Patents

Literature

37results about How to "Rich technical means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

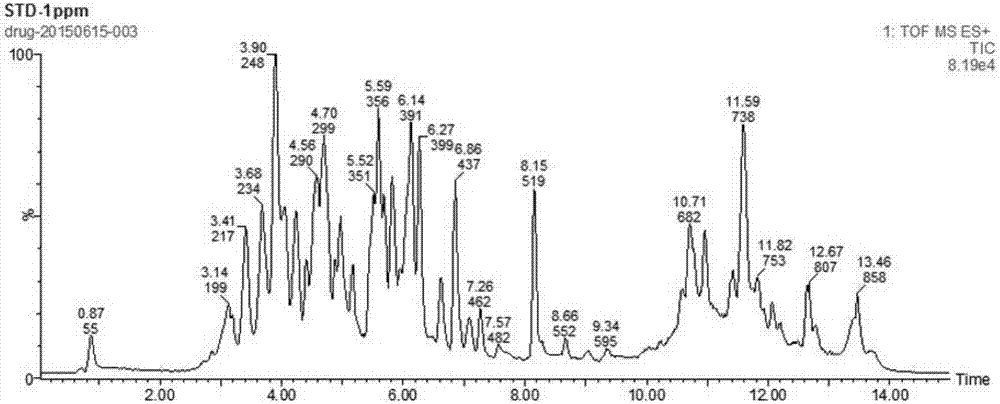

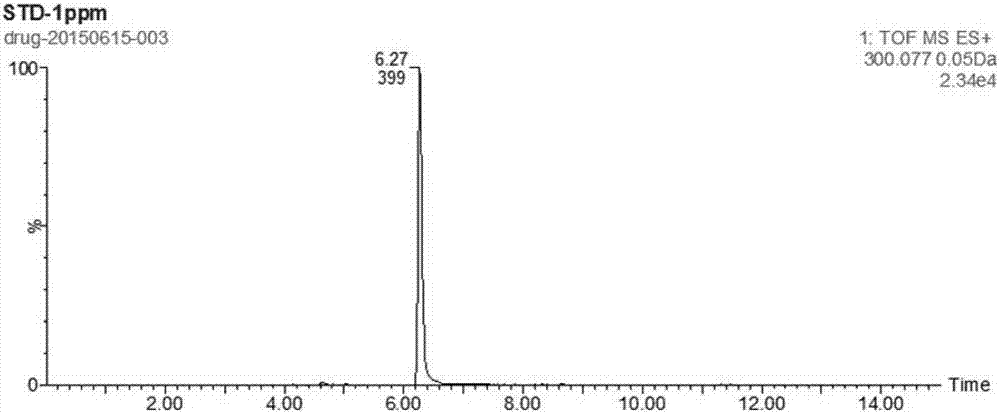

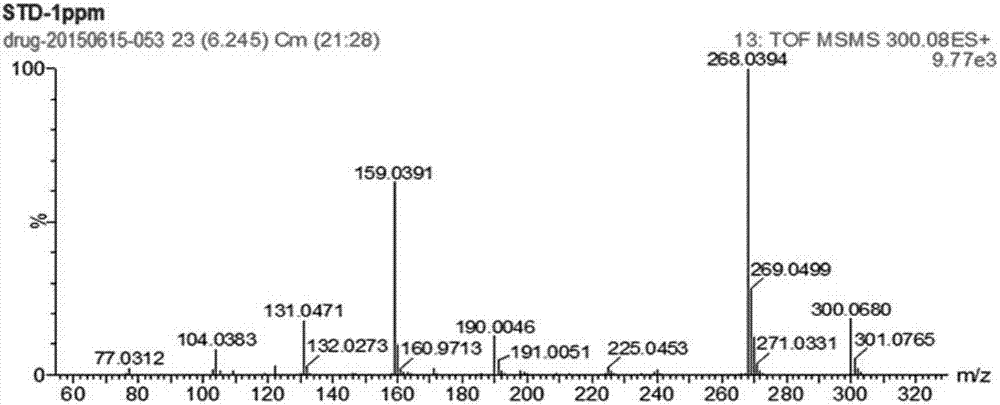

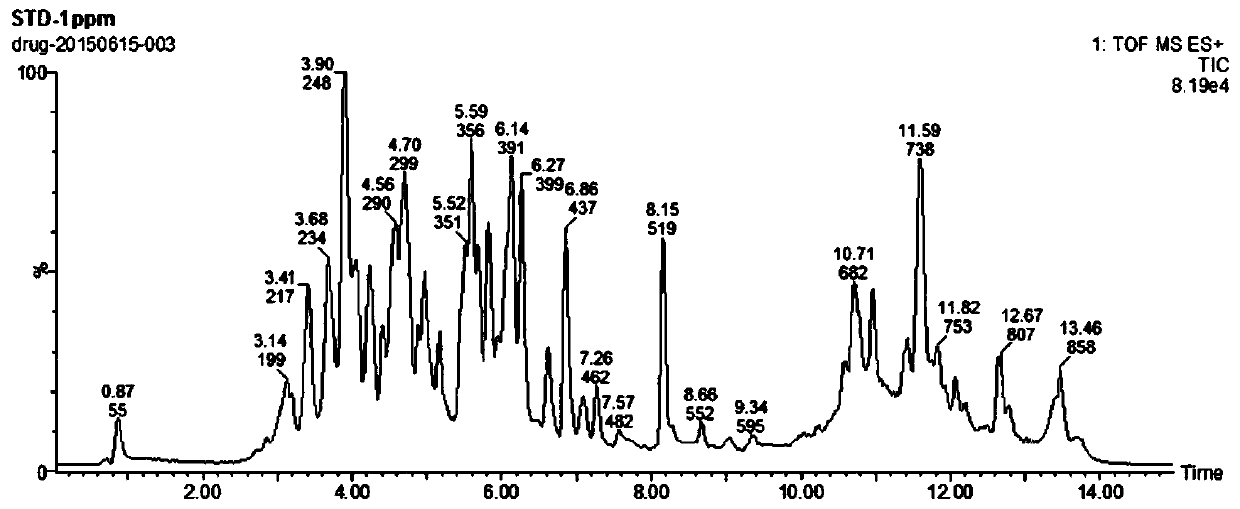

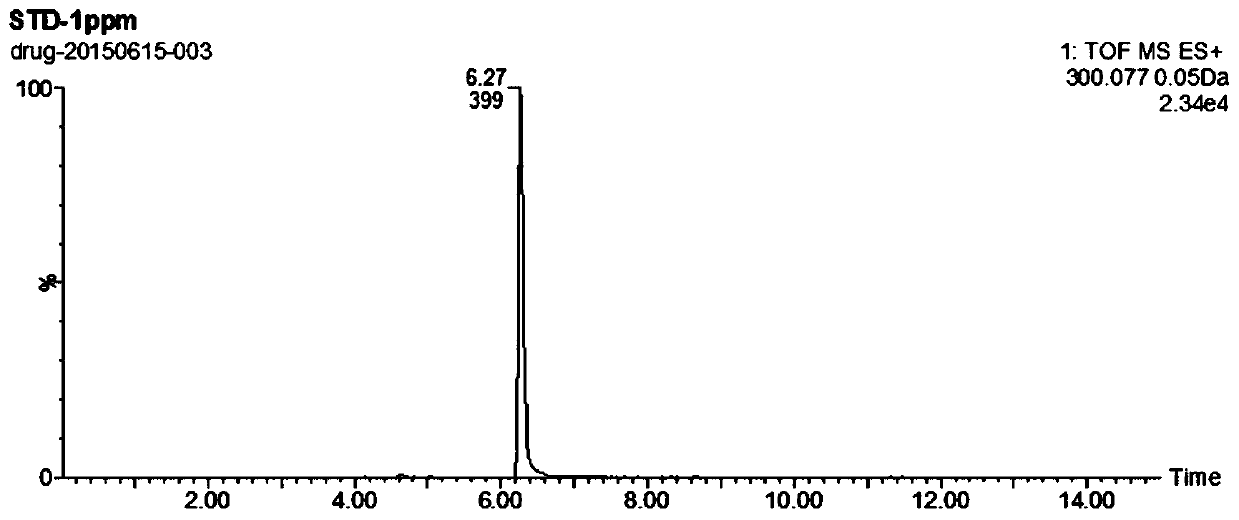

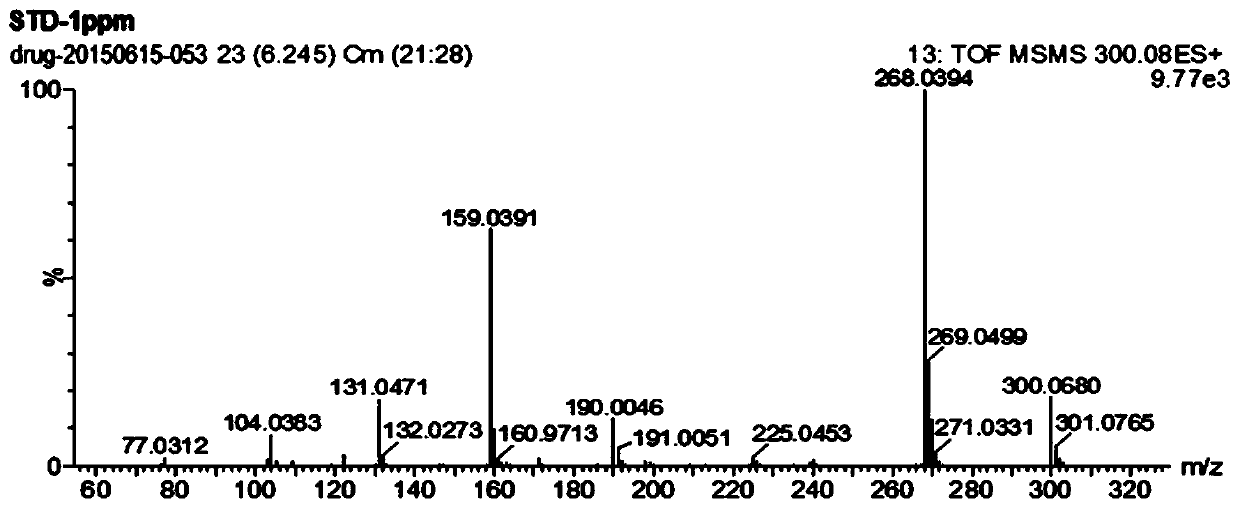

Screening method for 122 nonprescription drugs in veterinary medicine preparations

ActiveCN107202839APromote healthy developmentRich technical meansComponent separationHigh-Throughput Screening MethodsMedicine

The invention discloses a screening method for 122 nonprescription drugs in veterinary medicine preparations. The screening method comprises the following steps specifically: preparation of a standard working solution, analysis pretreatment of a sample to be measured, establishment and qualitative analysis of a database and the like. Through a constructed high-throughput screening and qualitative detection platform, the detection of a single compound is developed into simultaneous detection of various compounds in the field, and compared with the prior art, the technical means for detecting various compounds in one substance is more perfect, so that the cost is greatly reduced, and the work efficiency is greatly improved. The method plays an important role in veterinary medicine illegal addition and bacterial drug resistance plan implemented in the department of agriculture. Sample detection is carried out in provincial animal product quality detection center of our country, and through incomplete statistics, ten thousands of samples are popularized and applied.

