Patents

Literature

164 results about "Mucor species" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

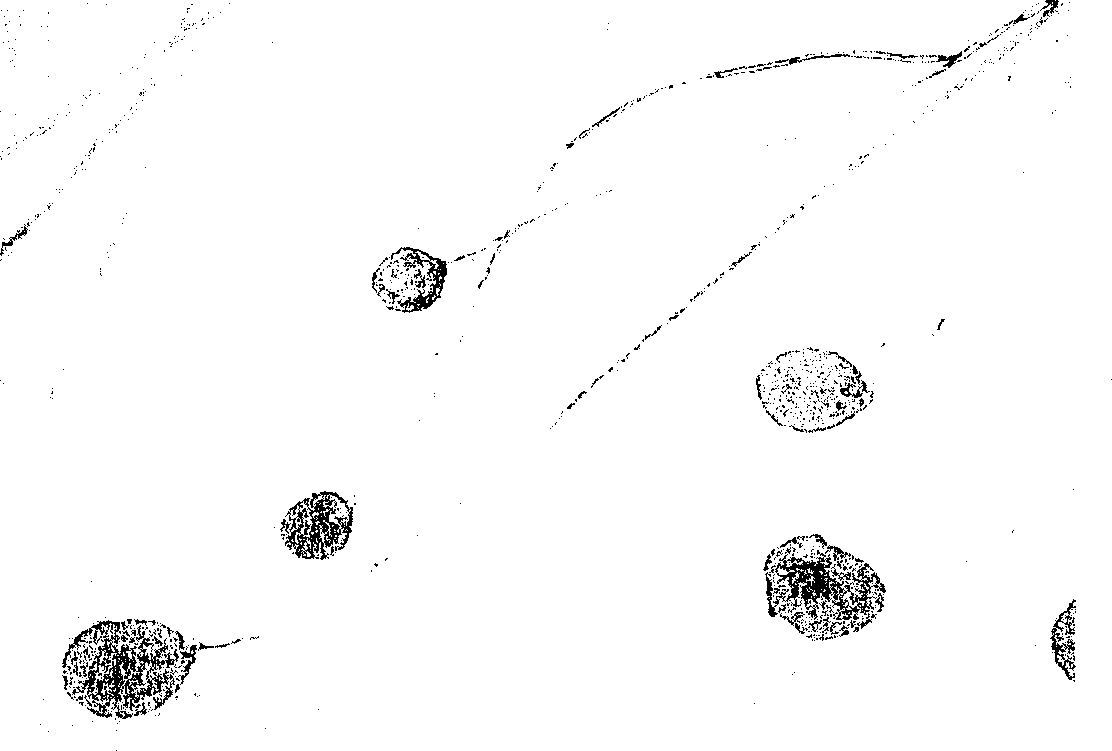

Mucor is a microbial genus of approximately 40 species of moulds commonly found in soil, digestive systems, plant surfaces, some cheeses like tomme de savoie, rotten vegetable matter and iron oxide residue in the biosorption process.

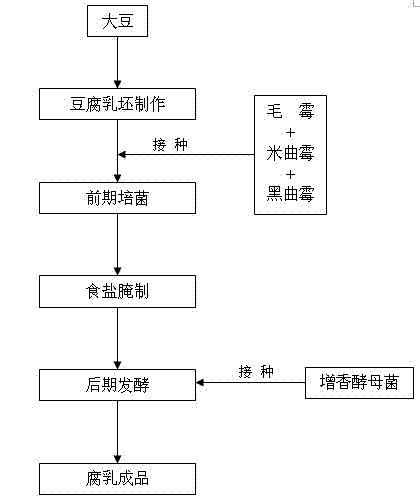

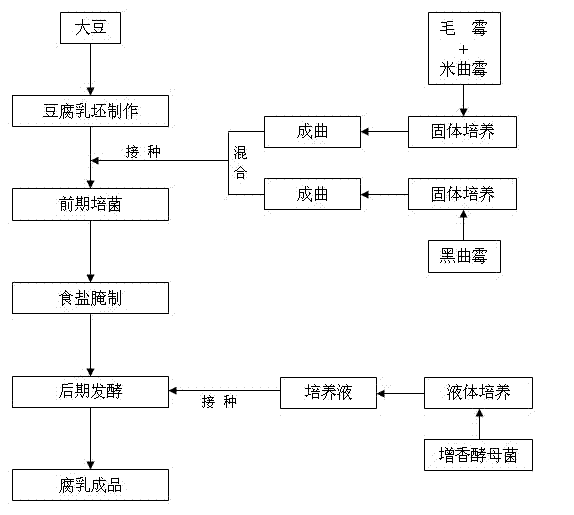

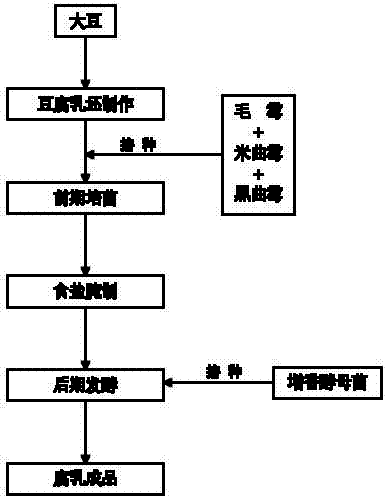

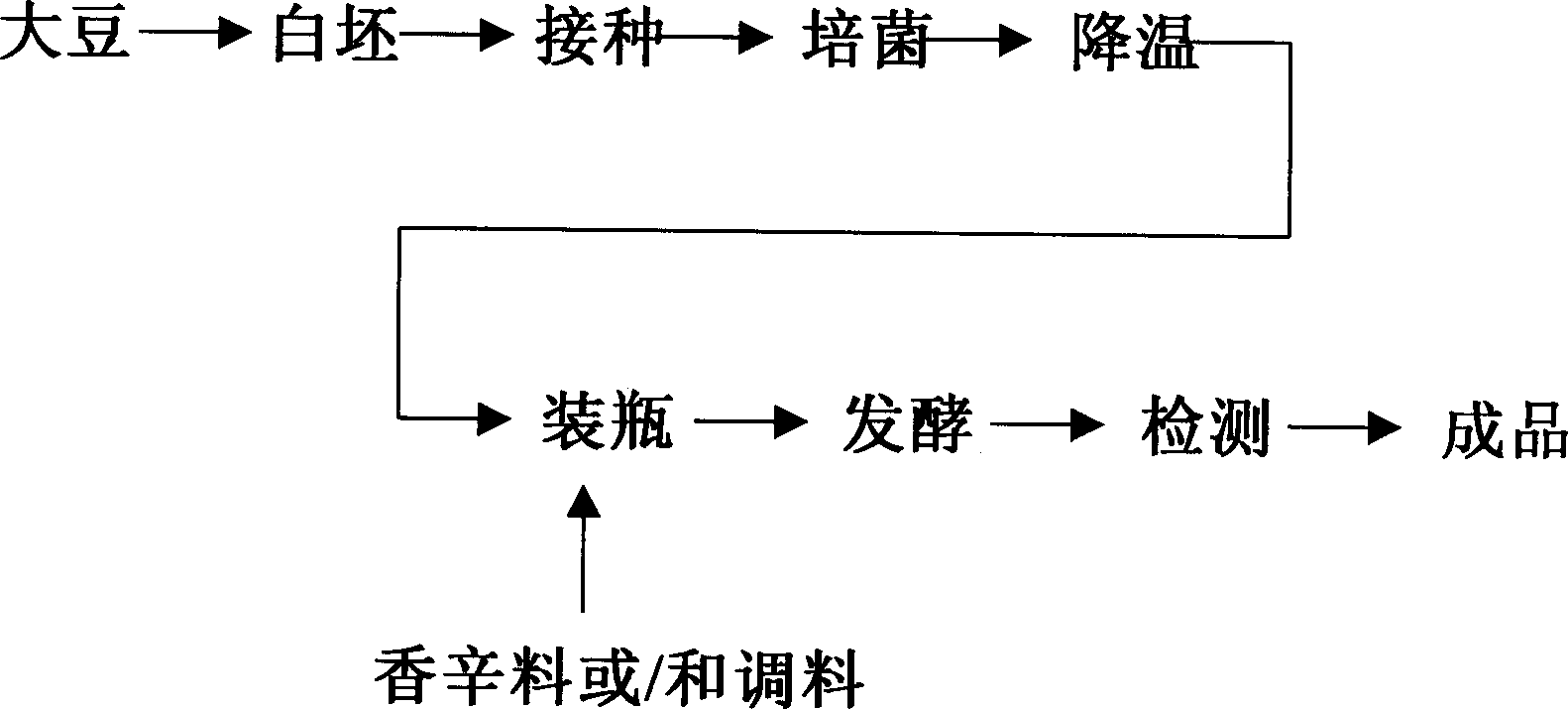

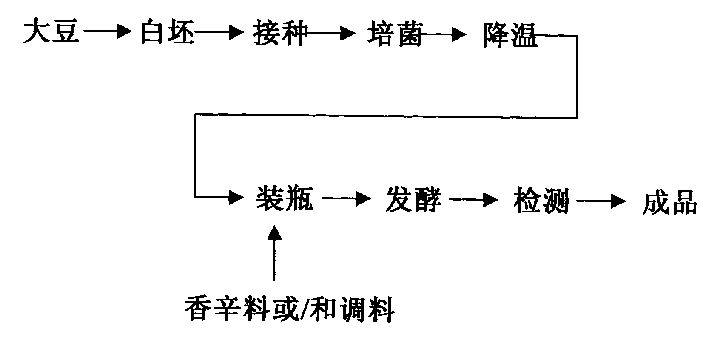

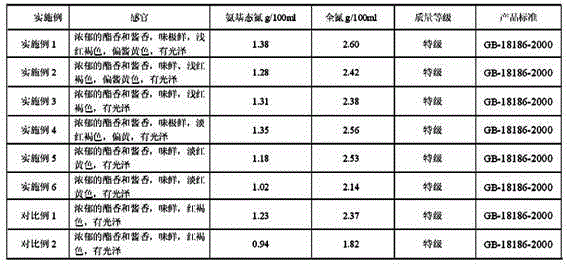

Method for producing fermented bean curd through multi-strain mixed fermentation

ActiveCN102197847APromote decompositionRich flavorCheese manufactureFood scienceYeastAspergillus oryzae

The invention discloses a method for producing fermented bean curd through multi-strain mixed fermentation. The method comprises the following steps of: (1) preparing raw fermented bean curd, namely preparing the raw fermented bean curd from soybean; (2) culturing bacteria at the early stage, namely inoculating mixed strains comprising mucor, Aspergillus oryzae and Aspergillus niger into the raw fermented bean curd to culture bacteria at the early stage to obtain the fermented bean curd blanks; (3) pickling by using salt, namely placing the fermented bean curd blanks obtained in the step (2) into a rubber box, scattering salt layer by layer, and pickling with the salt to prepare salty blanks; (4) fermenting at the later stage, namely placing the pickled fermented bean curd salty blanks into a bottle, inoculating flavor-increasing yeast into wine liquid of semifinished products, and fermenting at the later stage; and (5) obtaining the fermented bean curd. By the method, the flavor of the fermented bean curd products can be enriched and the fermenting period of the fermented bean curd is shortened.

Owner:GUANGDONG CHUBANG FOOD

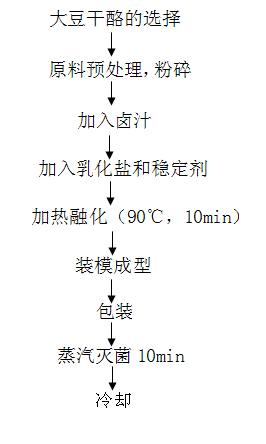

Processing method of remaking soybean cheese combinations

InactiveCN101156632AHigh nutritional valueImprove featuresCheese manufactureFood preparationSporeButterfat

The invention provides a process method for remade soybean cheese products, belongs to the food processing filed, and relates to improved remade cheese made by soybean and the producing method thereof. Firstly, lactobacillus leaven is inoculated in the bean milk, and through ferment, the clabber is made into; clabber grains are obtained through compression; mucor spore liquid is inoculated, proper metal ion is added, after cultivation, sodium chloride is added in the clabber grains, and through compression, the soybean cheese is formed; the soybean cheese is positioned with 4-8 DEG C for maturing; butterine, butterfat, stabilizing salt, or flavoring are added in the soybean cheese, through thaw, concentration, compression, and figuration, the remade soybean cheese is produced. The product has high nutrition value with low salt content, is easy to be stored, can satisfy the taste of the Chinese, and is cheap.

Owner:YANGZHOU UNIV

Method for producing green tea soycheese

The invention relates to a method for producing green tea soycheese, which is characterized in that 5-15% parts by weight of the green tea, 85-95% parts by weight of the water and sopped bean are gridded to be green tea pulp and soya-bean milk; the green tea pulp and the soya-bean milk are filtered through 100 screen mesh filter screen; the filtered pulp liquid is heated up to be 85-95 DEG C; the pulp liquid is beat to be grain with salt water; the pulp grain is pressed to be plates by sanitized cotton cloth; the shaped plates are rough green tea soycheese; the rough green tea soycheese is cut to be small square blocks; the small square blocks are put into a cleaned and sanitized cage in sequence; the surfaces of the small square blocks of the rough green tea soycheese are sterilized by means of jetting; the small square blocks are put into a temperature control room with temperature being 30 DEG C to be fermented till that the surfaces of the rough green tea soycheese have cotton-shaped white mucor; the surface of the rough green tea soycheese is coated with a layer of slat; the rough green tea soycheese is put into a container with normal temperature for 12-24 hours; the rough green tea soycheese is extracted from the container to be filled into a bottle; alcohol with alcoholic strength being 16-18% is poured into the bottle; and the bottle is sealed for 10-30 days to prepare the green tea soycheese. The method improves the additional value of the green tea, increases the tea polyphenol, the coffeic alkali and the amino acid of the green tea and the red tea, and improves human body immunity as well as anticancer effect.

