Kitchen waste aerobic fermentation system and process

A technology of aerobic fermentation and kitchen waste, applied in the chemical industry, sustainable manufacturing/processing, organic fertilizers, etc., can solve the problems of restricting the processing effect of the processor, secondary pollution of the surrounding environment, and unfavorable microbial growth, etc., to reduce Treatment costs, increase in grease release, and effects of reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

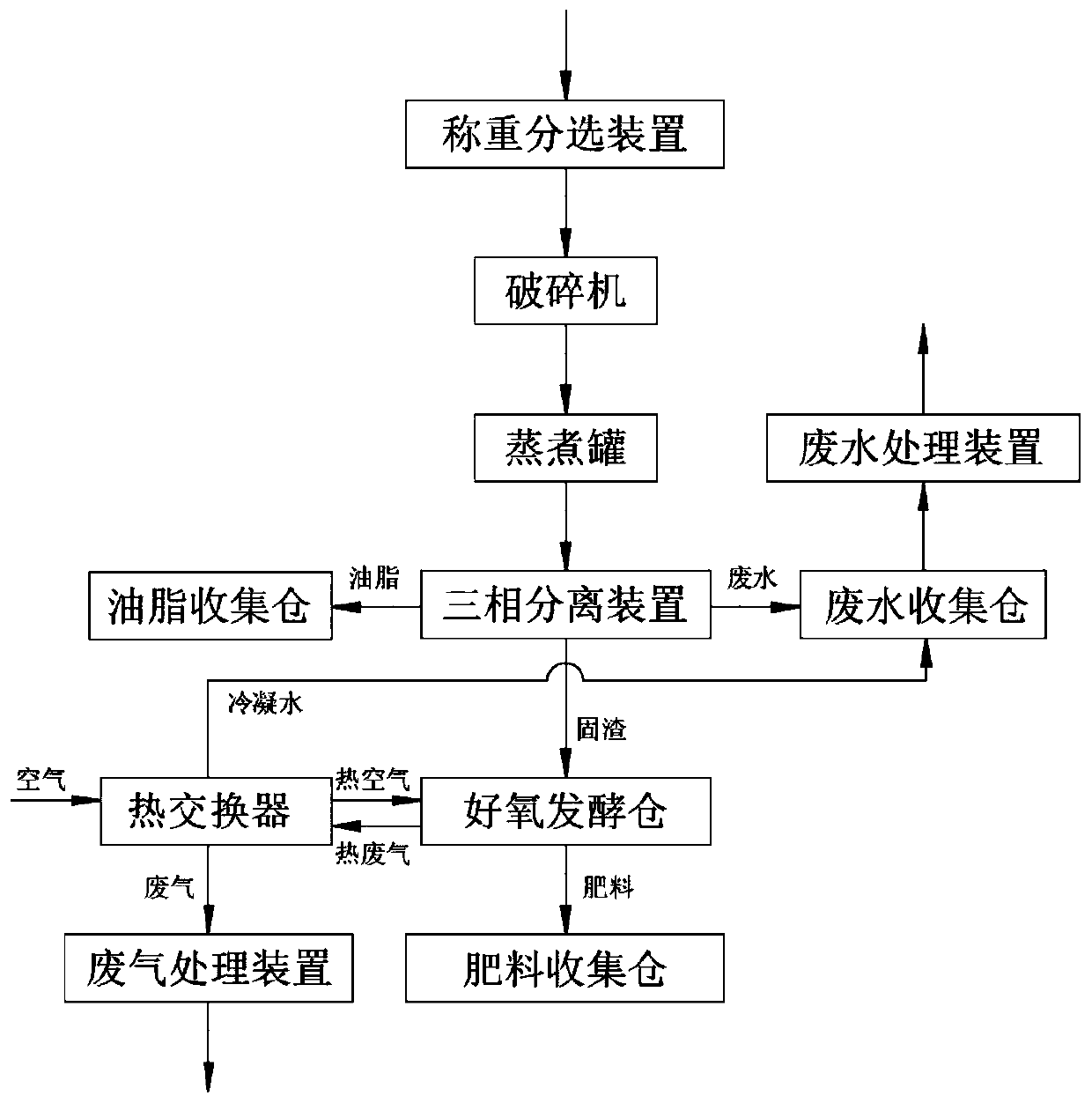

[0022] Such as figure 1 As shown, the present embodiment provides an aerobic fermentation system for food waste, which comprises a weighing and sorting device, a crusher, a cooking tank, a three-phase separating device, and an aerobic fermentation bin in sequence according to the processing route; The sorting device is used to weigh and sort the food waste; the crusher is used to receive and crush the food waste sorted by the weighing and sorting device; the cooking tank is used to heat, cook and pulverize the food waste Food waste; the three-phase separation device is used to separate solid residue, waste water and oil from the heated and cooked food waste; the aerobic fermentation bin is used to receive solid residue and carry out aerobic fermentation.

[0023] In the aerobic fermentation system for food waste in this embodiment, the aerobic fermentation system further includes a grease collection chamber for collecting the grease separated by the three-phase separation devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com