Brewing method of light soy sauce

A technology of light-colored soy sauce and bacterial strains, applied in the fields of application, food preparation, food science, etc., can solve the problems of complex process, high cost, and poor quality of light-colored soy sauce, achieve strong protein decomposition ability, easy operation, and weaken Maillard The effect of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

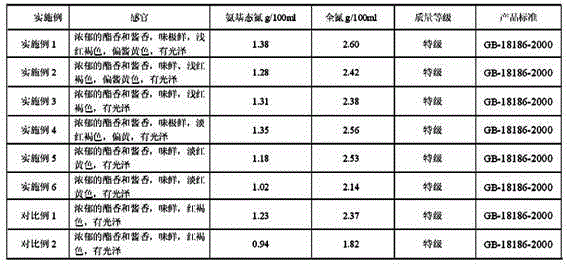

Examples

Embodiment 1

[0022] (1) Activated strains: Prepare PDA medium (potato dextrose agar medium) according to the conventional method, specifically, weigh 200g of peeled potatoes and cut them into small pieces, add water and boil them (boil for 20-30 minutes, can be soaked by glass stick to puncture), filter with eight layers of gauze, heat, add 15g of agar powder, continue to heat and mix well, after the agar is dissolved, add 20g of glucose, stir evenly, and then make up water to 1000 ml after cooling down slightly. Divide into test tubes, stopper and bandage, sterilize at 121°C for 30 minutes, take out the test tubes and put them on a slant, cool, inoculate Aspergillus oryzae strain 3042 and Mucormyces ruckeri strains respectively on the PDA slant medium under aseptic conditions, so that rice Aspergillus was cultured at a constant temperature of 32°C for 72 hours; Mucor was cultured at a temperature of 28°C for 48 hours, and the slant was covered with spores;

[0023](2) Preparation of Mucor...

Embodiment 2

[0029] (1) Activated strains: Prepare PDA medium according to the method described in Example 1, sterilize at 121°C for 30 minutes, take out the test tube and place it on an inclined plane, cool to room temperature, and infect aspergillus oryzae strain 3042 and tall hair The mold species were respectively inoculated on the PDA slant medium, and Aspergillus oryzae was incubated at a constant temperature of 32°C for 72 hours; Mucor was cultured at a constant temperature of 28°C for 48h, and the slopes were all covered with spores;

[0030] (2) Preparation of Mucor seed koji: Preparation of pure soybean meal medium: Weigh 100 g of soybean meal and 80 g of water respectively according to the mass ratio of soybean meal and water of 1:0.8, mix them evenly, and distribute them in several 50 ml triangles In the bottle, sterilize at 0.1MPa for 30 minutes, cool to room temperature for later use; inoculate a ring of Mucor spores activated in step (1) into pure soybean meal medium in a 50m...

Embodiment 3

[0036] (1) Activated strains: Prepare PDA medium according to the method described in Example 1, sterilize at 121°C for 30 minutes, take out the test tube and place it on an inclined plane, cool to room temperature, and aseptically separate Aspergillus oryzae strain 3042 and raceme The mucormycetes were respectively inoculated on the PDA slant medium, and the Aspergillus oryzae was cultured at a constant temperature of 32°C for 72 hours; the mucormycetes were cultured at a constant temperature of 28°C for 48 hours, and the slant was covered with spores;

[0037] (2) Preparation of Mucor seed koji: Preparation of pure soybean meal medium: Weigh 100 g of soybean meal and 120 g of water according to the mass ratio of soybean meal and water of 1:1.2, mix them evenly, and distribute them in several 50 ml triangles In the bottle, sterilize at 0.1MPa for 30 minutes, cool to room temperature for later use; inoculate a ring of mucormycetes spores activated in step (1) on pure soybean me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com