Owner:刘志良

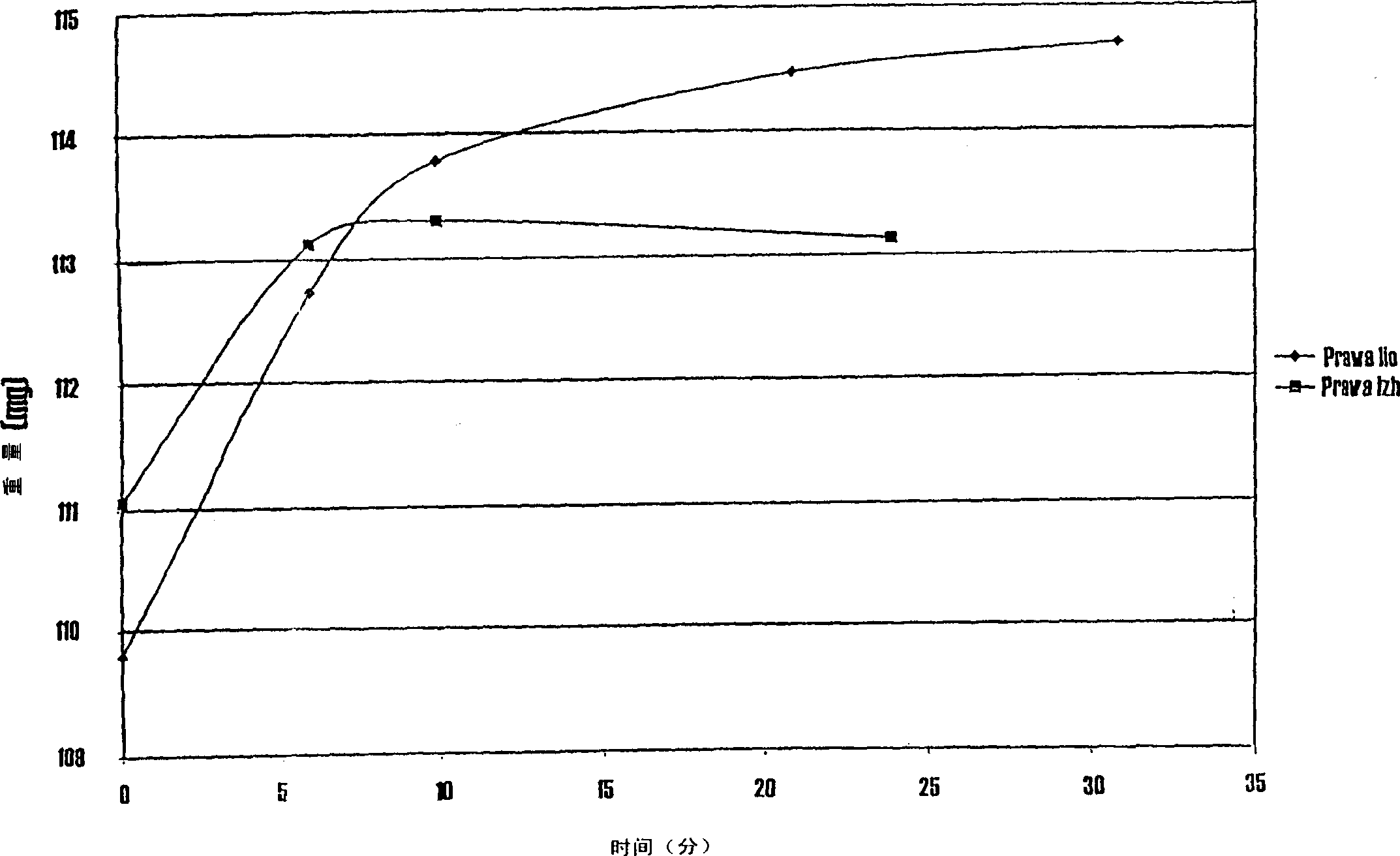

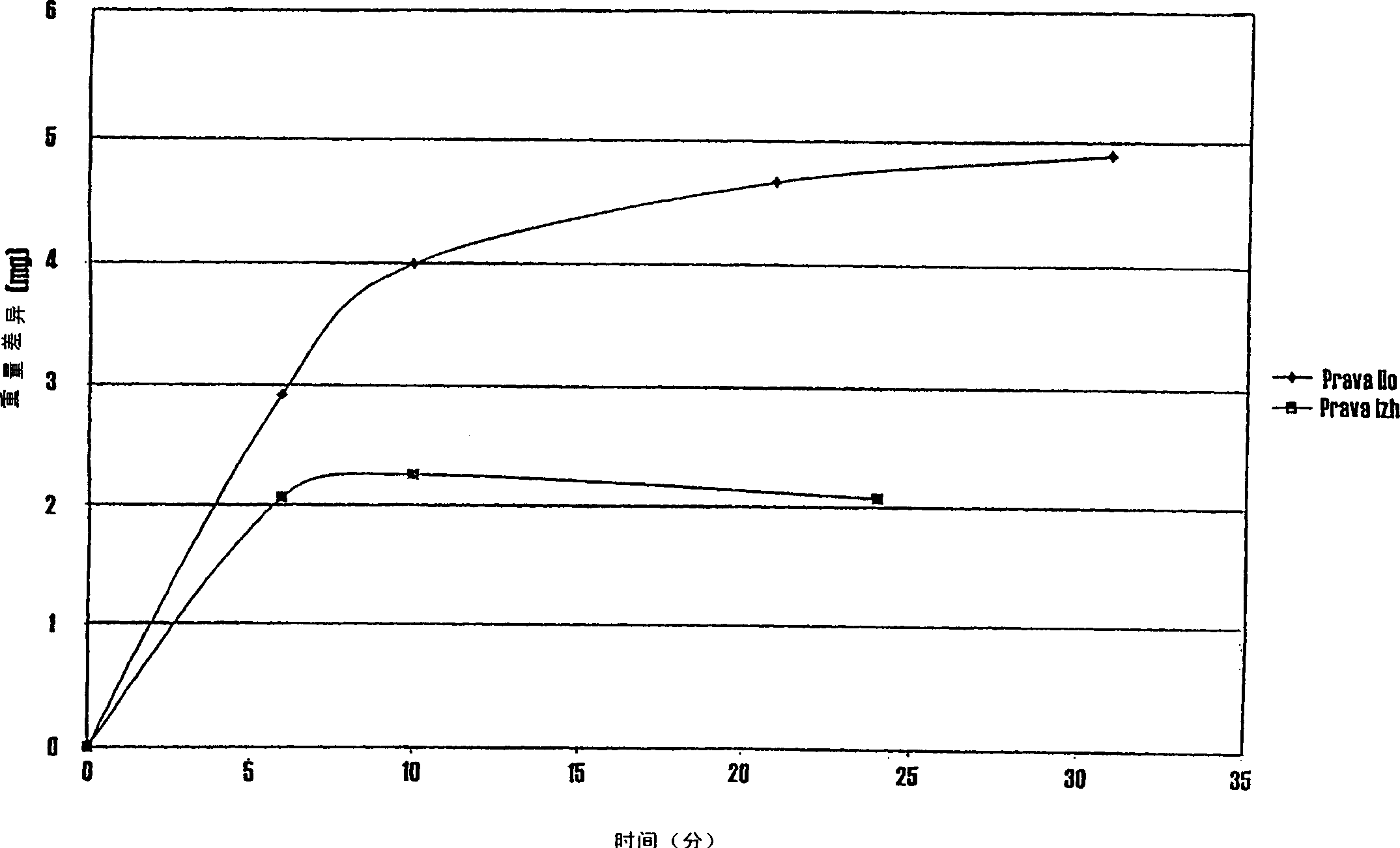

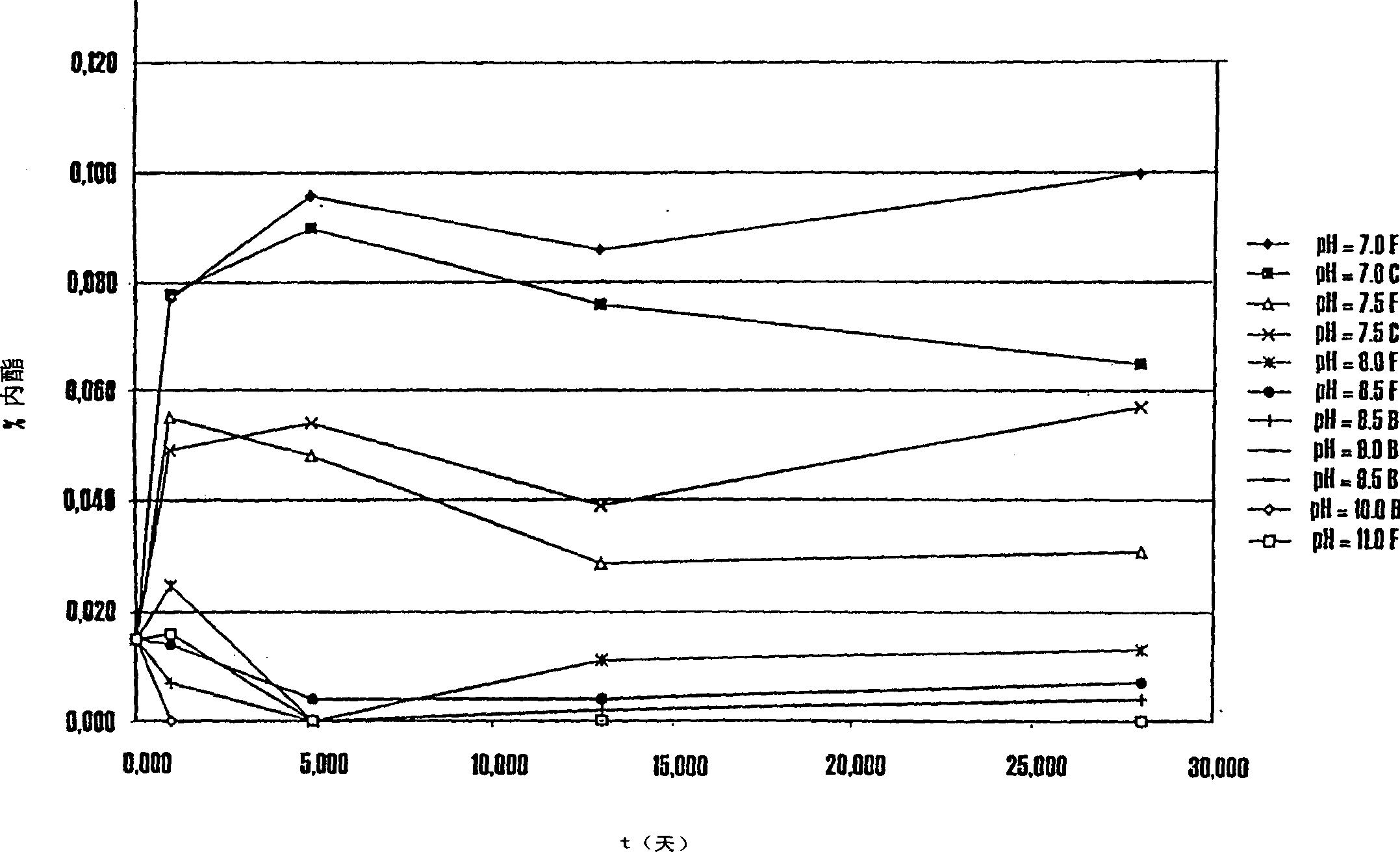

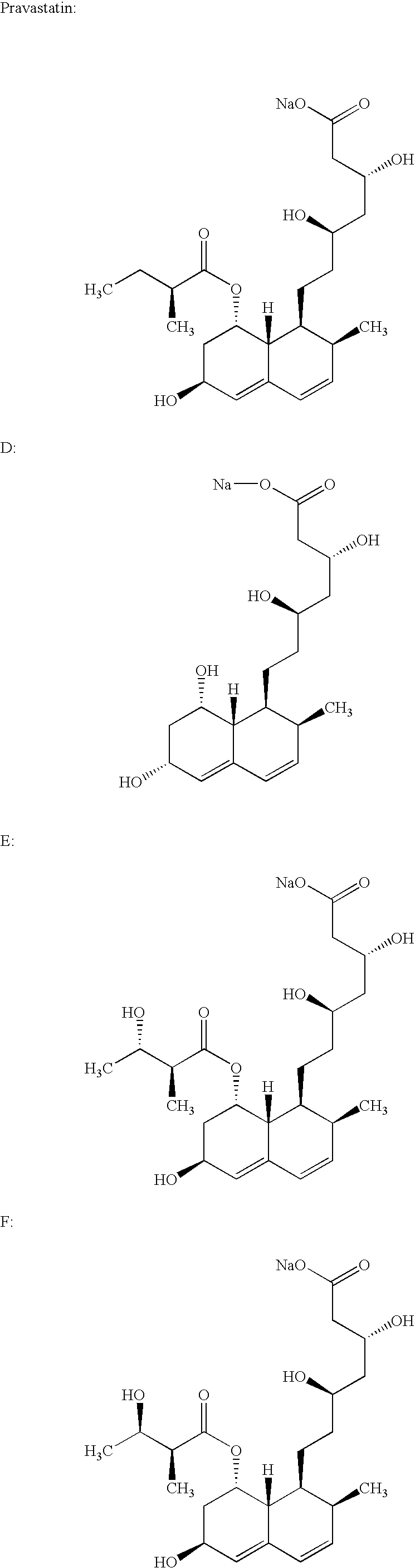

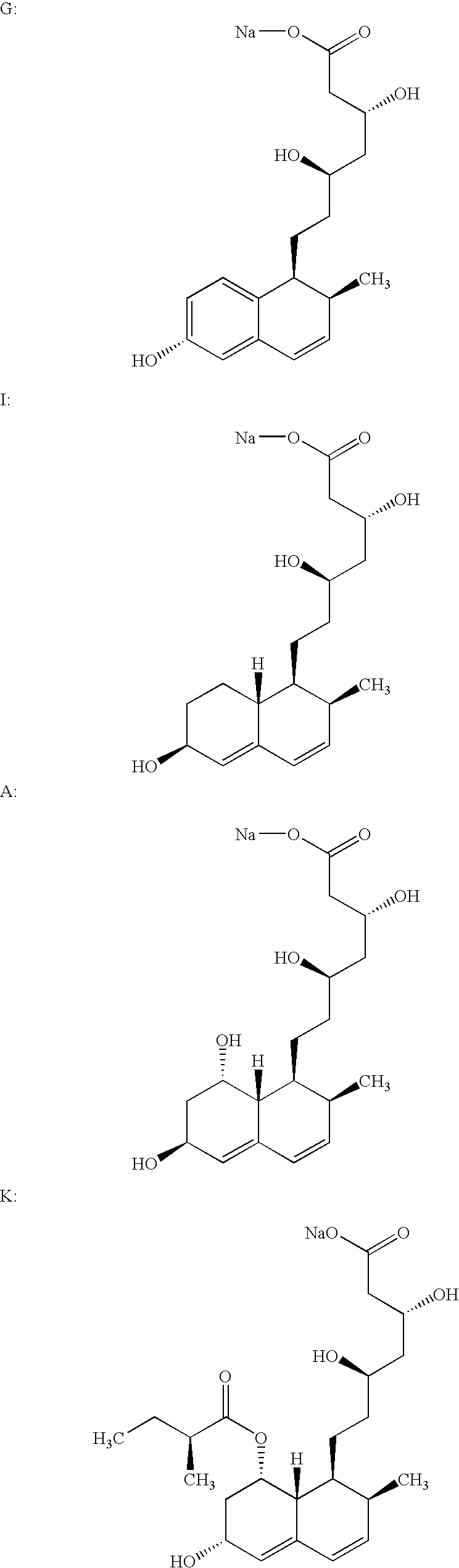

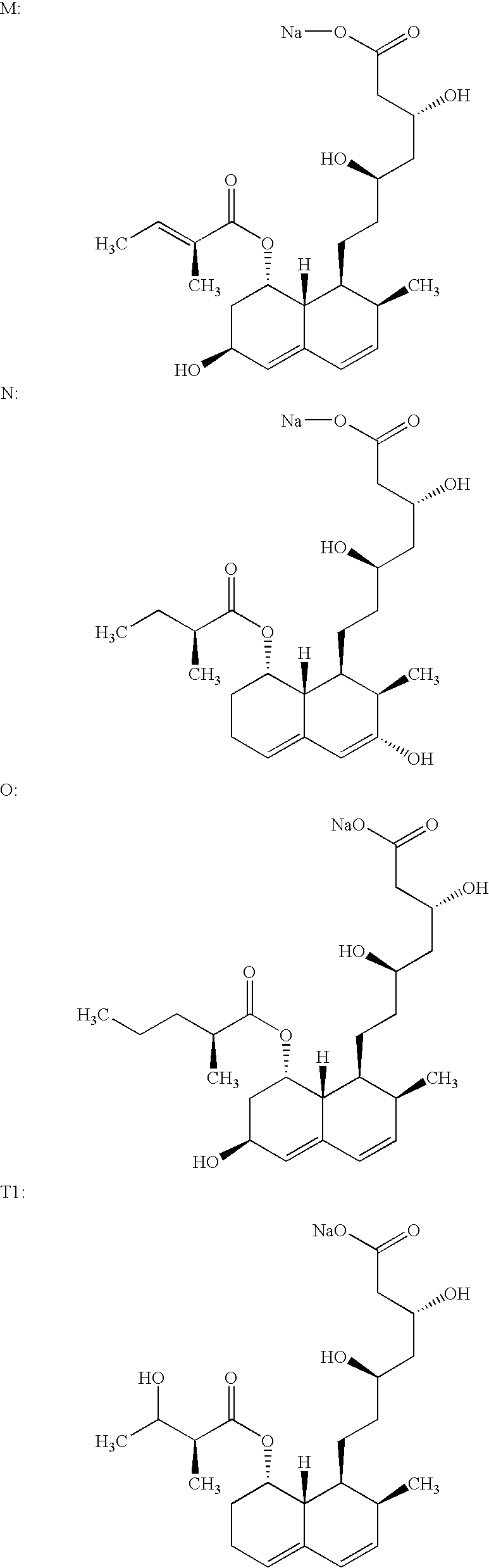

Stable pharmaceutical formulation comprising HMC-CoA reductase inhibitor

Lovastatin, pravastatin, simvastatin, mevastatin, atorvastatin, and derivatives and analogs thereof are known as HMG-CoA reductase inhibitors and are used as antihypercholesterolemic agents. The majority of them are produced by fermentation using microorganisms of different species identified as species belonging to Aspergillus, Monascus, Nocardia, Amycolatopsis, Mucor or Penicillium genus, and some are obtained by treating the fermentation products using the methods of chemical synthesis or they are the products of total chemical synthesis. The aforementioned active substances may be destabilised by the environmental factors, their degradation may also be accelerated by interactions with other pharmaceutical ingredients, such as fillers, binders, lubricants, glidants and disintegrating agents, therefore the pharmaceutical ingredients and the process for preparation of the pharmaceutical formulation should be meticulously chosen to avoid the aforementioned undesired interactions and reactions. The present invention relates to a stable solid pharmaceutical formulation for the treatment of hypercholesterolemia and hyperlipidemia. More precisely, the present invention relates to the new stable solid pharmaceutical formulation containing as an active ingredient a HMG-CoA reductase inhibitor, such as atorvastatin, pravastatin, fluvastatin and cerivastatin or pharmaceutically acceptable salts thereof.

Owner:LEK PHARMA & CHEM

Processing method of fermented bean curd

InactiveCN102696782ADelicate entranceQuality improvementCheese manufactureFood scienceRhizopusMucor species

