Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Rhizopus oligosporus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

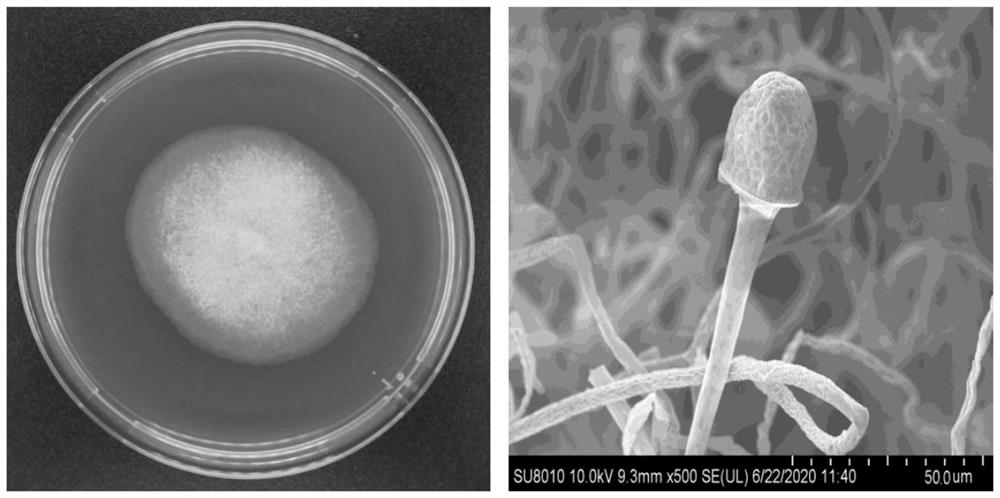

Rhizopus oligosporus is a fungus of the family Mucoraceae and is a widely used starter culture for the production of tempeh at home and industrially. As the mold grows it produces fluffy, white mycelia, binding the beans together to create an edible "cake" of partly catabolized soybeans. The domestication of the microbe is thought to have occurred in Indonesia several centuries ago.

Food material mixed with rhizopus oligosporus and preparation method of food material

InactiveCN104719780AEliminate cumbersomenessEasy to manufactureFood preparationRhizopus oligosporusFood material

The invention relates to a food material mixed with rhizopus oligosporus and a preparation method of the food material. The food material comprises the following components in parts by weight: 80 to 99.999 parts of food materials, 0.001 to 20 parts of rhizopus oligosporus and 0 to 150 parts of water. By adopting the food material and the preparation method, the prepared food material mixed with the rhizopus oligosporus can be provided for consumers and can be directly insulated and fermented to obtain a rhizopus oligosporus product by the consumers, so that not only is the production process simplified, but also convenience in eating is realized, meanwhile, the fresh rhizopus oligosporus product can be provided for the consumer, and the rhythm of modern life and the development direction can be satisfied.

Owner:王晓东

Complex microbial inoculant and method for preparing organic fertilizer by using same

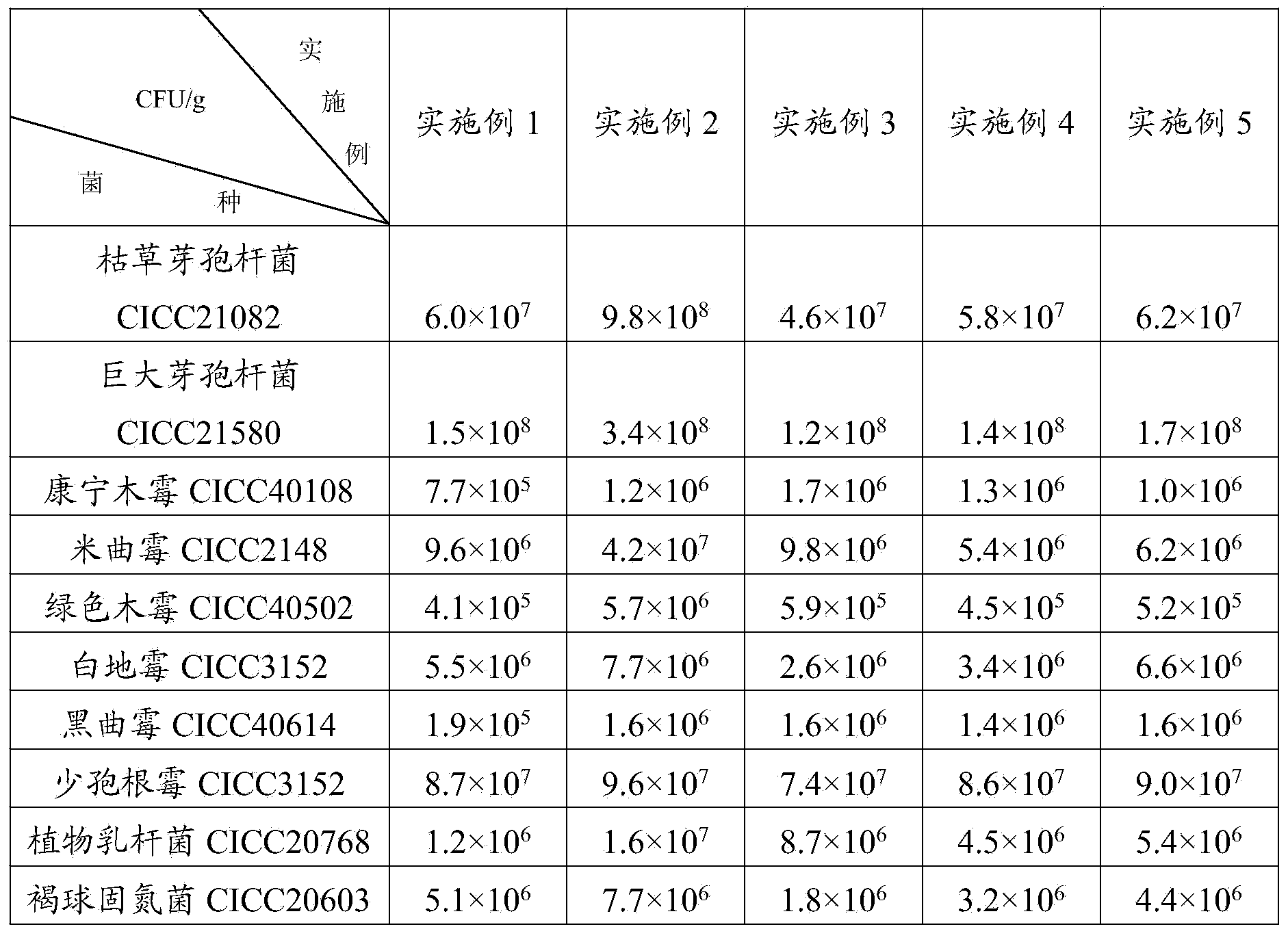

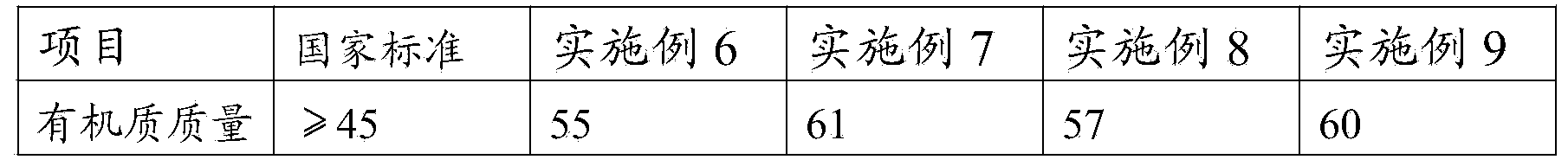

InactiveCN103898032AImprove qualityEffective cooperationBio-organic fraction processingFungiFiberAzotobacter chroococcum

The invention discloses complex microbial inoculant which comprises the following active ingredients: bacillus subtilis, bacillus megatherium, trichoderma koningii, aspergillus oryzae, trichoderma viride, geotrichum candidum, aspergillus niger, rhizopus oligosporus, lactobacillus plantarum CICC20768 and azotobacter chroococcum. Correspondingly, the invention further discloses a method for preparing an organic fertilizer from the complex microbial inoculant. The method comprises the following steps: a. uniformly mixing the complex microbial inoculant with a plant fiber raw material to obtain a fermented raw material; b, composting and fermenting the fermentation raw material; c, drying the composted fermentation raw material to obtain the organic fertilizer. microbes of the complex microbial inoculant have no antagonism, and can effectively cooperate in the production process of the organic fertilizer, and the chemical components of the production raw materials can be sufficiently utilized to finally produce the high-quality organic fertilizer. The produced organic fertilizer reaches the parameter indexes of the standard (NY884-2012) of China, can improve the planting property of soil, is beneficial to optimization of soil microbial flora, and can provide comprehensive nutrients to a plant root system.

Owner:江苏联海生物科技有限公司

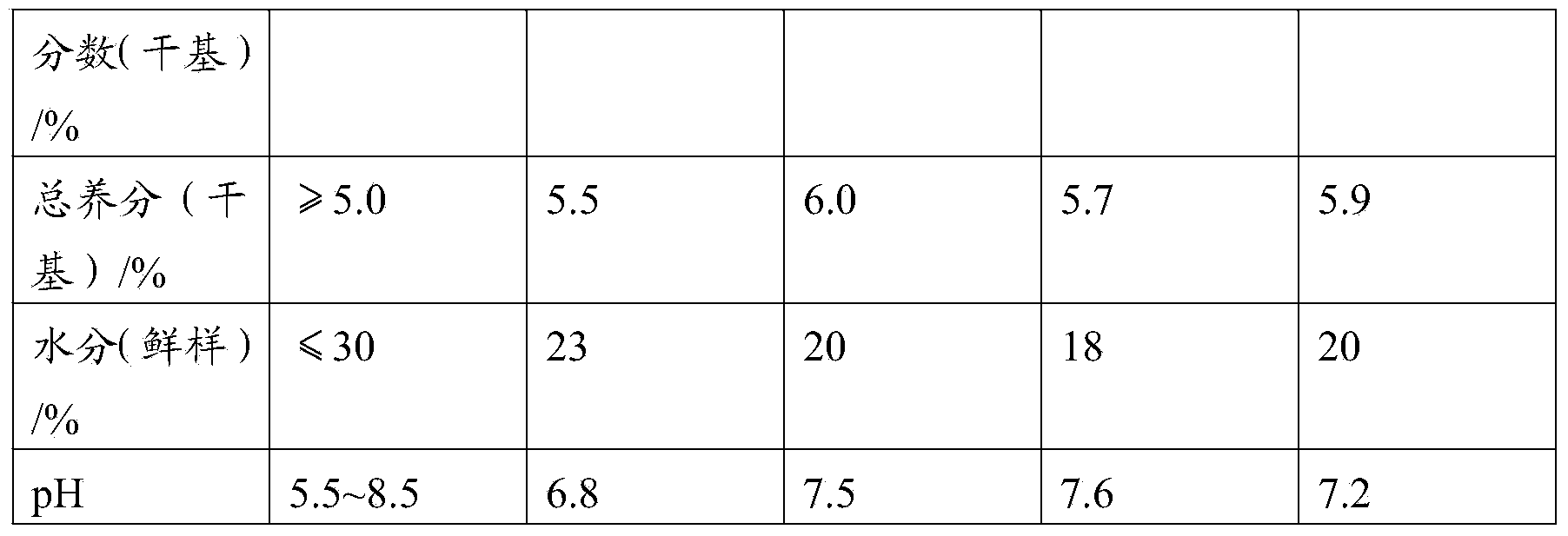

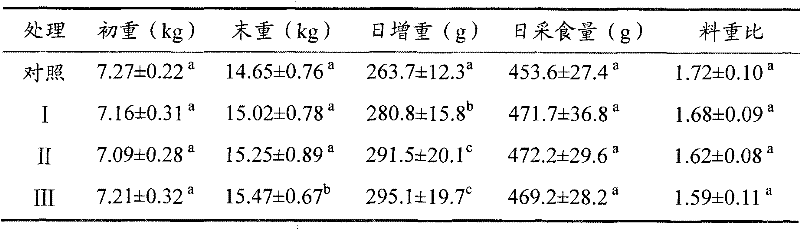

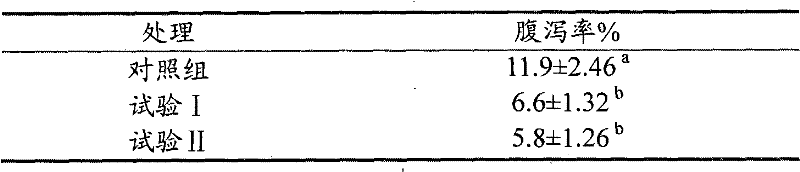

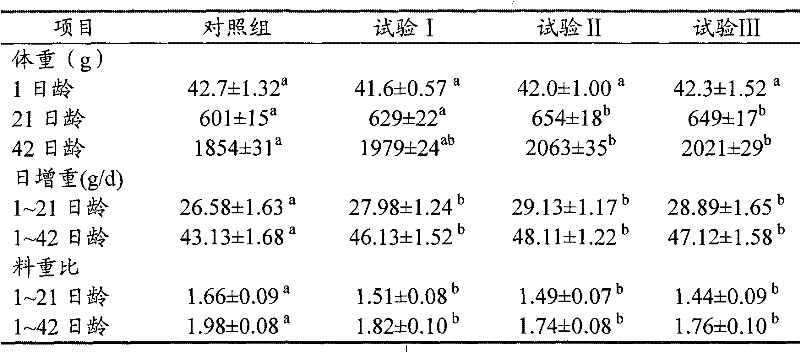

Micro-ecology fermentation protein feedstuff and preparation method thereof

InactiveCN101449739AEasy feedingIncrease production capacityBacteriaFood processingFecesAnimal protein

