Wall face coating spraying equipment for building decoration

A technology for spraying equipment and coatings, applied in the direction of construction and building structure, can solve the problems of difficult continuous spraying, poor practicability, and pulling up the inner box, so as to achieve full and fast stirring, good stirring effect and good spraying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

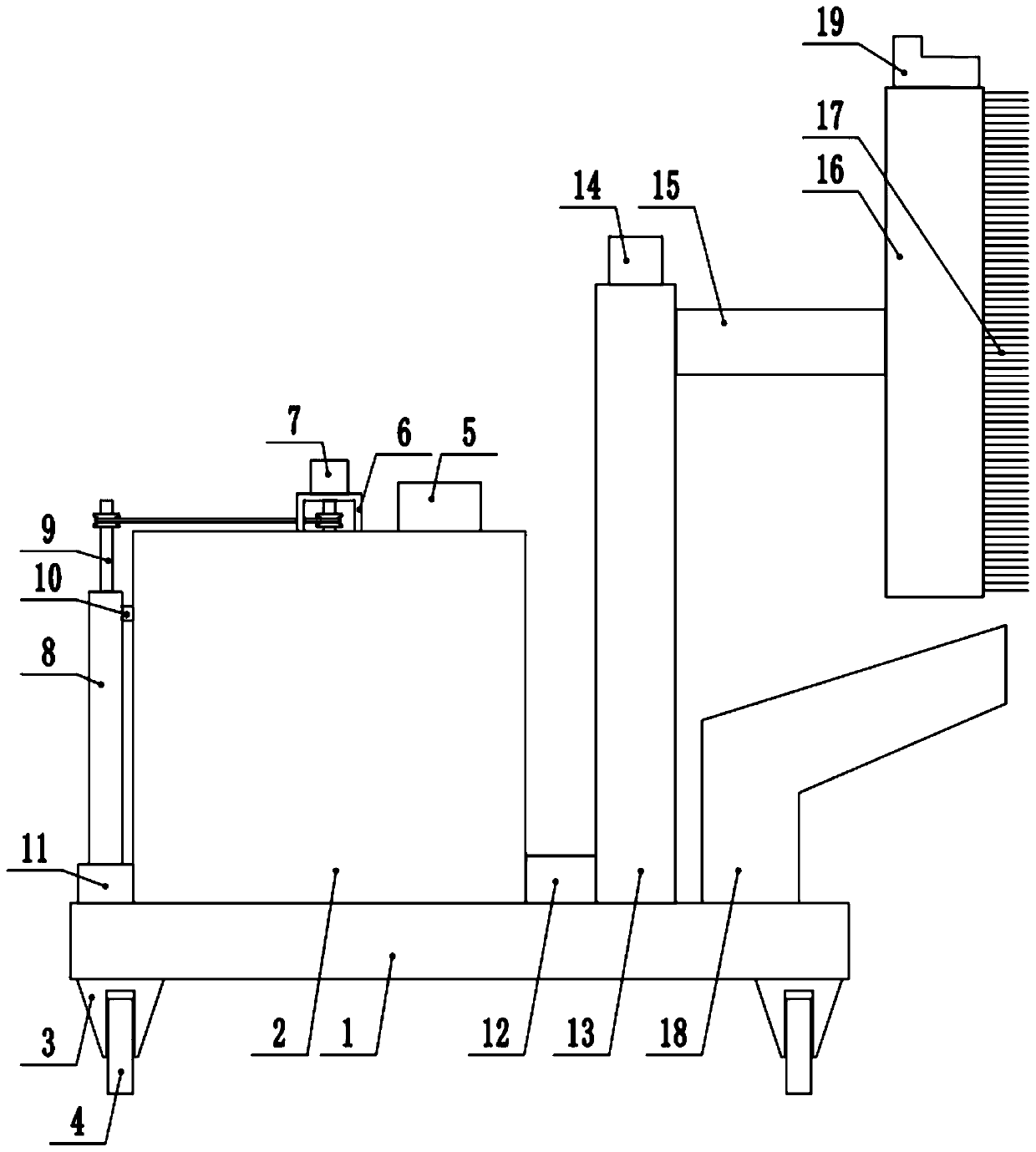

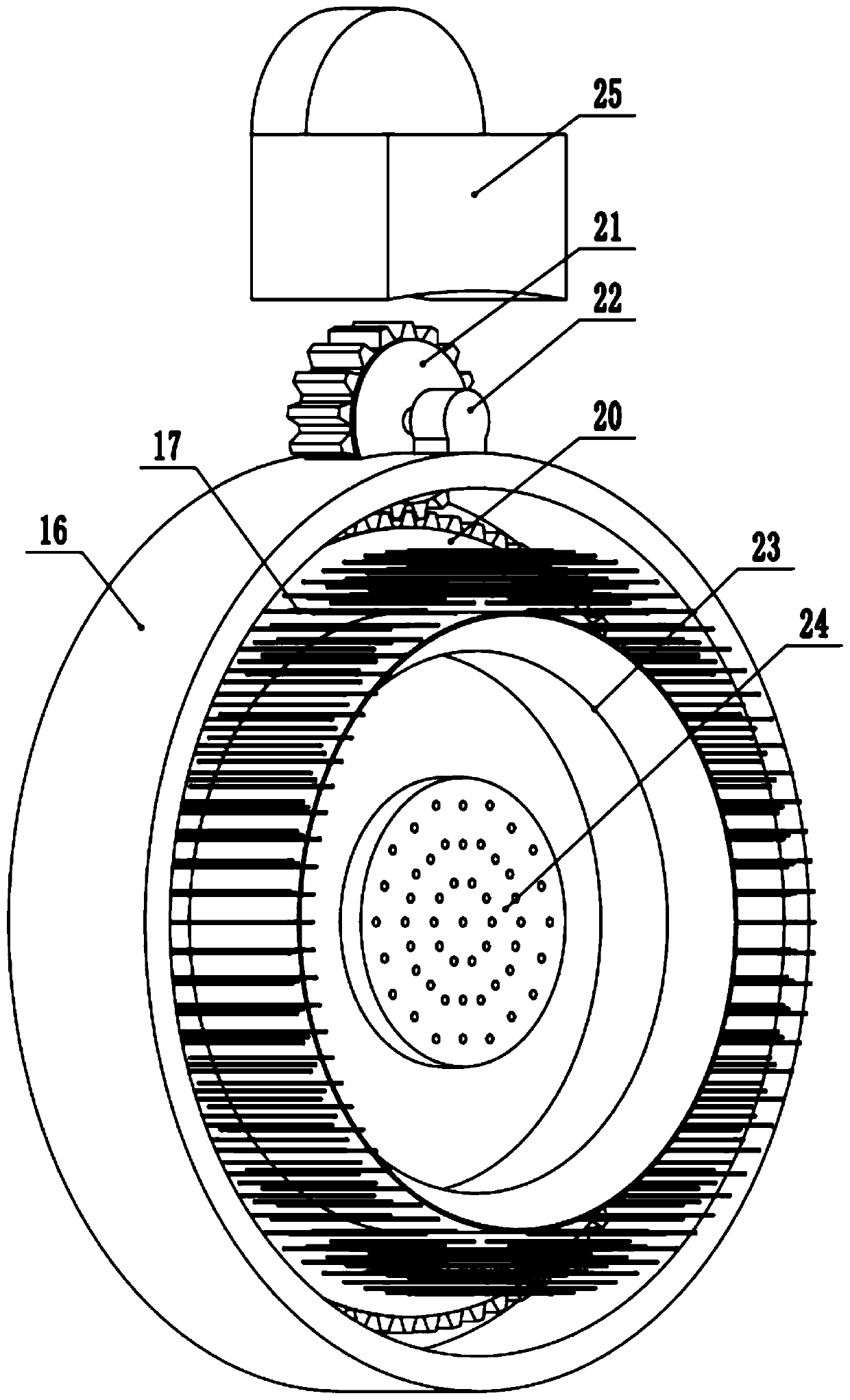

[0025] see Figure 1-4 , a wall paint spraying equipment for architectural decoration, comprising a base 1, the four corners of the bottom of the base 1 are fixedly connected to a wheel base 3, the wheel base 3 is rotatably connected to a walking wheel 4, and the top of the base 1 is fixedly provided with a mixing box 2, One end of the top of the mixing box 2 is fixedly connected to the feed hopper 5, and one side of the mixing box 2 is provided with a lifting device 13, and the delivery pump 12 is fixedly connected between the lifting device 13 and the mixing box 2. The column 15 is fixedly connected to the outer baffle 16, and the outer baffle 16 is provided with a dust removal device and a spraying device, the inside of the mixing box 2 is provided with a stirring mechanism, and the outside of the mixing box 2 is provided with an external circulation mixing mechanism.