The invention discloses a processing method of a fermented bean curd. The method comprises the following steps of: soaking, pulping, filtering and boiling high quality soybeans; depositing an obtained pulp by using a plant coagulant when the pulp is slightly cooled, so as to obtain a white bean curd; cutting the white bean curd into big blocks; loading the big blocks into a wood box; squeezing water from the big blocks; and then cutting the big blocks into small blocks; inoculating the small blocks by using mucor and Rhizopus chinentis; fermenting the inoculated blocks for 3-4 days at the first time, so as to obtain a fermented bean curd blank; after sterilizing the fermented bean curd blank, uniformly scattering a mixed flavoring material, a proper amount of pure grain white spirit and salt on the fermented bean curd blank; loading a mixture into a bottle; sending the bottle into a heat insulating chamber at 15-25 DEG C to carry out second fermentation on the mixture for 6-8 days. The plant coagulant comprises any one wild vegetable squeezed and sterilized juice with high calcium content and a mixed solution of a plurality of wild vegetable squeezed and sterilized juices with high calcium contents, including Agrimonia pilosa, capsicum leaves, rapes and shepherd's purses. The processing method of the fermented bean curd, disclosed by the invention, has the advantages of simplicity, standardability, short production period, capability of achieving a large-scale perennial production, delicate mouth feel of the fermented bean curd, delicious taste, slightly peppery taste, stable quality, greenness, health and capability of obtaining quality guarantee period of 24 months.

Owner:镇巴县长兴实业有限责任公司

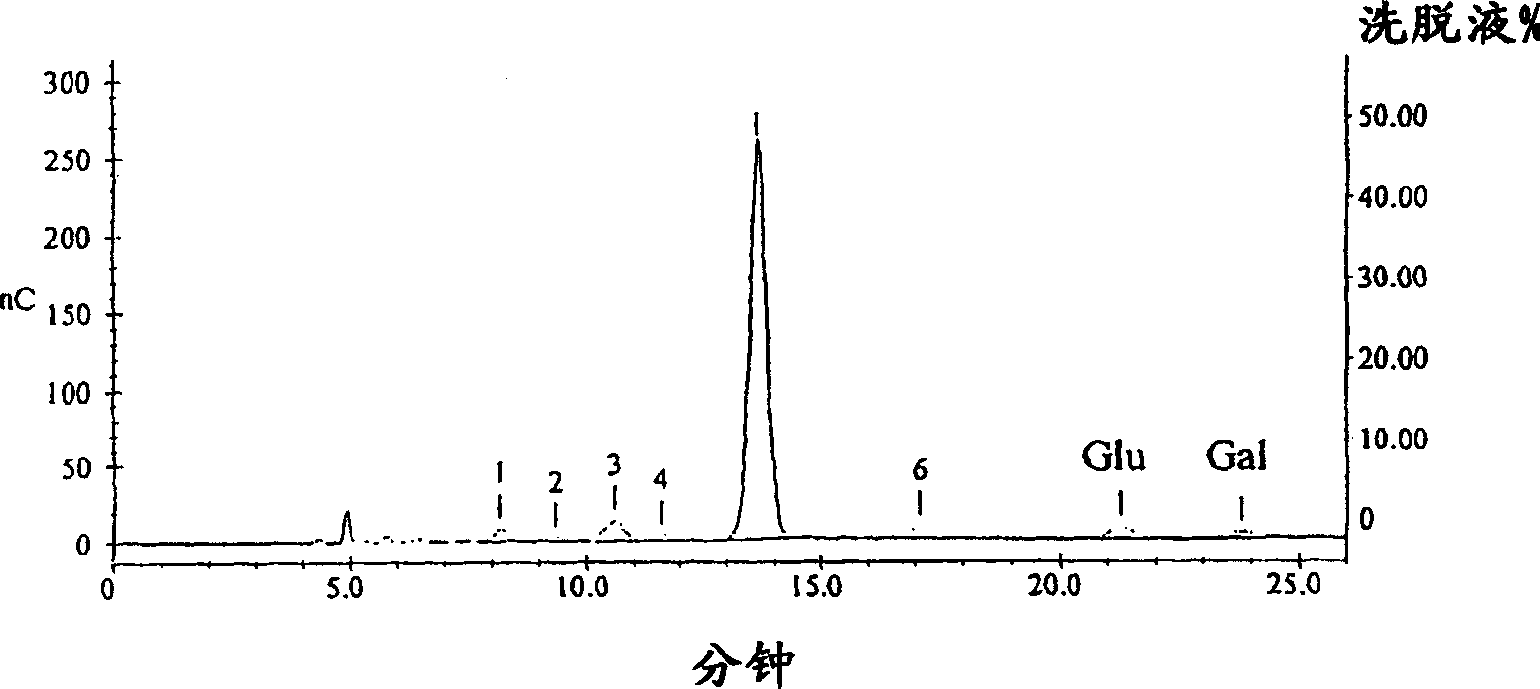

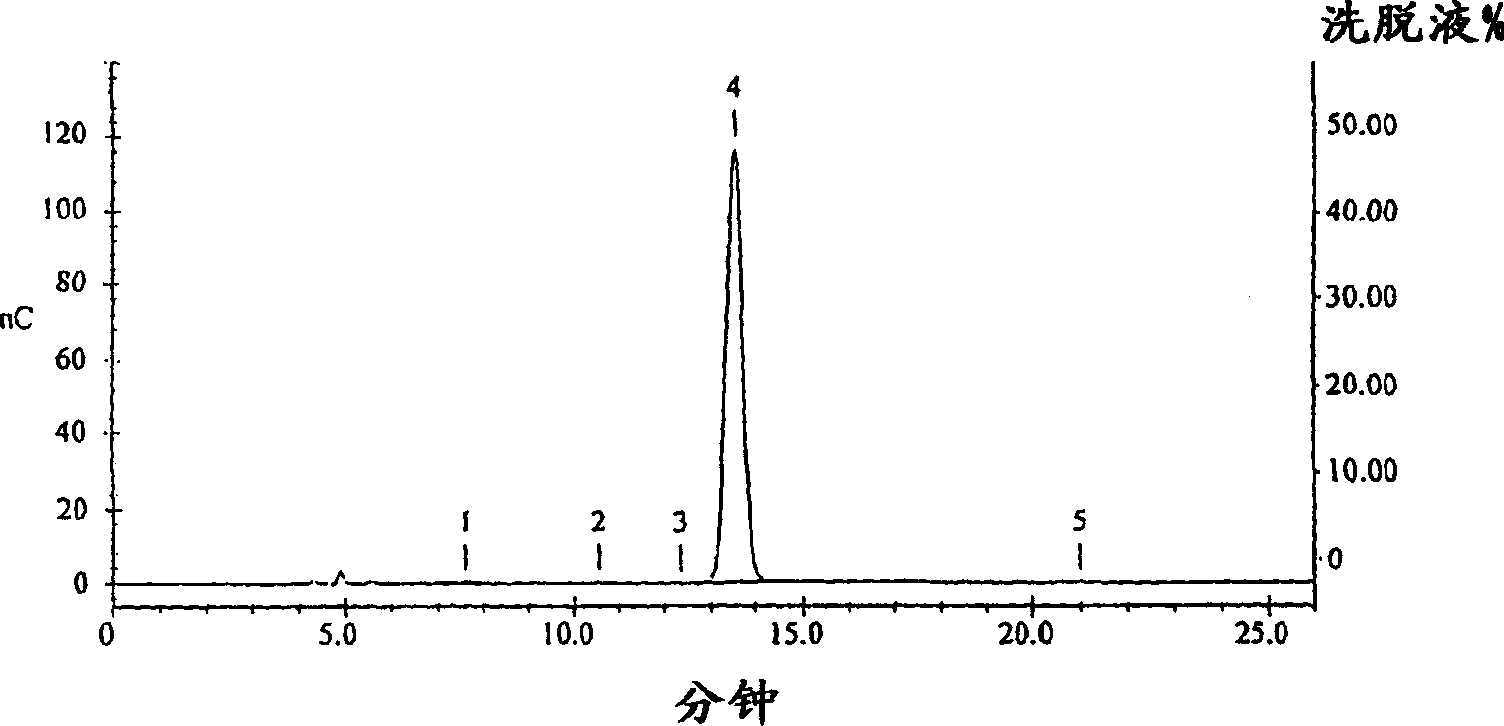

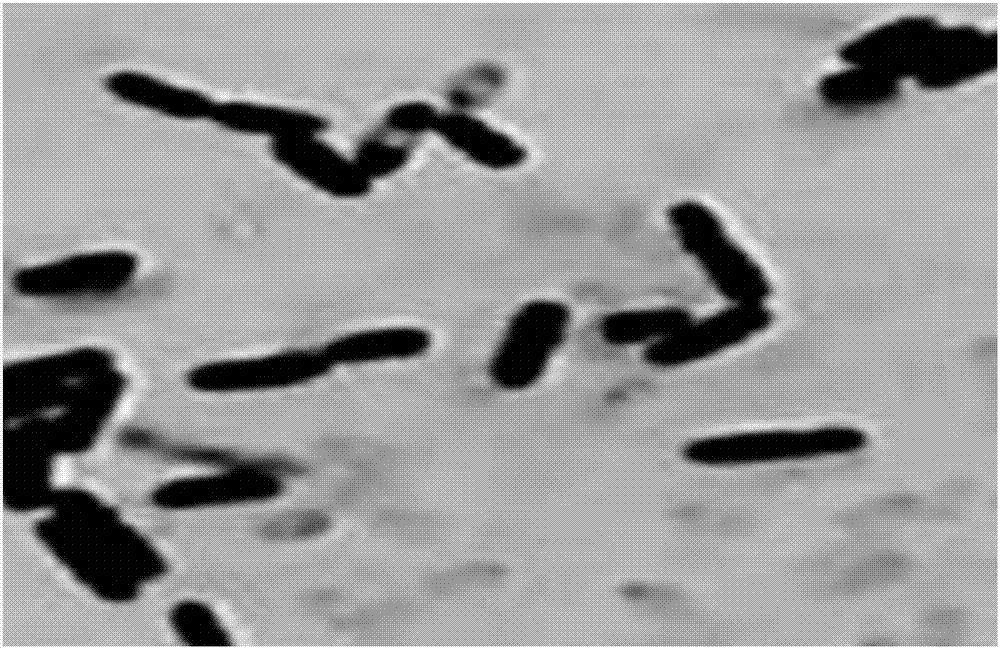

Mucor racemosus strain and process for producing fermented bean curd thereby

A Mucor racemosus var chinensis M.H.C-7 (CCTCCM 201026) is disclosed. It can be used for preparing the fermented bean curd through inoculating it to raw bean curd, culturing at 25 deg.C and 93-97% of relative humidify for 40 hr, adding table salt, bottling, and fermenting at 30 deg.C or ordinary temp for 2-3 months. The resultant fermented bean curd has features of fine mass, delicious taste, and beautiful appearance.