The invention provides a micro-ecological fermented protein feed and a preparation method, wherein the feed is prepared by mixing bean pulp and silkworms with quality ratio 90-98:2-10, then cooking to obtain solid state fermention medium, then inoculating mixed strains of bacillus subtilis, Saccharomyces cerevisiae, lactobacillus and Rhizopusoligosporus on solid fermention medium, then co-mixing for 30-45 hours at 33-37 DEG C, drying fermentation products after completing fermenting, crushing and obtaining the micro-ecological fermented protein feed. The inventive micro-ecological fermented protein feed contains a plurality of biological active peptides, content of small peptide reach more than 22%, which is favourable for digestion and development; contains lactobacillus, microzyme, which is favourable for controlling useful microbiological population in intestinal tracts of animals; has good delicious flavor and good luring effect, advances young animals for ingestion; contains soybean isoflavone more than 0.05%, markedly increases immunity of bodies, increases producibility of animals; relieving odmour of fecal waste; fully takes place of animal protein feed of fish meal and plasma protein flour and the like.

Owner:ZHEJIANG UNIV

Process for producing fermented foods rich in gamma-aminobutyric acid and free amino acids

InactiveUS20030161910A1Improve charging capacityIncrease volumeAnimal feeding stuffTeaGamma-Aminobutyric acidRhizopus oryzae

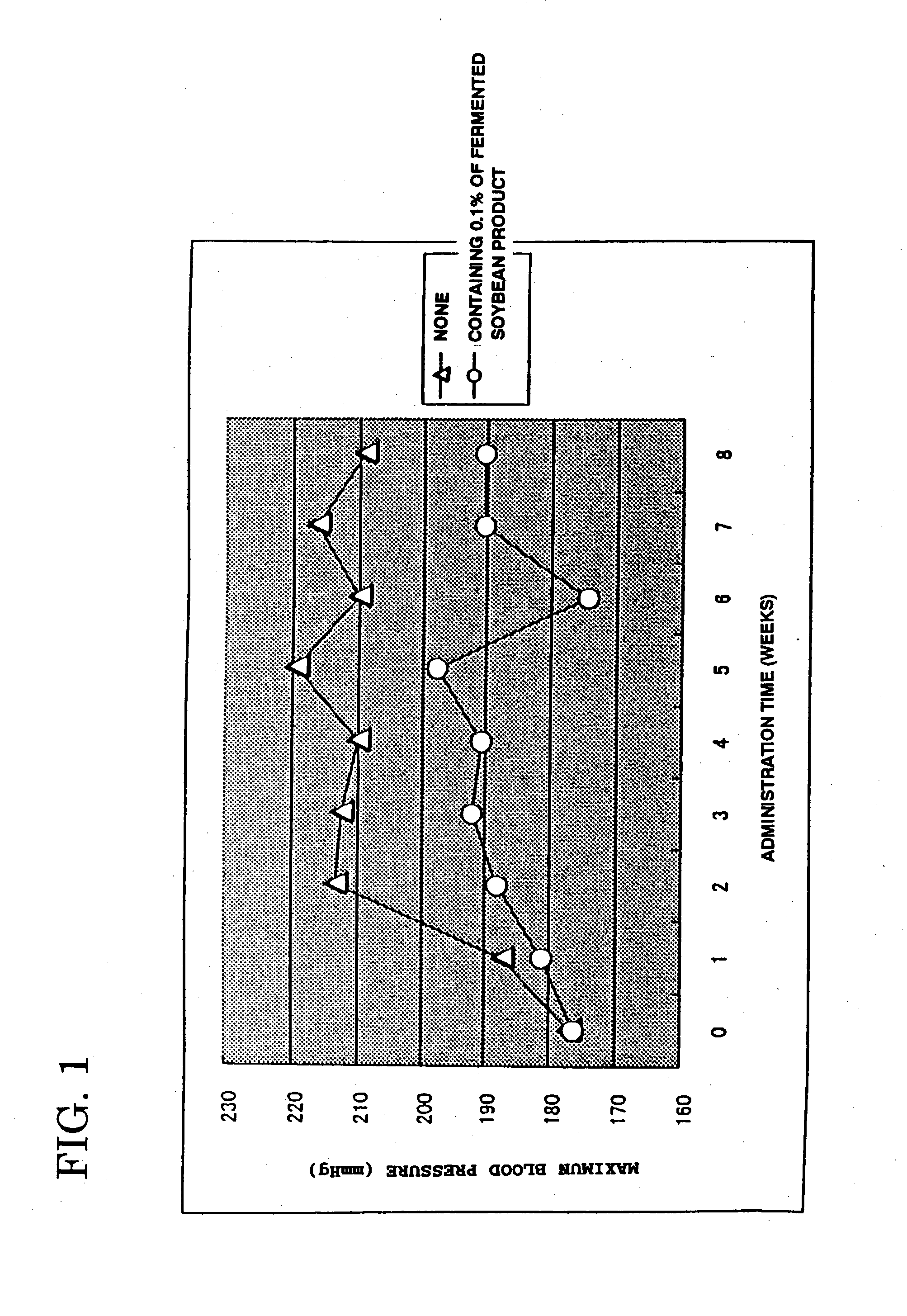

Fermented soybean foods rich in gamma-aminobutyric acid are produced by fermentation of soybean using Tempe molds. Fermented soybean foods rich in gamma-aminobutyric acid and free amino acids are produced by fermentation of soybean using Tempe molds with anaerobic treatment. Fermented cereal foods rich in gamma-aminobutyric acid and free amino acids are also produced by fermentation of cereals with anaerobic treatment. Rhizopus oligosporus and Rhizopus oryzae are favorably used as the Tempe mold and Koji molds.

Owner:AOKI HIDEYUKI +5

Hibiscus esculentus brewed wine and brewing method thereof

InactiveCN103484294ALarge primary recoverySolution areaMicroorganism based processesAlcoholic beverage preparationBiotechnologyHibiscus esculentus

The invention discloses a hibiscus esculentus brewed wine and a brewing method thereof, and relates to a wine preparation technology. The method mainly comprises the following steps: 1) picking and cleaning; 2) homogenizing; 3) performing enzymolysis; 4) sugaring; 5) compounding juice; 6) homogenizing and deaerating; 7) sterilizing; 8) inoculating and fermenting; 9) filtering, removing impurities and sterilizing; and the like. The brewed wine is prepared by respectively homogenizing hibiscus esculentus flowers and hibiscus esculentus fruits and then mixing and fermenting, and the fermentation method is that activated apergillus oryzae and rhizopus oligosporus compound strain is inoculated firstly to carry out culture fermentation, and then activated Angel yeast is inoculated to carry out fermentation. The hibiscus esculentus brewed wine prepared by the invention is rich in nutrition, unique in flavor, soft in taste and good in health care effect.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Process for preparing fermented bean curd powder

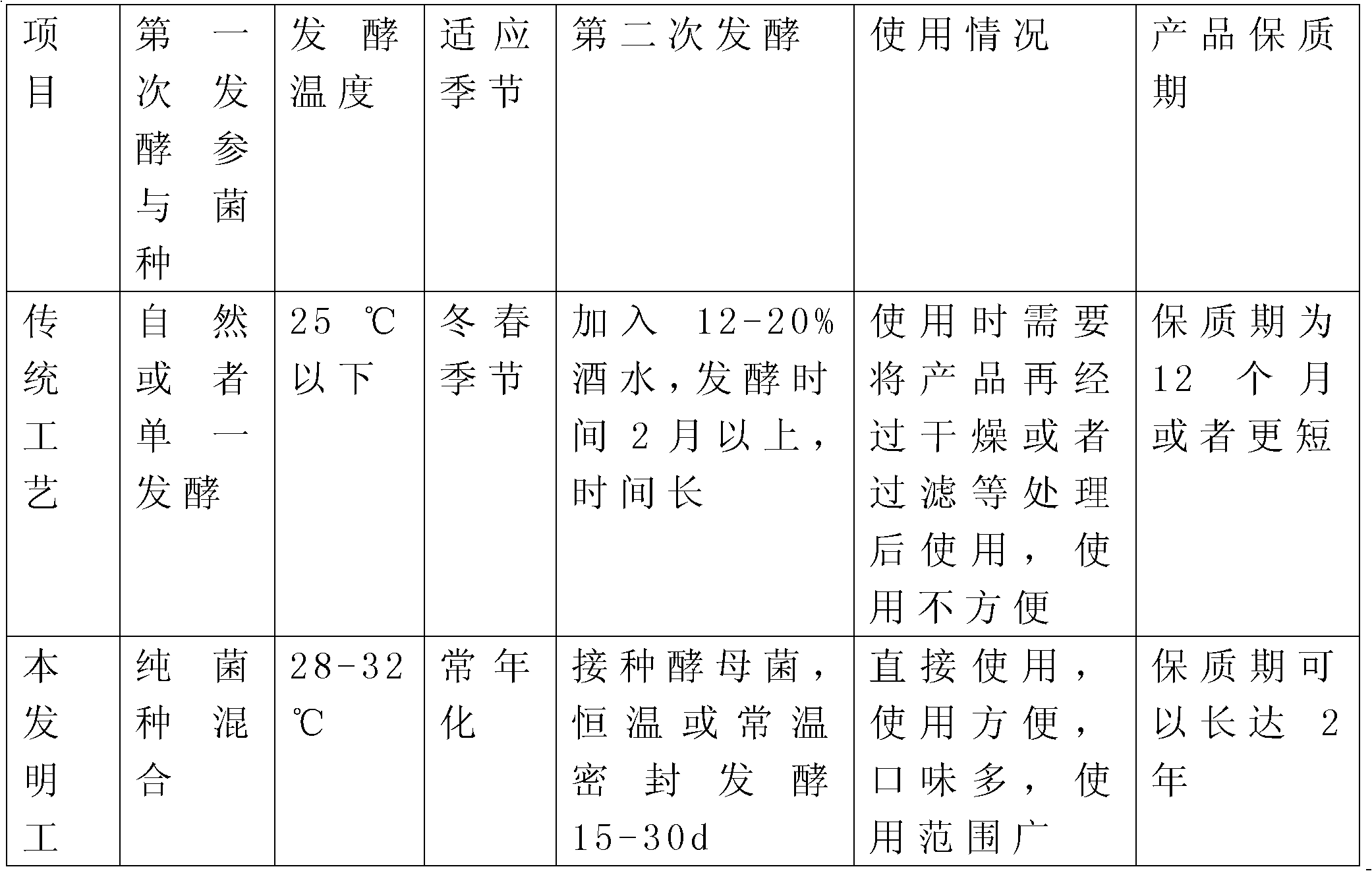

InactiveCN102058068AReduce inhibitionRaise the fermentation temperatureFood preparationFreeze-dryingAdditive ingredient