Owner:河南省兽药饲料监察所

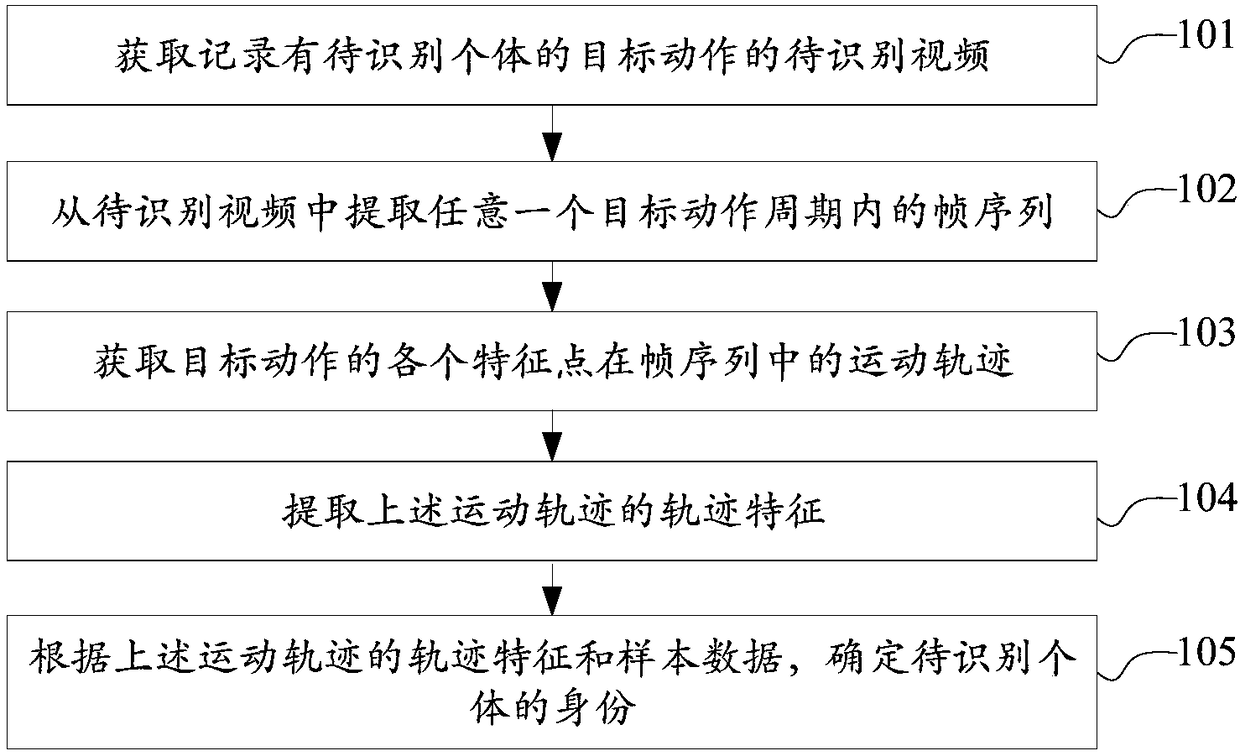

Identity identification method and device

PendingCN108304757ARich technical means of identificationRich technical meansCharacter and pattern recognitionPattern recognitionFrame sequence

The invention discloses an identity identification method and device, and relates to the technical field of image analysis. The method comprises that a to-be-identified video recording a target motionof a to-be-identified individual is obtained; a frame sequence within a random target motion period is extracted from the to-be-identified video, and the target motion period represent time to execute a complete target motion; a movement track of characteristic points of the target motion in the frame sequence is obtained; and according to characteristics of the movement track and sample data, the identity of the to-be-identified individual is determined. The sample data comprises identity of at least one sample individual and corresponding characteristics of a sample movement track. The identity of the individual is identified on the basis of motion, and technical means to identify the identity of the individual is enriched.

