Glucosamine and method of making glucosamine from microbial biomass

A technology of glucosamine and biomass, which is applied in the preparation of sugar derivatives, amino sugar, sugar derivatives, etc., and can solve problems such as the negative impact of crustaceans on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

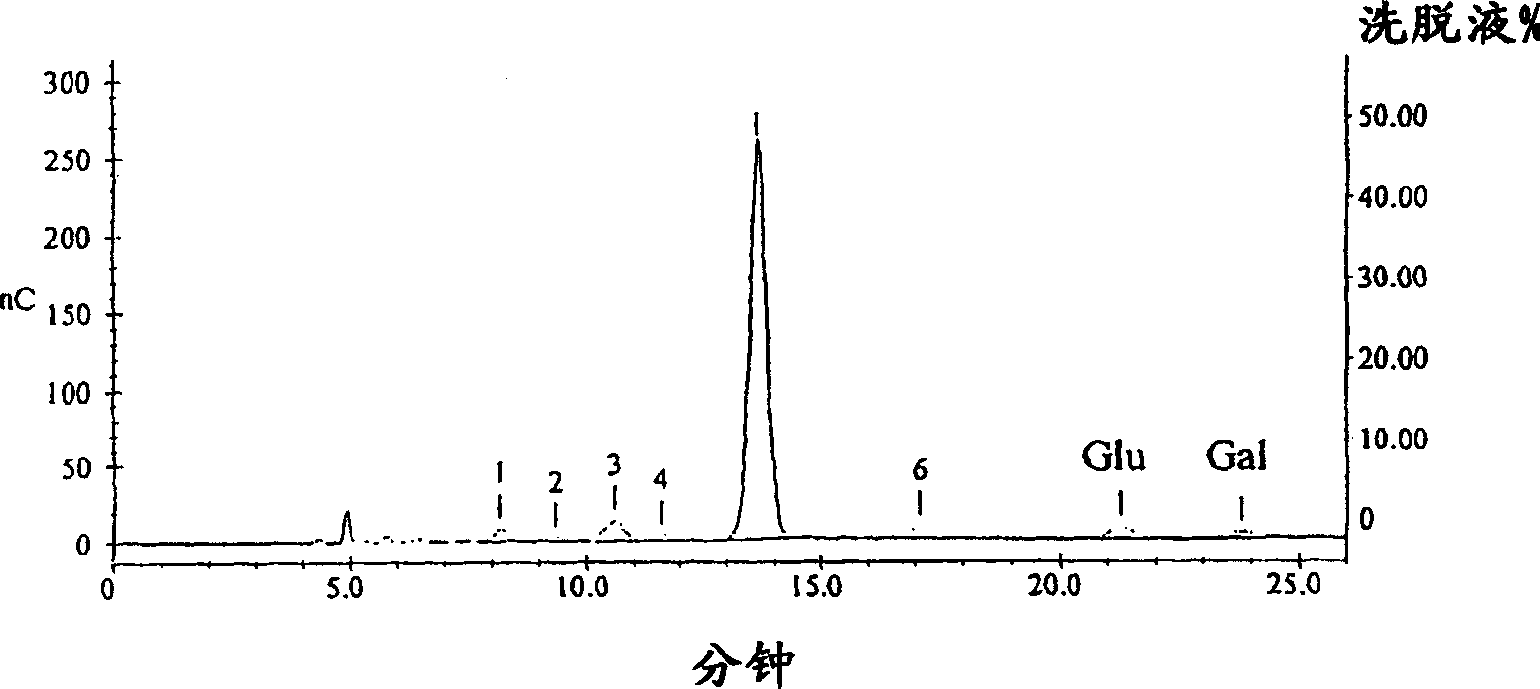

[0046] Citric acid biomass was pretreated with 4% aqueous sodium hydroxide (NaOH) by autoclaving at 120° C. for 1 hour, a step that removed excess protein and other undesirable materials. The biomass was then washed thoroughly with deionized water until the pH was approximately 7.0. The washed material is mixed with concentrated hydrochloric acid (HCl) and water to form a mixture containing 10-15% hydrochloric acid and 5-6% biomass (by dry weight of biomass). The mixture was heated to reflux. Samples were taken from time to time and the reaction was analyzed by Dionex HPLC high pressure liquid chromatography (trade name DX-500).

