Patents

Literature

253 results about "Fermentation gut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-propelled turning device for sludge compost and treatment method

ActiveCN102030570AEasy to walkSmall footprintSludge processingOrganic fertiliser preparationSludge compostOxygen

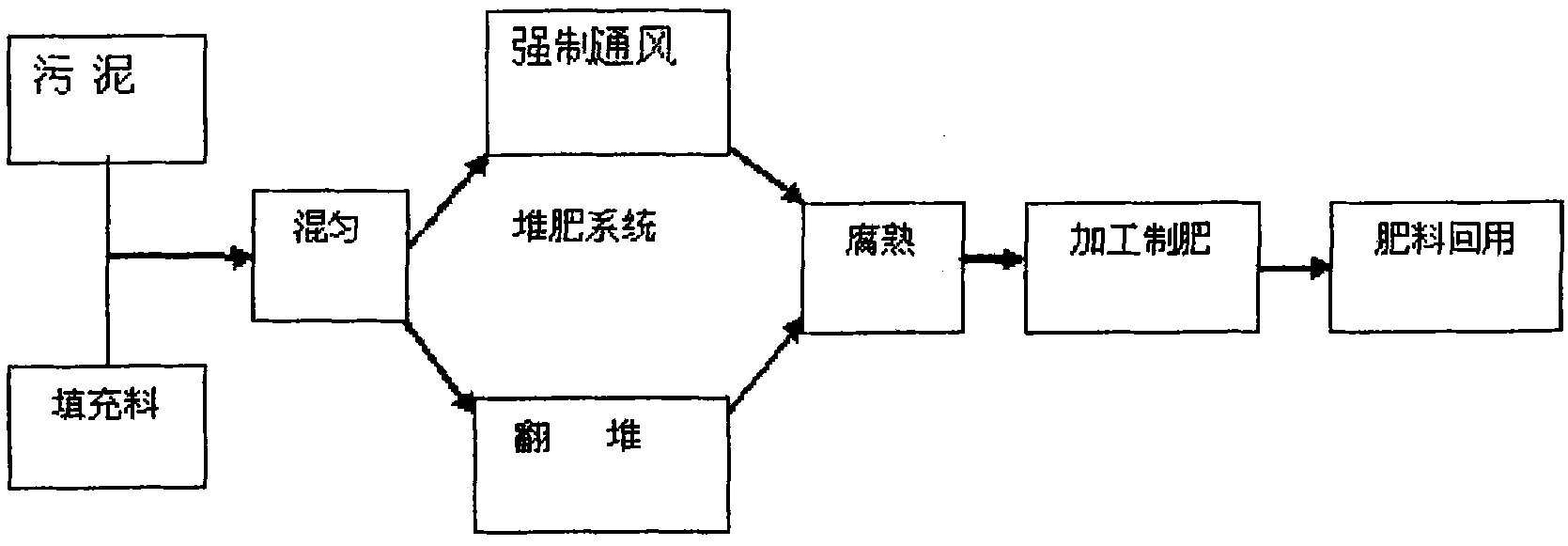

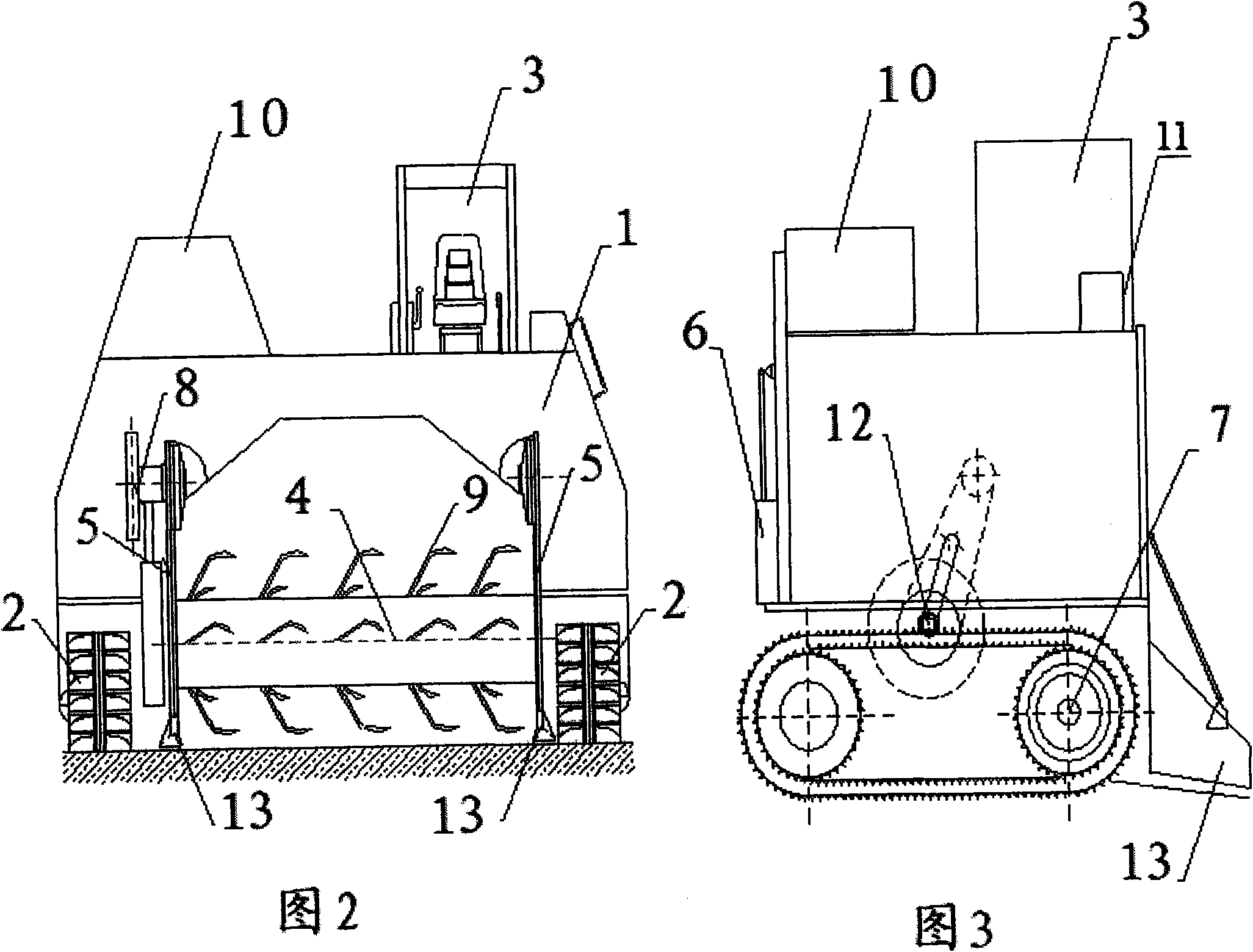

The invention relates to a self-propelled turning device for sludge compost and a treatment method and belongs to environmentally-friendly solid waste treatment. The method comprises that: a mixing step, an aerobic compost period, a thoroughly decomposing step, a processing and compost production step and an odor treatment step, wherein the mixing step aims to adjust the moisture and the carbon nitrogen rate of dewatered sludge, improve the loosening degree, increase a contact area with air and contributes to aerobic fermentation; in the aerobic compost period, the oxygen is supplied through forced ventilation, and organic matters in materials begin to ferment under the action of aerobes; the thoroughly composting step comprises that: the sludge subjected to compost fermentation is not thoroughly decomposed, and is required to continuously undergo a thoroughly decomposing and ageing stage, namely secondary fermentation; the processing and compost production step comprises that: the sludge compost is processed according to fertilizer use and market demand to serve as a product for sales so as to improve overall economic efficiency; and the odor treatment step comprises that: odor is generated in the process of aerobic compost and can be discharged after deodorization treatment. In recent years, solid wastes have become important environmental problems limiting urban development. The composting treatment is a way to utilize solid waste resources and is gradually taken into account at home and abroad.

Owner:BMEI

Process for preparing organic fertilizer by biological mud and grass refuse of papermaking plant

InactiveCN1793072APromotes main stem growthPromote the number of side branchesBio-organic fraction processingOrganic fertiliser preparationPotassiumNitrogen

The invention relates to a method of using biochemistry sludge and grass of paper mill to make organic fertilizer that belongs to organic fertilizer technology field. It contains 3-6 portions of grass, 3-5 portions of biochemistry sludge, 1-2 portions of fly ash, 1-2 portions of chicken manure, 0.005-0.01 portion of bio-fermentation agent, water content is 55%-60%. Putting the material into fermenting tank, after the temperature reaching to 50 degree centigrade, turning over, keeping fermenting for 7-12 days when the temperature altering not so obvious, drying the material, adding chemical fertilizer and microelement, normal organic fertilizer and organic inorganic mixture fertilizer would be gained. The invention is simple technology, and would stop the pollution to the environment from fertilizer.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

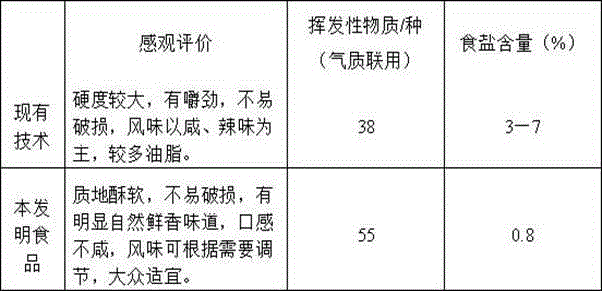

Fermented soda biscuit and its production process

InactiveCN1973636AImproving dough propertiesShorten fermentation timeDough treatmentPre-baking dough treatmentBiotechnologyIcing sugar

The fermented soda biscuit and its production process belong to the field of food producing technology. The fermented soda biscuit is produced with flour, yeast, milk powder, sugar powder, maltose, ammonium bicarbonate, palm oil, baking soda, table salt, protease preparation and water, and through mixing the materials, fermentation and roasting. The present invention replaces enzyme preparation for food level sodium metabisulfite, and adopts low temperature roasting, laminating and short fermentation time.