Owner:CHENGDU GUONIANG FOOD

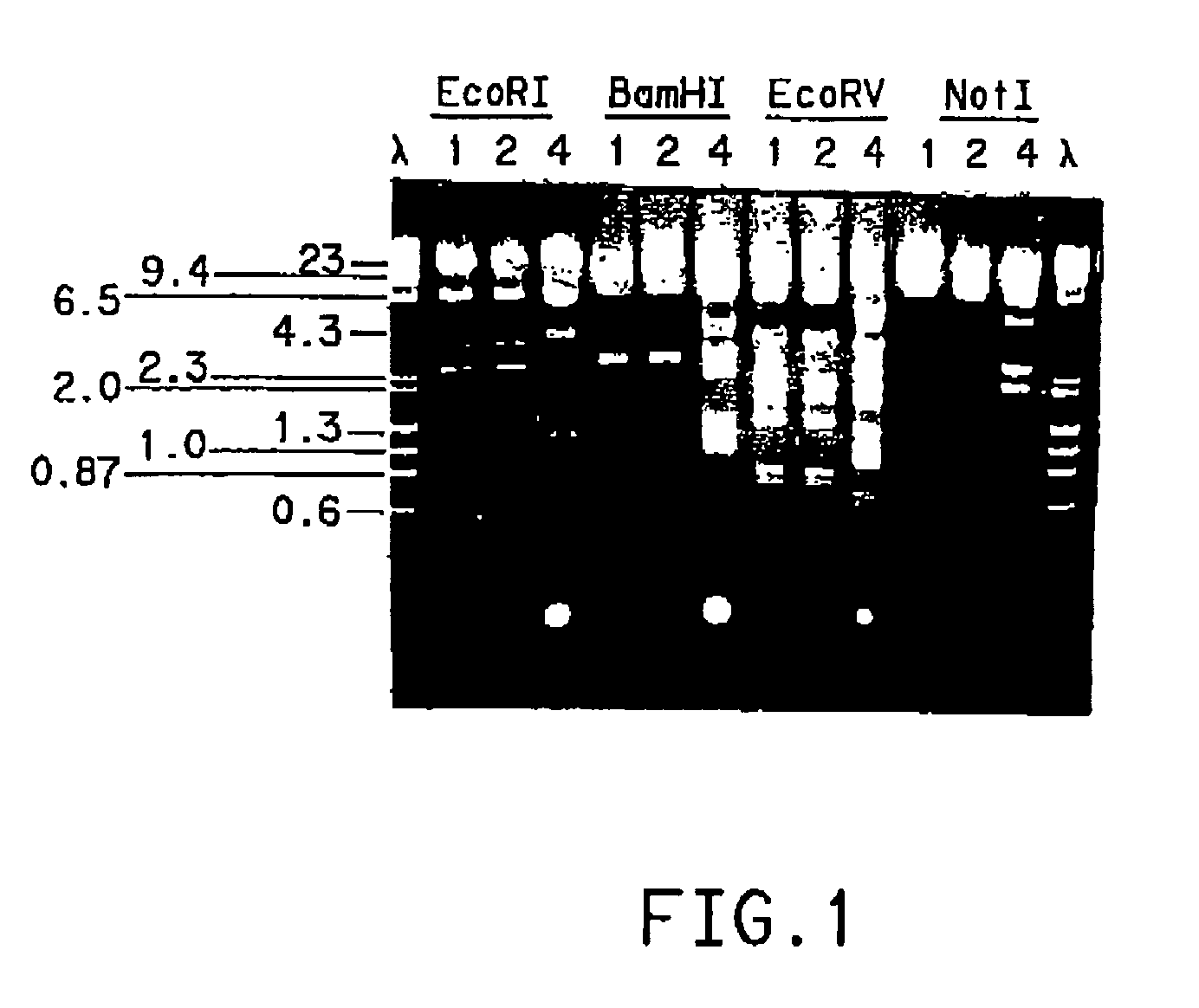

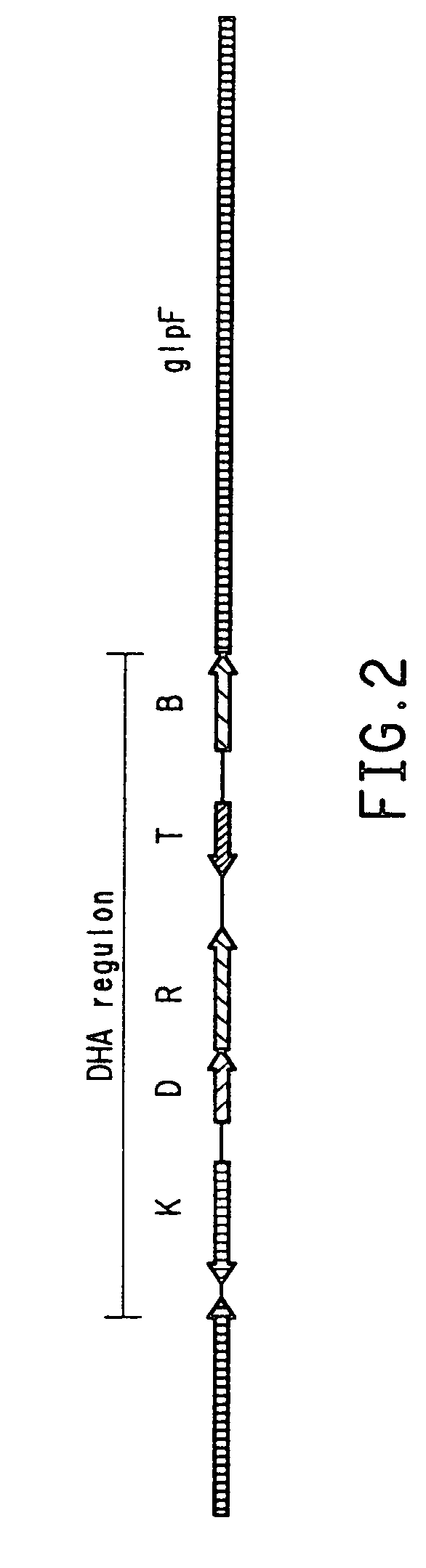

Processes for the bioconversion of a fermentable carbon source to 1,3-propanediol by a single microorganism

A process is provided for the bioconversion of a carbon substrate to 1,3-propanediol by a single organism utilizing microorganisms, such as, Citrobacter, Enterobacter, Clostridium, Klebsiella, Aerobacter, Lactobacillus, Aspergillus, Saccharomyces, Zygosaccharomyces, Pichia, Kluyveromyces, Candida, Hansenula, Debaryomyces, Mucor, Torulopsis, Methylobacter, Escherichia, Salmonella, Bacillus, Streptomyces and Pseudomonas, containing the genes encoding for an active glycerol or diol dehydratase enzyme by contacting these organisms with a carbon substrate under the appropriate fermentation conditions. Specifically, Citrobacter and, Klebsiella provide the source of exogenous genes for such active dehydratase enzyme.

Owner:EI DU PONT DE NEMOURS & CO +1

Bitterless soybean polypeptide and its production method

InactiveCN1544646AIncrease the degree of hydrolysisEliminate bitternessFermentationSolubilityChemical products

The invention is a bitterless soybean polypeptide producing method, adding water or directly mucor proteinase extract to soybean protein or low-temperature desolventized soybean dregs in the proportion of 5%-10% (W / V), additionally, adding in neutral or basic proteinase of edible mushroom of soybean protein, like Alcalase or Protamex 2.4L, dehydrating, then raising temperature to 80deg.C-100deg.C and preserving heat for 15min-60min, filtering and obtaining soybean polypeptide filtrate; it uses the self-prepared mucor proteinase to act on the soybean protein and can obtain the soybean polypeptide with good flavor, extremely good water solubility and molecular weight distribution ranger at 400D about. The obtained product can be widely used on general food, function food and refined chemical products, especially applied to dietetic food for the patients suffering from gastric ulcer, drinks for athletes, etc.

Owner:SOUTH CHINA UNIV OF TECH

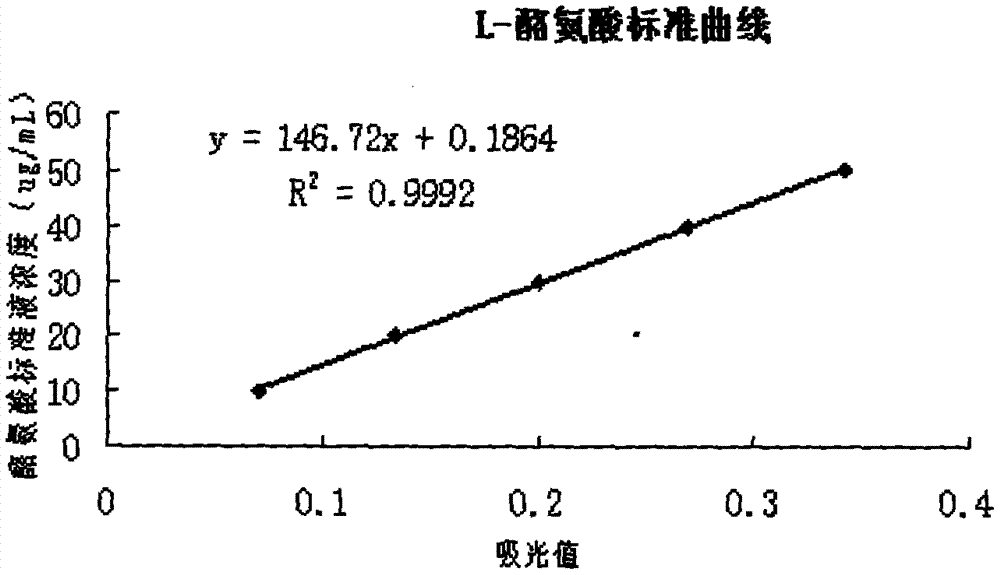

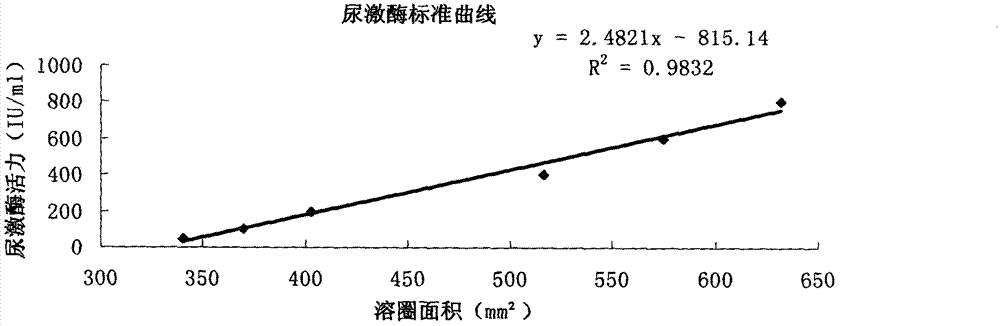

Preparation method for fibrinolytic fermented soya beans

InactiveCN103829166APromote growthProtease content has little effectFood preparationProduction linePlasmin

The invention provides a preparation method for fibrinolytic fermented soya beans. The preparation method comprises the steps of activating strains, preparing a mucor seed solution; preparing a bacillus natto seed solution; processing soya beans; inoculating; culturing and after-ripening. Under the conditions that mucor and bacillus natto produced protease and bacillus natto produced plasmin are used as evaluation indexes, the mucor grows well after bacillus natto is inoculated; influence to protease content is not large; nattokinase activity in the obtained fermented soya beans can reach 823.51 U / g; and protease activity reaches 1983.91 U / g. By seeking optimum conditions for fermentation of the fermented soya beans, the time required by a conventional fermentation process for the fermented soya beans is greatly shortened without influencing the flavor of the fermented soya beans. At the same time, during an operation process, condition control is convenient, thereby facilitating production operations. The preparation method can finish co-fermentation of the bacillus natto and the mucor to the soya beans only by using an original production line of the fermented bean curd blanks, without increasing any equipment, thereby greatly saving production cost.

Owner:CHONGQING NORMAL UNIVERSITY

Microorganism organic fertilizer and preparation thereof

InactiveCN101417896AIncrease productionImprove decomposition abilityClimate change adaptationExcrement fertilisersZymogenMucor species

The invention relates to a fertilizer and the preparation method thereof, in particular to a microbial organic fertilizer and the preparation method thereof, belonging to the organic fertilizer production field. The invention consists of pretreated chicken manure, pretreated pig manure, straw power, mineral fertilizer, complex microorganism zymogen inoculum, mucor, humic acid and attapulgite soil. The invention has the advantages that proper amount of mucor is added to the ordinary microorganism zymogen and the mucor is obtained from the local soil rich of humus and storing crop straws which can provide a plurality of carbon source for microorganism zymogen, thereby raising fermentation efficiency. Adding proper amount of mineral fertilizer into the materials of the microorganism organic fertilizer can increase trace elements and other nutrient elements necessary for crop growth and development, thereby raising the productivity of crops and improving the quality of farm products.

Owner:王明芹 +1

Animal feed additives

InactiveUS7217433B2Improve feed utilizationReduce chyme viscosityMicroorganismsMicroorganism based processesDNA constructMucor species

The present invention relates to animal feed additives, which additives comprise a monocomponent xylanase derived from a strain of Byssochlamus, Chaetomium, Humicola, Malbranchea, Mucor, Myceliophthora, Paecilomyces, Talaromyces, Thermoascus, or Thielavia. In other aspects, the invention relates to monocomponent xylanase preparations, DNA constructs, recombinant expression vectors, host cells, and methods of producing monocomponent xylanase preparations.