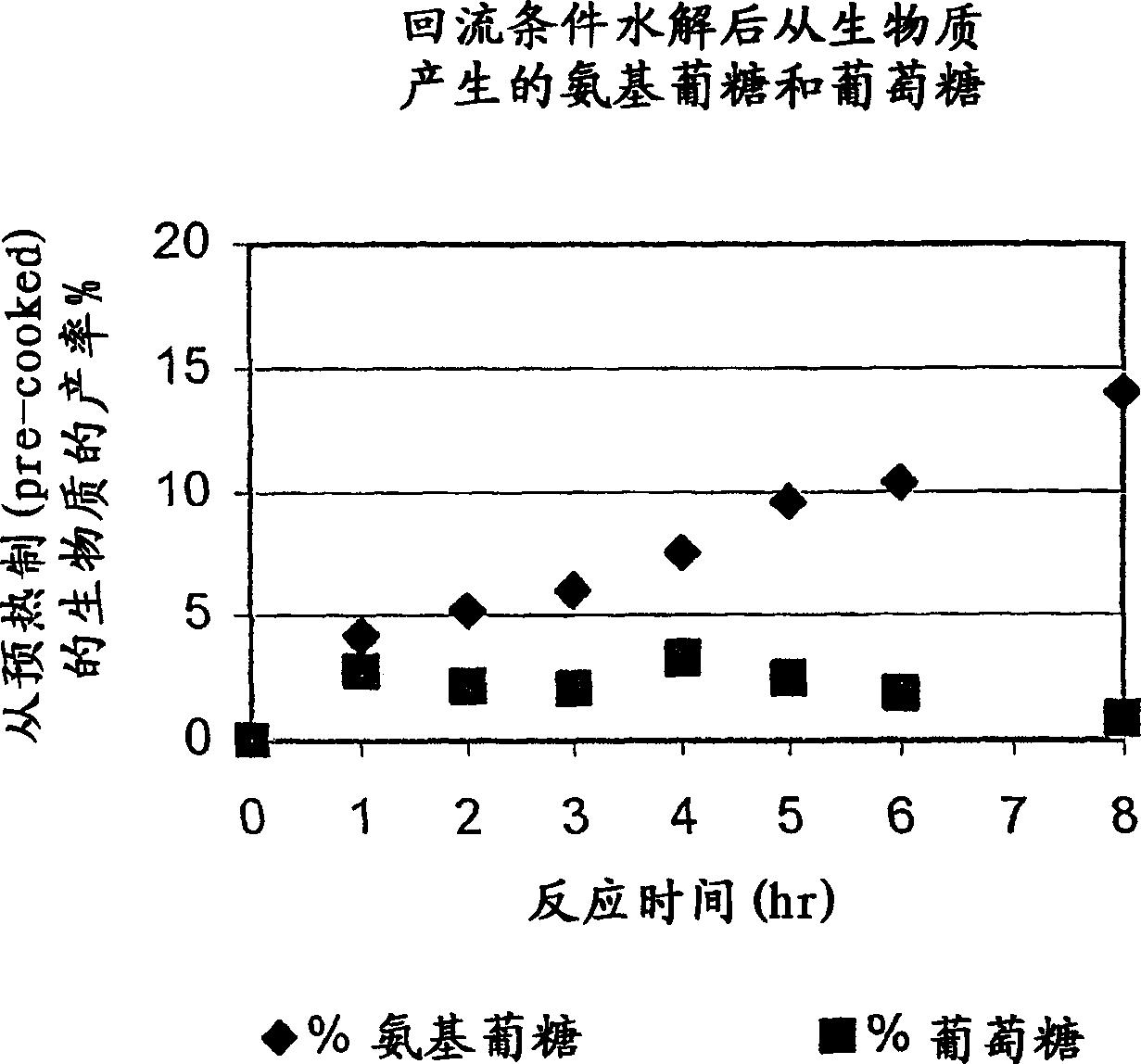

[0047] The results are shown in figure 1 , which is an indicator graph of glucosamine production, and shows that glucosamine production is increasing within 8 hours of reaction, but the amount of glucose is decreasing after 4 hours. The yield of glucosamine after 8 hours was 14%. The chromatogram of the product is as follows figure 2 shown.