The invention relates to a process for preparing fermented bean curd powder. The process comprises the following steps of: vaccinating equivalent 0.1-0.3 percent pure racemomucor M.H.C-7CCTCCM 201026 subjected to enlargement culture and rhizopus oligosporus CGMCC 3.4392 and fermenting to form a mould billet; adding salt and Chinese rice wine, uniformly mixing and then vaccinating 0.2 percent activated Angel high-temperature-resistant active dry yeast; sealing for fermenting; pulverizing to form a viscous fluid and precooling; drying into freeze-drying powder in vacuum; and bottling and sealing to obtain the fermented bean curd powder. Ingredients can be added to the freeze-drying powder to be prepared into various seasoners which have the fermented bean curd flavor and different applications, and the freeze-drying powder can be widely applied to seasoners of potato chips, flour products, rice products, roasted meat products, and the like and can be also used as an ingredient of instant noodle seasoning bags. The fermented bean curd powder has the advantages of scientific process design and short process period, is particularly suitable for annual production and is obviously different from fermented bean curd products of other forms. The process can be used for realizing industrial continuous production and has the advantages of controllable process, stable quality and wide application and provides a feasible method for developing novel seasoners.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Method for producing enzyme by using black soya bean tempeh

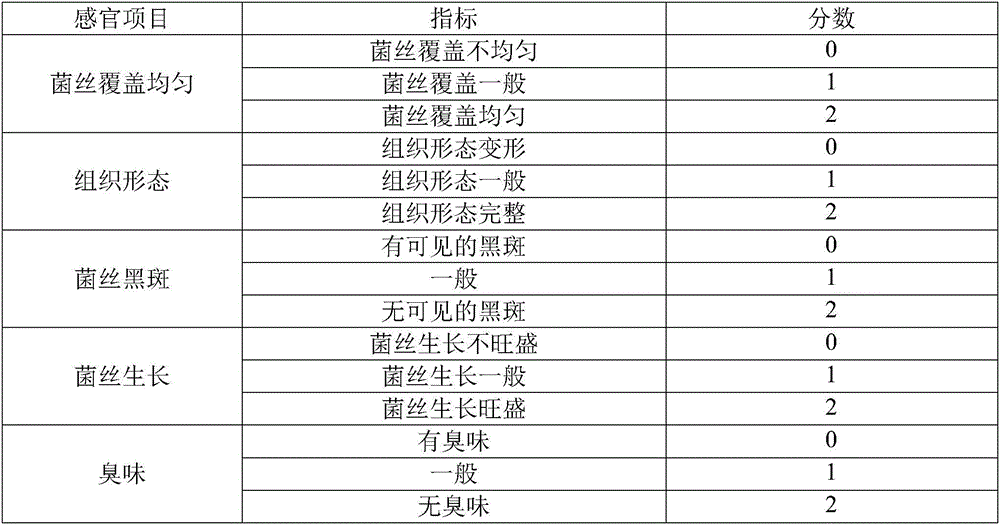

ActiveCN103876147ANot easy to infect bacteriaUniform and plump growthFood ingredient functionsFood preparationLiquid productHypha

The invention discloses a method for producing an enzyme by using black soya bean tempeh. The method comprises a production method for the black soya bean tempeh and preparation of the enzyme. According to the method disclosed by the invention, black soya beans with high content of proteins, mineral substances and unsaturated fatty acids and with a strong health-care function are taken as a raw materials and fermented by rhizopus oligosporus to prepare the tempeh; then the tempeh is used as a culture material for producing the enzyme; nutrient substances of the culture material are increased by the nutritional synergistic effect of the black soya beans and the rhizopus oligosporus; meanwhile, functional substances which are enriched with probiotics and are good for a human body are contained. The method disclosed by the invention not only provides a good nutrition environment for the probiotics fermented by the enzyme, but also improves the health-care function of an enzyme raw liquid product. The unique method is adopted to hold the raw materials so that the culture material is not easily infected by bacteria and has good ventilation and moisture-penetrability; mycelia can grow uniformly and fully and the cost is low, so that more common people can afford the enzyme.

Owner:蒋凯男

Making technology of low-salt flavored fermented bean curd

InactiveCN107873857AImprove permeabilityAvoid elevationCheese manufactureFood scienceAntioxidantMucor species

The invention provides a making technology of low-salt flavored fermented bean curd, and relates to the technical field of food processing. The making technology comprises the following steps of pretreating raw materials; performing grinding to obtain pulp, and cooking the pulp; making semi-finished products; performing inoculation with bacteria and performing fermentation; rubbing hair and performing pickling; and performing later-stage fermentation. Through the adoption of the making technology, the amount of pickling salt is reduced; and vacuum pickling is adopted, so that on one hand, permeation of the salt can be well promoted, and on the other hand, the situations that bacteria are increased and the low-salt flavored fermented bean curd is putrid and deteriorated due to reduction ofsalt content can be avoided. Mucor and rhizopus oligosporus are mixed to be made into yeast, and two kinds of strain systems are relatively stable. In the later-stage fermentation process, an antioxidant and a flavoring agent are added. The made fermented bean curd is low in salt content, unique in flavor and fragrant and rich in taste, and has health-care effects; and besides, formation of whitespots is reduced, and taste of the fermented bean curd is improved.

Owner:桂林国农生态农业科技有限公司

Rosa roxburghii tratt lung-moistening health-care wine and preparation method thereof

InactiveCN105754805AClarificationSoft tasteMicroorganism based processesAlcoholic beverage preparationPectinaseSucrose

The invention discloses rosa roxburghii tratt lung-moistening health-care wine and preparation method thereof. The rosa roxburghii tratt lung-moistening health-care wine is prepared from the following raw materials in parts by weight: 80 to 100 parts of rosa roxburghii tratt, 30 to 50 parts of polished glutinous rice, 10 to 15 parts of dry sweet potato powder, 5 to 7 parts of aspergillus oryzae culture liquid, 5 to 7 parts of rhizopus oligosporus culture liquid, 10 to 15 parts of active dry yeast culture liquid, 10 to 20 parts of pectinase, 10 to 20 parts of cane sugar, 5 to 12 parts of honey and 5 to 100 parts of water. The preparation method comprises the following steps: (1), weighing and taking the raw materials; (2), processing the raw materials; (3), preparing rosa roxburghii tratt juice; (4), performing fermentation; (5), performing clarification; (6), performing cold treatment; (7), performing sterilization and filling. The rosa roxburghii tratt lung-moistening health-care wine prepared by brewing the rosa roxburghii tratt juice, the polished glutinous rice and the dry sweet potato powder is easily absorbed nutrient health-care wine, and has natural health-care functions of preventing and curing gout, clearing away the lung-heat, moistening lung, improving sub-health and the like if being drunk for a long term; the rosa roxburghii tratt wine is clear in wine body, mellow in vinosity and excellent in both taste and color.

Owner:ANHUI SCI & TECH UNIV

Preparation method of low-salt fermented bean curd

InactiveCN107889894AImprove permeabilityAvoid elevationCheese manufactureFood ingredient functionsSalt contentMucor species

The invention provides a preparation method of low-salt fermented bean curd, and belongs to the technical field of food processing. The preparation method comprises following steps: raw material pretreatment, pulp grinding, pulp cooking, soy cheese pehtze preparation, inoculation and fermentation, pressing of hypha and salting, and later fermentation. The preparation method is capable of reducingsalt using amount in the step of salting, and vacuum salting is adopted, so that on one hand, penetration of salt is promoted, and on the other hand, increasing of bacteria and corruption deterioration caused by low salt content are avoided. According to the preparation method, mucor and rhizopus oligosporus are mixed for starter propagation, and the two mould systems are relatively stable; an anti-oxidant is added in later fermentation. The obtained low-salt fermented bean curd is low in salt content, the whole taste of the low-salt fermented bean curd is not influenced, formation of white spots is reduced, and fermented bean curd taste is improved.

Owner:桂林国农生态农业科技有限公司

Hibiscus esculentus brewed wine and brewing method thereof

InactiveCN103484294BLarge primary recoveryEasy to process and useAlcoholic beverage preparationMicroorganism based processesBiotechnologyEnzymatic hydrolysis

An okra fermented wine and a brewing method thereof relate to a wine making process. It mainly includes 1) picking and cleaning; 2) homogenization; 3) enzymatic hydrolysis; 4) adding sugar; 5) juice compounding; 6) homogenization and degassing; 7) sterilization; Cleaning, sterilization and other steps. The fermented wine is prepared by homogenizing okra flowers and okra fruits and then mixing and fermenting them. The fermentation method is to first inoculate the compound strains of activated Aspergillus oryzae and Rhizopus oligosporus for cultivation and fermentation, and then inoculate the activated Angelica Yeast for fermentation. The okra fermented wine produced by the invention has rich nutrition, unique flavor, soft taste and good health care effect.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Preparation method of Yupingfeng herb residue polysaccharide synbiotic and application of synbiotic in immunoregulation

The invention discloses a preparation method of Yupingfeng herb residue polysaccharide synbiotic and application of the synbiotic in immunoregulation and belongs to the field of traditional Chinese medicine residue recycling technology and microecologics. The synbiotic is prepared by using rhizopus oligosporus SH to ferment Yupingfeng herb residue polysaccharide (YPD). The preparation method is characterized by taking YPD as a unique raw material to obtain the Yupingfeng herb residue polysaccharide synbiotic through rhizopus oligosporus SH fermentation and including the links of dissolving of YPD, circulating steam sterilization, cooling, inoculation, fermentation and freeze-drying. By the synbiotic, in-vitro proliferation activity, phagocytic activity and NO releasing capability of rice lymphocytes and macrophagocytes are improved remarkably, and expression of IL-6, TNF-alpha, IFN-gamma, NF-kB, TLR-4 and iNOS in cells can be increased; in an LPS-induced chronic inflammation model, the synbiotic remarkably inhibits in-vitro proliferation activity of lymphocytes and remarkably decreases expression of IL-6, TNF-alpha, IFN-gamma, NF-kB, TLR-4 and iNOS in cells. Consequently, the Yupingfeng herb residue polysaccharide synbiotic has bidirectional immunoregulation effect and can serve as an immunoregulator.

Owner:SICHUAN AGRI UNIV

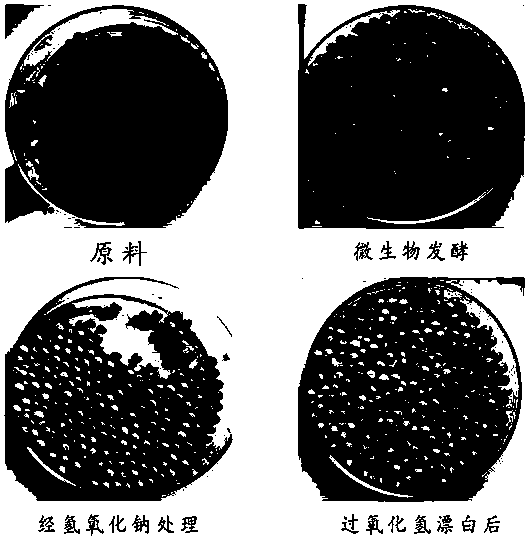

Method for decolorizing white pepper through microbial fermentation

ActiveCN108634170AThe effect of increasing fragrance is obviousSolve problems such as dull color (blackening) and peculiar smellFood ingredient as taste affecting agentFood ingredient as flavour affecting agentSnow moldMicroorganism

The invention discloses a method for decolorizing white pepper through microbial fermentation. The method comprises a step of subjecting hulled white pepper to liquid fermentation decoloring via lactic acid bacteria and / or mould, wherein the lactic acid bacteria are one or more selected from the group consisting of Lactobacillus plantarum CICC20264, Lactobacillus plantarum subsp. CICC20022, Lactobacillus plantarum CICC20264 and Lactobacillus plantarum subsp. CICC20022; and the mold is one or more selected from the group consisting of Rhizopus oryzae CICC41441, Aspergillus oryzae CICC41376, Rhizopus oligosporus ATCC22959, Rhizopus oryzae CICC41441, Aspergillus oryzae CICC41376, Actinomucor elegans CICC20252 and Actinomucor elegans CICC20252. The method for decolorizing white pepper providedby the invention has good decolorization effect, fast decolorization and obvious fragrance improving effect after decolorization, and solves the problems of a dark color (blackening), odor and the like of white pepper.