Owner:NOVOZYMES AS

High-inorganic nitrogen-sourced biological compound fertilizer and preparation method thereof

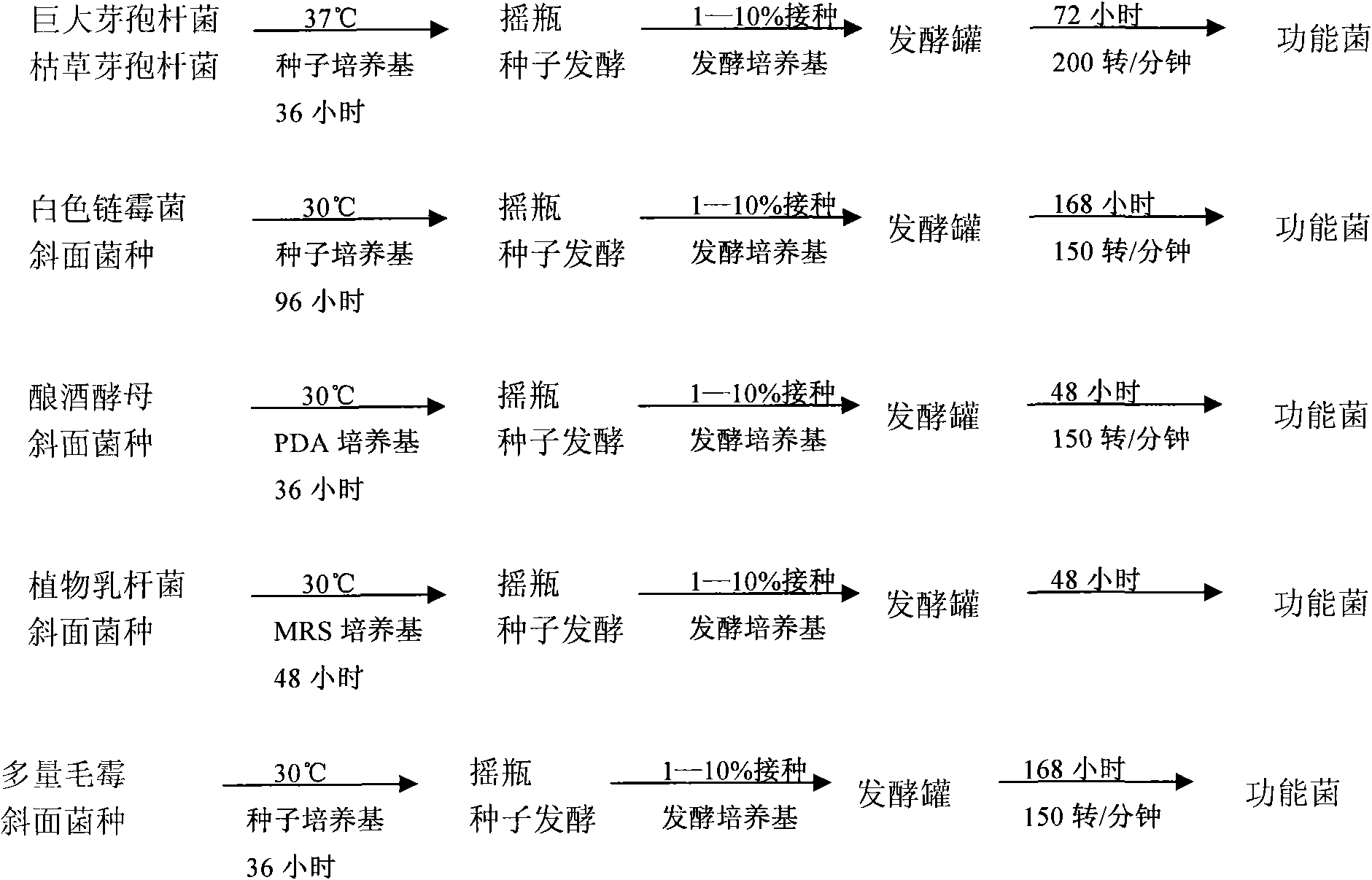

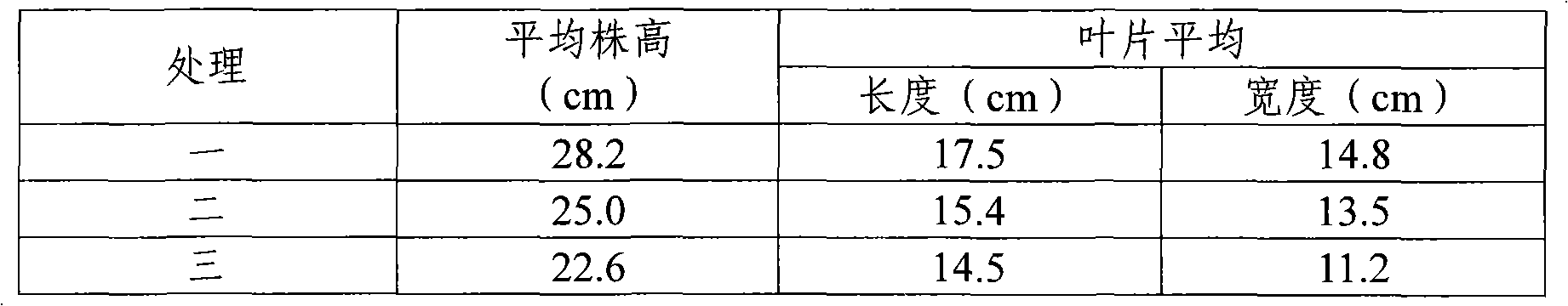

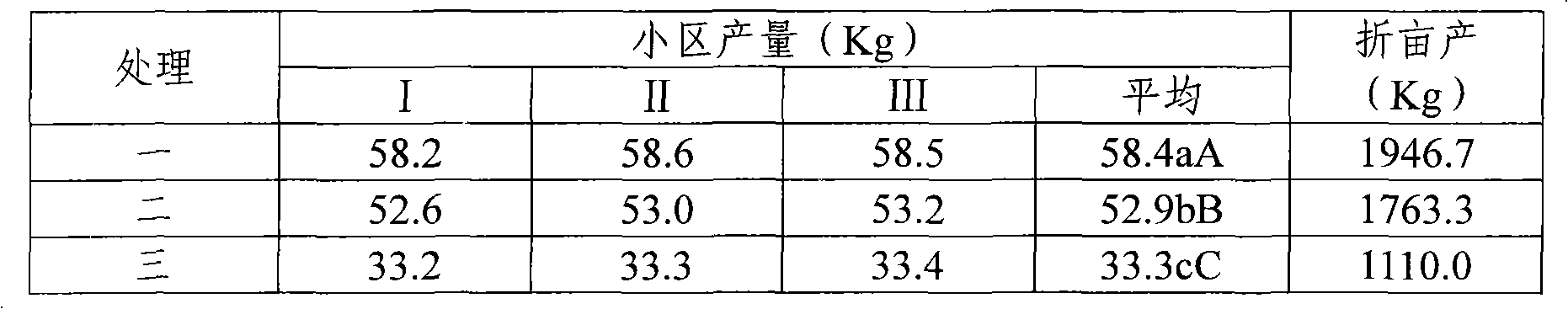

ActiveCN101603019AHigh Inorganic Nitrogen ContentIncreased fertilizer efficiency in the fieldFungiBacteriaBacillus megateriumMucor species

The invention provides a high-inorganic nitrogen-sourced biological compound fertilizer and a preparation method thereof. The fertilizer contains the following functional bacteria: bacillus megaterium, bacillus subtilis, saccharomyces cerevisiae, lactobacillus plantarum, Mucor abundans and streptomyces albus. The content of inorganic nitrogen of the compound fertilizer can be as high as 35 percent, while the number of live bacteria can still be up to 2*10 cfu / kg. Experiments show that the field fertilizer efficiency of the compound fertilizer is significantly improved.

Owner:北京沃土天地生物科技股份有限公司

High-efficiency engineering bacteria agent and method for producing active biological organic fertilizer

ActiveCN105176881AIncrease the number ofPromote absorptionFungiBacteriaPichia pastorisBacillus licheniformis

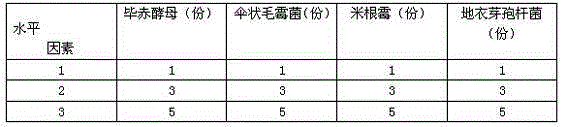

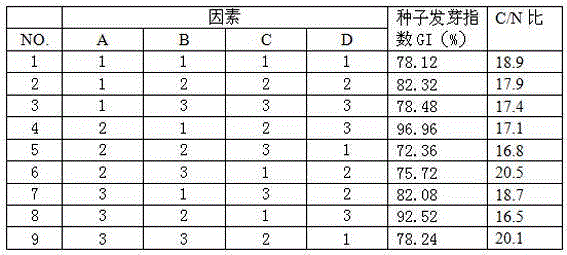

The invention relates to a high-efficiency engineering bacteria agent and a method for producing an active biological organic fertilizer and belongs to the technical field of biology. The bacteria agent consists of the following strains in parts by weight: 50 to 60 parts of enzyme producing bacteria, 6 to 10 parts of bacillus thuringiensis and 10 to 15 parts of bacillus subtilis, the enzyme producing bacteria consist of the following strains in parts by weight: 1 to 3 parts of umbrella mucor, 1 to 3 parts of rhizopus oryzae, 3 to 5 parts of bacillus licheniformis and 3 to 5 parts of Pichia pastoris. The high-efficiency engineering bacteria agent provided by the invention can realize high-efficiency conversion of harmlessly treated kitchen waste to obtain the high-efficiency active biological organic fertilizer. According to determination, the organic fertilizer satisfies relevant indicators of organic fertilizers in agricultural standard NT 525-2012 on organic fertilizers, can effectively increase the number of soil organic matters and effective microbial communities, can activate soil, can promote the absorption of plant root systems to nutrients, can improve the yield and quality of crops, and is a high-grade fertilizer for producing pollution-free and organic agricultural products.

Owner:杭州标航生物科技有限公司

Process for obtaining HMG-CoA reductase inhibitors of high purity

Lovastatin, pravastatin, simvastatin, mevastatin, atorvastatin, and derivatives and analogs thereof are known as HMG-CoA reductase inhibitors and are used as antihypercholesterolemic agents. The majority of them are produced by fermentation using microorganisms of different species identified as species belonging to Aspergillus, Monascus, Nocardia, Amycolatopsis, Mucor or Penicillium genus, Streptomyces, Actinomadura, Micromonospora, some are obtained by treating the fermentation products using the method of chemical synthesis or they are the products of total chemical synthesis. The purity of the active ingredient is an important factor for manufacturing the safe and effective pharmaceutical, especially if the pharmaceutical product must be taken on a longer term basis in the treatment or prevention of high plasma cholesterol. The accumulation of the impurities from the pharmaceuticals of lower purity may cause many side effects during the medical treatment. The present invention relates to a new industrial process for the isolation of HMG-CoA reductase inhibitors using so-called displacement chromatography. Use of the invention enables one to obtain HMG-CoA reductase inhibitors of high purity, with high yields, lower production costs and suitable ecological balance.

Owner:LEK PHARMA D D

Method for preparing fermentation type braised ready-to-eat dried bean curd

ActiveCN102187912ARetain nutrientsImprove digestibilityCheese manufactureFood scienceReady to eatMucor species

The invention relates to a novel method for preparing braised ready-to-eat dried bean curd by soybeans. The method comprises the following steps of: emulsifying lactic acid bacterial soybeans to obtain curd particles, inoculating Mucor AS3.52 to the curd particles for fermentation, ageing the curd particles at the temperature of between 4 and 8 DEG C for 5 and 18 days respectively, mixing the soybean cheese obtained by ageing the curd particles for 5 days and the soybean cheese obtained by ageing the curd particles for 18 days in a ratio of 1:2-1:3(w / w), adding bittern and buffer salt colloid, fully mixing, melting, performing pressing formation, and packaging to obtain the braised ready-to-eat dried bean curd. The ready-to-eat dried bean curd is similar to traditional spiced dried bean curd or bittern dried bean curd in hardness and taste, is rich in nutrition and is agreeable to Chinese people.

Owner:YANGZHOU UNIV

A kind of method of making fermented bean curd with bean dregs as raw material

InactiveCN102258176AIncrease added valueShorten the production cycleFood preparationBiotechnologyMucor species

The invention discloses a method for producing preserved beancurd with bean dregs as raw materials. The method comprises the following steps: (1) squeezing the bean dregs, cutting the bean dregs into chunks, sterilizing the chunks under high pressure and cooling the chunks to 27-32 DEG C to prepare bean dreg billets; (2) inoculating mucor undergoing amplification culture to the six surfaces of the bean dreg billets by a spraying inoculation method and carrying out fermentation and roughing; (3) carrying out salting; and (4) inoculating aspergillus oryzae and saccharomyces cerevisiae, thus preparing the preserved beancurd. The method has the following beneficial effects: the bean dregs, wastes from bean product processing, are taken as the raw materials, thus turning waste into wealth, solving the problem of pollution caused by bean product production and improving the added value of bean product processing; the industrial chain of bean product processing is lengthened; the used raw materials are cheap and easy to obtain, thus lowering the production cost of the preserved beancurd; the product has good taste and unique flavor; the sensory indexes of the product are close to the sensory indexes of sauce preserved beancurd; and the preserved beancurd is brown, has a little gloss, neat and uniform chunks and fine texture, is free from mould core and impurities, is tasty, has brackish palatability and is free from extraneous odor.

Owner:HENAN AGRICULTURAL UNIVERSITY

Pig feed capable of deodorizing, and preparation method thereof

The invention provides a pig feed capable of deodorizing, and a preparation method thereof, and belongs to the field of pig feed preparation. The pig feed is mainly prepared from, by weight, 60 to 80 parts of bean dregs, 15 to 20 parts of sugar beet pulp, 20 to 30 parts of rice bran, 10 to 20 parts of fly maggot powder, 2 to 3 parts of citric acid, 5 to 8 parts of vitamin, 25 to 35 parts of mixed mushroom bran, 0.5 to 0.8 part of nitrobacteria, 0.3 to 0.5 part of corynebacterium glutamicum, 0.2 to 0.3 part of mucor, 1 to 3 parts of an enzyme preparation, 6 to 9 parts of carbonized biomass, 20 to 30 parts of folium ginkgo powder, and 3 to 5 parts of waste tea powder. The pig feed is capable of providing pigs with sufficient and comprehensive nutrients, and can be absorbed easily; decomposition of intestinal tract waste residue is realized with microorganisms, ammonia substances in intestinal tract and excrement are absorbed by functional raw materials; the combined action of the raw materials is capable of promoting growth of pigs, reducing the stink of pig dung, and improving the environment in hog houses.