Owner:TENCENT TECH (SHENZHEN) CO LTD

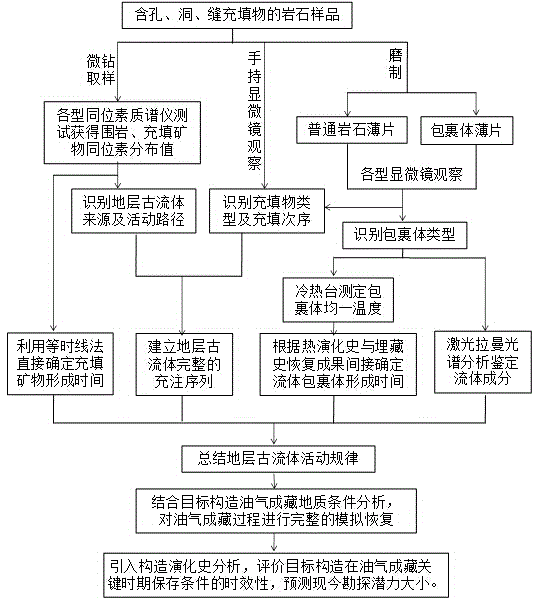

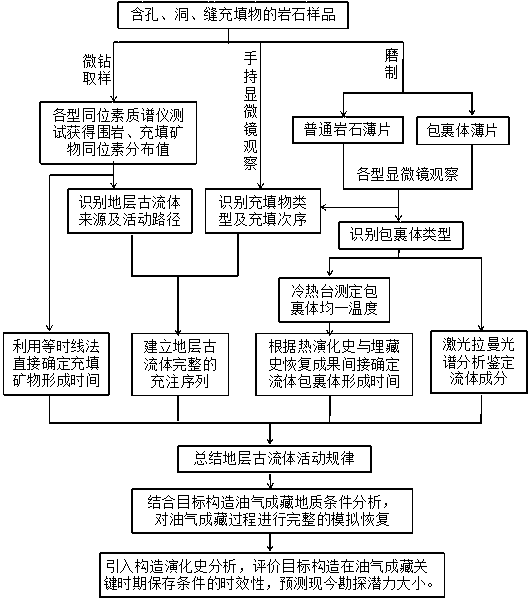

Comprehensive analysis method for paleo-fluid geochemistry

ActiveCN105572131ARich technical meansReliable research resultsRaman scatteringOil and natural gasIsotope geochemistry

The invention discloses a comprehensive analysis method for paleo-fluid geochemistry and mainly aims to solve the problems of single tracing method, strong subjectivity of interpretation process, untight combination of a formed reservoir and geological background and low credibility of obtained achievements in the existing method. According to the comprehensive analysis method disclosed by the invention, the defects of single tracing method, low argument credibility, strong subjectivity of interpretation process, untight combination of the geological background and unreliable obtained achievements in an existing isotope geochemical tracing technique in research on formation fluid movement and oil and gas reservoir formation are overcome; the comprehensive analysis method has important significance for pushing application of fluid geochemistry tracing in oil and natural gas reservoir formation research.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