...

Embodiment 2

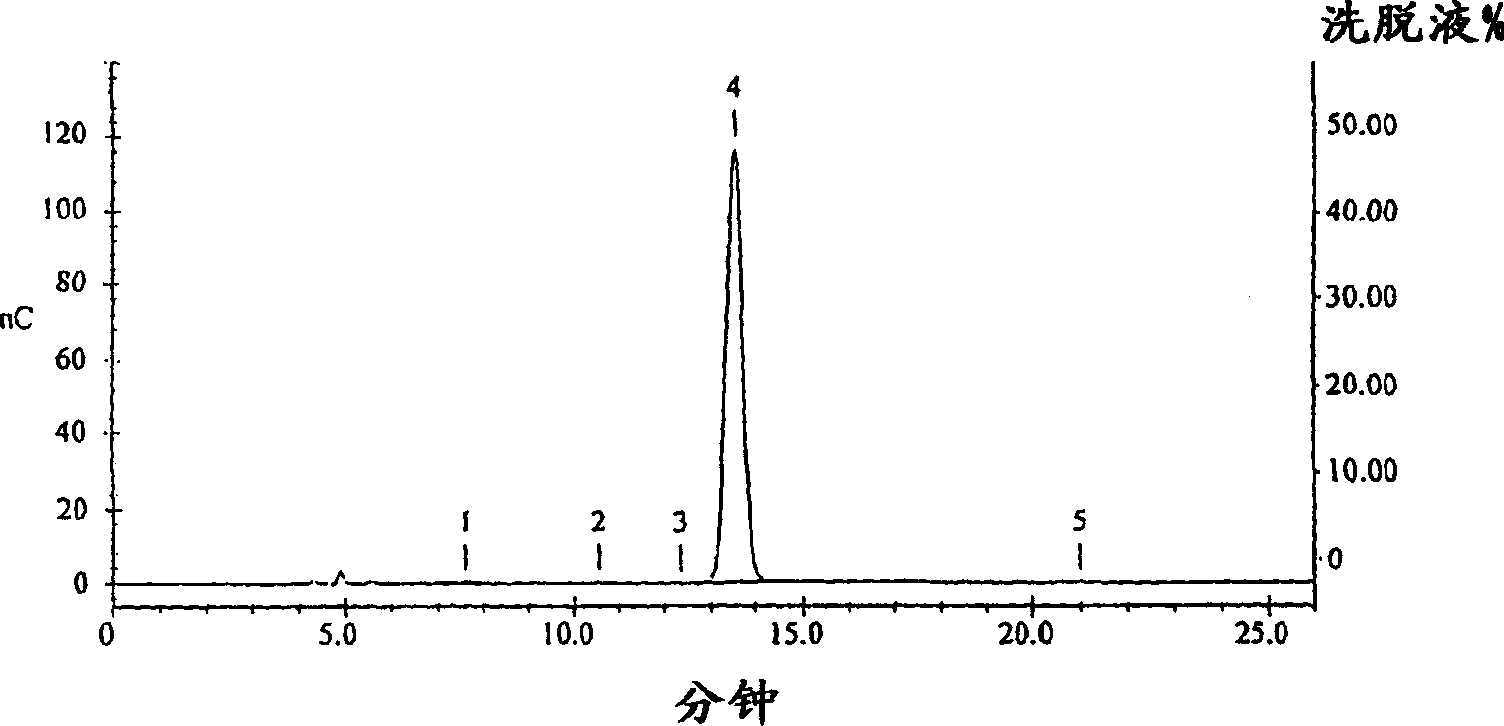

[0050] Example 1 was repeated, but the pretreated biomass was maintained at reflux for 13 hours. The glucosamine produced has a purity of over 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com