Owner:YUNNAN AGRICULTURAL UNIVERSITY +1

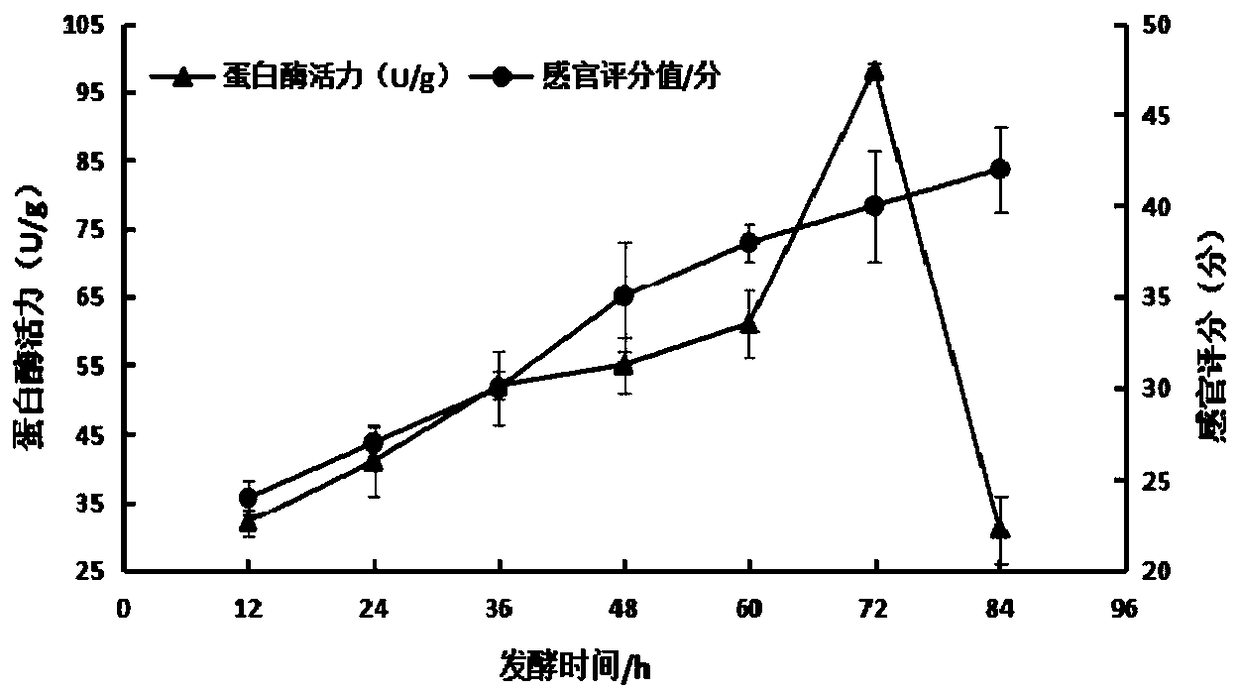

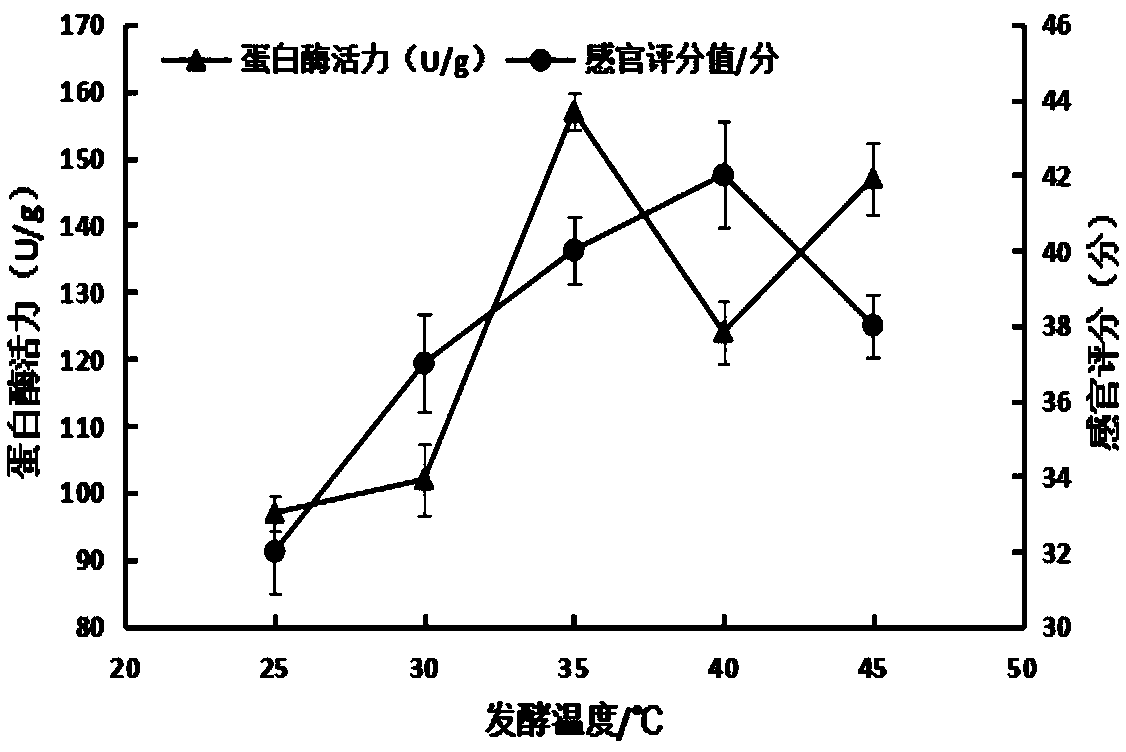

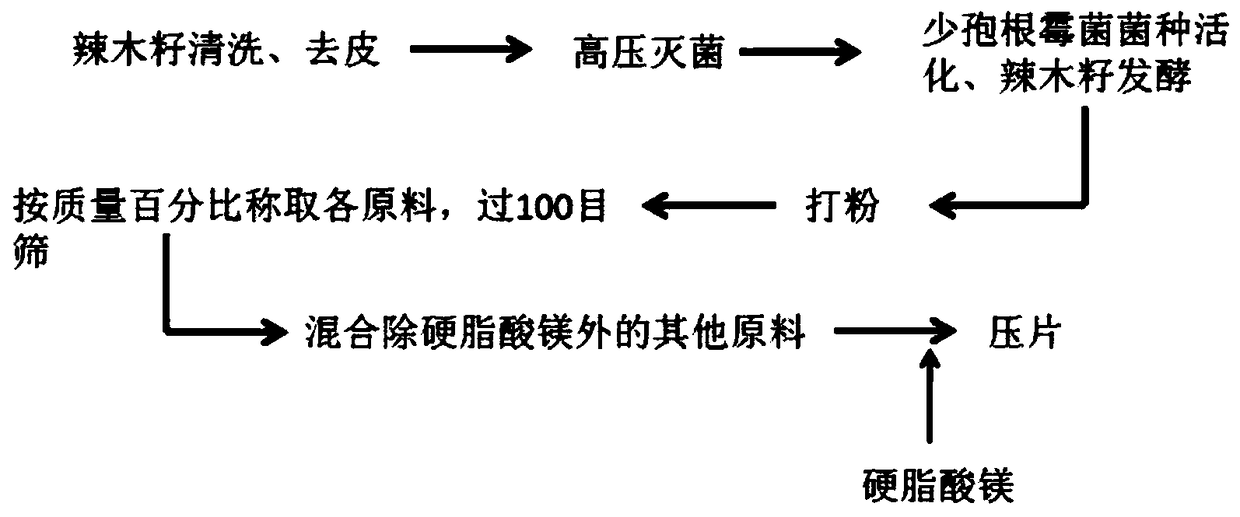

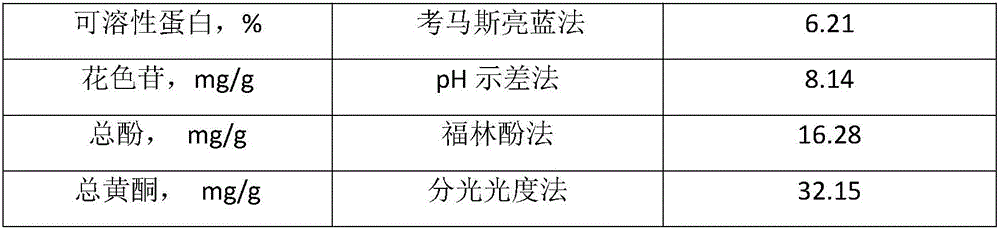

Moringa seed compound nutrient tablet and preparation method thereof

InactiveCN109198620AIncrease profitEasy to carryFood shapingFood ingredient functionsVitamin CDietary fiber

The present invention discloses a moringa seed compound nutrient tablet and a preparation method thereof. The moringa seed compound nutrient tablet comprises the following compositions in mass percentages: 20% of moringa seed tempeh powder, 32% of sugar powder, 26% of a filler, 7% of dietary fibers, 9% of vitamin C, 5% of calcium hydrogen phosphate and 1% of magnesium stearate. The filler is prepared by mixing beta-cyclodextrin and corn starch at a mass ratio of 2:1; the dietary fibers are prepared by mixing soybean dietary fibers and inulin at a mass ratio of 1:1; and the preparation method of the moringa seed compound nutrient tablet specifically comprises the following steps: moringa seed washing and peeling, high-temperature sterilizing, rhizopus oligosporus strain activating, moringaseed fermenting, powdering, weighing and tabletting. The prepared moringa seed compound nutrient tablet can remove lectin, retains nutrients in moringa seeds, enables the nutrients in the moringa seeds to be easily absorbed, also contains other nutrients, and is high in nutritional value, convenient to carry and eat, fruity and chewable.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Method for producing recombinant leisure food by blackberry and blueberry juice processing byproducts

InactiveCN106616588ABright colorAchieve full utilizationFood thermal treatmentFood dryingAdditional valuesRhizopus oligosporus

The invention discloses a method for producing recombinant leisure food by blackberry and blueberry juice processing byproducts. The method comprises the following steps of taking blackberry and blueberry juice processing byproducts; uniformly mixing the materials; adding polyphenol compounds; after the uniform mixing, performing ultrasonic treatment and low-temperature drying; then, performing crushing; adding mesona chinensis powder, ginkgo powder, honey and pure water; after the uniform mixing, performing prilling; adding peeled and steamed crushed soybeans; uniformly mixing the materials; then, inoculating rhizopus oligosporus oligospora variant conidial powder; charging the materials into dishes; performing fermentation; after the fermentation is completed, performing sterilization, slicing and drying; then, performing nitrogen injection packaging to obtain the recombinant leisure food. The method provided by the invention realizes the whole utilization of blackberries and blueberries; zero contaminant discharge is realized in the production process; the environment pollution is reduced; the added value of the blackberries and blueberries is improved; a novel path is provided for the fine and deep processing of the blackberries and blueberries; the obtained product has the core competitiveness and the wide market prospects.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Rhizopus oligosporus,bean dreg fermented product and preparation method of bean dreg fermented product