Owner:SHANDONG ZHENGHANG FOODSTUFF

Preparation method of fermented germinated brown rice milk beverage

ActiveCN102952663ARich technical means for deep processingRich technical meansAlcoholic beverage preparationAmylaseHydrolysate

The invention discloses a preparation method of a fermented germinated brown rice milk beverage, wherein the method comprises the following steps: 1. mixing distiller's yeast in steamed germinated brown rice, placing a wine jar in an incubator to ferment for 6-8 days at 27-30 DEG C; 2. adding water in the wine jar containing fermented rice wine and grain stillage, pulping, and grinding the pulp for 2-3 times through a colloid mill; 3. adding alpha-amylase and saccharifying enzyme in the pulp in step 2 for enzymolysis; and 4. adding water in the enzymatic hydrolysate prepared in step 3 until the concentration of the solid becomes 10-20%, and adding additives to prepare the enzymatic hydrolysate into the beverage. The traditional fermentation technology is combined with the modern biotechnology in the invention to enrich the technological means of rice deep processing, and the preparation method can be used for both improving the utilization rate of the byproduct, namely, the grain stillage in wine making, enabling enterprises to realize clean production, and increasing the economic benefit of the society.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

An instant pickled vegetables containing live probiotics and preparation method thereof

InactiveCN1961737AAdd flavorSimple production processFruit and vegetables preservationDigestive systemBiotechnologySalt content

The invention relates to a kraut with active healthy bacteria and relative production, wherein it comprises that washing and drying the fresh vegetable; adding pure healthy bacterial at 28-30Deg. C to ferment for 60-72h; adjusting the taste of said fermented kraut, vacuuming packing; laying it at normal temperature for six months, while the bacteria number can reach 105-106cfu / g and the salt content is lower than 3.0%. Said bacterial is Lactobacillus casei isodulcitol sub kind. The invention has short product time and stable quality.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing chicken manure fermented feed

InactiveCN102511653AYellow-green colorHas the smell of distiller's grainsAnimal feeding stuffNutritionVinasse

The invention discloses a method for preparing chicken manure fermented feed. The method is characterized by comprising the following steps of: mixing 70 to 75 parts of chicken manure, 20 to 30 parts of hay or straw powder and 10 to 15 parts of energy feed uniformly, and adding water till the water content reaches 58 to 65 weight percent; filling the uniformly mixed materials into a fermentation tank, keeping the temperature at 20 to 25 DEG C, and performing sealed fermentation for 20 to 40 days to obtain fermented feed; and drying the fermented feed, controlling the moisture to be 5-10 weight percent, grinding the dried feed, and thus obtaining finished feed. The silage fermented feed prepared by adopting the method has a shape of yellow sauce-like chicken manure, is yellow green, has vinasse taste and good palatability, is easy to absorb and digest by animals, and has rich nutrition.

Owner:ZHANGJIAGANG JINZHOU AGRI TECH DEV

Method for breeding earthworms in greenhouse

The invention discloses a method for breeding earthworms in a greenhouse. The method comprises the following steps: a place is selected to build an ecological greenhouse, wherein a ventilating system, breeding ponds and a vaporous water spray device are arranged in the greenhouse; a breeding feed is a mixture of fermented corn straw and cow dung, the fermented feed is put into the breeding ponds, a layer of loose soil with good air permeability is laid, 10000-15000 young earthworms are placed in each breeding pond, during daily management, the humidity of the breeding soil is controlled to be 20-70%, and the environment temperature is controlled to be 15-25 DEG C. According to the invention, a greenhouse breeding technology is adopted, the problems of diseases caused by environment temperature change can be effectively avoided during the breeding process, and a relatively stable growing environment is provided for earthworms; meanwhile, the breeding temperature is controlled to be 15-25 DEG C, so that the breeding period is shortened greatly; breeding in different ponds is adopted, so that a farmer can manage conveniently, the phenomenon that earthworms fleeing to other places during breeding is avoided, epidemic diseases can be effectively avoided, and breeding benefits of the farmer are increased.

Owner:YINGSHANG COUNTY ZHONGJUN AGRI TECHDEV

Blueberry beer and manufacturing technology thereof

InactiveCN103409265AFull of nutritionKeep amino acidsBeer brewingBiotechnologyManufacturing technology

The invention discloses blueberry beer and a manufacturing technology thereof. The main compositions of the blueberry beer are barley juice and hops. The manufacturing technology comprises the following steps: firstly, before fermentation, adding the following products by mass percent according to the quality of the product: 1-40% of blueberry fruit, 5-10% of blueberry honey, and 1-10% of blueberry scented tea, and performing cultivation and fermentation on all the products, wherein the traditional brewage technology is adopted, and the concentration of the original barley juice before yeast is added to ferment is 8-10 BX; secondly, after the ferment is completed, adding the following products by mass percent for mixing according to the quality of the product: 1-4% of blueberry juice, 1-10% of blueberry powder, 0.1-5% of blueberry jam, 0.001-0.4% of blueberry essence, 1-5% of blueberry honey water and 1-5% of blueberry scented tea water. The blueberry beer produced by adopting the method is nutrient-rich, gives off intense bouquet, and has the health protection function.

Owner:王京生

Method for preparing angleworm bait using industrial residue of Stevia rebaudiana and cultivating angleworm using the same

InactiveCN101473901AGood breathability and moisture retentionIncrease productionFood processingAnimal feeding stuffSugarFermentation

The invention discloses a method for preparing earthworm bait by stevia rebaudiana bertoni industrial residue and a method for breeding earthworm, belonging to the technical field of animal feed and breeding technology. A stack retting fermentation method is adopted to treat the stevia rebaudiana bertoni industrial residue, the stevia rebaudiana bertoni industrial residue is put into a fermentation vat where 10-50 kilograms of diluent of 0.5-2% EM bacterial and 0.1-0.5 kilogram of brown sugar is added to per cubic meter of the stevia rebaudiana bertoni industrial residue, then well water is used for drenching (humidity level 60-70%), closed fermentation is carried out for 15-20 days (15 days in summer and 20 days in winter), when the fermentation is over, air drying is carried out properly on the prepared earthworm bait for use. When earthworms are bred, the fermented stevia rebaudiana bertoni industrial residue is evenly paved on a smooth breeding bed in the open air which is 60-100mm in width and 20-50mm in height, 2500-3500 Daping NO.3 earthworms are put in each cubic meter, humidity level of the breeding bed is observed and water is moderately sprinkled every day and the humidity level of the breeding bed is preferably maintained to be 60-70%; and every 3-5 days 1-5 kilograms of diluent of 1-3% EM bacterial and 0.01-0.05 kilogram of brown sugar are added.

Owner:赣州市畜牧研究所

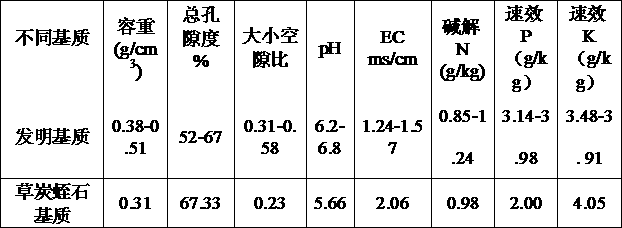

Method for producing special seedling substrate by taking stevia rebaudiana dregs as raw material

InactiveCN101830743ASimple recipeEasy to operateBio-organic fraction processingOrganic fertiliser preparationAnimal fecesShiitake mushrooms

The invention relates to a recycling and seedling technology of organic wastes, in particular to a method for producing a special seedling substrate by utilizing stevia rebaudiana dregs as a raw material. The method comprises the following steps of: mixing 50 to 70 percent of stevia rebaudiana dregs, 20 to 40 percent of waste shiitake logs and 10 to 20 percent of animal feces in percentage by weight, stirring, fermenting, screening and packaging to obtain a finished product. The method comprises the detailed steps of: adding a leavening agent in mixed raw materials according to the proportion of 8: 100; evenly stirring and beginning to ferment with the fermentation temperature of 55 to 70 DEG C and the fermentation time of 20 to 30 days; screening and grading the fermented substrate, crushing coarse grains, returning to working procedures before screening and mixing the fermented substrate, screening again and finally packaging. By adopting the invention, resources are fully utilized, carbon dioxide is fixed and the pollution is reduced. The special seedling substrate produced by taking the stevia rebaudiana dregs as the raw material not only reduces the cost, but also has the characteristics of simple formula, easy operation, strong permeability, sufficient nutrients, and the like, and is suitable for seedling of all plants.

Owner:天津市港源人力资源集团有限公司

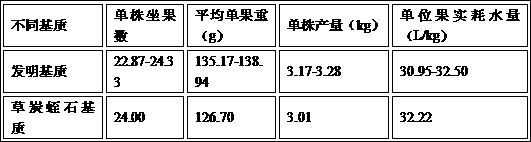

Bag-culture composite nutritional matrix for tomatoes and preparation and nutrient and water management methods thereof

The invention mainly relates to a bag-culture composite nutritional matrix for tomatoes and preparation and nutrient and water management methods thereof. The matrix comprises the following components in percentage by volume: 30% of furfural residues, 20%-40% of cow dung and 30%-50% of crushed maize straws. The preparation method comprises the step of adding 1kg-1.5kg of a water retaining agent, 1.5kg-2kg of urea and 2kg-2.5kg of potassium sulphate to the fermented composite matrix per cubic meter. The matrix provided by the invention is wide in raw material source, low in cost, environment-friendly and suitable for standardized and large-scale production and management, saves resources, solves the problems of successive cropping obstacle of facility soil and poor utilization of soils which cannot be cultivated are effectively solved, and is suitable for popularization and application.

