Novel method for extracting fulvic acids from industrially-produced waste edible fungi residues by fermentation

A technology of edible fungi and fulvic acid, applied in the biological field, can solve the problems of multiplication of bacteria, threats to the edible fungus industry, waste of organic resources, etc., and achieve the effect of creating economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

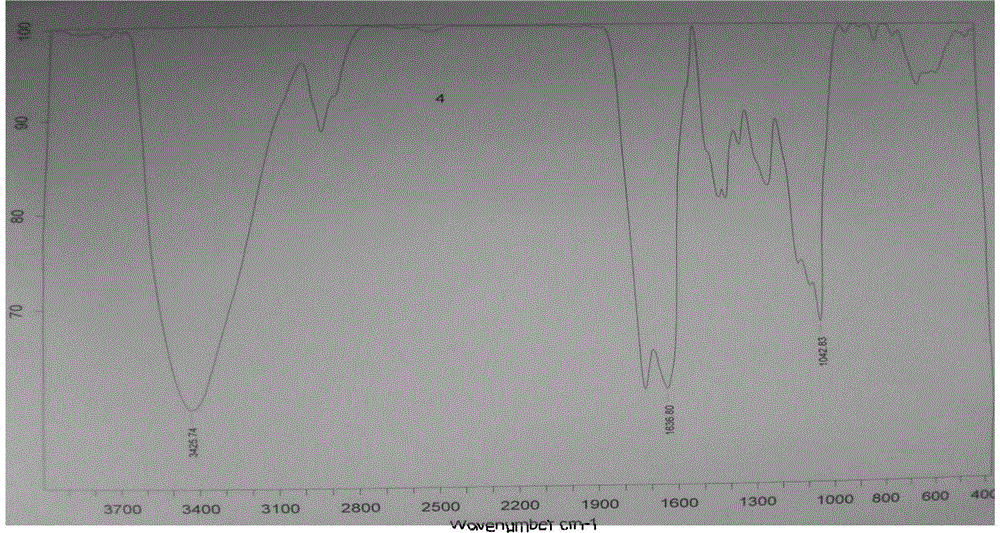

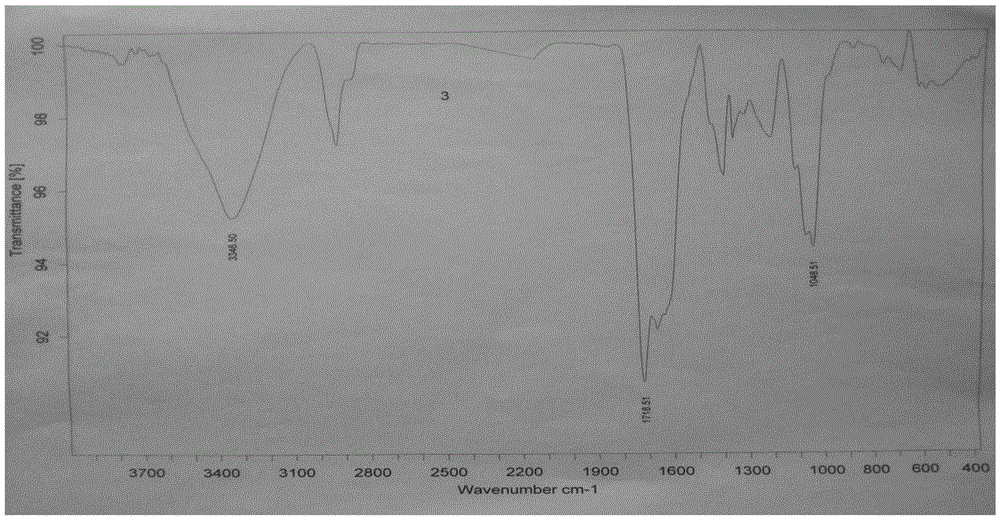

Image

Examples

Embodiment 1

[0033] 1 strain

[0034] Bacillus subtilis (Bacillus subtilis) is a strain numbered CGMCC1.210 of the China Microorganism Culture Collection Management Center; Bacillus subtilis CGMCC1.210 has a strong activity of producing α-amylase.

[0035] Trichodermapseudokoningii (Trichodermapseudokoningii) is a strain numbered CMCC3.6612 of the China Industrial Microbiology Culture Collection Management Center; it has a high cellulase activity

[0036] Candida tropicalis is a bacterial strain numbered CMCC2.402 in the China Industrial Microorganism Culture Collection and Management Center; it can assimilate five-carbon sugars.

[0037] 2 specific methods

[0038] (1) Medium: Bacillus subtilis seed medium: LB medium; Candida tropicalis, Trichoderma pseudoconii seed medium: PDA medium;

[0039] (2) Preparation of primary seed liquid: Inoculate Bacillus subtilis in LB medium and incubate at 32°C for 18 hours, inoculate Candida tropicalis and Trichoderma pseudoconii into PDA respectively,...

Embodiment 2

[0057] The processing steps are the same as in Example 1, except that the edible fungi are oyster mushrooms.

Embodiment 3

[0059] The processing steps are the same as in Example 1, except that the edible mushroom is Pleurotus eryngii.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com