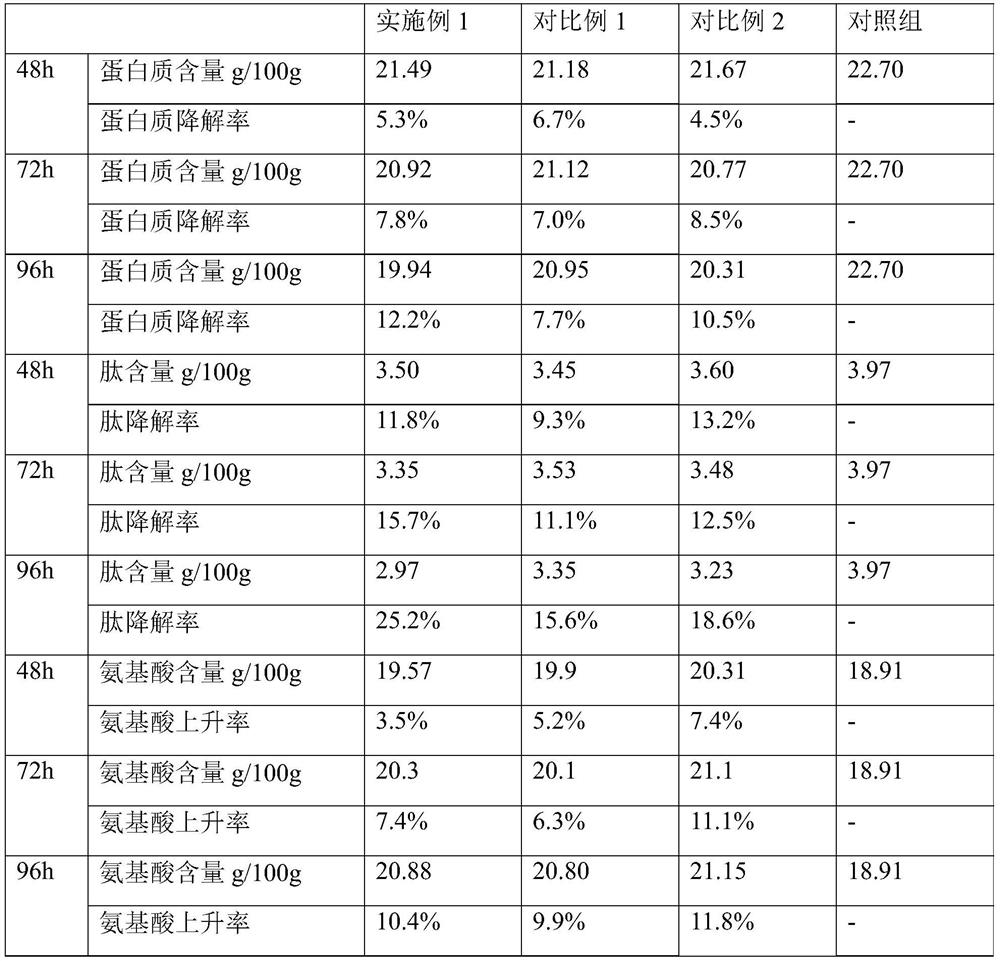

PendingCN113025500AIncreased content of essential amino acidsPromote degradationFungiAnimal feeding stuffBiotechnologyNutrition

The invention relates to a rhizopus oligosporus CGMCC NO.21461, and provides application of the rhizopus oligosporus in the preparation of fermented products and a method for preparing a bean dreg fermented product by using the rhizopus oligosporus. The rhizopus oligosporus has excellent capability of degrading proteins and peptides in raw materials in the fermentation process, and is an excellent strain for preparing fermented products. The nutritional quality of the bean dreg fermented product prepared by using the rhizopus oligosporus disclosed by the invention as a fermentation strain is remarkably improved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Processing method of high-nutrition grains

The invention provides a processing method of high-nutrition cereals. The method comprises the following operation steps: preparing a cereal raw material containing embryos, performing screening, performing cleaning, performing soaking, performing germinating, performing enzymolysis, performing drying and performing packaging. The soaking treatment is carried out in chlorine-containing tap water;the germinating treatment is carried out by culturing the soaked cereals until embryos break through seed coats; the enzymolysis treatment is carried out by adding xylanase, cellulase, beta-glucanase,glutamine transaminase and a microbial agent into the germinated cereals for enzymolysis, wherein the microbial agent is rhizopus oligosporus and / or bacillus, the addition amount of each enzyme is 10-300g / ton, and the addition amount of each microbial agent is 100-3000g / ton. The method is simple and easy to operate, the technical means is most natural, and cost is the lowest. The obtained producthas a same eating method as common cereals, but the nutrient content and the functional value are higher than those of unprocessed cereals, and washing is not needed during eating.

Owner:TIANJIN ZHONGYING HEALTH FOOD

High-bioactivity fermented soybean meal and preparation method and application thereof

InactiveCN108541824AImprove biological activityHigh nutritional valueFood processingAnimal feeding stuffFeed conversion ratioAbsorption effect

The invention discloses high-bioactivity fermented soybean meal and a preparation method and an application thereof; the high-bioactivity fermented soybean meal is composed of following components inparts by weight: 500-600 parts of dry soybeans, 1-2 parts of sodium chloride, 1-2 parts of ammonium sulfate, 2-3 parts of urea, 1-2 parts of magnesium sulfate, 10-20 parts of acetic acid, 1500-2000 parts of water, 600-700 parts of ethanol, 30-36 parts of rhizopus oligosporus RT-3 and 60-72 parts of beer yeast. A feed prepared from the high-bioactivity fermented soybean meal after high temperature,ethanol and fermentation treatment has the advantages of higher conversion rate, higher nutritional value and better absorption effect.

Owner:ANHUI TECH BANK BIO TECH

Moringa seed tempeh manufacturing method

The invention discloses a moringa seed tempeh manufacturing method. The moringa seed tempeh manufacturing method includes steps of soaking moringa seeds; adding rhizopus oligosporus suspension into the moringa seeds and fermenting the moringa seeds. The moringa seed tempeh manufacturing method has the advantages that taste of the moringa seeds can be improved, accordingly, the moringa seeds are free of bitterness, astringency and pungency, and the contents of beneficial components in the moringa seeds can be increased.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

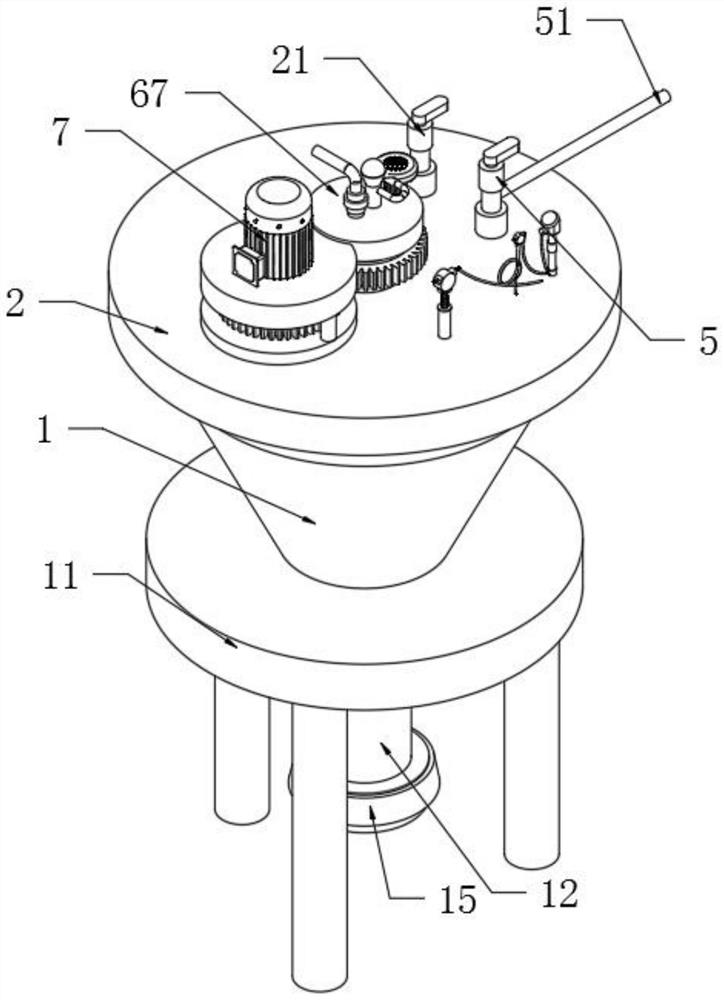

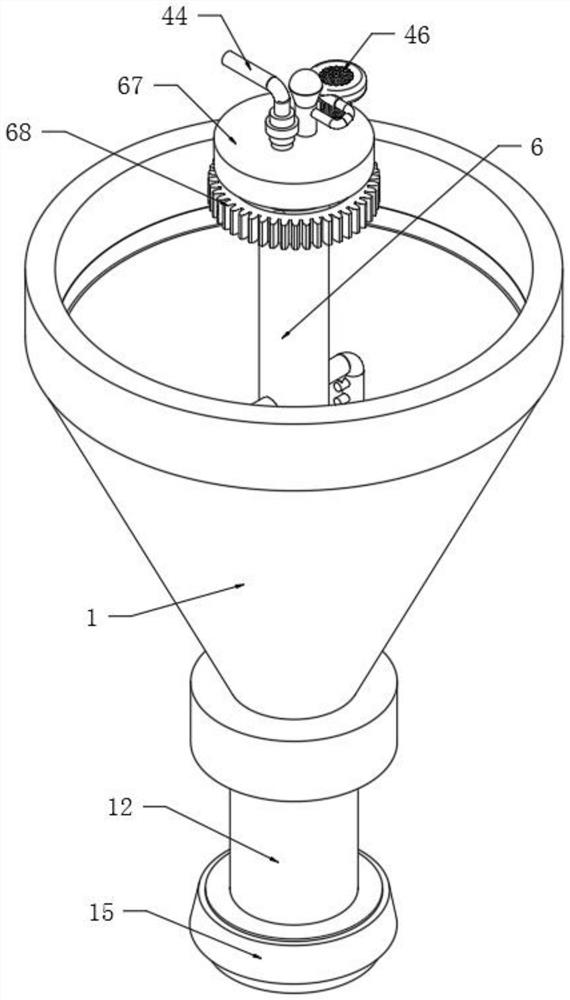

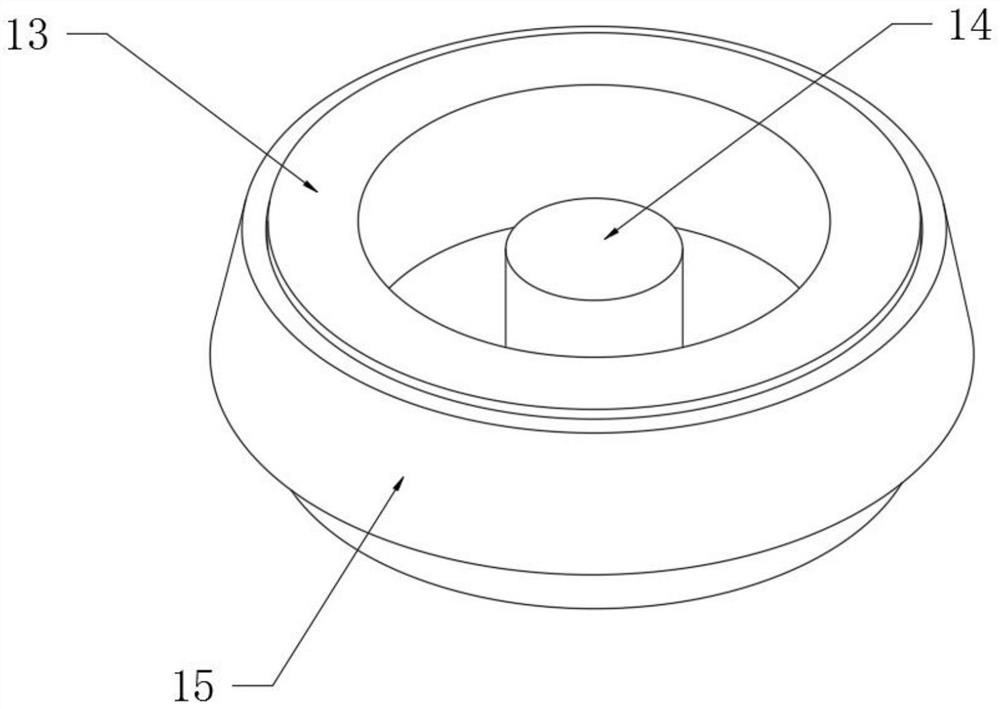

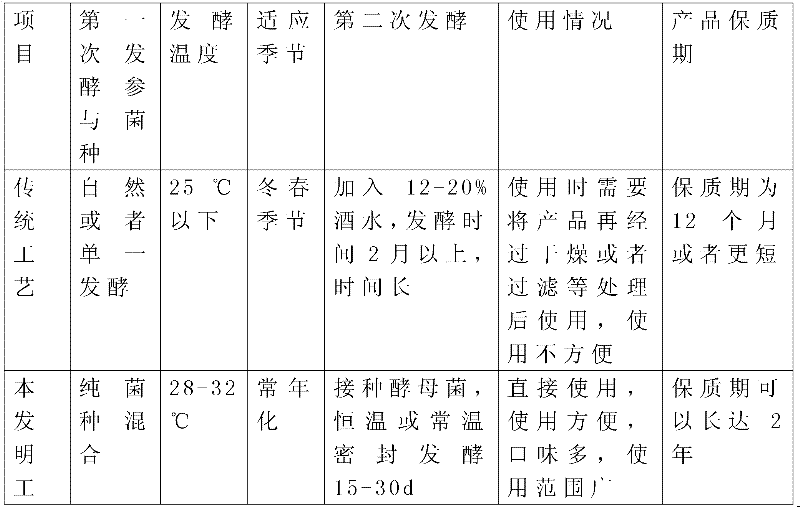

Method and equipment for preparing straw protein through secondary fermentation of rhizopus oligosporus

PendingCN114230412AIncrease contentSmall structureBio-organic fraction processingBioloigcal waste fertilisersBiotechnologyRhizopus

The invention belongs to the technical field of fertilizer production, and particularly relates to equipment for a preparation method of rhizopus oligosporus secondary fermentation straw protein.The equipment comprises a fermentation tank, the outer surface of the fermentation tank is fixedly connected with a supporting frame, the fermentation tank is of a conical structure, the lower surface of the fermentation tank is fixedly communicated with a discharging pipe, and the upper surface of the fermentation tank is connected with a sealing cover in a covering mode; a stirring device is arranged in the fermentation tank and comprises an arc-shaped stirring pipe, the outer surface of the arc-shaped stirring pipe is attached to the inner wall of the fermentation tank, and materials in the fermentation tank are uniformly stirred. According to the preparation method and equipment of the rhizopus oligosporus secondary fermentation straw protein, the auger stirring rod rotates along with rotation of the main stirring pipe, the auger stirring rod can drive materials in the discharging pipe to stir up and down, so that the materials are uniformly stirred, and when the cover body is taken down, the auger stirring rod rotates to stir the materials in the discharging pipe up and down, so that the materials are uniformly stirred. And the fermented materials can be conveyed out from the discharge pipe, so that the fermentation efficiency of the materials in the fermentation tank is improved.