Owner:SHENYANG AGRI UNIV

Rapid high-efficient fermentation production method of health fermented soya bean

InactiveCN103621913AHigh quality fermentationPollution controlFood preparationBiotechnologyNutrition

The invention relates to a rapid high-efficient fermentation production method of a health fermented soya bean. The rapid high-efficient fermentation production method comprises following steps: soybean is immersed, and is mixed with wheat bran, and the mixture is disinfected at a temperature of 121 DEG C for 30min; the cooked mixture is cooled to a temperature about 40 DEG C, is inoculated with triangular flask mold starter, and is cultured at a temperature of 30 DEG C until the surface of the cooked mixture becomes white so as to obtain fermented soya bean mold; salt solution with a concentration of 10% is added into the obtained fermented soya bean mold so as to get water content of a fermented soya bean mash reaching 80 to 100%, and the fermented soya bean mash is subjected to high temperature fermentation at a temperature of 50 DEG C for 7 days so as to obtain a matured fermented soya bean mash; hot water with a temperature of 90 DEG C is added into the fermented soya bean mash, the fermented soya bean mash is subjected to heat preservation for 2 to 4h, and then is filtered so as to obtain crude soybean sauce, wherein a left solid material is linyou fermented soya bean; 0.1 to 1% of a fermented bacillus natto solution (more than 2000IU / mL) is added into the linyou fermented soya bean so as to obtain a basic fermented soya bean; and different spices such as rice wine, capsicum and Chinese prickly ash are added into the basic fermented soya bean so as to obtain the health fermented soya bean. Compared with traditional production methods, advantages of the rapid high-efficient fermentation production method are that: microbial contamination is less, fermentation period is short, product salt content is low, and contained nattokinase is stable. In addition, one-step fermentation is adopted, the obtained soybean source and the health fermented soya bean are rich in nutrients, are varied, and are suitable for large scaled fermentation production.

Owner:河南省南街村(集团)有限公司

Fermentation type chopped chilli and processing technology thereof

InactiveCN104905195AUnique flavorClimate change adaptationFood preparationBiotechnologyMonosodium glutamate

The invention relates to fermentation type chopped chilli, which is prepared from fresh red peppers, ginger, garlic, peppers, monosodium glutamate, salt and fermentation broth. A processing technology comprises the following steps: washing the fresh red peppers with bases removed by using 0.5% saline, soaking the red peppers after washing into citric acid solution at 95-98 DEG C for 5 minutes, fishing out, rapidly placing into clear water, thus obtaining the blanched fresh red peppers; mixing saccharomycetes, bacillus aceticus, hydrocarbon corynebacterium and lactic acid bacteria, activating for 3-5min by using hot water at 30-40 DEG C, pouring the bacterium solution after activation into saline, adding rice wine into the saline, thus obtaining the fermentation broth, and regulating the pH of the fermentation broth to 4-5 by using 5% acetic acid solution for later use; and pouring the fermentation broth into the blanched fresh red peppers, adding with the ginger, the garlic, the peppers, the monosodium glutamate and salt, and performing fermentation culture for 10-15h at 20-25 DEG C, and thus obtaining the fermentation type chopped chilli. The fermentation type chopped chilli is unique in flavor and bright red and crispy, and has the shelf life longer than three years.

Owner:HUBEI YUANYEFENG FOOD

Semi-fermented low-salt fish leisure food and production method thereof

ActiveCN104544312AImprove textureHigh nutritional valueFood preparationBiotechnologyNutritive values

The invention discloses a semi-fermented low-salt fish leisure food, which is prepared by the following steps: (1) inoculating the cultured hansenula polymorpha and aspergillus oryzae into fresh fish sections for primary fermentation, and standing for 6-10hours; (2) placing the primarily fermented fish sections into a chain type drying oven for segmented temperature-variable drying, wherein the drying time is controlled for 30-60 minutes, and the moisture content of fish is controlled at 15-18%; and (3) adding the activated lactobacillus acidophilus and streptococcus lactis fermentation liquor into the dried fish sections for secondary fermentation, and fermenting for 30-50 hours at 10-15 DEG C; discharging liquid, standing and clarifying. No edible salt is added, primary fermentation is combined with the segmented temperature-variable drying, and water in fish sections can be evenly evaporated through the temperature change so as to form a porous cavity, so that the fish has a loosened structure, the texture of the fish can be improved and the secondary fermentation is facilitated, and the fermentation efficiency can be increased. Unique taste and mouth feeling can be generated through secondary fermentation, and the nutritional value and flavor of the fish products can be enhanced.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

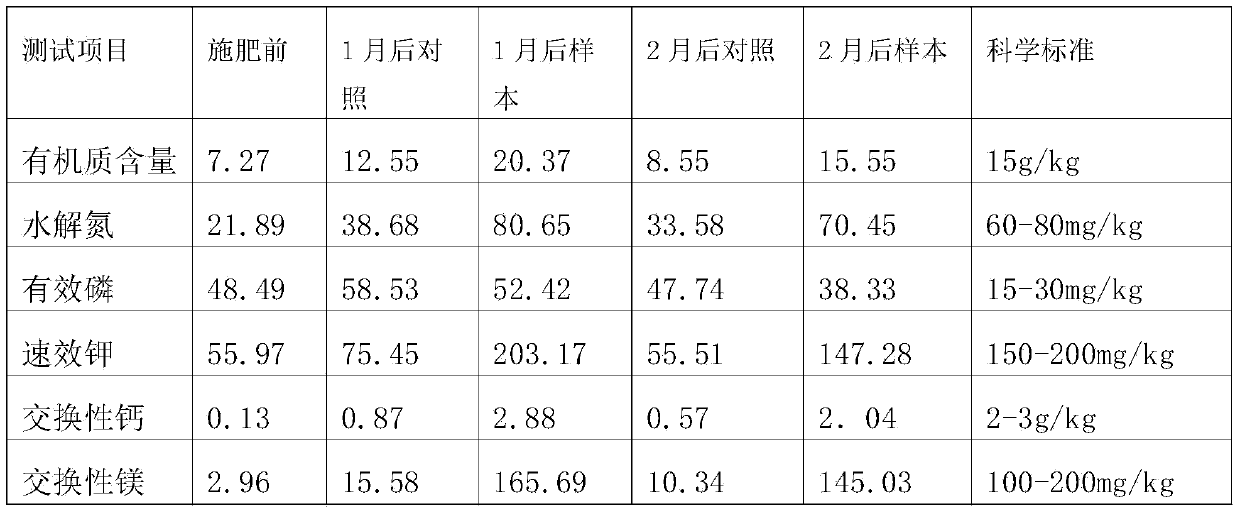

Fertilizer for rapidly improving sandy soil and preparation method thereof

A disclosed fertilizer for rapidly improving sandy soil comprises 2-4 parts of a rapid-release organic fertilizer(chicken manure, duck manure, pig manure, bean cakes and the like), 2-4 parts of a sustained-release organic fertilizer(crop straws, cow dung and the like), and 3-5 parts of a water-retaining fertilizer (turf or coconut shell powder). The fertilizer is capable of rapidly improving the fertilizer-retaining water-retaining capability of sandy soil and improving crop yield. A preparation method of the fertilizer comprises: airing 2-4 parts of the rapid-release organic fertilizer to a half-dry state, crushing 2-4 parts of the sustained-release organic fertilizer, mixing the rapid-release organic fertilizer with the sustained-release organic fertilizer, adding water to have the humidity of 60-70%, adding an EM microbial bacterial fertilizer according to a standard of 0.5-1 Kg of the microbial bacterial fertilizer for 1 cubic meter of the mixture, piling up fermentation piles and fermenting for 10-50 days, adding water into the water-retaining fertilizer to have the humidity of 80-90%, and uniformly mixing with the fermented fertilizer, so as to obtained the final fertilizer.

Owner:徐州绿维现代农业科技有限公司

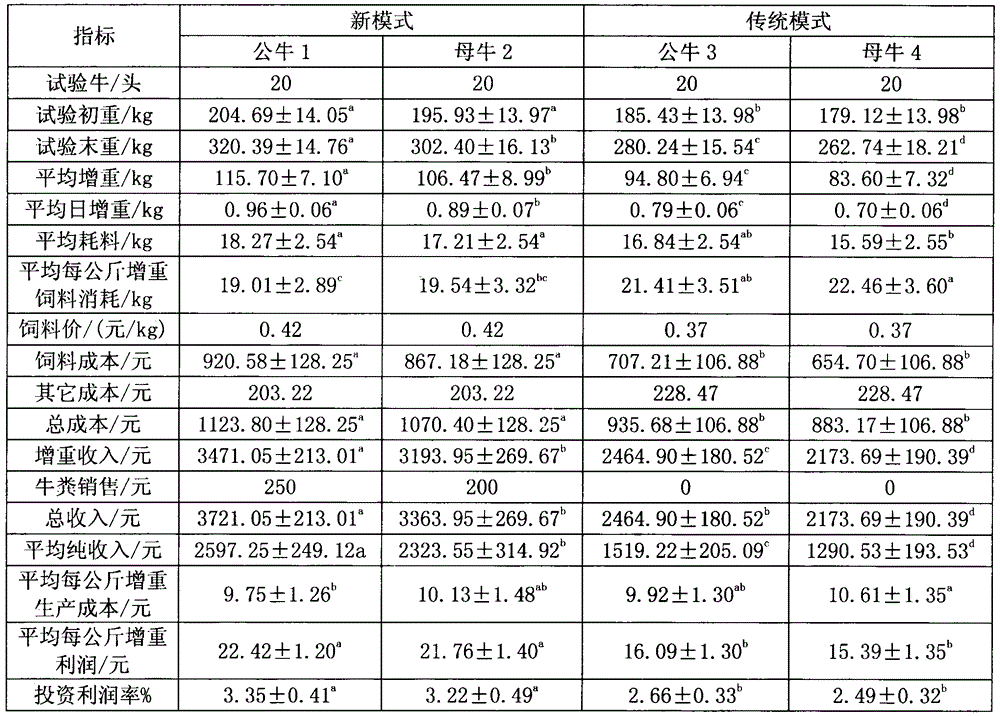

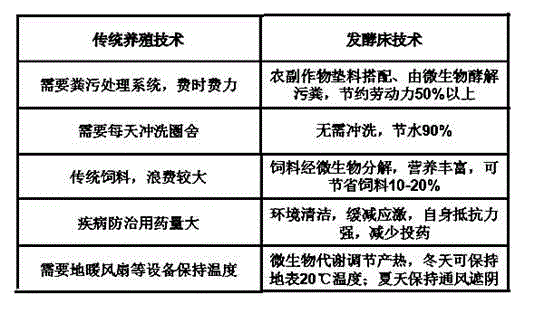

Micro-ecological beef cattle breeding technology and mode thereof

InactiveCN106359296AImprove qualityPromote growthFood processingAnimal feeding stuffEarly weaningAntibiotic Y

