Method and equipment for preparing straw protein through secondary fermentation of rhizopus oligosporus

A secondary fermentation and rhizopus technology, applied in the preparation of organic fertilizers, chemical fertilizer treatment control, fertilizers made from biological waste, etc., can solve the problems of difficulty in controlling the humidity of bean dregs, uneven mixing, and failure to increase the content of active selenium in the soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

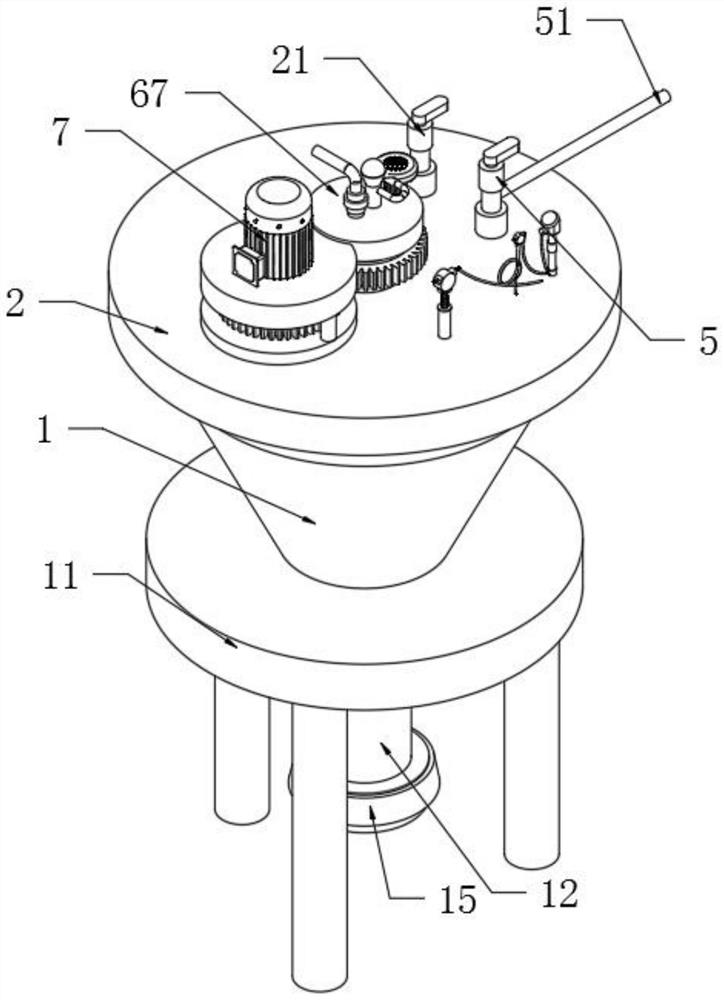

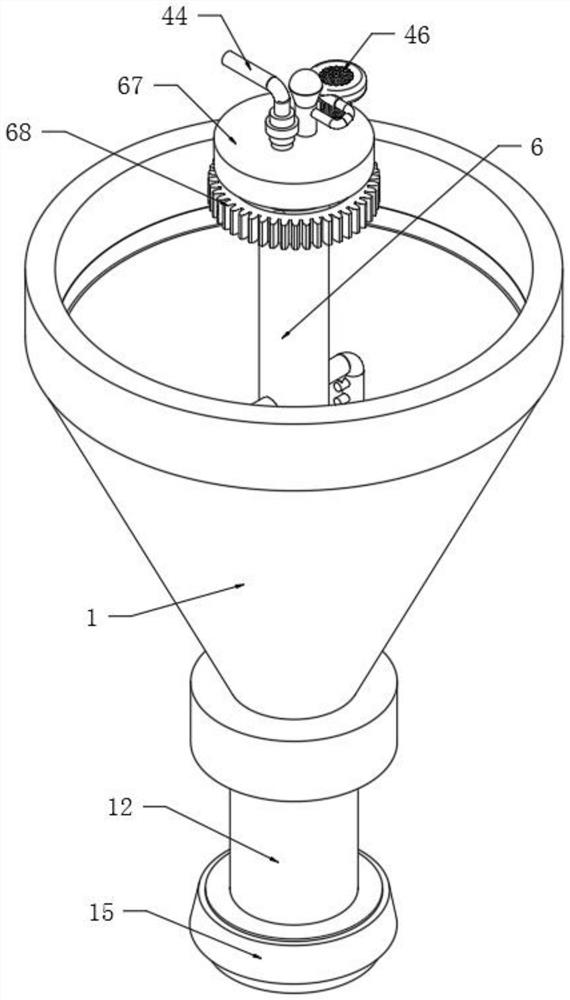

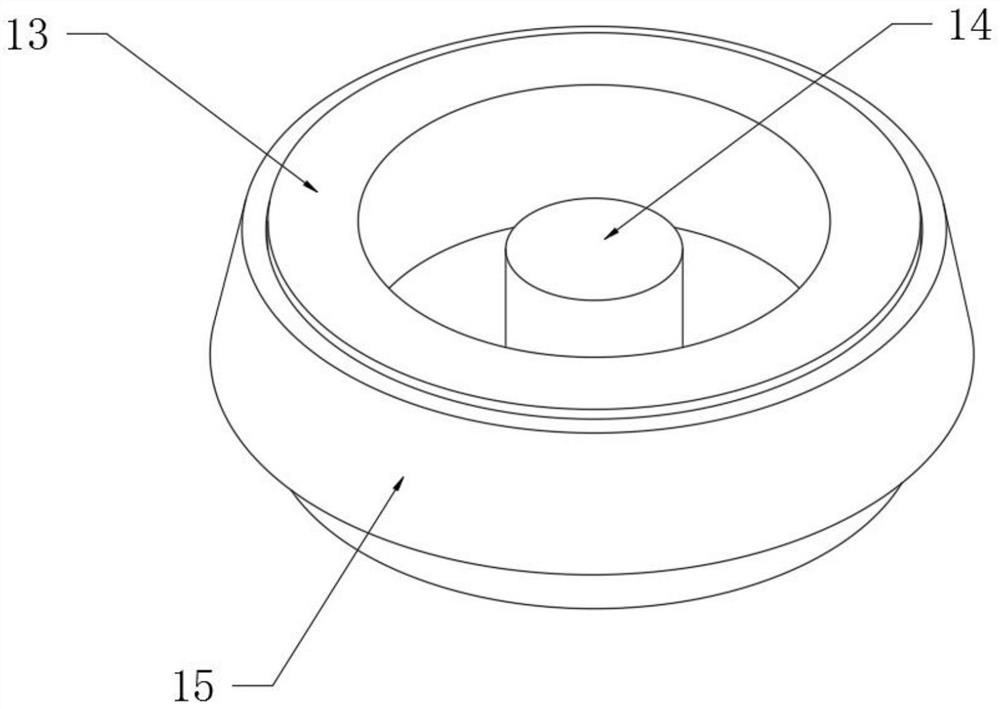

[0046] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0047] A preparation method of rhizopus oligosporin secondary fermentation straw protein, the preparation method comprising the following steps:

[0048] (a), preparation of microbial inoculum, mix Bacillus subtilis, brown sugar, soybean milk into 30 DEG C of water in proportion and stir evenly, control temperature in 30 DEG C of environment, make it ferment for 48 hours, fermentation activates microbial inoculum When the quantity is measured, oxygen should be added to the fermented liquid regularly in the middle;

[0049] (b), the preparation of straw fermentation material, the crop straw is pulverized into 5-8 centimeter powder with pulverizer, according to the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com