Owner:广西神龙王农牧食品集团有限公司

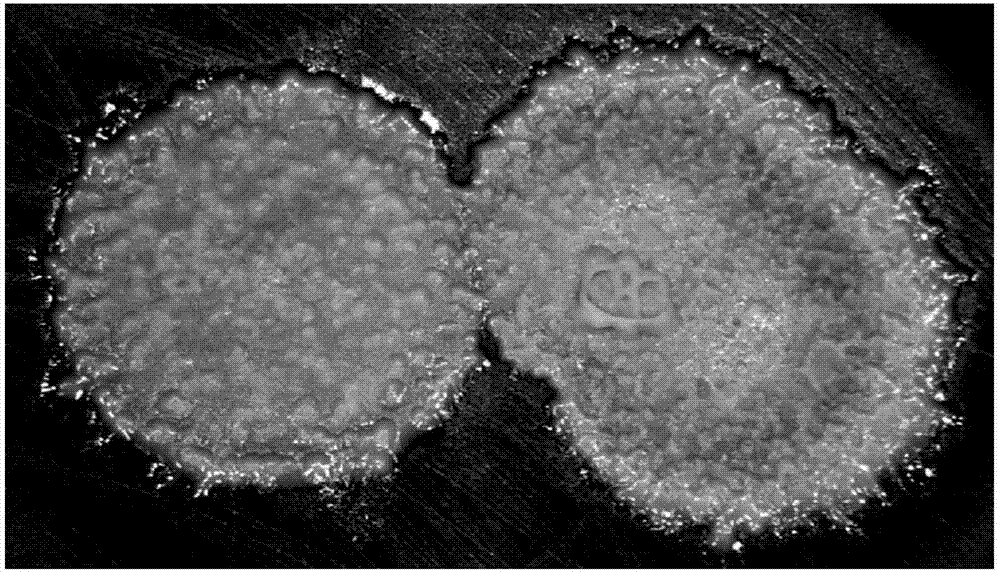

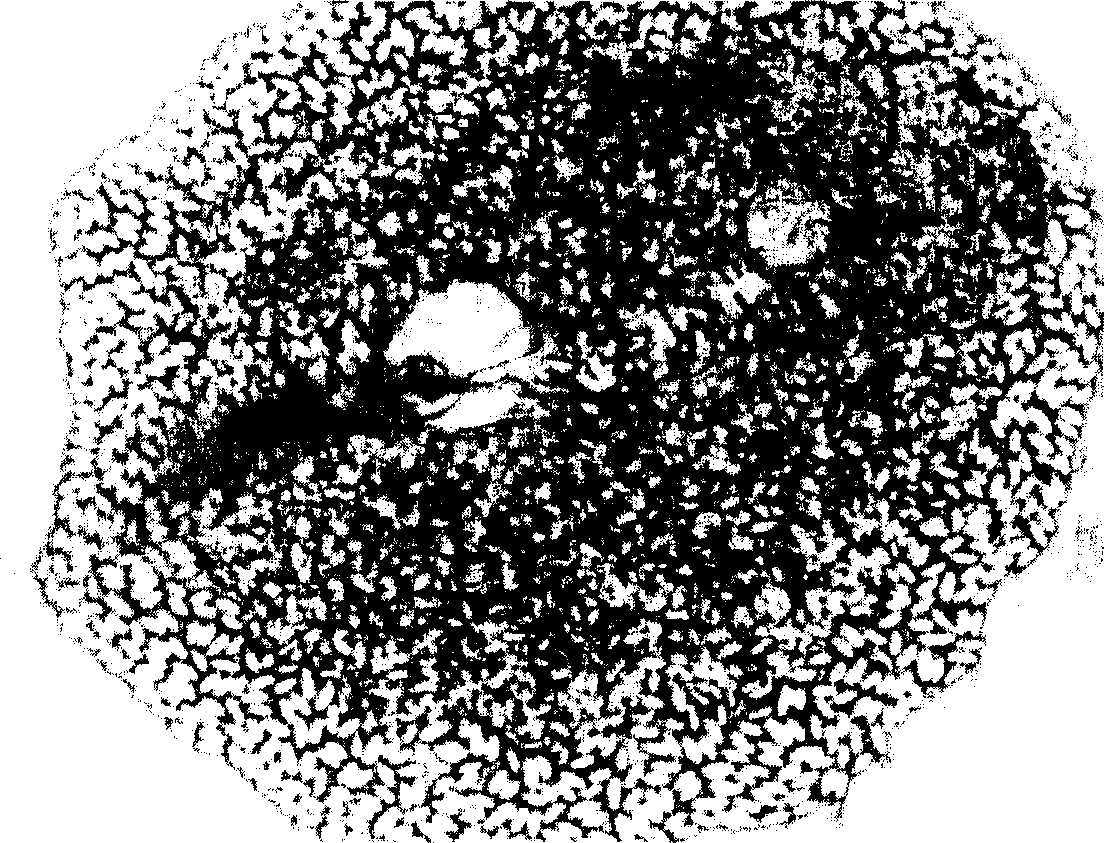

Preparation method for villi bean curd

InactiveCN102488019AEasy to operate and controlGreat tasteCheese manufactureFood scienceFlavorHigh volume manufacturing

The invention discloses a preparation method for a villi bean curd. The method comprises the following steps: soaking: adding water and sodium carbonate, of which the weight is 0.2%-0.3% of the weight of soybeans, soaking till the soybeans are swelled and two petals of the soybeans are split into flat plates; preparing slurry: grinding while adding a starch solution, grinding till no grain feel exists when the soybeans are touched by fingers, and separating soybean milk from bean dregs; cooking the slurry: quickly boiling the soybean milk to 100 DEG C and sieving cooked bean dregs; curdling: injecting a pouring starch solution, uniformly stirring and solidifying; squeezing and dividing blocks: squeezing the solidified slurry into a bean curd base; sealing for 3-4 hours during a cooling process at 40-30 DEG C and dividing into small blocks; and emulsifying: putting the naturally cooled small blocks of the bean curd base into a mucor strain suspension, standing for 4-5 days at 20-25 DEG C, and then growing uniform, fine and white villi on the surface of the bean curd. The whiteness of the villi of the prepared villi bean curd is approached to the whiteness of cotton; the grey inferior-quality products are few; the villi bean curd smells slight fragrant and is free from other peculiar flavors; during the preparation process, the quality of products is controllable and the taste is stable; and the villi bean curd is suitable for industrialized bath production.

Owner:HUANGSHAN WANAN FOOD

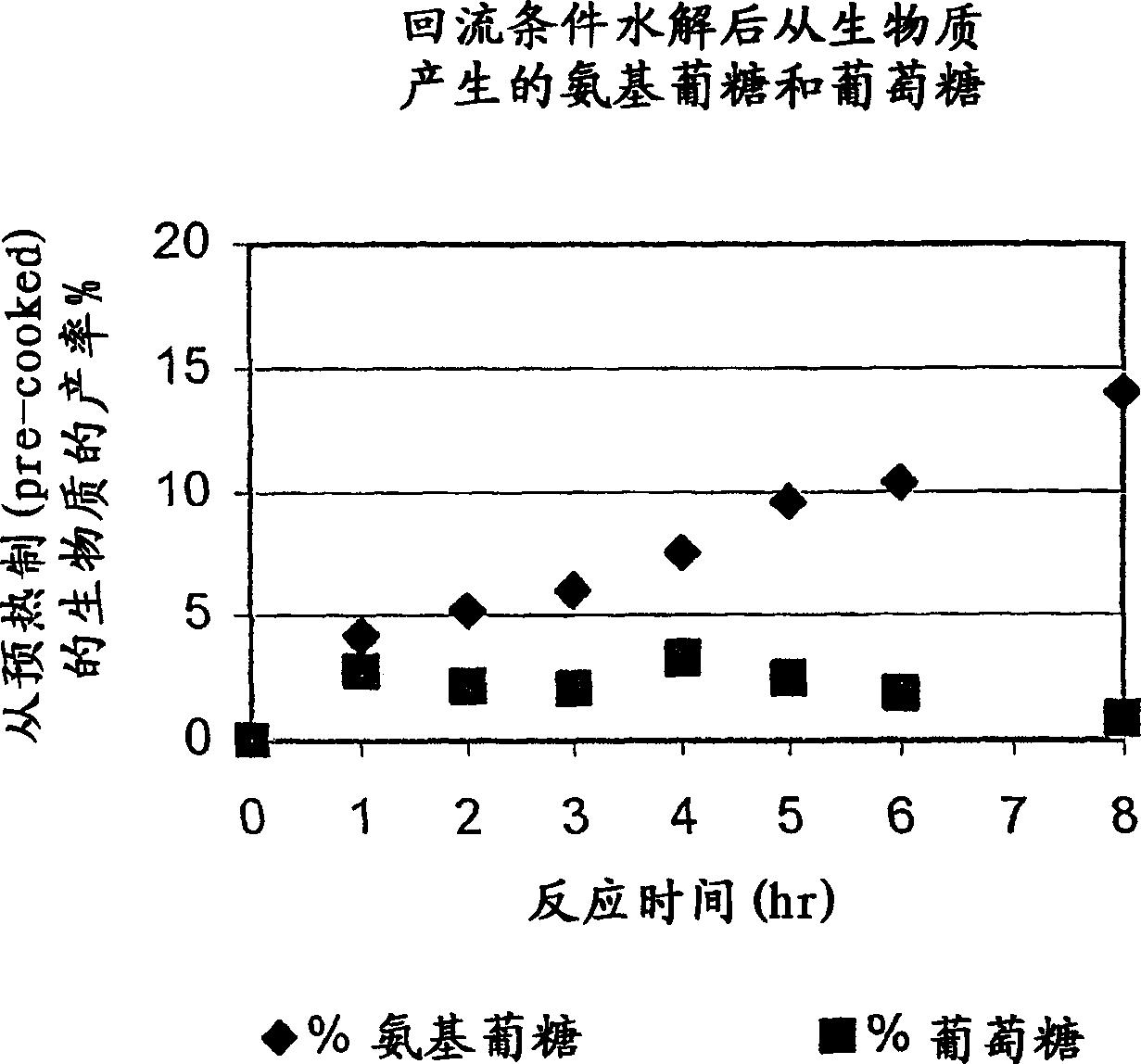

Glucosamine and method of making glucosamine from microbial biomass

Glucosamine suitable for human or animal consumption is disclosed. The glucosamine is derived from microbial biomass containing chitin. Suitable starting materials include substantially uniform microbial fungal sources, such as fungal sources derived from Aspergillus sp., Penicillium sp., Mucor sp. and combinations thereof. Methods of producing glucosamine by acid hydrolysis of fermented fungal biomass are also disclosed.

Owner:CARGILL INC

Bacillus amyloliquefaciens with broad-spectrum pathogen inhibition function and application of bacillus amyloliquefaciens

ActiveCN107338202AImprove antibacterial propertiesHas inhibitory effectBiocideBacteriaBacteroidesEscherichia coli

The invention discloses bacillus amyloliquefaciens. Bacillus amyloliquefaciens has a conservation number of CGMCC No.13492. Bacillus amyloliquefaciens is used for inhibiting bacteria, molds and phytopathogen; the bacteria are escherichia coli, staphylococcus, tetrads and bacillus subtilis; the molds are mucor, aspergillus niger and penicillium; phytopathogen is rhizoctonia cereal, lily root rot, fusarium oxysporum vasinfectum, fusarium oxyspirum F sp niveum, colletotrichum capsici, botrytis cinerea, apple ring spot and peach brown rot.