The invention discloses a micro-ecological beef cattle breeding technology and a mode thereof, and belongs to the technical field of beef cattle industry. The micro-ecological beef cattle breeding technology and the mode thereof provided by the invention adopt the traditional ecological breeding as the basis, are fused with a microbial full intervention method, a TMR feeding way, early weaning, cow body condition regulation and a postnatal care technology, adopt links of microbial treatment of feed nutrition, feeding environment, fecal treatment, disease prevention and control and the like, almost needs no stable flushing, and produces little sewage, so as to solve a problem of ammonia odor in a cattle breeding environment and realize clean breeding. According to the invention, non-nutritional additives (including antibiotics) for animal health are abandoned; the animal health dominated by microbial fermented traditional Chinese herbal medicines is innovated; the fermented traditional Chinese herbal medicines are mixed with feed for secondary fermentation; domestic vaccines and antibiotic-free Chinese patent medicines can be used safely, thereby both improving the quality of beef and solving the problem of epidemic diseases. The micro-ecological beef cattle breeding technology and the mode thereof provided by the invention improve the growth and reproduction performance of the beef cattle and improve the potential productivity of the beef cattle through combination driving of integrated technologies, so as to achieve a high-input, high-quality and high-yield benign production situation of beef cattle production.

Owner:来宾市畜牧站

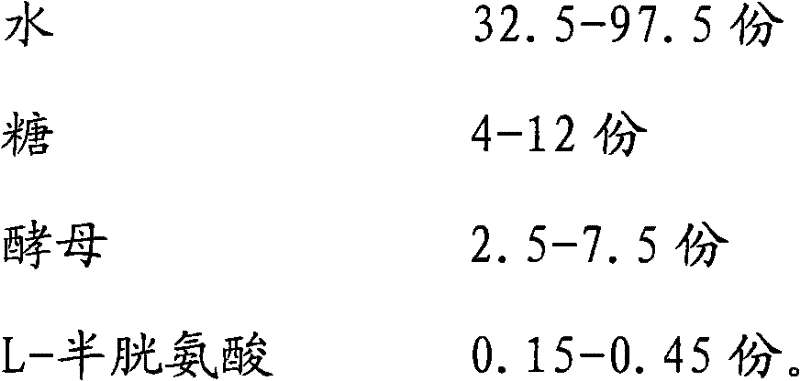

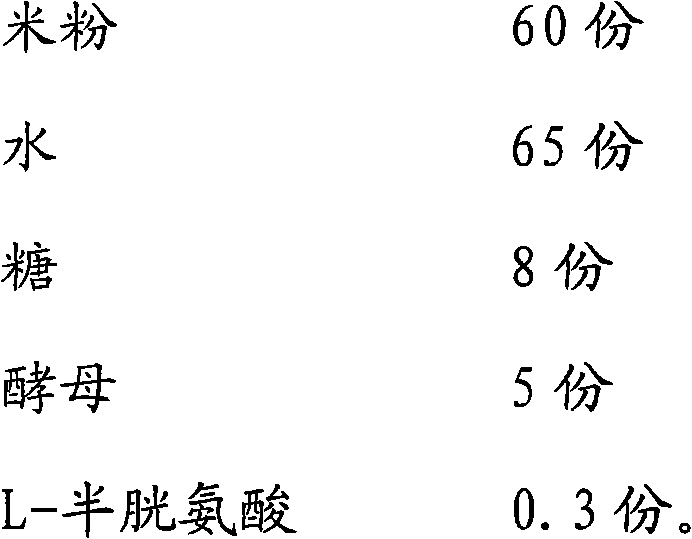

A kind of preparation method of pure rice flour bread and pure rice flour bread

InactiveCN102283269AChange structural propertiesIncrease gluten strengthBakery productsYeastGlutelin

The invention discloses a method for preparing pure rice flour bread and the pure rice flour bread prepared by the same, and relates to the technical field of food production. The method comprises the following steps of: (1) preparing rice flour by using fresh polished round-grained rice; (2) mixing the rice flour and an additive, and adding water and stirring to obtain a dough; (3) covering a preservative film on the prepared dough, standing and reacting; (4) adding water to dissolve a mixture of yeast and sugar, and stirring obtained solution and the dough which is stood and reacted; (5) dividing the dough in which auxiliary materials are added into block doughs, standing and fermenting; (6) spraying steam into a baking oven, regulating relative humidity, and putting the fermented blockdoughs into the baking oven and baking; and (7) cooling at normal temperature to obtain finished pure rice flour bread. By the method, after the additive, namely L-homocysteine is added, the structural performance of glutelin in rice flour can be effectively changed, the gluten strength of the rice flour during water adding can be effectively increased, the gluten structure of the rice flour bread cannot be collapsed in fermentation and baking processes, and finally various properties of the pure rice flour bread are effectively improved.

Owner:汪琳

Milk-cow breeding method without clearing cow dung

InactiveCN103947562APromote milk productionReduce stressBio-organic fraction processingAnimal housingMilk cow'sAgricultural engineering

The invention relates to the field of breeding, in particular to a milk-cow breeding method without clearing cow dung. The milk-cow breeding method comprises the following steps of laying fermented padding in a cowshed, wherein the padding is obtained through fermentation, and the padding is made by fermenting the following raw materials in parts by weight: 20 parts of chaff, 55 parts of sawdust, 4 parts of rice bran, 20 parts of cornstalk or peanut coat powder and 0.5 to 1 part of zymogenic agent; stirring the padding after laying, stacking the padding to be trapezoidal, continuously sprinkling water in the stacking and stirring processes to keep the moisture of the padding to be 45 to 50 percent, covering sackcloth around for heat preservation after stacking, and beginning fermentation for four to ten days; laying, spreading and laying the fermented padding in the cowshed. A fermenting-bed breeding technology comprises the processes that wood chips, rice husks, straws as well as agricultural and sideline products which are mixed with strains are used as the padding, the excreta of livestock are changed into valuables by utilizing the function of microbial glycolysis and are reutilized. Therefore, zero emission and zero pollution are truly realized.

Owner:徐美庆

Method of preparing fertilizer by fermenting tobacco waste, phosphogypsum and muck

InactiveCN1923762AImprove microbial activityIncrease calcium cationBio-organic fraction processingOrganic fertiliser preparationNicotiana tabacumAgricultural engineering

The invention discloses a fertilizer preparing method of fermented tobacco waste, phosphogypsum and slurry, which comprises the following parts: 63-69% tobacco waste, 3-6% phosphogypsum, 28-31% slurry, wherein the moisture of organic composite fertilizer is about 70% with even ingredient of N at 0.7-0.8%, P2O5 at 0.38-0.40% and K2O at 0.7-0.8.

Owner:青岛海联植物科技研究所 +1

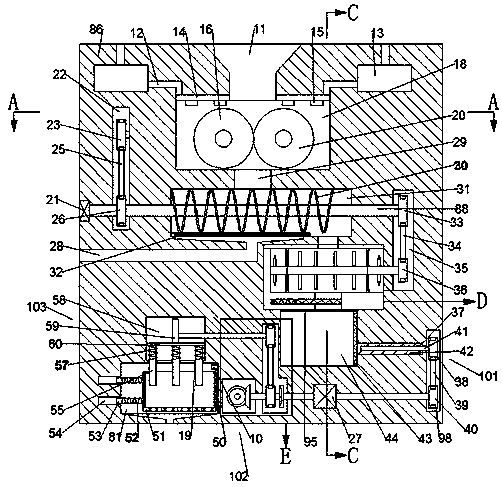

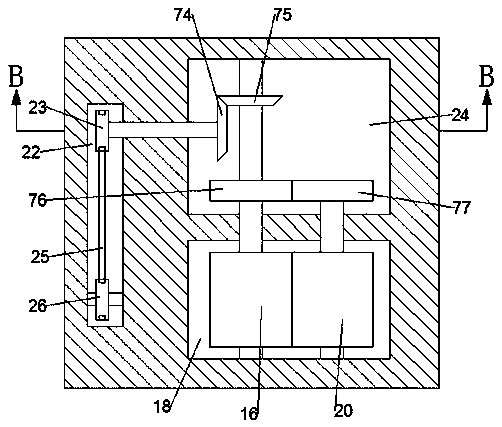

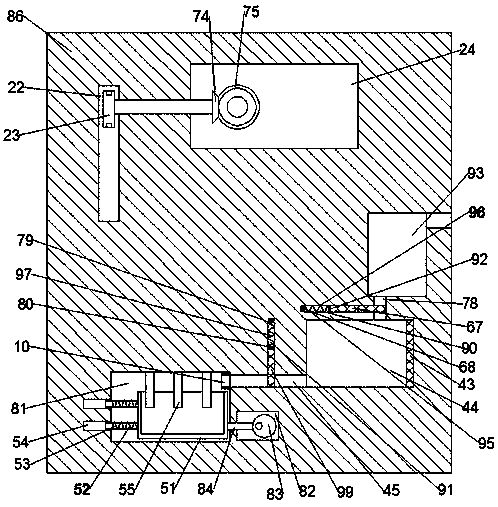

Device for preparing fertilizer from kitchen garbage

InactiveCN111499424AGood for fallingSimple structureBio-organic fraction processingClimate change adaptationAgricultural engineeringBiology

The invention discloses a device for preparing a fertilizer from kitchen garbage. The device comprises a fermentation box; a crushing cavity is formed in the fermentation box, a solid-liquid separation cavity is formed in the lower side of the crushing cavity, a stirring cavity is formed in the lower side of the solid-liquid separation cavity, drying cavities are symmetrically formed in the left side and the right side of the stirring cavity, a fermentation cavity is formed in the lower side of the stirring cavity, an enzyme storage cavity is formed in the rear side of the fermentation cavity,and a granulation cavity is arranged on the left side of the fermentation cavity. Kitchen garbage is crushed through crushing rollers and oil stains are removed from the kitchen garbage; excessive water is discharged through solid-liquid separation, the separated kitchen garbage is dried, a fermentation enzyme can be quantitatively added during fermentation, then the kitchen garbage is fermentedinto a fertilizer, out-pushing, vibration and granulation of the fertilizer are controlled through a motor, and control is simpler and faster.

