Method for improving viscoelastic behavior of bread dough by employing complex enzyme preparations containing recombined lipase

A compound enzyme preparation and bread dough technology, applied in the field of food processing, can solve problems such as carcinogenicity, and achieve the effects of improving viscoelastic properties, improving quality and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

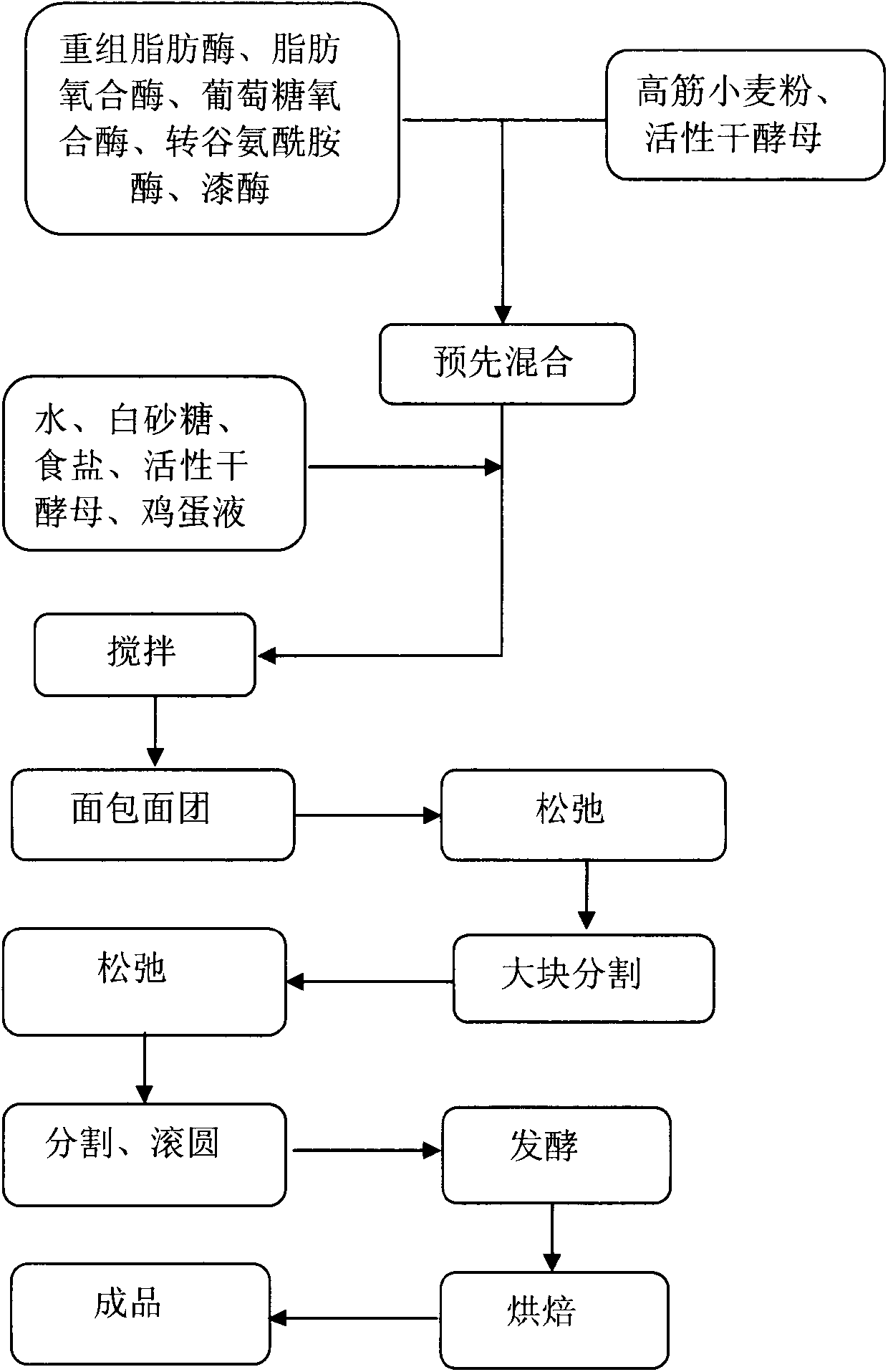

Image

Examples

Embodiment 1

[0019] In this example, 47 parts of high-gluten wheat flour, 34 parts of water, 5 parts of white sugar, 7 parts of shortening, 0.3 parts of table salt, 0.5 parts of active dry yeast, and 0.5 parts of egg liquid : 5.5 parts, recombinant lipase: 0.001 parts, lipoxygenase: 0.003 parts, glucose oxidase: 0.004 parts, transglutaminase: 0.662 parts, laccase: 0.03 parts.

[0020] Take high-gluten wheat flour, active dry yeast, recombinant lipase, lipoxygenase, glucose oxidase, transglutaminase and laccase, and pre-mix evenly; then pour in water, white sugar, salt and egg liquid and stir Stir in the tank at a slow speed for 3 minutes, then stir quickly for 2 minutes; add shortening, stir at a slow speed for 1 minute, and then stir quickly for 3.5 minutes to obtain bread dough; take out the dough, let it rest for 10 minutes at room temperature, then divide it into large pieces, and then After 10 minutes of relaxation, spread the large piece of dough in a dough divider and rounder, divid...

Embodiment 2

[0022] In this example, 52 parts of high-gluten wheat flour, 27 parts of water, 8 parts of white sugar, 8 parts of shortening, 0.6 parts of table salt, 0.75 parts of active dry yeast, and 0.75 parts of egg liquid : 3 parts, recombinant lipase: 0.005 parts, lipoxygenase: 0.001 parts, glucose oxidase: 0.005 parts, transglutaminase: 0.61 parts, laccase: 0.029 parts.

[0023] Take high-gluten wheat flour, active dry yeast, recombinant lipase, lipoxygenase, glucose oxidase, transglutaminase and laccase, pre-mix evenly; then pour in water, white sugar, salt and egg liquid and stir Stir in the cylinder for 1.5 minutes at a slow speed and then stir for 3.5 minutes quickly; add shortening, stir for 2.5 minutes at a slow speed and then stir for 2.5 minutes quickly to obtain bread dough; take out the dough, let it rest for 12 minutes at room temperature, then divide it into large pieces, and then After 8 minutes of relaxation, spread the large piece of dough in a dough divider and rounde...

Embodiment 3

[0025] In this example, take high-gluten wheat flour: 56 parts, water: 30 parts, white sugar: 2 parts, shortening: 2.7 parts, salt: 0.8 parts, active dry yeast: 1 part, egg liquid: : 7 parts, recombinant lipase: 0.001 parts, lipoxygenase: 0.005 parts, glucose oxidase: 0.001 parts, transglutaminase: 0.483 parts, laccase: 0.01 parts.

[0026] Take high-gluten wheat flour, active dry yeast, recombinant lipase, lipoxygenase, glucose oxidase, transglutaminase and laccase, pre-mix evenly; then pour in water, white sugar, salt and egg liquid and stir Stir in the cylinder for 2 minutes at a slow speed and then stir for 3 minutes quickly; add shortening, stir for 2 minutes at a slow speed and then stir for 3 minutes quickly to obtain bread dough; take out the dough, let it rest at room temperature for 15 minutes, then divide it into large pieces, and then After 5 minutes of relaxation, spread the large piece of dough in a dough divider and rounder, divide it into 70g sizes, and round i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com