Organic Fermentation Stirring Device

A technology of stirring device and organic matter, which is applied in the fields of biochemical cleaning device, enzymology/microbiology device, bioreactor/fermenter combination, etc., can solve the problem of insufficient stirring, and achieve the effect of improving fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

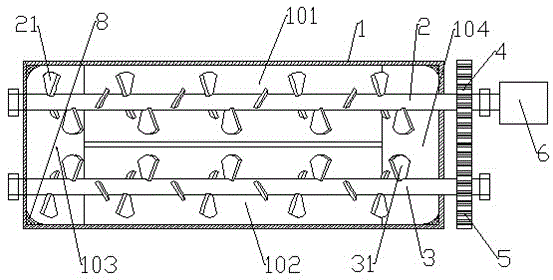

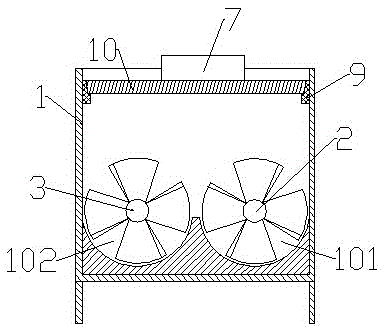

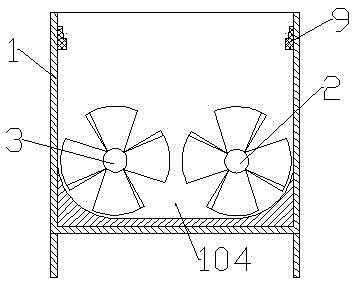

[0015] like figure 1 and figure 2 As shown, the organic matter fermentation stirring device includes a stirring box 1, a cover plate 10, a main stirring shaft 2, and a secondary stirring shaft 3; a microwave heater 7 is installed on the cover plate 10; the inner cavity of the stirring box 1 is divided into four area, the two ends are respectively the front reflux zone 103 and the back reflux zone 104, the front reflux zone 103 and the back reflux zone 104 are divided into a main stirring zone 101 and a secondary stirring zone 102, and the main stirring shaft 2 and the secondary stirring shaft The two ends of 3 are respectively installed on the side walls of both ends of the mixing box 1 through bearing seats, the main stirring shaft 2 and the auxiliary stirring shaft 3 are installed in parallel; the middle part of the main stirring shaft 2 is located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com