Owner:临海永存智能技术有限公司

Method for producing fermented feed protein by adopting mobile fermentation

InactiveCN103766601AIncrease production costEasy feedingAnimal feeding stuffBiotechnologyNutritive values

The invention relates to a method for producing fermented feed protein by adopting mobile fermentation, and belongs to the technical field of feed processing. The method comprises the following concrete steps: by adopting plant feed protein or a mixture of plant feed protein and low-value aquatic product protein as a fermentation raw material, inoculating bacillus, yeasts and lactic acid bacteria, adding water, uniformly mixing, and controlling the water content of a uniformly mixed material to be 50%-70%; adding an oxygen producer, a water absorbent and water into a waterproof breathable film bag, sealing, and putting the sealed waterproof breathable film bag into a silica gel breathable film feed fermentation bag; putting the mixed fermentation raw material into the silica gel breathable film feed fermentation bag with the oxygen producer, and sealing for fermenting at 20-40 DEG C for 2-10 days. According to the method, the mixed fermentation raw material is bagged and transported to a farm and then is directly used, the fermentation of the mixed fermentation raw material in transportation and storage processes is automatically finished, the process is simple, the cost is low, and the fermented feed protein is high in nutritional value and good in raising effect.

Owner:ZHANJIANG EVERGREEN AQUATIC +1

Novel method for extracting fulvic acids from industrially-produced waste edible fungi residues by fermentation

InactiveCN105331669ATake advantage ofEfficient use ofMicroorganism based processesFermentationBiotechnologyCandida tropicalis

The invention relates to a novel method for extracting fulvic acids from industrially-produced waste edible fungi residues by fermentation. The novel method includes the steps of (1) preparing a primary seed solution; (2) preparing a secondary seed solution; (3) inoculating the secondary seed solution, bacillus subtilis, candida tropicalis and trichoderma pseudokoningii into a 1000-2000L of fermentation tank respectively and fermenting for 10-15 days so as to obtain a fermented seed solution; (4) treating pleurotus ostreatus residues; (5) inoculating the fermented seed solution into the pleurotus ostreatus residues to be inculated, and fermenting at the temperature 20-40 DEG C aerobically for 4-5 days so as to obtain fermented fungi residues; (6) extracting the fulvic acids; (7) performing spray drying so as to obtain flavescent fulvic acid powder. The fulvic acid content can be above 35% after fermentation, and yield of crude fulvic acids can be up to about 30% (dry matter percentage) through extraction.

Owner:SHANDONG UNIV

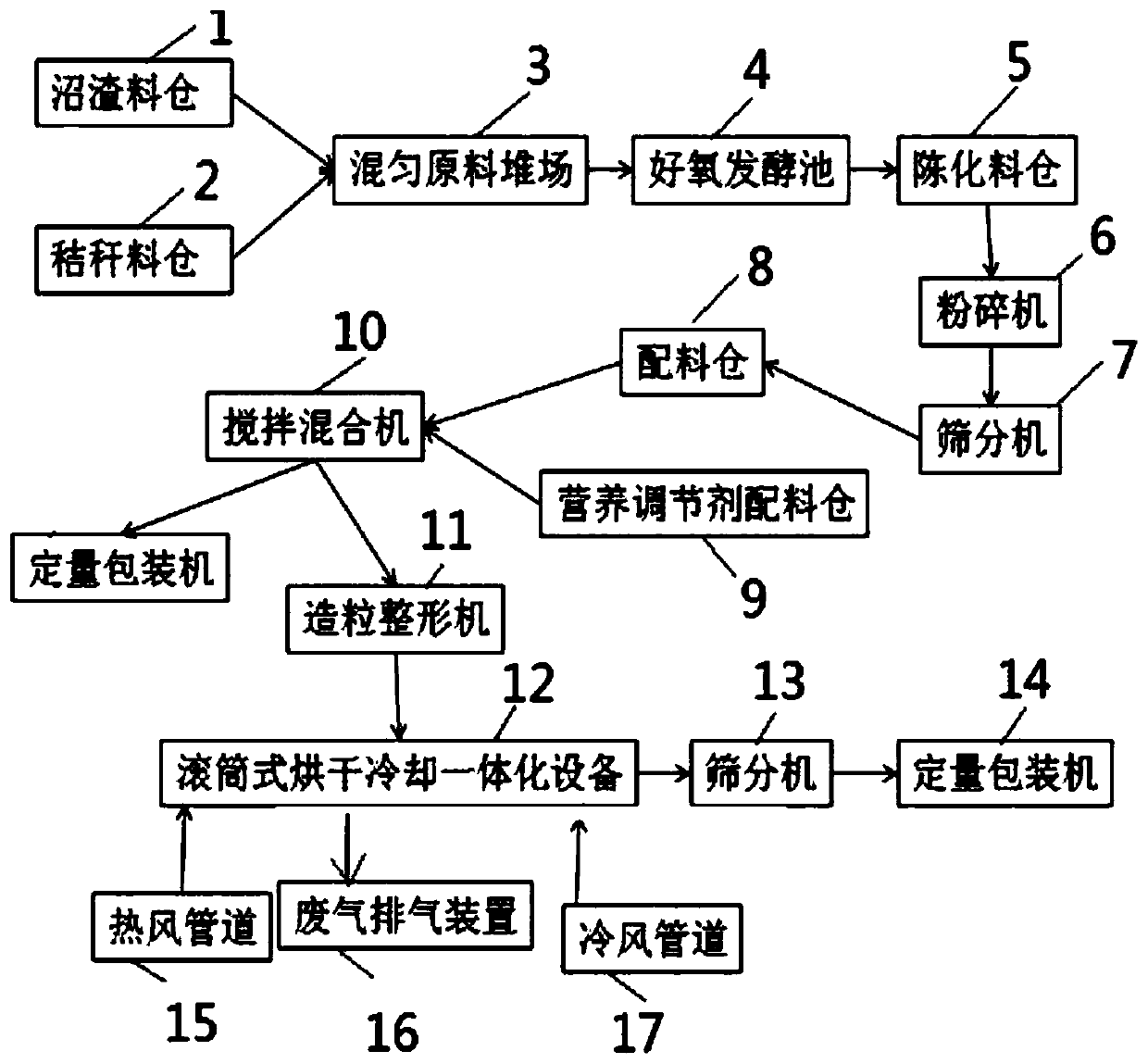

Production technology for producing solid organic fertilizer from anaerobic biogas residues

InactiveCN110407622AWon't burnShort fermentation cycleBio-organic fraction processingChemical industryOrganic fertilizerFermentation

The invention discloses a production technology for producing a solid organic fertilizer from anaerobic biogas residues. The technology comprises the following steps: blending of raw materials, distribution and aerobic fermentation of the obtained mixture, secondary aging of a material obtained after the aerobic fermentation, preparation of a powdery fertilizer, and preparation of the granular fertilizer. The production technology provided by the invention is perfect and economical, rationally utilizes biogas residues and straws, and also has the advantages of short production cycle, energy saving and environmental protection. The organic fertilizer produced by the technology has a high production efficiency and a good fertility.

Owner:JIANGSU YIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

Convenient and nutritional sweet rice wine and making method

Convenient and nutritional sweet rice wine comprises the following components in parts by weight: 5-10 parts of sweet rice wine, 1-5 parts of Fructus Lycii, 1-5 parts of Radix Angelicae Sinensis and 1-5 parts of Radix Codonopsis. The making method comprises the following steps: weighing sticky rice according to weight proportion, cleaning and soaking for 10-24 hours; draining the soaked sticky rice, and steaming into rice with steam; pouring steamed rice into a fermenting container, adding distiller's yeast, stirring evenly and fermenting for the first time for about 24 hours to obtain the sweet rice wine; taking the raw materials including the Fructus Lycii, the Radix Angelicae Sinensis and the Radix Codonopsis in parts by weight, and shredding the raw materials together; pouring the three shredded materials into the fermented sweet rice wine, and stirring evenly; mixing and fermenting for the second time for 6-9 days; separating sweet vinasse from sweet wine of the mixed raw materials; heating the separated sweet wine to the temperature of 100 DEG C and stopping fermenting; packing the cooled sweet wine to obtain sweet bag-packed or box-packed sweet wine products; and after stripping and slicing the separated sweet vinasse, processing the sweet vinasse into vinasse blocks in a quick-freezing mode, and packing to obtain the bag-packed or box-packed vinasse block products. The sweet rice wine is convenient to carry and high in nutritional value.