Owner:ZHEJIANG SCI-TECH UNIV

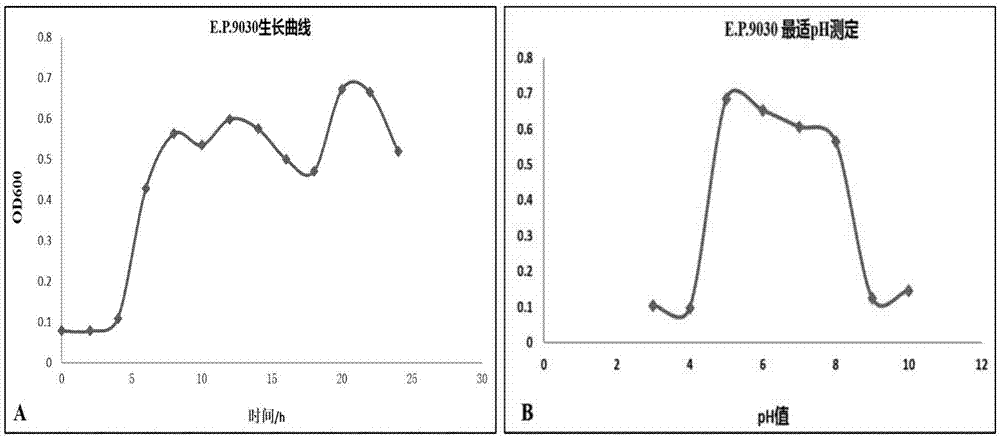

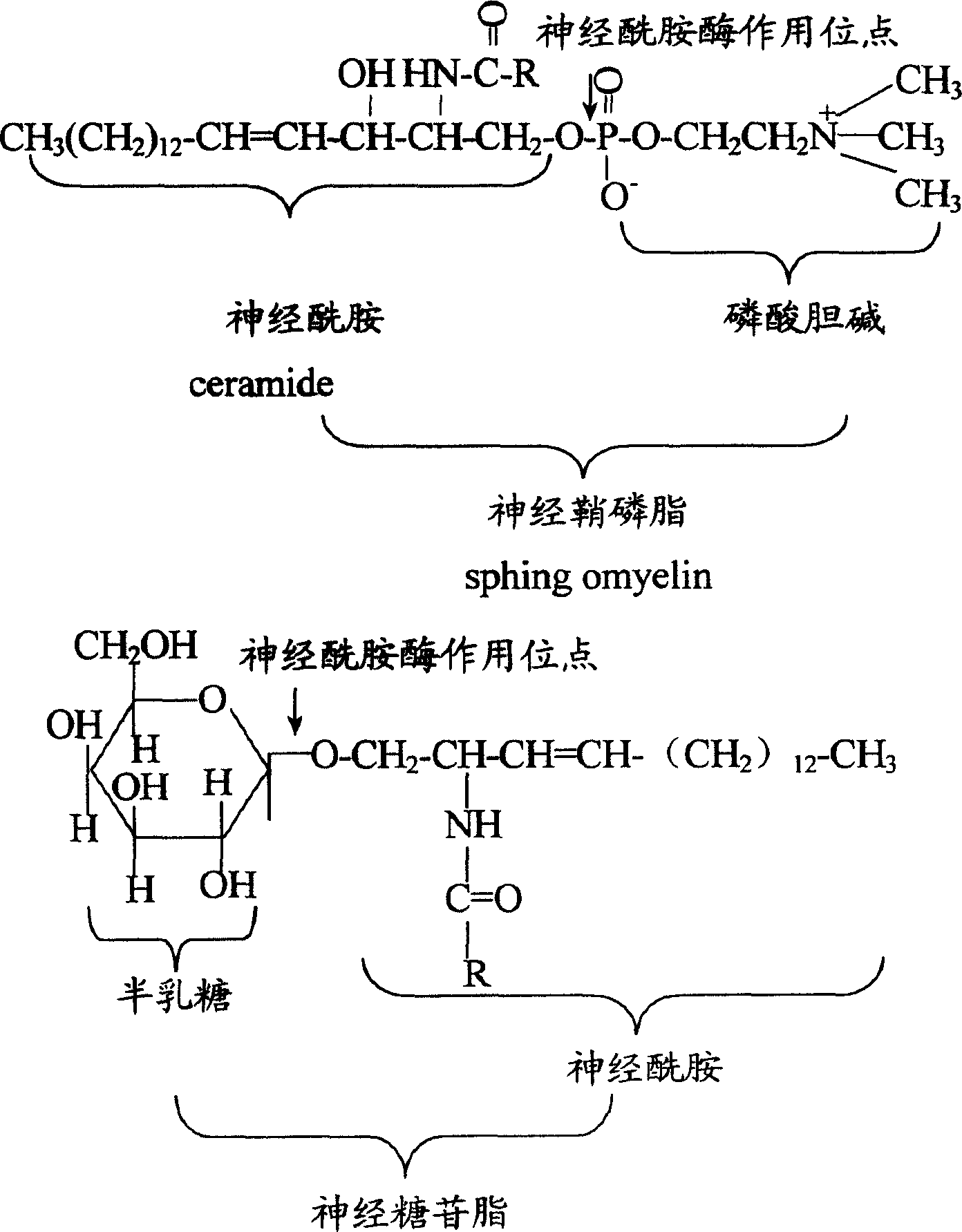

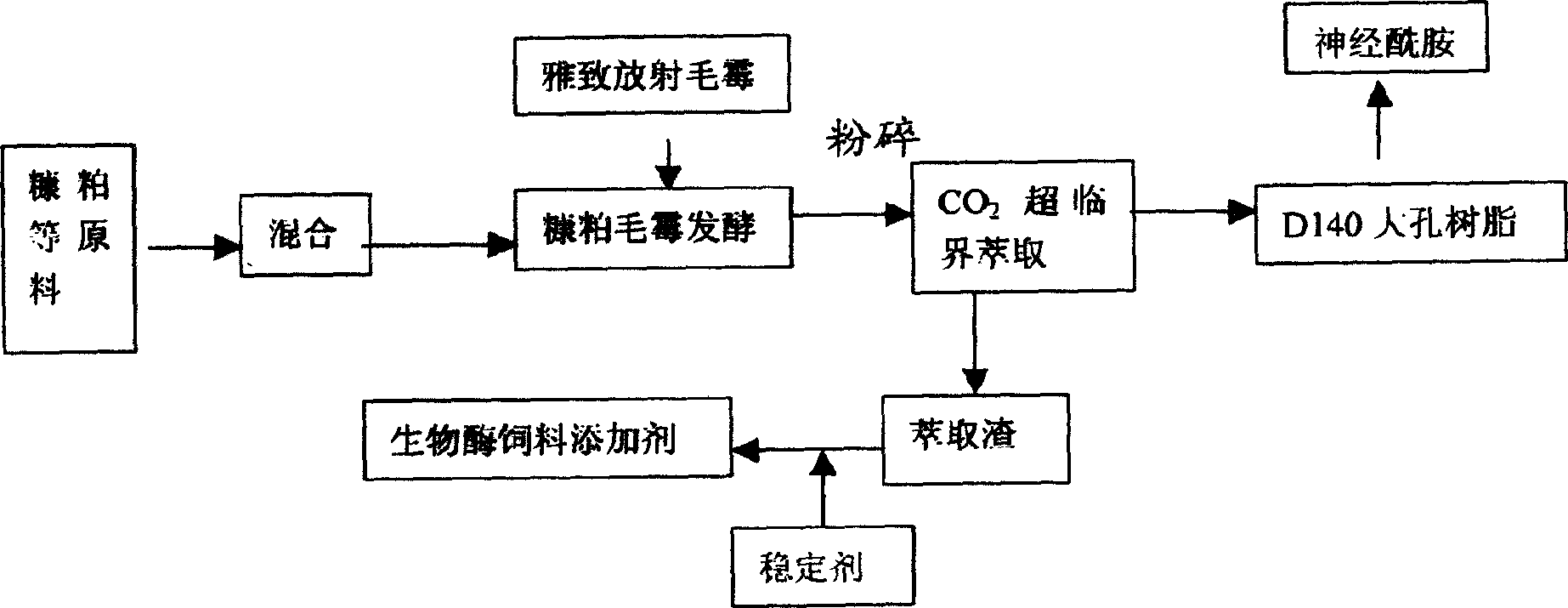

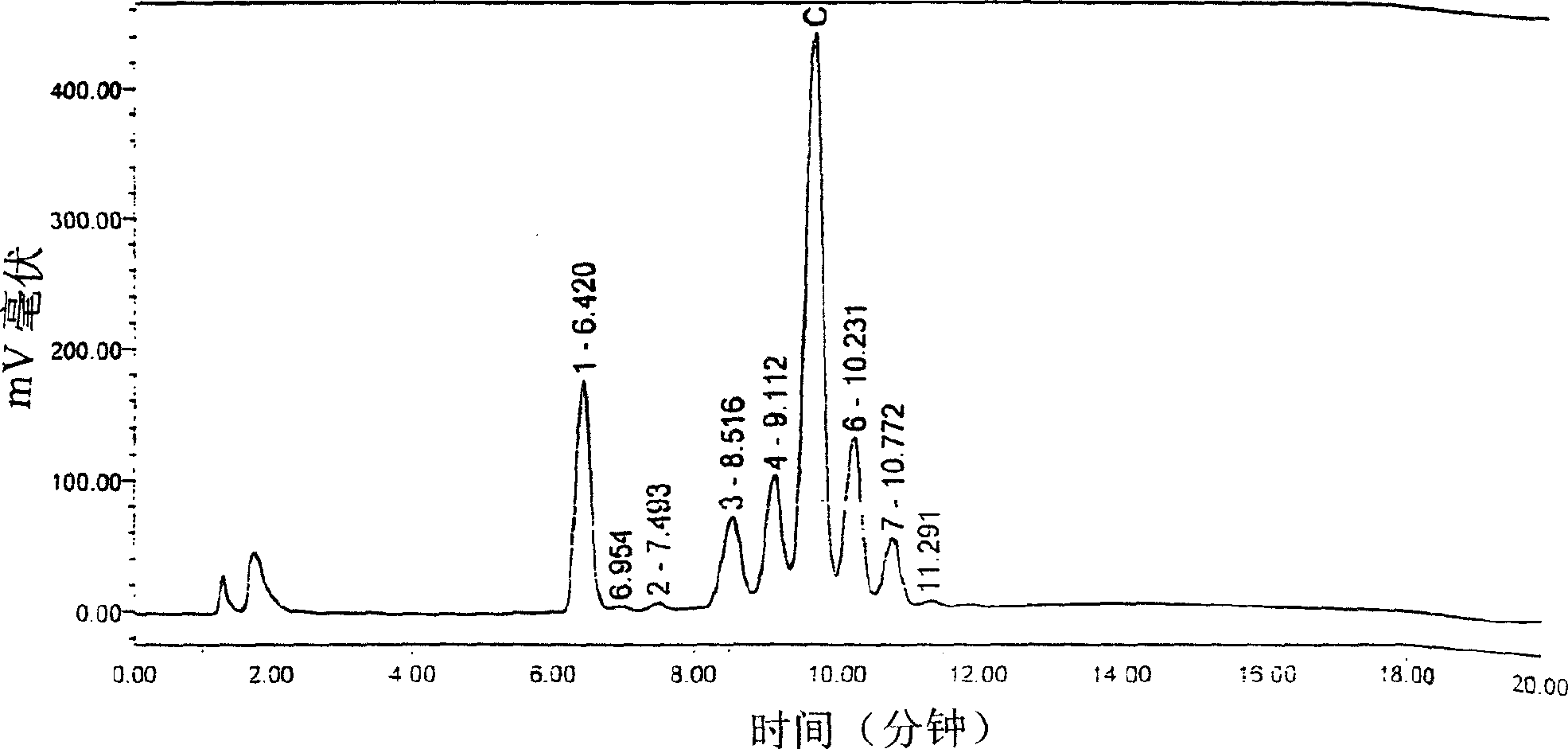

Application of Yazhi-fangshe Mucor in use for preparing ceramide

This invention provides a new usage of actinomucor elegents, especially for the production of ceramide which is prepared by taking tikitiki as the raw material after fermentation, extraction and separation and purification. Another technology is byroduct of such preparation, namely, a zyme type feed additive.

Owner:SICHUAN UNIV +1

Nucleic acids for detecting fusarium species

Nucleic acids for detecting Aspergillus species and other filamentous fungi are provided. Unique internal transcribed space 2 coding regions permit the development of nucleic acid probes specific for five different species of Aspergillus, three species of Fusarium, four species of Mucor, two species of Penecillium, five species of Rhizopus, one species of Rhizomucor, as well as probes for Absidia corymbifer, Cunninghamella elagans, Pseudallescheria boydii, and Sporothrix schenkii. Methods are disclosed for the species-specific detection and diagnosis of infection by Aspergillus, Fusarium, Mucor, Penecillium, Rhizomucor, absidia, Cunninghaemella, Pseudallescheria or Sporthrix in a subject. Furthermore, genus-specific probes are also provided for Aspergillus, Fusarium and Mucor, in addition to an all-fungus nucleic acid probe.

Owner:HEALTH & HUMAN SERVICES CENTS FOR DISEASE CONTROL & PREFENTION THE GOVERNMENT OF THE US SEC THE DEPT OF +2

Rapid fermentation process for preparing fermented soybeans by pure strains

ActiveCN101984853AControllable formationShorten fermentation timeFood preparationVegetable oilSoybean product

The invention provides a rapid fermentation process for preparing fermented soybeans by pure strains, which comprises the following steps: cooking and curing the soaked soybeans with a water level higher than the soaked beans; inoculating the pure mucor strains after intermediate culture; fermenting at constant temperature and humidity for 48-72 hours to obtain mucor blank; adding salt and slicedginger; compacting, sealing and fermenting in the case of voidage being less than 5%; dehydrating with circulating hot air; frying with vegetable oil at the temperature of 170-190 DEG C for 30-50 seconds; mixing with blending materials timely; hot-filling at 85-90 DEG C; pressing tightly so that the oil level is 1-1.5cm higher than the surface of the beans; and carrying out vacuum sealing to finally obtain the instant fermented soybeans after being cooled. The process provided by the invention has the advantages of scientific process design, short process cycle, good color stability, continuous industrial production, controllable process, stable quality and no addition of preservative and anti-staling agent and color fixative, and can obtain the fermented soybeans which are significantly different from the products of other types, thus providing a feasible method for safely and conveniently producing fermented soybean products.

Owner:HUNAN AGRICULTURAL UNIV

Active dry yeast for accelerating growth and development of animals and preparation method of active dry yeast

The invention discloses active dry yeast for accelerating the growth and the development of animals and a preparation method of the active dry yeast. The active dry yeast comprises the following raw materials in parts by weight: 60-80 parts of ageing grape seed meal, 12-18 parts of mushroom powder, 1-2 parts of dry ginger powder, 7-9 parts of celery leaf pulp, 1-1.5 parts of mucor seed liquid, 0.2-0.4 part of sorghum flour, 0.3-0.6 part of beef extract, 0.1-0.2 part of egg yolk powder, 0.1-0.3 part of microzyme seed liquid, 2-3 parts of seaweed glue, 1-2 parts of lotus nut starch, 2-3 parts of yellow peach powder, 0.3-0.5 part of corn syrup and 0.2-0.4 part of spearmint powder. According to the active dry yeast and the preparation method thereof disclosed by the invention, the activity and the stability of the active dry yeast are improved, the pollution of sundry bacteria is avoided, the shelf life is prolonged, the palatability of the dry yeast is improved, the food consumption of animals is increased, the gastrointestinal tract health of the animals is improved, the utilization rate of the feed is increased, the growth and the development of the animals are accelerated, the breeding time is shortened, the breeding cost is reduced, and the breeding benefits are improved.

Owner:HEFEI LAISI BIOLOGICAL ENG

Production process of preserved beancurd having nutrition and health-care function

InactiveCN101647541AIncrease contentImprove the ability of fermentation to produce proteaseFood preparationMetaboliteProtease preparation

The invention discloses a production process of preserved beancurd having a nutrition and health-care function, comprising the following steps: screening mucor strains; injecting N<+> ions; producinghigh-yield metabolite plasmin; producing the preserved beancurd; and adding a protease preparation. The preserved beancurd has the advantages of rich nutrition, nutrition and health-care function enhancement and low cost. Industrialized low-salt thrombolytic preserved beancurd having a nutrition function and lowering cholesterin can be produced through the invention.

Owner:JIANGSU XINZHONG BREWING

Preparation method of konjac fermented-bean-curd sauce and konjac fermented-bean-curd sauce

ActiveCN103549028AApparent proliferation factorCheese manufactureFood scienceMucor speciesFood flavor

The intervention provides a preparation method of a konjac fermented-bean-curd sauce and the konjac fermented-bean-curd sauce, and specifically the konjac fermented-bean-curd sauce is prepared by taking konjac glucomannan and bean curd as raw materials and performing early-stage fermentation and later-stage fermentation. The preparation method of the konjac fermented-bean-curd sauce comprises the following steps: (1) picking integrated soya bean, shelling and cleaning, immersing at 25-30 DEG C for 3-5 h, grinding to obtain milk, filtering, boiling the milk, curdling and at the same time adding konjac glucomannan according to a weight ratio of soya bean to konjac glucomannan being 1:1-5:1, to prepare a fermented bean curd blank; (2) inoculating a mixed bacterial strain containing mucor and monascus to the fermented bean curd blank for axenic cultivation to obtain a fermented bean curd rough blank, putting in a pickling device, spilling salt layer by layer to pickle for obtaining a salty blank, pouring inoculum containing microzyme into the pickling device for fermentation; and (3) taking out the fermented bean curd obtained in the step (2), adding flavoring agents, performing high-temperature disinfection, subpackaging toobtain the konjac fermented-bean-curd sauce with unique flavor.

Owner:湖北顺溪生物食品股份有限公司

Mucor for producing picropodophyllin and its glucoside and kaempferol flavone kind substance, its method and application

InactiveCN1718723AProtect ecological diversitySimple nutritional requirementsFungiFermentationPicropodophyllinMucor species

A mucor podophyllus GJ-TW8 (CCTCC No. M205032) used to prepare podophyllotoxin, its glucoside and kaemplerol flavone is prepared from the root of sinopodophyllum through separation, screening and purifying. It has multiple medicine values.

