Method for producing recombinant leisure food by blackberry and blueberry juice processing byproducts

A snack food and by-product technology, applied in the field of food processing, can solve the problems of processing by-product waste and environmental pollution, and achieve the effects of improving digestion and absorption, improving nutrient absorption, increasing content and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

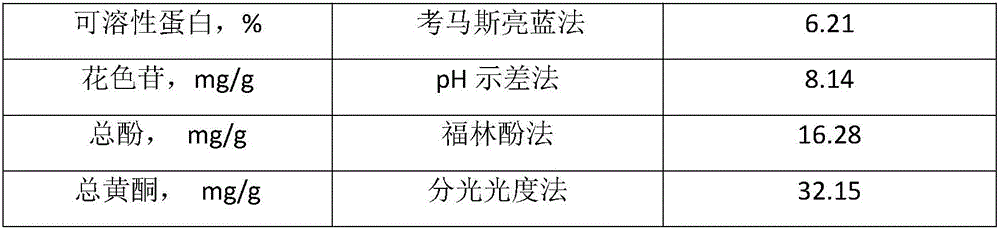

Examples

Embodiment 1

[0031] The method that present embodiment produces recombined snack food, comprises the following steps:

[0032] Get blackberry juice processing by-product 40kg after squeezing the juice, blueberry juice processing by-product 60kg to mix uniformly respectively, add 0.08kg polyphenol compound (30% resveratrol, 40% caffeic acid, 30% tea polyphenol), in Ultrasonic power 600W, duty cycle 50%, ultrasonic treatment 45min, 60 ℃ baked 25 hours, ultrafine grinding, add 0.08kg jelly powder, 1.0kg ginkgo powder, 4kg honey, 10kg pure water, mix evenly, granulate, The particle diameter of granulation is controlled at 20-30 order, mixes and inoculates 6% Rhizopus microsporus oligosporum varietal spore powder with 25kg peeled and steamed crushed soybean (the size of crushed soybean is controlled at 10-20 mesh), packs Plate, fermented at 32°C for 40 hours, treated with superheated steam at 123°C for 16 minutes, sliced (8X2X0.3cm), vacuumed at 0.1MPa, microwave power at 320W, dried for 45mi...

Embodiment 2

[0038] The method that present embodiment produces recombined snack food, comprises the following steps:

[0039] Take respectively 10kg of blackberry juice processing by-products and 90kg of blueberry juice processing by-products after squeezing to mix, add 0.1kg of polyphenol complex (35% resveratrol, 36% caffeic acid, 29% tea polyphenols), and Power 650W, duty cycle 56%, ultrasonic treatment for 50min, drying at 60°C, ultra-fine grinding, adding 0.1kg jelly powder, 0.7kg ginkgo powder, 5kg honey, 13kg pure water, mixing evenly, granulating, granulating The diameter of the grains is controlled at 20-30 mesh, mixed with 30kg peeled and steamed crushed soybeans (the size of the crushed soybeans is controlled at 10-20 mesh) and inoculated with 4% Rhizopus microsporum oligospore varietal, plated, 35°C Ferment for 35 hours, 128 ℃ superheated steam treatment 10min high temperature steam treatment, slice (8X2X0.3cm), vacuum degree 0.2MPa, microwave power 360W, drying time 41min, fl...

Embodiment 3

[0044] The method that present embodiment produces recombined snack food, comprises the following steps:

[0045]Get blackberry juice processing by-product 50kg and blueberry juice processing by-product 50kg respectively after squeezing the juice and mix uniformly, add 0.12kg polyphenol complex (25% resveratrol, 46% caffeic acid, 29% tea polyphenols), in Ultrasonic power 680W, duty cycle 60%, ultrasonic treatment 50min, 80 ℃ baked 18 hours, ultra-fine grinding, add 0.12kg jelly powder, 0.8kg ginkgo powder, 3kg honey, 15kg pure water, mix evenly, granulate, The particle diameter of granulation is controlled at 20-30 order, mixes and inoculates 8% Rhizopus microsporus oligosporum varietal spore powder with 20kg peeled and steamed crushed soybean (the size of crushed soybean is controlled at 10-20 mesh), packs Plate, fermented at 35°C for 40 hours, treated with superheated steam at 130°C for 20 minutes, sliced (8X2X0.3cm), vacuumed at 0.3MPa, microwave power 400W, dried for 50m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com