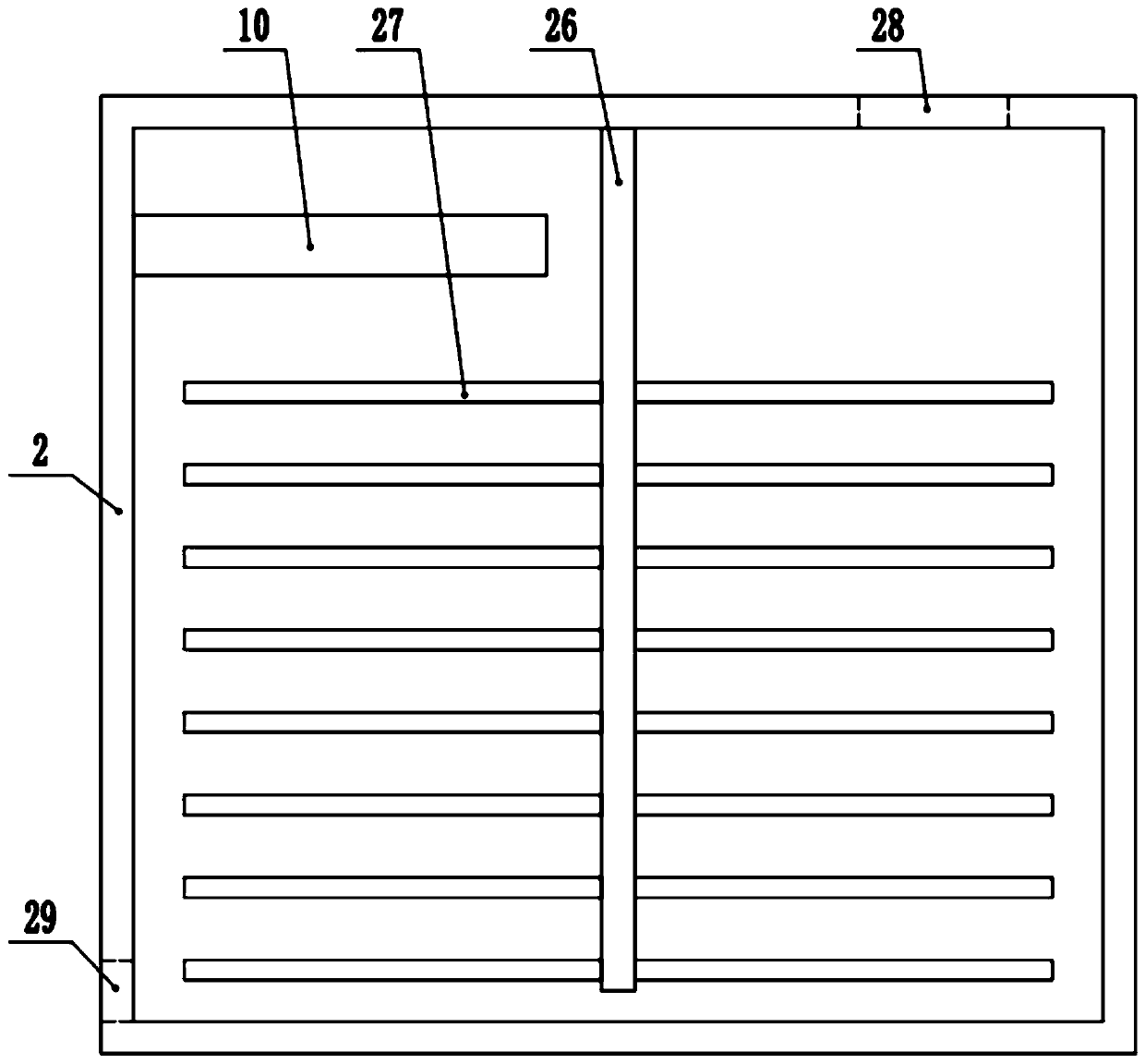

[0026] Described stirring mechanism comprises the motor frame 6 that is fixedly arranged on the top of mi...

Embodiment 2

[0034] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, except that the outer circulation mixing mechanism includes a return bottom cover 11 fixedly arranged on the bottom of the outer side of the mixing box 2, and the top end of the return bottom cover 11 is fixedly connected to lift The pipe 8, the top side of the riser 8 and the mixing tank 2 are fixedly connected to the return pipe 10, the riser 8 is coaxially provided with a lift shaft 9, and the outer side of the lift shaft 9 is fixedly connected to the spiral lift plate, and the lift shaft 9 is connected to the mixing tank. Motor 7 transmission is connected.

[0035] The top and bottom sides of the mixing box 2 are respectively provided with a feed inlet 28 and a feed inlet 29 corresponding to the feed hopper 5 and the return bottom cover 11 .

[0036] The present invention can realize the cyclic stirring of the paint by setting the stirring mechanism and the external circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com