Owner:嘉兴上柒寸生物科技有限公司

Production process of fermented bean curd and fermented bean curd powder

ActiveCN113142492AAdd flavorQuality improvementFood ingredient as antioxidantYeast food ingredientsBiotechnologyRhizopus oligosporus

The invention relates to a production process of fermented bean curd and fermented bean curd powder. The production process of the fermented bean curd comprises the following steps of Step 1, inoculating a mixed strain containing Actinomucor elegans and Rhizopus oligosporus on a bean curd blank, and carrying out early-stage fermentation; Step 2, after the early-stage fermentation is finished, performing placement for 24 to 48 hours under the conditions of the temperature being 10 to 12 DEG C and the humidity being 45 to 60 percent, then performing placement for 6 to 24 hours under the conditions of the temperature being 28 to 31 DEG C and the humidity being 80 to 95 percent, performing circulation for 2 to 3 times, and performing hair pinching on the bean curd blank; Step 3, performing pickling; and Step 4, immersing the bean curd blank obtained in the Step 3 into a soup material, and carrying out later-stage fermentation at 22 to 30 DEG C for 30 to 45 days. The production process provided by the invention has the effects that the flavor, the aroma and the quality of the fermented bean curd are improved; and better production benefits are achieved. The fermented bean curd powder is prepared by the production process of the fermented bean curd according to any one of claims 1 to 7, and comprises the following raw materials in parts by weight: 90 to 110 parts of fermented bean curd blocks, 5 to 10 parts of seasonings, 2 to 15 parts of oil materials and 10 to 30 parts of spices. The effect that the flavor and the aroma of the fermented bean curd powder are improved is achieved.