Owner:NORTHWEST UNIV(CN)

Brewing method of light soy sauce

InactiveCN104543940AHigh in nutrientsStrong umamiFood preparationAspergillus oryzaeNational standard

The invention discloses a brewing method of light soy sauce. The brewing method of the light soy sauce disclosed by the invention comprises the following steps: (a), activating an aspergillus oryzae strain and a mucor strain; (b), preparing a pure bean pulp culture medium, sterilizing, cooling, inoculating the activated mucor, and culturing to obtain a mucor koji starter; (c), carrying out enlarged cultivation of the mucor mould starter to obtain a mucor finished koji; (d), preparing a bean pulp flour culture medium, sterilizing, cooling, inoculating the activated aspergillus oryzae, culturing to obtain an aspergillus oryzae koji starter, and carrying out enlarged cultivation to obtain an aspergillus oryzae finished koji; (e), mixing the mucor finished koji with the aspergillus oryzae finished koji according to a proportion, adding water and salt, and fermenting to obtain soy sauce paste mash; and (f), hanging and filtering the soy sauce paste mash, and clarifying precipitation to obtain the light soy sauce. The disadvantages in the existing light soy sauce production technology are overcome by using the method disclosed by the invention; the method disclosed by the invention is simple and easy to operate; extra equipment investment and post-treatment processes are unnecessary; the implementation performance is high; the prepared light soy sauce is enriched in nutrition and full-bodied in fragrance; all the physicochemical indexes of the light soy sauce beyond those of the national standard special soy sauce, and thus, the brewing method of the light soy sauce disclosed by the invention is wide in market application prospect.

Owner:HEBEI UNIVERSITY

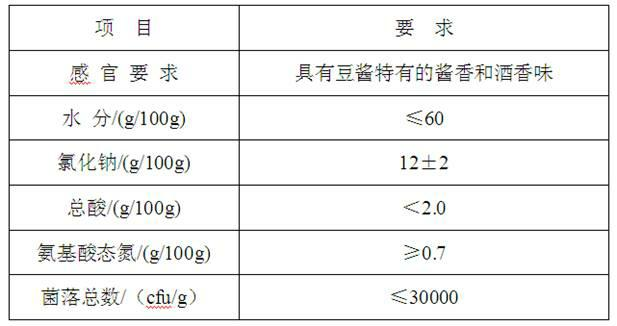

Preparation technology of soybean paste

Belonging to the technical field of soybean paste condiments, the invention especially relates to a preparation technology of soybean paste. The technology comprises the steps of: a. soybean soaking; b. soybean cooking: steam cooking the soybean raw material in a pressure cooker for 35min-45min, with the pressure of the pressure cooker between 0.1mPa to 0.3mPa; c. starter making: cooling the soybean raw material to a temperature of 30DEG C-32DEG C, then spreading the raw material into a soybean stockpile of 4cm-6cm in thickness, and leaving mucors to grow for 6d-8d in the soybean stockpile; d. soybean washing: cleaning the mucors with clear water at normal temperature; e. alcoholic fermentation: placing the soybean raw material in alcohol for fermentation for 3d-4d at a temperature of 33DEG C-36DEG C, thus obtaining a soybean paste primary product; f. fermentation in a fermentation vat: putting the soybean paste primary product in the fermentation vat for fermentation for 90d-100d, thus obtaining a soybean paste finished product. Characterized by simple operation, lowered soybean paste production cost, and easily controllable production environment, the technology of the invention can prepare soybean paste reserving a natural flavor and mouthfeel and possessing a unique bouquet and sauce aroma.

Owner:广东百味佳味业科技股份有限公司

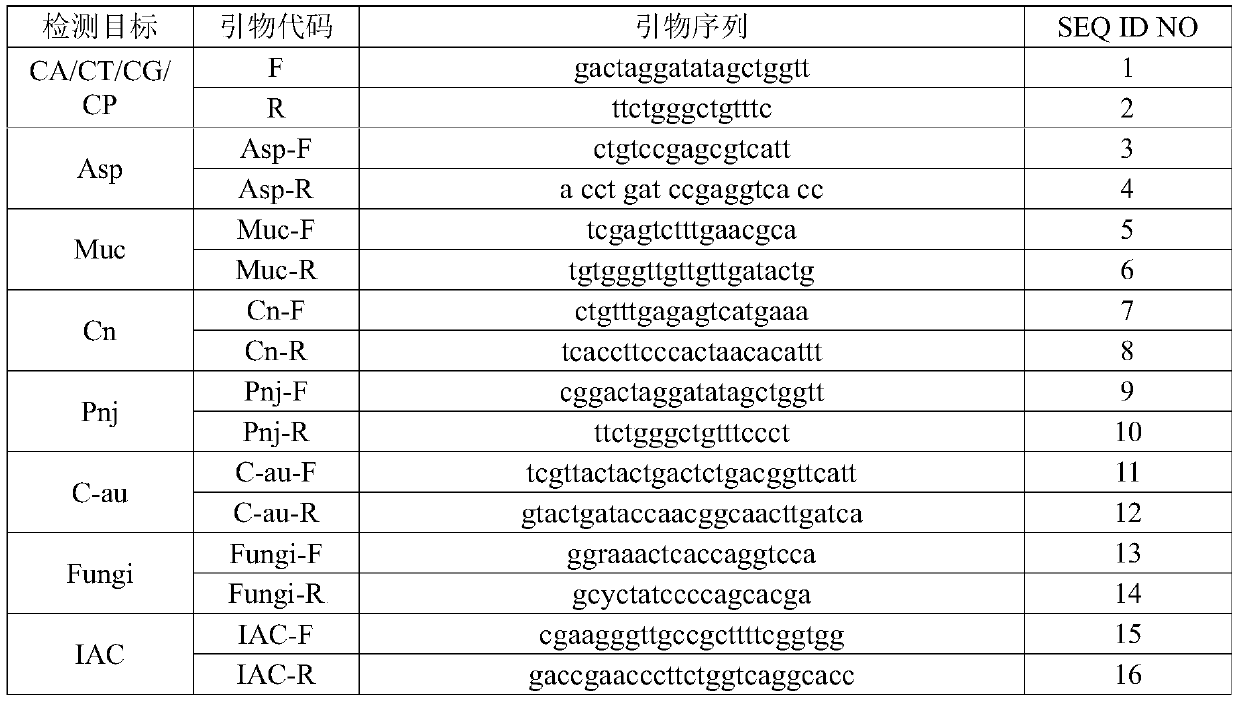

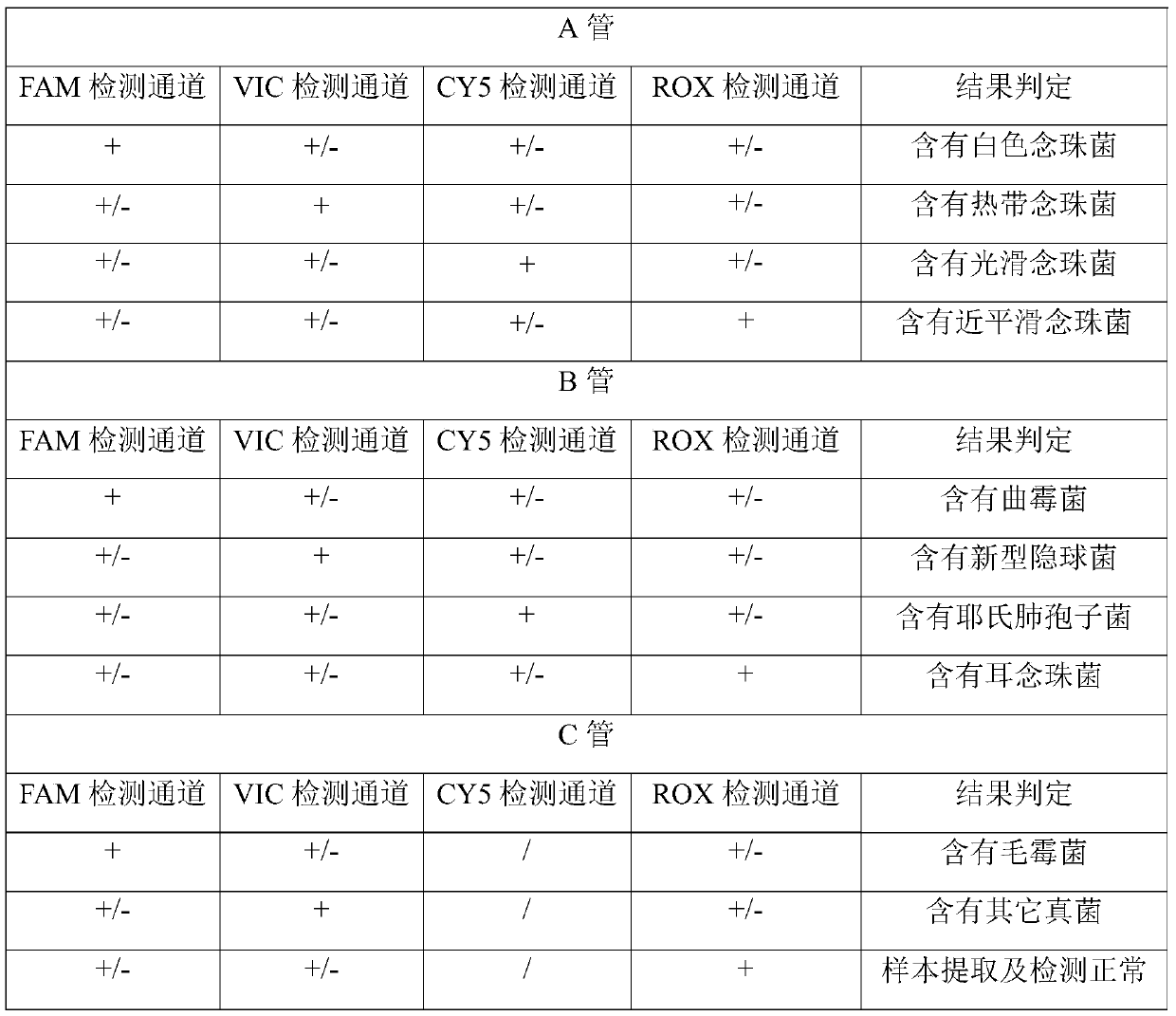

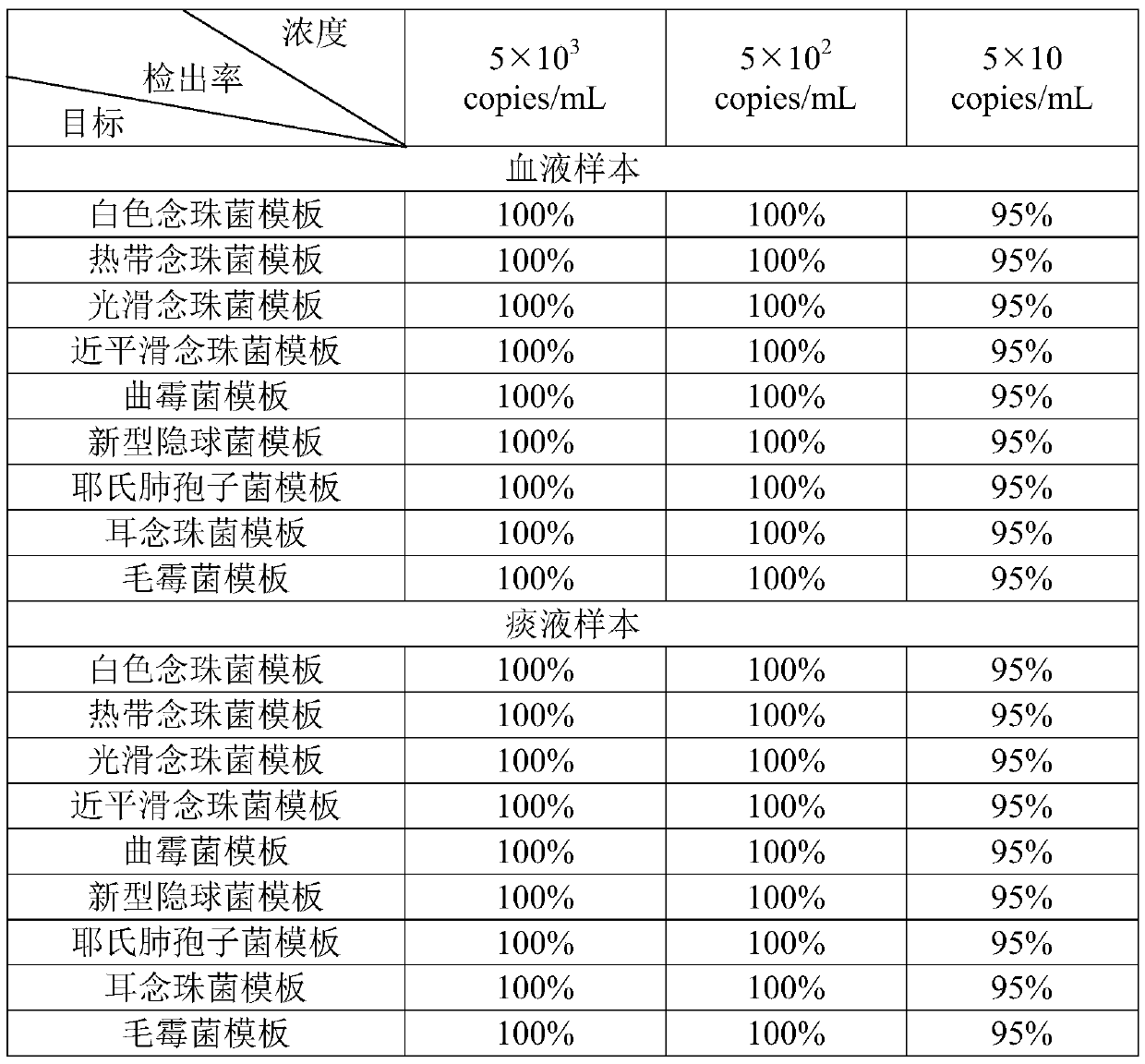

Nucleic acid reagent, kit, system and method for detecting invasive fungi

InactiveCN110551840AQuick checkAccurate detectionMicrobiological testing/measurementMicroorganism based processesCandida tropicalisCandida famata

The invention relates to a nucleic acid reagent, kit, system and method for detecting invasive fungi. The nucleic acid reagent comprises a primer shown in SEQ ID NO.1-14 and a probe shown in SEQ ID NO.17-26, and the primer and the probe are stored independently with each other correspondingly or mixed with each other at will. Through the primer and the probe, the nucleic acid reagent, the kit, thesystem and the method of at least 9 invasive fungi of candida albicans, candida tropicalis, candida glabrata, candida parapsilosis, mucor, aspergillus, cryptococcus neoformans, pneumocystis jeroveciand candida auris, fast, comprehensive, sensitive, specific and automatic detection result determination can be achieved, and the sensitivity, specificity, simplicity and convenience of simultaneous detection of the detection target genome are significantly improved.

Owner:北京卓诚惠生生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com