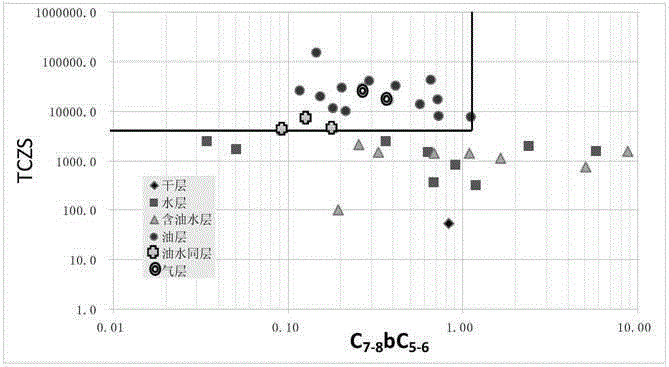

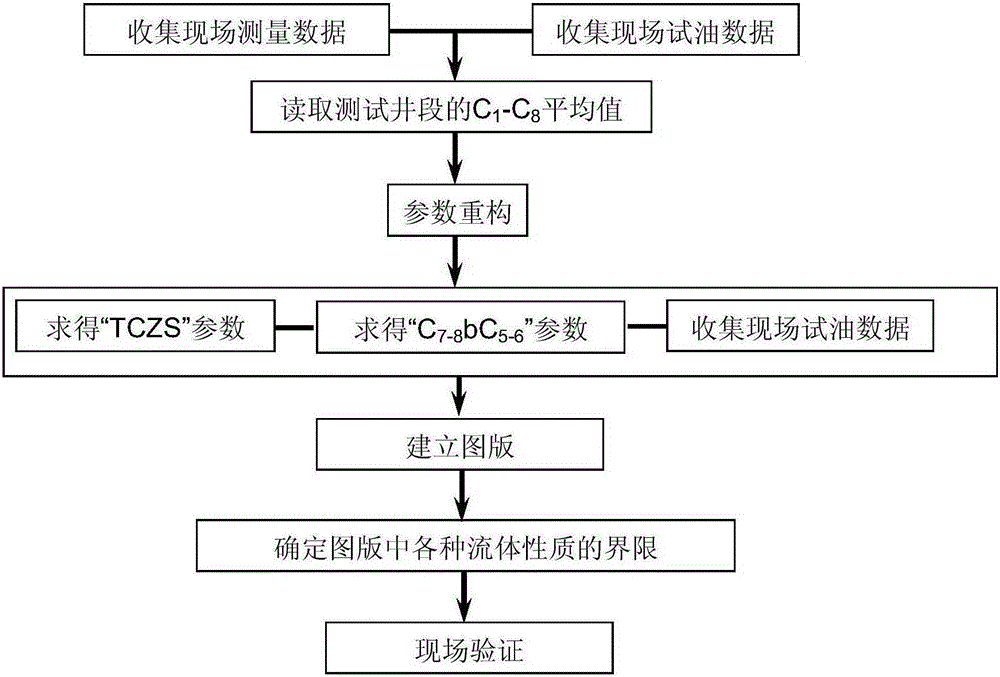

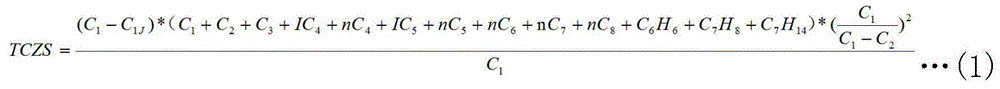