Owner:北京市老才臣食品有限公司

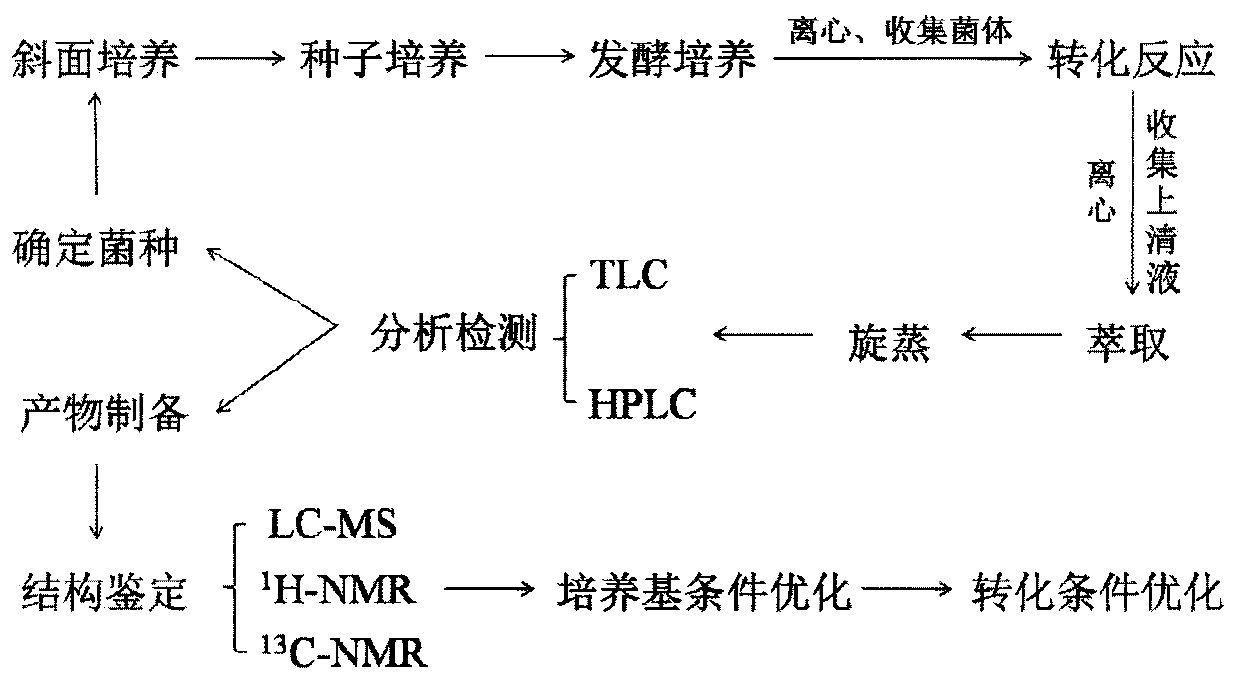

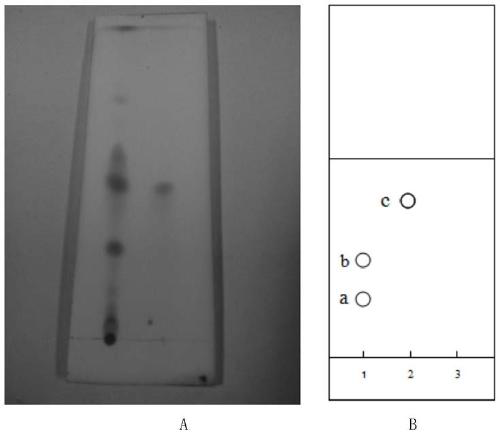

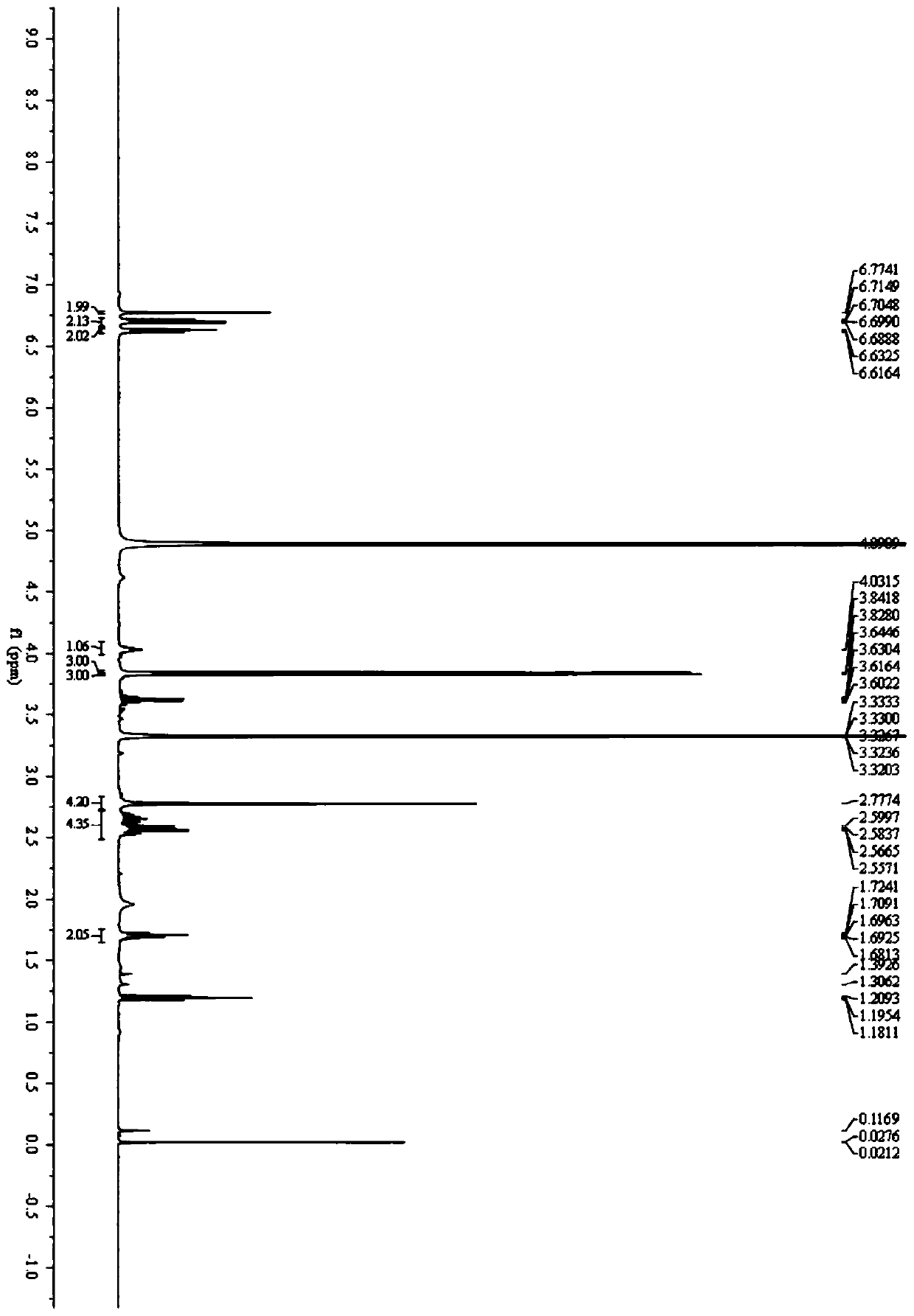

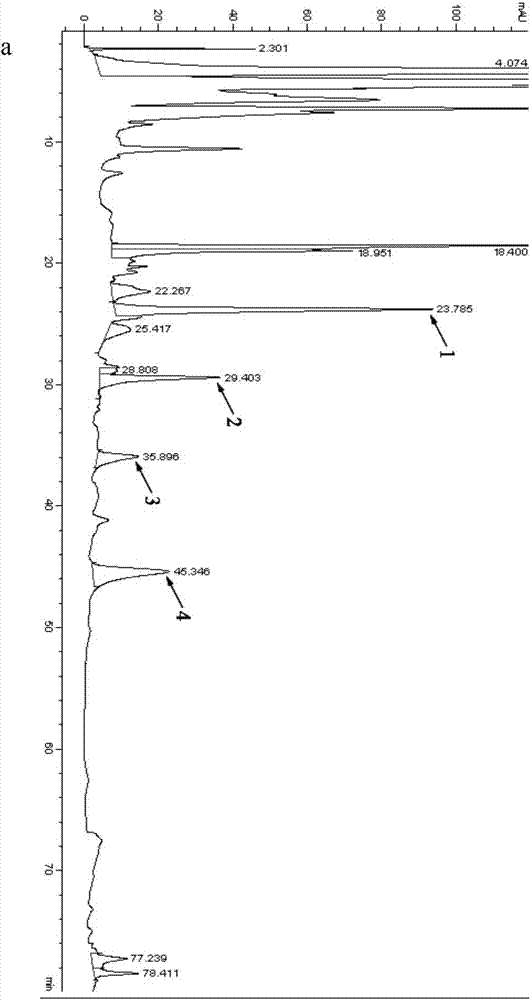

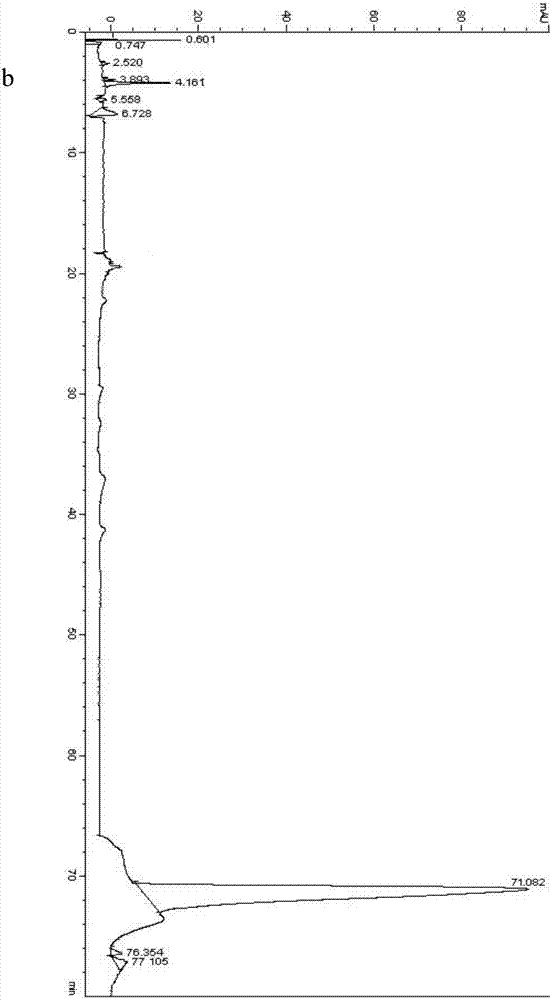

A kind of preparation method of curcumin derivative

ActiveCN106957881BImprove pharmacological activityImprove biological activityMicroorganism based processesFermentationPtru catalystPhosphate

The invention discloses a preparation method for a curcumin derivative. The method comprises the following steps: by taking a phage acquired from the ferment cultivation of rhizopus oligosporus bearded variety ZJPH1308 as a catalyst, taking curcumin as a substrate, taking phosphate buffer with pH value from 5.4 to 8.0 as a reaction medium, forming a transformation system, performing conversion reaction under the conditions of 25-50 DEG C and 150-250rpm, and separating and purifying the conversion solution after the ending of the reaction, thereby acquiring 4,4'-(3-Hydroxyheptane-1,7-diyl)-bis-2-methoxyphenol and hexahydrocurcumin at the yield of 33.9% and 35.8%.

Owner:ZHEJIANG UNIV OF TECH

Process for preparing fermented bean curd powder

InactiveCN102058068BReduce inhibitionRaise the fermentation temperatureFood preparationChipped potatoesFreeze-drying

The invention relates to a process for preparing fermented bean curd powder. The process comprises the following steps of: vaccinating equivalent 0.1-0.3 percent pure racemomucor M.H.C-7CCTCCM 201026 subjected to enlargement culture and rhizopus oligosporus CGMCC 3.4392 and fermenting to form a mould billet; adding salt and Chinese rice wine, uniformly mixing and then vaccinating 0.2 percent activated Angel high-temperature-resistant active dry yeast; sealing for fermenting; pulverizing to form a viscous fluid and precooling; drying into freeze-drying powder in vacuum; and bottling and sealing to obtain the fermented bean curd powder. Ingredients can be added to the freeze-drying powder to be prepared into various seasoners which have the fermented bean curd flavor and different applications, and the freeze-drying powder can be widely applied to seasoners of potato chips, flour products, rice products, roasted meat products, and the like and can be also used as an ingredient of instant noodle seasoning bags. The fermented bean curd powder has the advantages of scientific process design and short process period, is particularly suitable for annual production and is obviously different from fermented bean curd products of other forms. The process can be used for realizing industrial continuous production and has the advantages of controllable process, stable quality and wide application and provides a feasible method for developing novel seasoners.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Preparation method of fermented rice and bean clear liquid composite beverage

ActiveCN110754595AImprove conversion rateFungiMicroorganism based processesBiotechnologyAlcohol content

The invention relates to a preparation method of a fermented rice and bean clear liquid composite beverage, which takes bean clear liquid and rice as main raw materials, takes sweet distiller's yeastand rhizopus oligosporus as fermentation strains, and prepares the composite flavor beverage through a secondary fermentation technology. The method provided by the invention not only can provide an effective way for reasonable utilization of the bean clear liquid, but also can promote conversion of glucoside isoflavone in the bean clear liquid into aglycone isoflavone; meanwhile, compared with atraditional rice wine beverage making process, the conversion and utilization rate of the rice raw materials is effectively increased, a proper pH value can be kept in the later fermentation period, and the problem that the beverage is too sour or rancid is avoided. In the product obtained by the process, the conversion rate of converting glucoside isoflavone into aglycone isoflavone is 75-82%, and the raw material conversion rate of rice can reach 85-92%. The pH value of the prepared beverage is 3.9-4.5, and the volume percentage of the alcohol content in the beverage is less than or equal to0.5%.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

