High-efficiency engineering bacteria agent and method for producing active biological organic fertilizer

A bio-organic fertilizer and engineering bacteria technology, applied in the biological field, can solve the problem of single fermentation bacteria and achieve the effects of activating the soil, increasing the quantity, and improving the yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

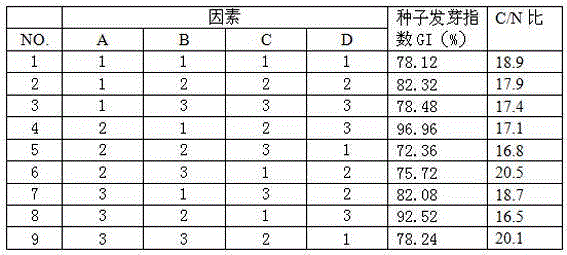

Embodiment 1

[0013] 1 Experiment description

[0014] 1.1 Culture and preparation of bacteria

[0015] Pichia pastoris, Bacillus thuringiensis, Bacillus subtilis, Bacillus licheniformis, Mucor umbelliferum, and Rhizopus oryzae were inoculated in different culture media respectively.

[0016] Bacillus culture medium for Bacillus thuringiensis, Bacillus subtilis and Bacillus licheniformis: 20 parts of bran, 2 parts of soybean cake powder, 5 parts of rice bran, mixed with 25 parts of nutrient solution, and sterilized. The nutrient solution formula is: (NH 4 ) 2 SO 4 0.2%, MgSO 4 0.05%, KH 2 PO 4 0.3%, NaNO 3 0.4%, CaCl 2 0.05%, prepared with water.

[0017] Culture medium for Mucor umbellatus and Rhizopus oryzae: 15 parts of corn flour, 8 parts of bran, 5 parts of rice bran, 0.5 part of glucose, mixed with 25 parts of nutrient solution, and sterilized. Nutrient solution formula is MgSO 4 0.2%, K 2 HPO 4 0.3%, KH 2 PO 4 0.4%, yeast powder 0.05%, prepared with water.

[0018] Pi...

Embodiment 2

[0040] Pichia pastoris, Bacillus thuringiensis, Bacillus subtilis, Bacillus licheniformis, Mucor fungus, and Rhizopus oryzae were respectively inoculated in different culture media, and the culture medium formula was formulated according to the cultivation and preparation requirements of Example 1. . Aerobic culture to obtain different strains. The solid culture of bacillus is based on 37°C culture for 72-80h. At this time, the colonies of Bacillus thuringiensis, Bacillus licheniformis and Bacillus subtilis reach 4.78×10 9 CFU / g, 7.15×10 9 CFU / g and 1.01×10 10 CFU / g. Other strains such as Pichia pastoris, Rhizopus oryzae and Mucorella umbellatus were cultured at 30°C for 6-7 days, and the number of Pichia pastoris colonies was 1.41×10 9 CFU / g, the number of spores of Rhizopus oryzae and Mucor umbrella reached 1.04×10 10 CFU / g and 1.38×10 10 CFU / g.

[0041] Mix 3 parts of Pichia pastoris, 1 part of Mucorella umbellatus, 3 parts of Rhizopus oryzae, and 5 parts of Bacillus...

Embodiment 3

[0043] The culture preparation of bacteria is the same as in Example 1, the difference is that after the bacteria are cultured separately, the mixing ratio of the enzyme-producing bacteria, wherein 5 parts of Pichia pastoris, 3 parts of Mucor umbellatus, 1 part of Rhizopus oryzae, and 5 parts of Bacillus licheniformis Combine and mix, and then combine 50 parts of enzyme-producing bacteria, 6 parts of Bacillus thuringiensis and 10 parts of Bacillus subtilis to form a high-efficiency engineering bacterial agent. The bacteria agent was inoculated in the compost raw material composed of kitchen waste and straw at a ratio of 1%. After 2 weeks of aerobic fermentation, the germination index GI of active bio-organic fertilizer seeds reached 92.5%, and the C / N ratio was 16.5. The number reaches 105 million / g, and other indicators are in line with the indicators of organic fertilizer organic matter, pH, fecal coliform group, roundworm eggs, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mortality rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com