Owner:东莞市恒运调味食品有限公司

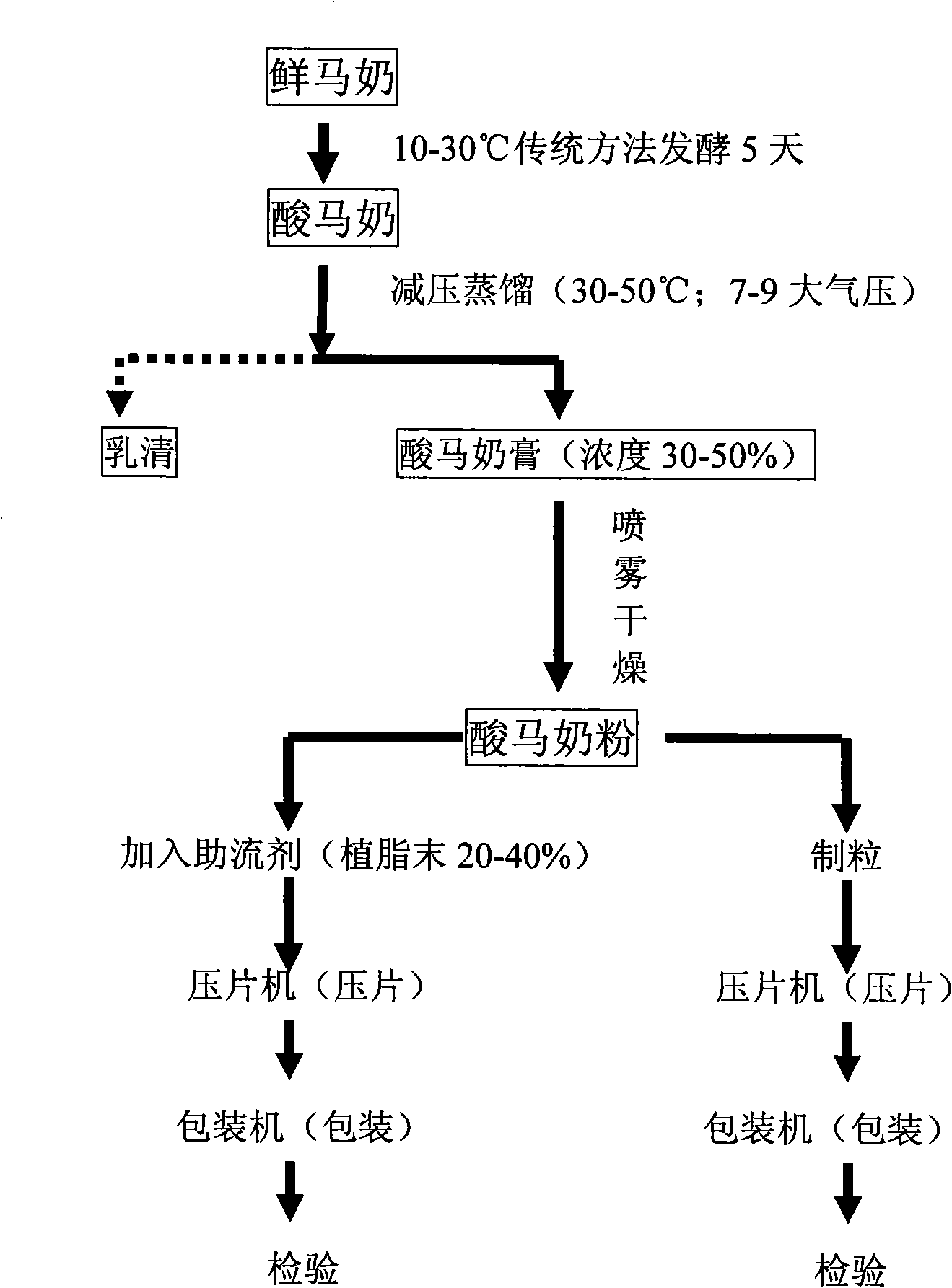

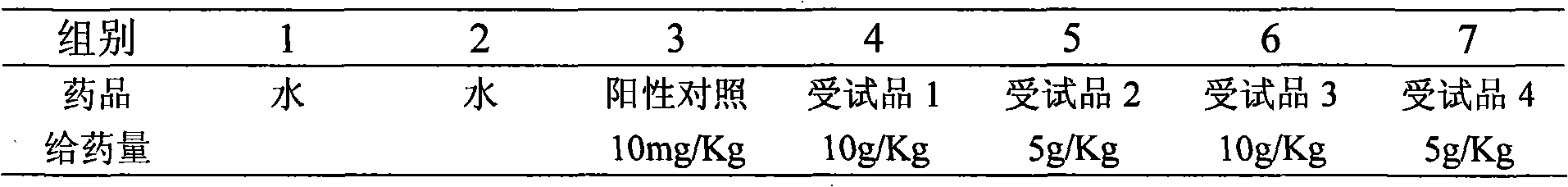

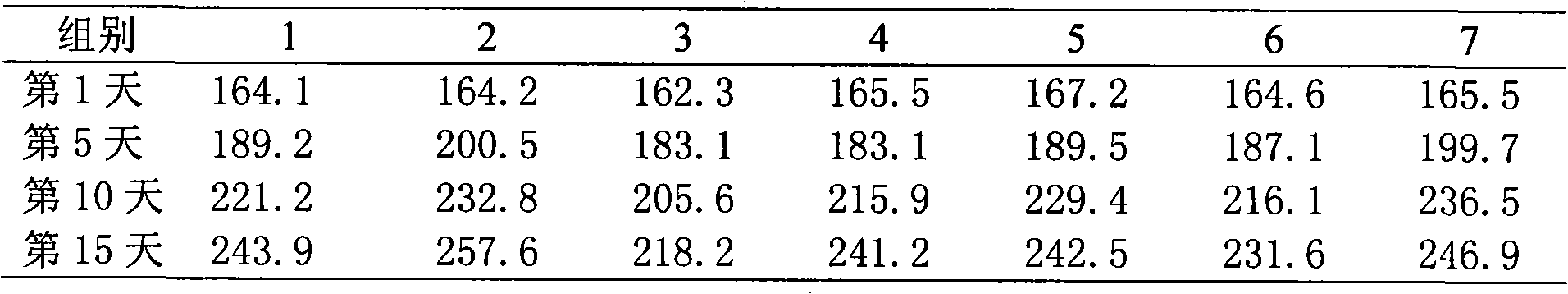

Active sour mare's milk slice and producing method and application thereof

InactiveCN101273784AHigh nutritional valueMilk preparationFood preparationBiotechnologyAdditive ingredient

The invention relates to an active fermented milk slice of mares and a producing method and application thereof; the active fermented milk slice of mares comprises the ingredients that: 60 percent to 80 percent of dry powder of fermented milk of mares and 20 percent to 40 percent of edible non-dairy creamer; the producing method comprises the following steps: (1) fresh milk of mares is collected and filtered; (2) the filtered fresh milk of mares is fermented for 3 to 7 days by the traditional method at the temperature of 10 DEG C to 30 DEG C; (3) the fermented milk of mares after fermentation is inspected from three aspects of sensory index, physiochemical index and bacterial index; (4) the qualified, fermented and fresh fermented milk of mares is distilled in a vacuum distillation tower, wherein, the distilling temperature is 30 DEG C to 50 DEG C, the degree of vacuum is 7 to 9 atmospheres, and the liquid fermented milk of mares is concentrated into fermented milk paste of mares occupying 20 percent to 40 percent of original volume; (5) the fermented milk paste of mares is taken and sprayed into a spray tower by a high pressure pump, thus obtaining spray dry powder; (6) the spray dry powder and the edible non-dairy creamer are placed in a mixer, granulated after being mixed, squashed, packed and inspected by quality finally; the invention also provides the application of the active fermented milk slice of mares in the process of manufacturing health products used for regulating blood-fat.

Owner:INNER MONGOLIA UNIVERSITY

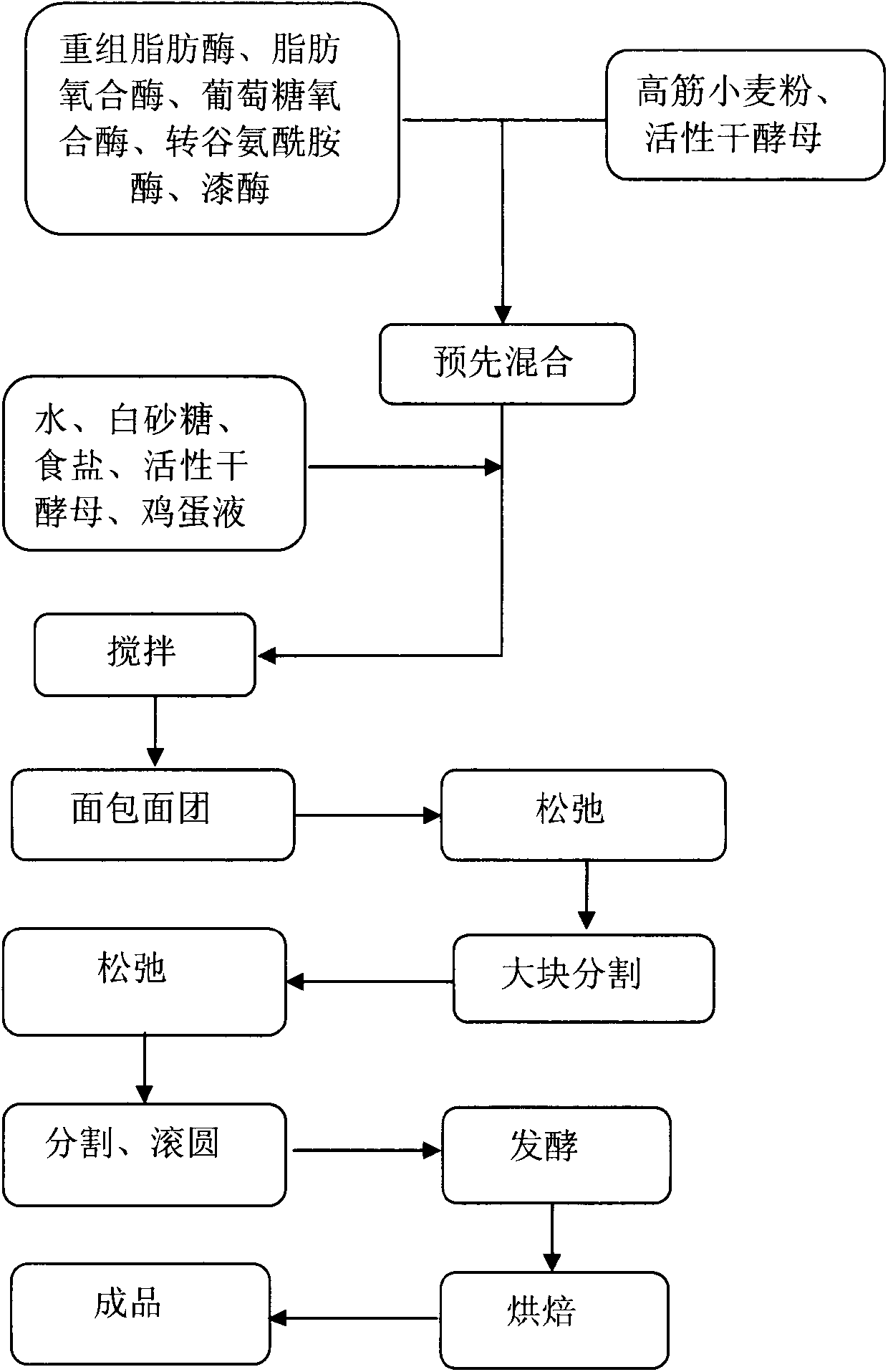

Method for improving viscoelastic behavior of bread dough by employing complex enzyme preparations containing recombined lipase

