Moringa seed tempeh manufacturing method

A production method and technology of Moringa seeds, which are applied in the field of food processing and can solve problems such as increased consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

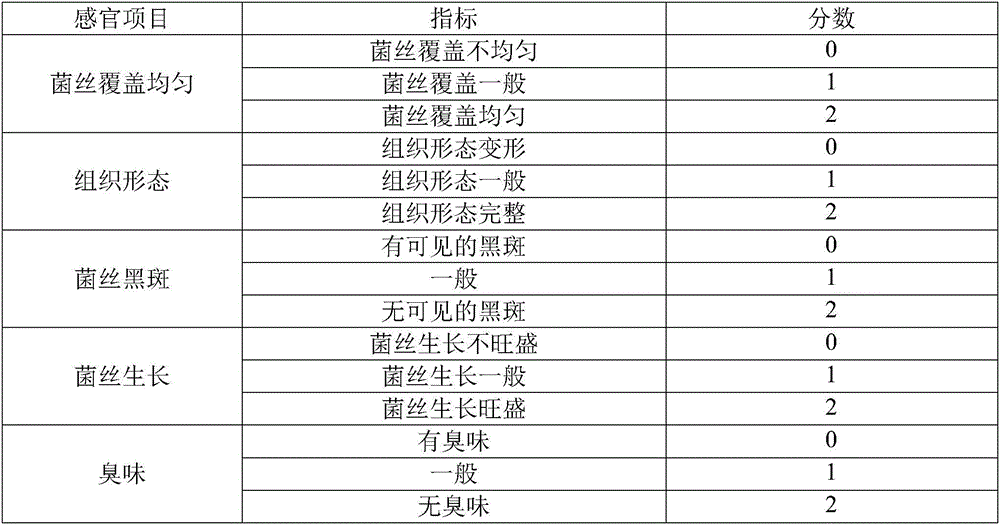

Image

Examples

Embodiment 1

[0016] A kind of preparation method of Moringa seed tempeh, comprises the following steps: take 100kg Moringa seed, select by sieving, remove impurity and chip, soak 15 hours with 200kg water, make Moringa seed fully absorb water and swell, then knead in water Peel off the skin and break the petals, drain the water, put it in a polypropylene box, add the suspension of Rhizopus oligosporus, shake it well to make the inoculation even, and then ferment for 72 hours at a temperature of 30°C and a humidity higher than 85%. The preparation method of described Rhizopus oligosporus suspension comprises the following steps: dissolving Rhizopus oligosporus spore powder in normal saline or purified water, containing 100 spores to every milliliter of normal saline or purified water; Rhizopus oligospore suspension The addition amount of adding 1ml carries out according to every 100g Moringa seed adds 1ml Rhizopus oligosporus suspension. In order to improve the shelf life, cryopreservation ...

Embodiment 2

[0019] A kind of preparation method of Moringa seed tempeh, comprises the following steps: take 100kg Moringa seed, select by sieving, remove impurity and chip, soak 12~24 hours with 150kg water, make Moringa seed fully absorb water and swell, then in Knead in water, peel off the skin and break the petals, drain the water, put it in a polypropylene box, add the suspension of Rhizopus oligosporus, shake it well to make the inoculation even, and then ferment at a temperature of 28-30°C and a humidity higher than 85%. 48-72 hours. The preparation method of the described Rhizopus oligosporus suspension comprises the following steps: dissolving the spore powder of Rhizopus oligosporus species in normal saline or purified water to contain 80 to 120 spores per milliliter of normal saline or purified water; The addition amount of the suspension is carried out according to adding 0.5-1.5ml of Rhizopus oligosporus suspension per 100g of Moringa oleifera seeds. In order to improve the s...

Embodiment 3

[0022] A kind of preparation method of Moringa seed tempeh, comprises the following steps: take 100kg Moringa seed, select by sieving, remove impurity and chip, soak 12~24 hours with 300kg water, make Moringa seed fully absorb water and expand, then in Knead in water, peel off the skin and break the petals, drain the water, put it in a polypropylene box, add the suspension of Rhizopus oligosporus, shake it well to make the inoculation even, and then ferment at a temperature of 28-30°C and a humidity higher than 85%. 48-72 hours. The preparation method of the described Rhizopus oligosporus suspension comprises the following steps: dissolving the spore powder of Rhizopus oligosporus species in normal saline or purified water to contain 80 to 120 spores per milliliter of normal saline or purified water; The addition amount of the suspension is carried out according to adding 0.5-1.5ml of Rhizopus oligosporus suspension per 100g of Moringa oleifera seeds. In order to improve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com