Process for preparing fermented bean curd powder

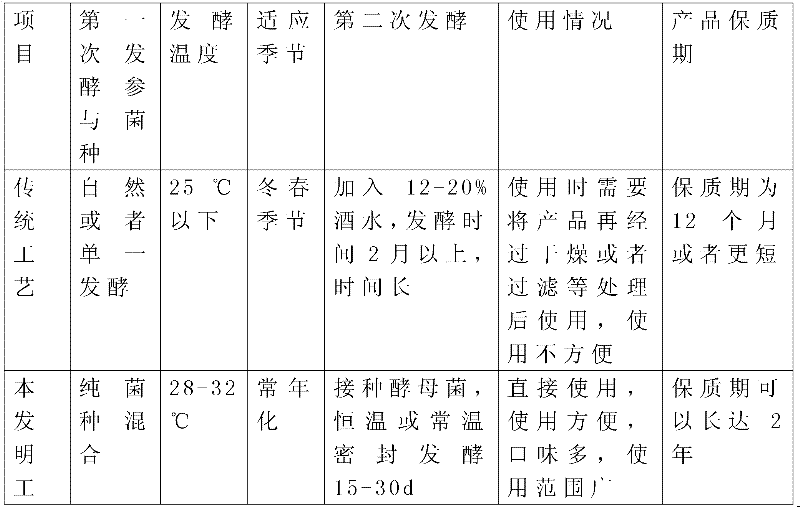

A production process and technology of fermented bean curd, which is applied in the field of condiment processing, can solve the problems of inconvenient use of fermented bean curd, and achieve the effects of reducing inhibition, long product shelf life, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Place the provided bean dregs in a sterilized fermentation frame, and inoculate 0.3% of purebred Mucor racemosus M.H.C-7 and Rhizopus oligosporus CGMCC3.4392 respectively according to the weight of bean dregs, and control the bean dregs after inoculation. The water content is 63-67%, and at a temperature of 28-32°C and a relative humidity of 90-96%, ferment for 48 hours to complete a fermentation to form a mold base; put the mold base into a fermentation tank and add 9 % table salt and 15% sweet fermented rice, mix well, inoculate with 0.2% activated Angel high-temperature-resistant active dry yeast, compact, keep warm at 40°C, and temperature-controlled sealed fermentation for 20 days. It is measured that the amino acid nitrogen reaches 0.60% at this time , after being ground into a viscous fluid with an ultrafine pulverizer, put it into a freezer, place it in a vacuum state at minus 20°C for 12 hours, and then put it in a vacuum dryer at a vacuum degree of 0.11 to 0.12...

Embodiment 2

[0026] Place the provided bean dregs in a sterilized fermentation frame, and inoculate 0.2% of purebred Mucor racemosus M.H.C-7 and Rhizopus oligospore CGMCC3.4392 respectively according to the weight of bean dregs, and control the bean dregs after inoculation. The water content is 63-67%. At a temperature of 28-32°C and a relative humidity of 90-96%, ferment for 60 hours to complete one fermentation and form a mold base; put the mold base in a fermentation tank and add 7 % of table salt and 12% of sweet fermented rice, mix well, inoculate with 0.2% of activated Angel high-temperature-resistant active dry yeast, compact, and seal and ferment at room temperature for 30 days. After being ground into viscous fluid by machine, put it into the freezer, pre-cool it at minus 40°C for 8 hours in a vacuum state, and then put it in a vacuum dryer with a vacuum degree of 0.11-0.12 mbar and minus 50°C. Dried for 50 hours to obtain freeze-dried bean curd powder, bottled and sealed.

Embodiment 3

[0028] Place the provided bean dregs in a sterilized fermentation frame, and inoculate 0.1% of purebred Mucor racemosus M.H.C-7 and Rhizopus oligosporus CGMCC3.4392 respectively according to the weight of bean dregs, and control the bean dregs after inoculation. The water content is 63-67%, and at a temperature of 28-32°C and a relative humidity of 90-96%, ferment for 72 hours to complete one fermentation and form a mold base; put the mold base in a fermentation tank and add 8 % table salt and 10% sweet fermented glutinous rice, mix well, inoculate 0.2% activated Angel high-temperature resistant active dry yeast, compact, keep warm at 45°C, temperature-controlled sealed fermentation for 15 days, and the amino acid nitrogen reaches 0.50% at this time , after being ground into a viscous fluid with an ultrafine pulverizer, put it into a freezer, place it in a vacuum state at minus 30°C for pre-cooling for 10 hours, and then put it in a vacuum dryer at a vacuum degree of 0.11-0.12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com