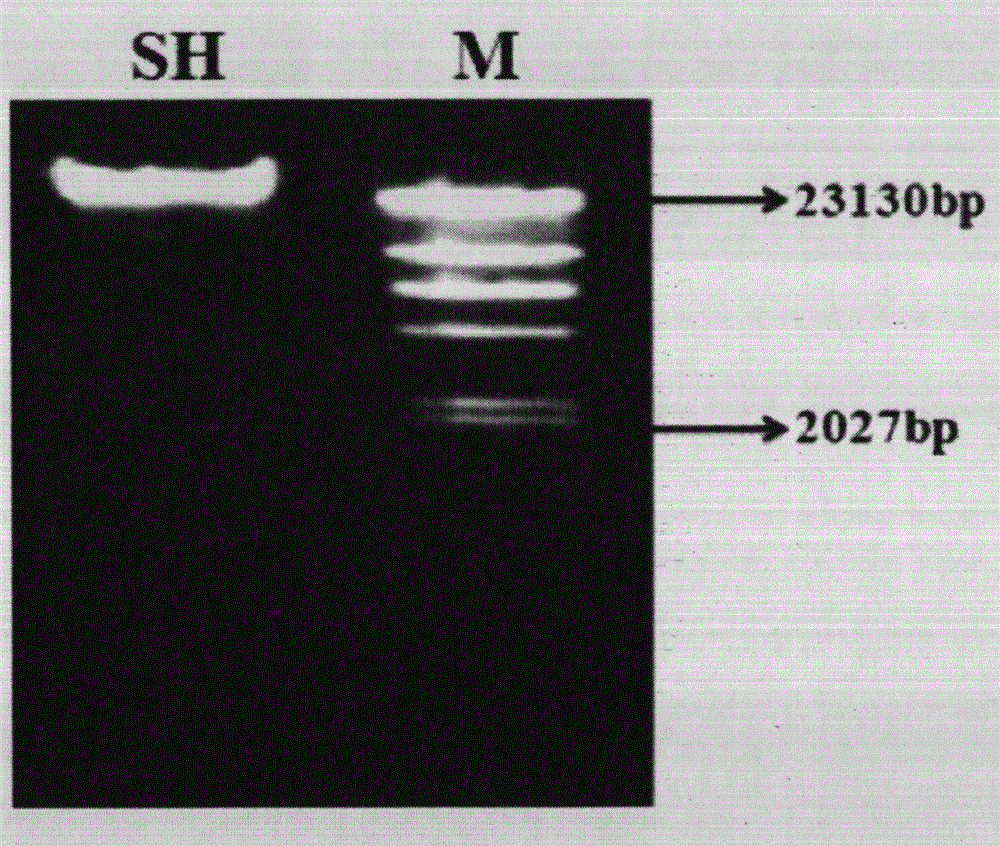

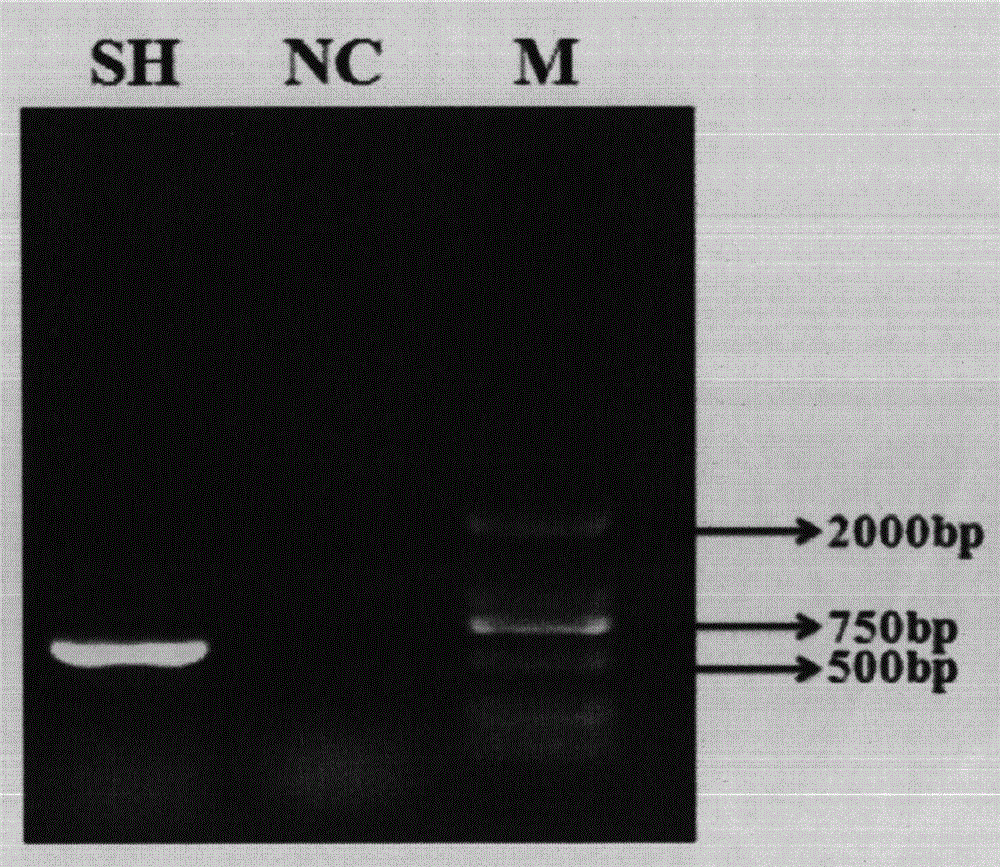

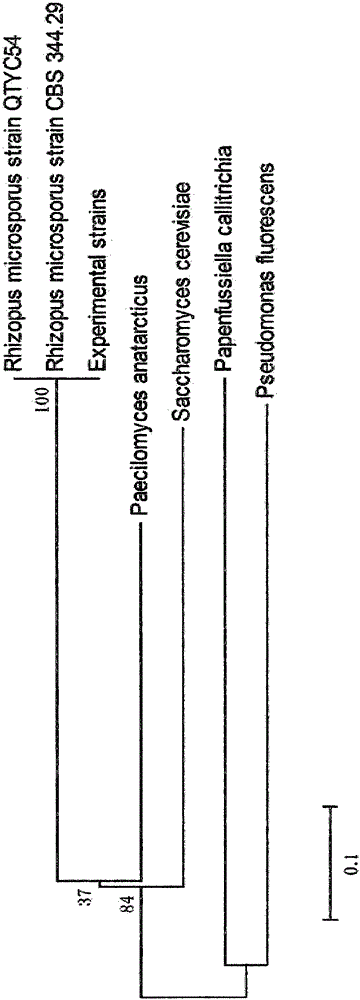

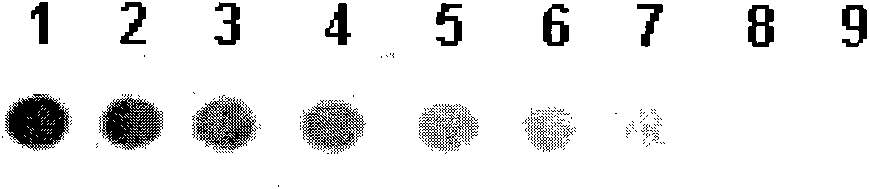

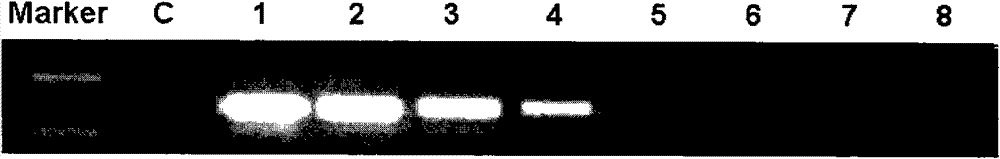

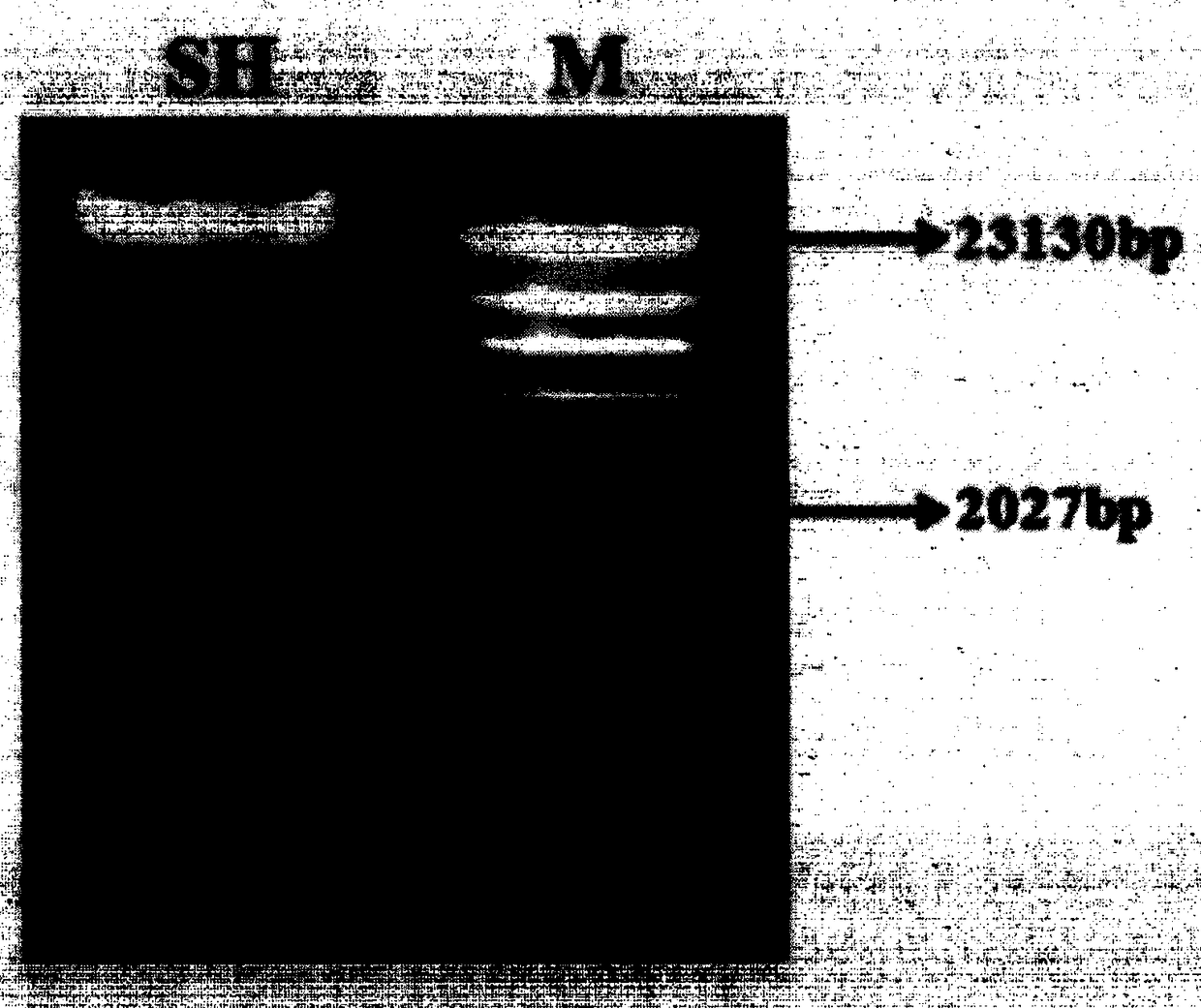

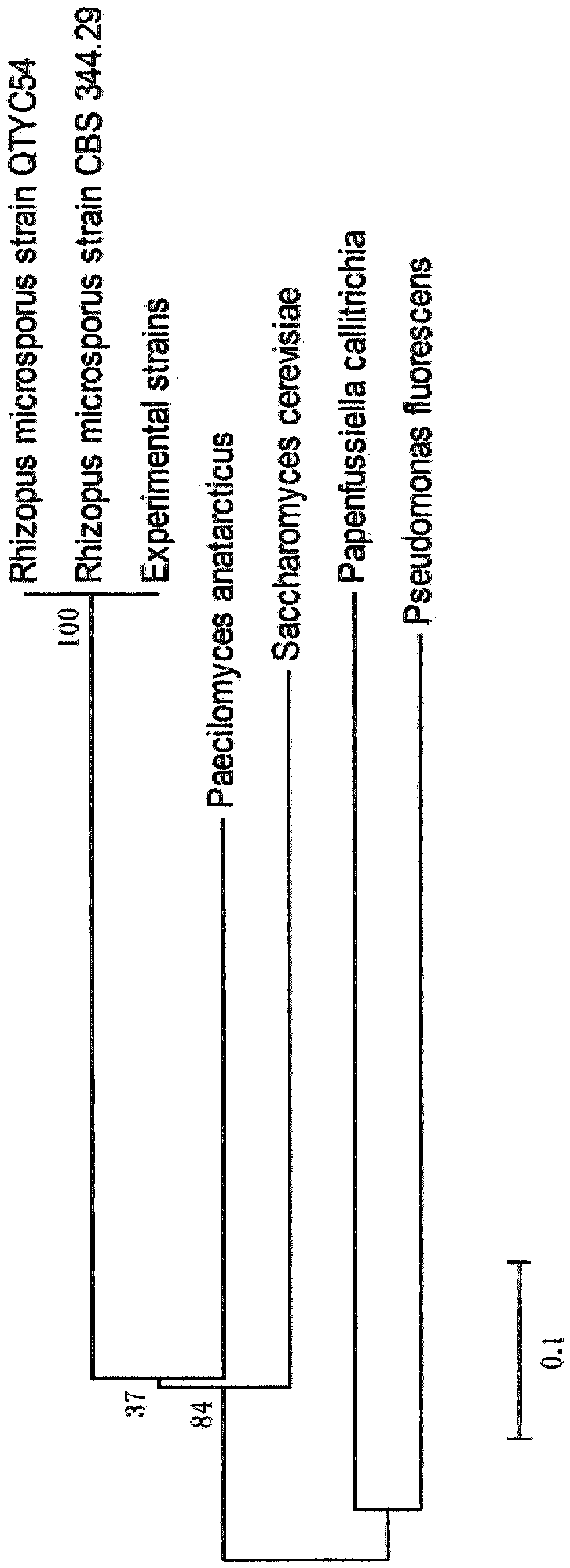

DNA probe for detecting rhizopus oligosporus, gene chip and application thereof

InactiveCN102031295BReduce consumptionGuaranteed accuracyMicrobiological testing/measurementDNA/RNA fragmentationNucleotideRhizopus oligosporus

The invention discloses a DNA probe for detecting rhizopus oligosporus, which relates to the field of biotechnology. The DNA probe for detecting rhizopus oligosporus has a mucleotide sequence shown as the sequence table SEQ ID No.1, has high specificity for detecting rhizopus oligosporus and high sensitivity up to 0.04ng. The invention also provides a gene chip consisting of the DNA probe. By adopting the gene chip, high-throughput, automatic and rapid detection on samples which possibly contains rhizopus oligosporus can be realized. The gene chip has high specificity, can ensure the accuracyof the detection result, and has wide application prospect.

Owner:李国辉

Preparation method for curcumin derivative

ActiveCN106957881AImprove pharmacological activityImprove biological activityMicroorganism based processesFermentationPhosphateRhizopus oligosporus

The invention discloses a preparation method for a curcumin derivative. The method comprises the following steps: by taking a phage acquired from the ferment cultivation of rhizopus oligosporus bearded variety ZJPH1308 as a catalyst, taking curcumin as a substrate, taking phosphate buffer with pH value from 5.4 to 8.0 as a reaction medium, forming a transformation system, performing conversion reaction under the conditions of 25-50 DEG C and 150-250rpm, and separating and purifying the conversion solution after the ending of the reaction, thereby acquiring 4,4'-(3-Hydroxyheptane-1,7-diyl)-bis-2-methoxyphenol and hexahydrocurcumin at the yield of 33.9% and 35.8%.

Owner:ZHEJIANG UNIV OF TECH

Micro-ecology fermentation protein feedstuff and preparation method thereof

InactiveCN101449739BEasy feedingIncrease production capacityBacteriaFood processingFecesAnimal protein

The invention provides a micro-ecological fermented protein feed and a preparation method, wherein the feed is prepared by mixing bean pulp and silkworms with quality ratio 90-98:2-10, then cooking to obtain solid state fermention medium, then inoculating mixed strains of bacillus subtilis, Saccharomyces cerevisiae, lactobacillus and Rhizopusoligosporus on solid fermention medium, then co-mixing for 30-45 hours at 33-37 DEG C, drying fermentation products after completing fermenting, crushing and obtaining the micro-ecological fermented protein feed. The inventive micro-ecological fermented protein feed contains a plurality of biological active peptides, content of small peptide reach more than 22%, which is favourable for digestion and development; contains lactobacillus, microzyme, which is favourable for controlling useful microbiological population in intestinal tracts of animals; has good delicious flavor and good luring effect, advances young animals for ingestion; contains soybean isoflavone more than 0.05%, markedly increases immunity of bodies, increases producibility of animals; relieving odmour of fecal waste; fully takes place of animal protein feed of fish meal and plasma protein flour and the like.

Owner:ZHEJIANG UNIV

A kind of method of making enzyme with black bean tempeh

ActiveCN103876147BGrowth inhibitionPromote growthFood ingredient functionsBiotechnologyLiquid product

Owner:蒋凯男

How to make Moringa seed tempeh

The invention discloses a preparation method of Moringa seed tempeh, comprising the following steps: taking Moringa seeds, soaking, adding a suspension of Rhizopus oligospora for fermentation. The invention has the advantages that the mouthfeel of the moringa seeds can be improved, the moringa seeds have no bitterness and spicy taste, and the content of beneficial components in the moringa seeds can also be increased.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Preparation of a polysaccharide synbiotic from Yupingfeng dregs and its application in immune regulation

The invention discloses a preparation method of polysaccharide synbiotics from Yupingfeng dregs and its application in immune regulation. The synbiotic is prepared by fermenting Yupingfeng dregs polysaccharide (YPD) by Rhizopus oligospore SH, and belongs to the field of resource utilization technology of traditional Chinese medicine dregs and microecological preparations. The gist of the invention is to use YPD as the only raw material to obtain the polysaccharide synbiotics from Yupingfeng dregs through SH fermentation of Rhizopus oligosporus, including YPD dissolution, circulation steam sterilization, cooling, inoculation, fermentation, freeze-drying and other links. The synbiotic significantly improved the in vitro proliferation activity, phagocytosis activity and NO release ability of mouse lymphocytes and macrophages; and could up-regulate intracellular IL‑6, TNF‑α, IFN‑γ, NF‑κB, TLR‑ 4 and iNOS expression; while in the LPS-induced chronic inflammation model, synbiotics significantly inhibited the in vitro proliferation of lymphocytes, and significantly down-regulated intracellular IL‑6, TNF‑α, IFN‑γ, NF‑κB, TLR‑ 4 and expression of iNOS. It shows that polysaccharide synbiotics from Yupingfeng medicinal dregs have two-way immunoregulatory effect and can be used as an immunomodulator.

Owner:SICHUAN AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com