InactiveCN104186597AImprove qualityGood viscoelastic propertiesPre-baking dough treatmentGlutaminaseFermentation

The invention relates to a method for improving viscoelastic behavior for bread dough by employing complex enzyme preparations containing recombined lipase and belongs to the technical field of food processing. The method includes uniformly pre-mixing high and pouring gluten wheat flours, active dry yeasts, the recombined lipase, lipoxygenase, transglutaminase and laccase in a stirring bowl, then adding water, egg liquid, white sugars and salts in the mixture to stir, and adding shortening in the mixture to stir, so that the bread dough is achieved; after standing, dividing and rolling the bread dough; placing the dough in a fermenting box for fermentation; finally placing the fermented dough in an oven to achieve the final product. By applying the complex enzyme preparations such as the recombined lipase, the lipoxygenase, glucose oxidase, the transglutaminase and the laccase, gluten network structure of the bread dough is increased, and the viscoelastic behavior is improved, thus product quality is enhanced, and the problem of poor bread quality caused by insufficient flour strength during bread production is solved; and meanwhile, the chemical gluten strengthening agent is replaced by the biological enzyme preparations applied to fermented flour food, thus food safety is enhanced, and the method is safe.

Owner:JIANGNAN UNIV +2

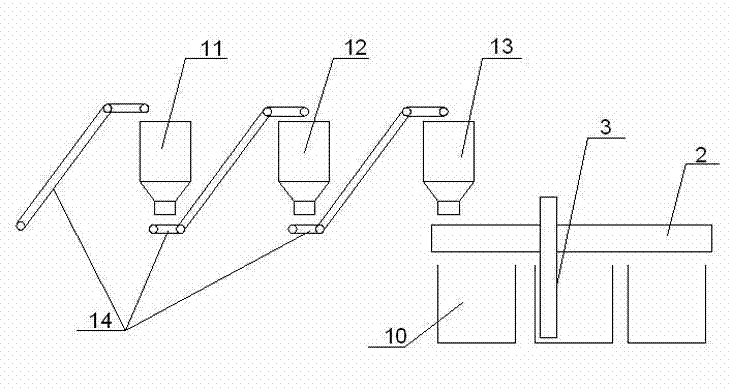

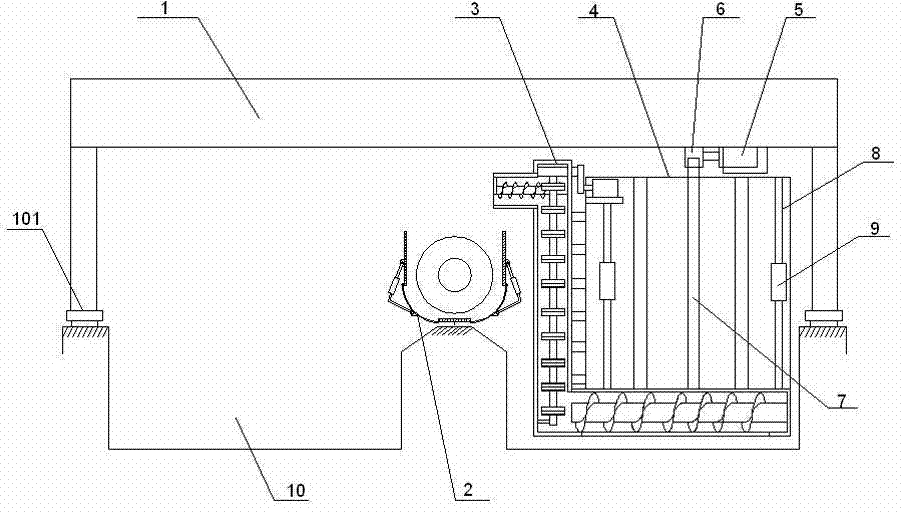

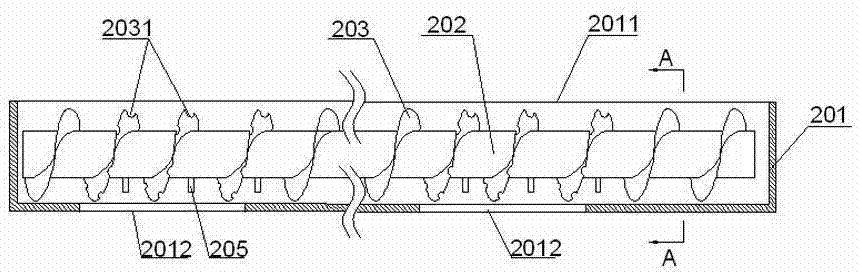

Front conveying and lifting transferring system for processing straw

InactiveCN102925338AGuaranteed fluencyImprove delivery efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringConveyor belt

The invention provides a front conveying and lifting transferring system for processing straw. The front conveying and lifting transferring system mainly comprises a crushing mechanism, a distributing bin, a mixing bin, a crushed material conveying device, a fermenting tank and a lifting device; the crushing mechanism, the distributing bin and the mixing bin are sequentially connected in series by conveyor belts; after being cut by the crushing mechanism, the straw sequentially passes through the distributing bin and the mixing bin by the conveyor belts and then is processed by the mixing bin and conveyed into the crushed material conveying device; the lifting device comprises a moving frame, a material transferring device, a supporting frame and a lifting mechanism which are transversely spanned on the fermenting tank; the material transferring device is moved to a part above a specified fermenting tank by the moving frame, and then is moved into the fermenting tank to transfer the fermented crushed straw by the lifting mechanism. By adopting the system, automatic operation steps of crushing straw, storing, mixing and agitating crushed material and culture, blanking during conveying, controlling, and transferring the fermented material straw can be achieved; and moreover, the system is high in conveying efficiency, so that a performance of the whole system can be improved.

