves the mixing effect, and is suitable for wide application in the mixing field.

Owner:扬州扬工机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com