Owner:洛阳市光瑞农业科技有限公司

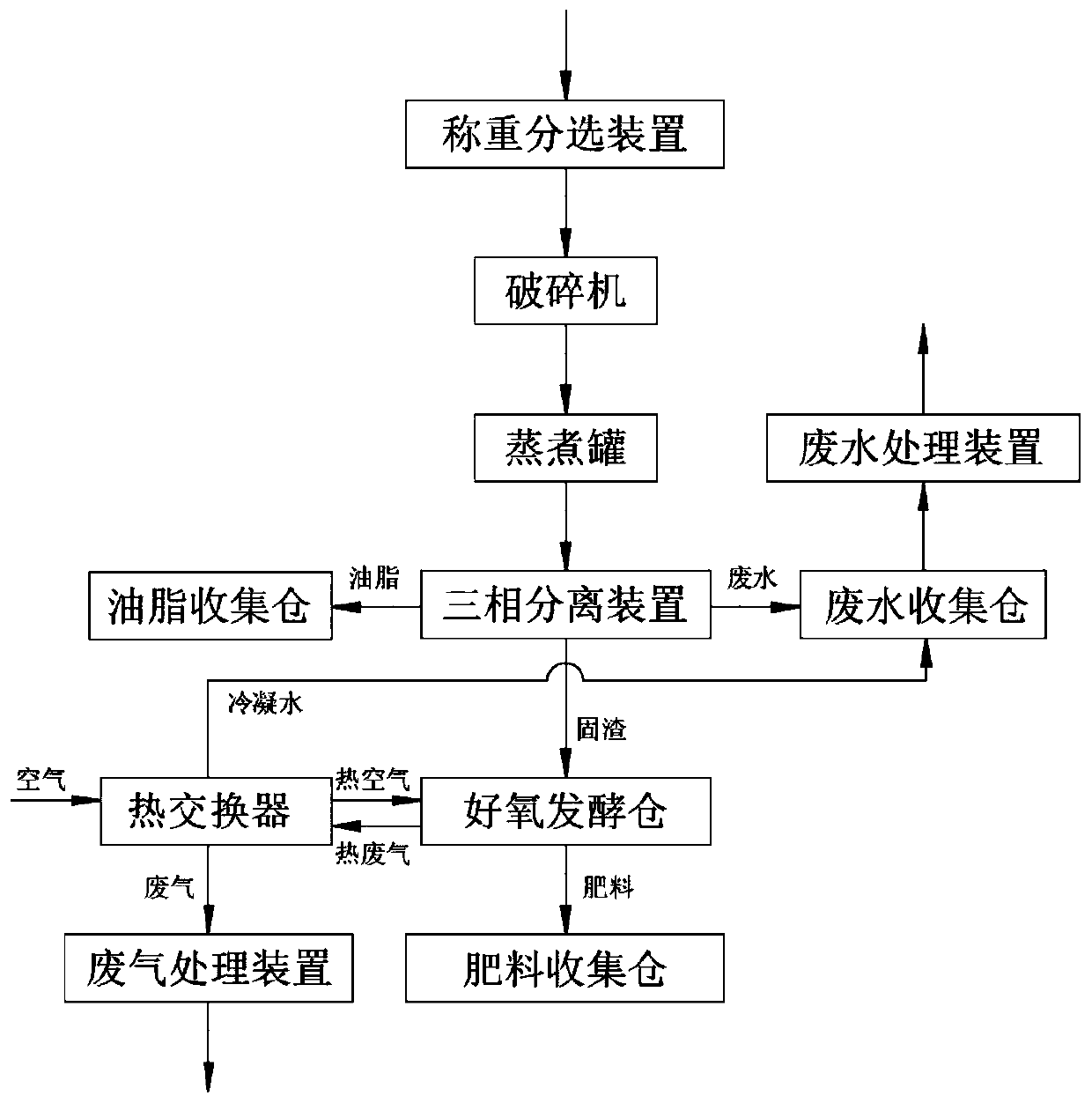

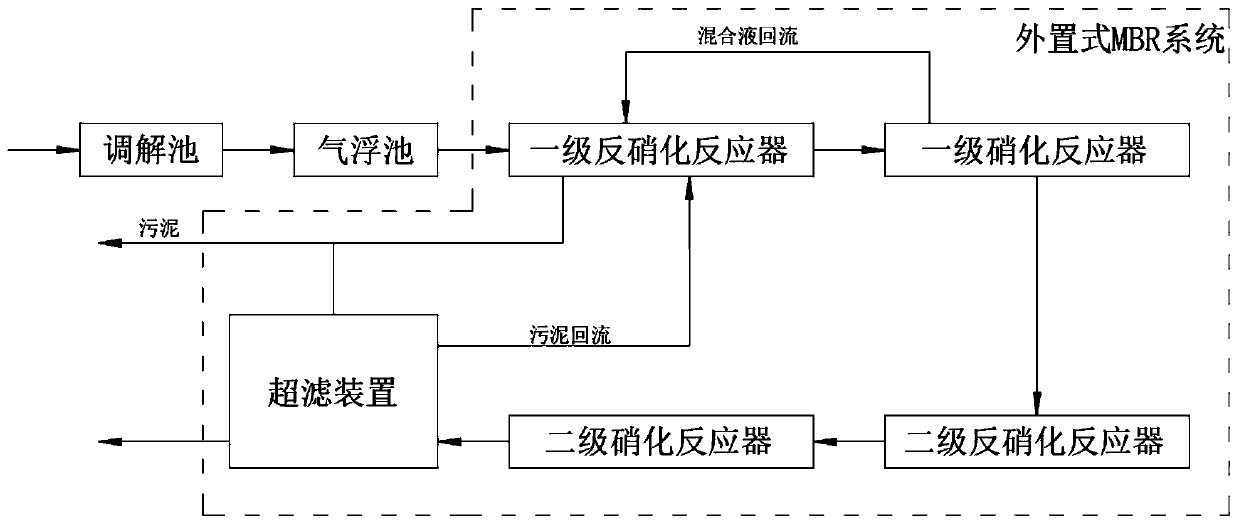

Kitchen waste aerobic fermentation system and process

PendingCN111233528AReduce processing costsLower requirementClimate change adaptationChemical industryOil and greaseExhaust fumes

The invention relates to kitchen waste aerobic fermentation system and process. The aerobic fermentation system sequentially comprises a weighing and sorting device, a crusher, a cooking pot, a three-phase separation device and an oxygen-generating fermentation bin according to a treatment route. The aerobic fermentation process comprises the steps of weighing and sorting, crushing, cooking and three-phase separation; aerobic fermentation on solid residues, collection of grease and treatment of wastewater; aerobic fermentation waste gas treatment; and collection of an aerobic fermentation product as a fertilizer. According to the kitchen waste aerobic fermentation system and process, the grease precipitation amount of kitchen waste is increased, the three-phase separation effect is improved, and the requirement for follow-up treatment equipment is lowered; besides, the heat loss is greatly reduced, and a good energy-saving effect is achieved; the process flow of aerobic fermentation isperfected, so that the whole system and process are harmless, and the influence on the environment is reduced; separated grease is collected; in addition, the solid-liquid mixture fermented by the aerobic fermentation bin is used as a fertilizer, so that economic benefits can be generated, resource reutilization is maximized, and the kitchen waste treatment cost is reduced.

Owner:上海龙马环境科技有限公司

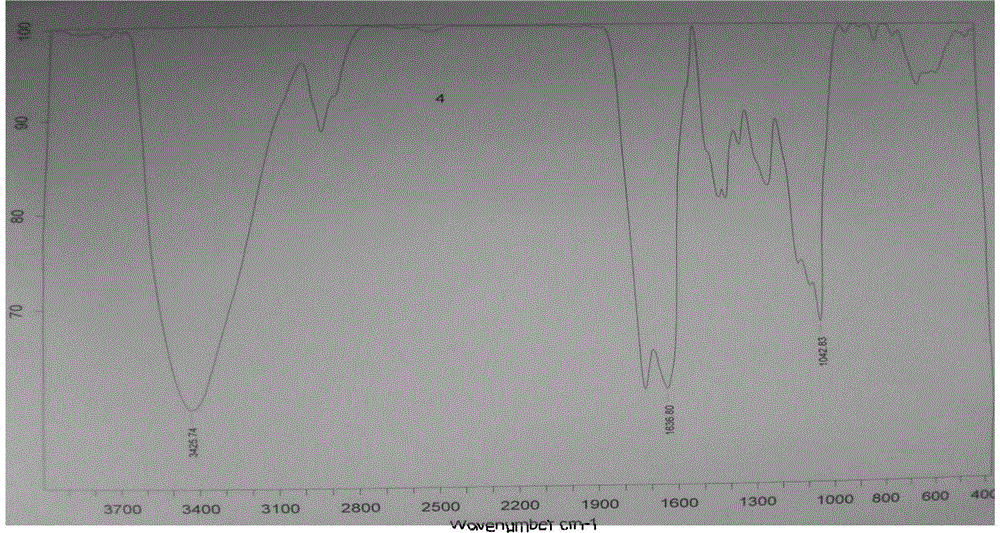

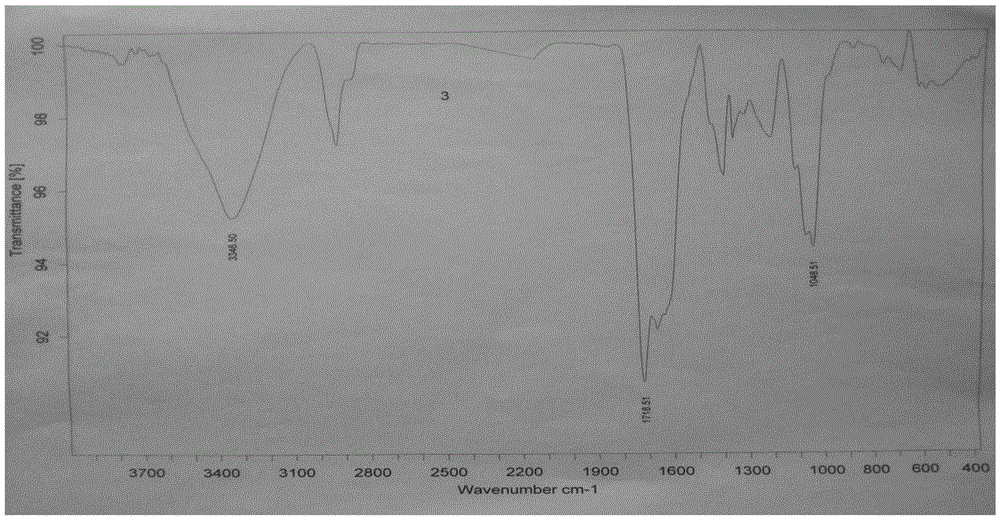

Preparation process of lactic acid bacteria lysis complex

InactiveCN111334450ASuitable for efficient preparationSimple processBacteriaMicroorganism lysisBacilliFermentation gut

The invention provides a preparation process of lactic acid bacteria lysis complex, relates to an extraction technology of a microbial complex, and in particular relates to a preparation process of the lactic acid bacteria lysis complex. The complete simplified process for the extraction of the lactic acid bacteria lysis complex is provided. The preparation process comprises the following steps: preparing a seed solution: inoculating lactobacillus plantarum, bifidobacterium longum and lactobacillus paracasei in MRS test tube culture media respectively, performing culture at 37-38 DEG C for 22-26 h, inoculating the test tube strain to a triangular flask liquid MRS culture medium for fermentation culture, and performing culture at 37-38 DEG C for 35-38 h; performing fermentation: inoculatingthe seed liquids into a fermentor according to the inoculation amounts, and performing anaerobic fermentation; performing homogenization wall breaking: performing treatment on the fermented lactic acid bacteria fermentation liquid in a high-pressure homogenizer, and performing homogenization wall breaking to obtain a broken-wall liquid; performing centrifugation: performing centrifugation on thehomogenized broken-wall liquid in a tubular centrifuge to obtain a broken-wall supernatant after centrifugation; and performing filtration: performing filtration on the centrifuged broken-wall supernatant in a food-grade liquid filter to obtain the lactic acid bacteria lysis complex. The method provided by the invention is simple, the process is simplified, and the operation is easy.

Owner:YANGZHOU ZHENWEI BIOTECH CO LTD

Method for producing fuel ethanol by using chemical method and microorganism to comprehensively treat banana stalk

InactiveCN101260413AYou supplement the defect of low glycation rateHigh yieldBiofuelsMicroorganism based processesMicroorganismYeast

The invention discloses a method for processing banana stalks with integrated treatment by chemical method and microbiology to prepare fuel ethanol, comprising the following steps of: (1) cutting the banana stalks, adding sodium hydroxide solution with the mass concentration between 1 and 11 percent, hydrolyzing for 1 to 6h under the condition between 25 and 45 DEG C, and regulating the pH value of hydrolysate between 6.0 and 8.0 after hydrolyzing; (2) processing the pretreated banana stalks to be inoculated with microbial solution and added with yeast to lead the mass ratio of the banana stalks to microbial solution to the yeast of 1 to between 0.1 and 0.5 to between 0.01 and 0.05; (3) processing the inoculated banana stalks to be evenly agitated and filled into a fermentation vessel, and processing closed fermentation for 15 to 30 days under the condition between 25 to 30 DEG C; (4) preparing the fuel ethanol by atmospheric distillation, which is to distill the fermented material to acquire the fuel ethanol. The invention processes the banana stalks with the integrated treatment by the chemical method and the microbiology to enable the saccharification technology of the banana stalks to be easily operated so as to improve the saccharification rate, and shortens the period of using the banana stalks to prepare ethanol, thereby reducing the manufacturing cost of ethanol.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com