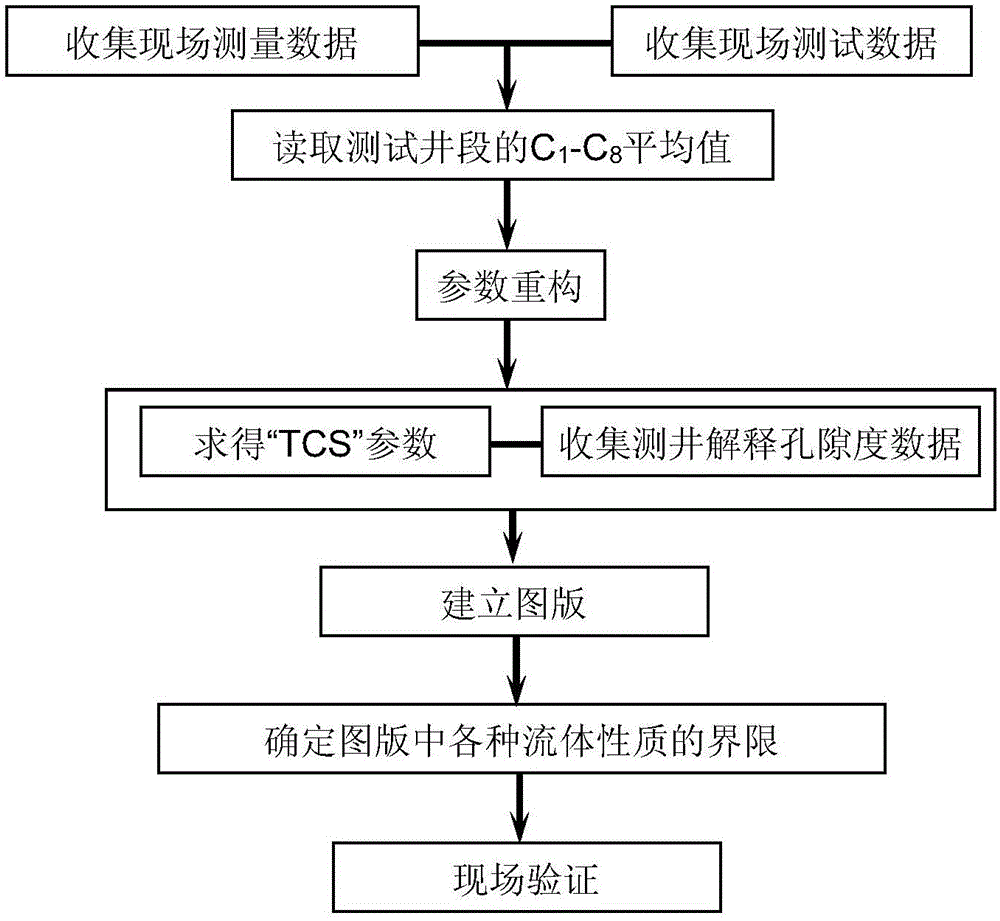

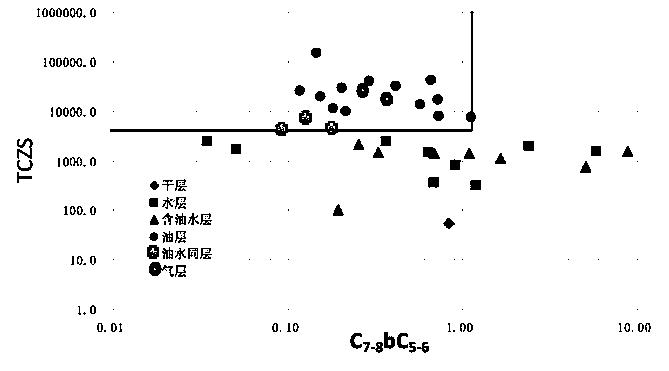

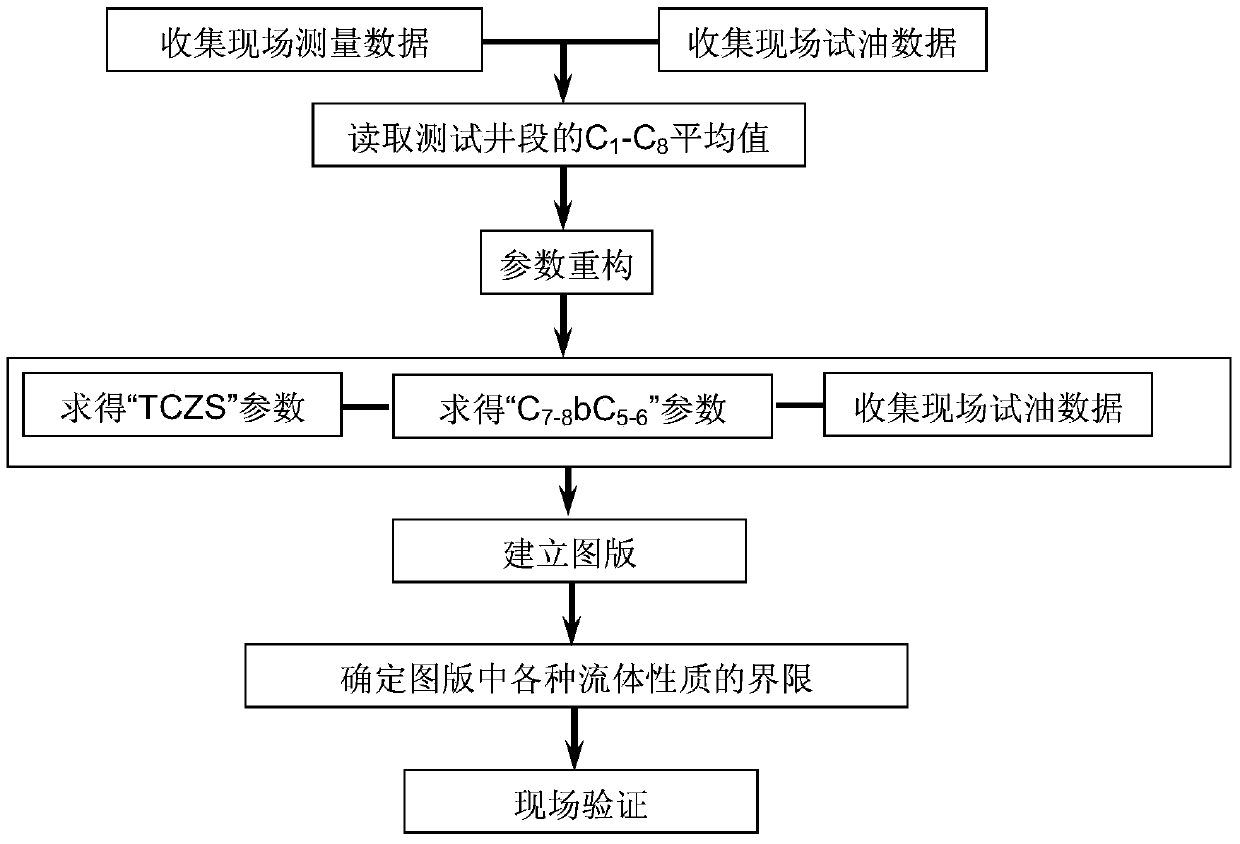

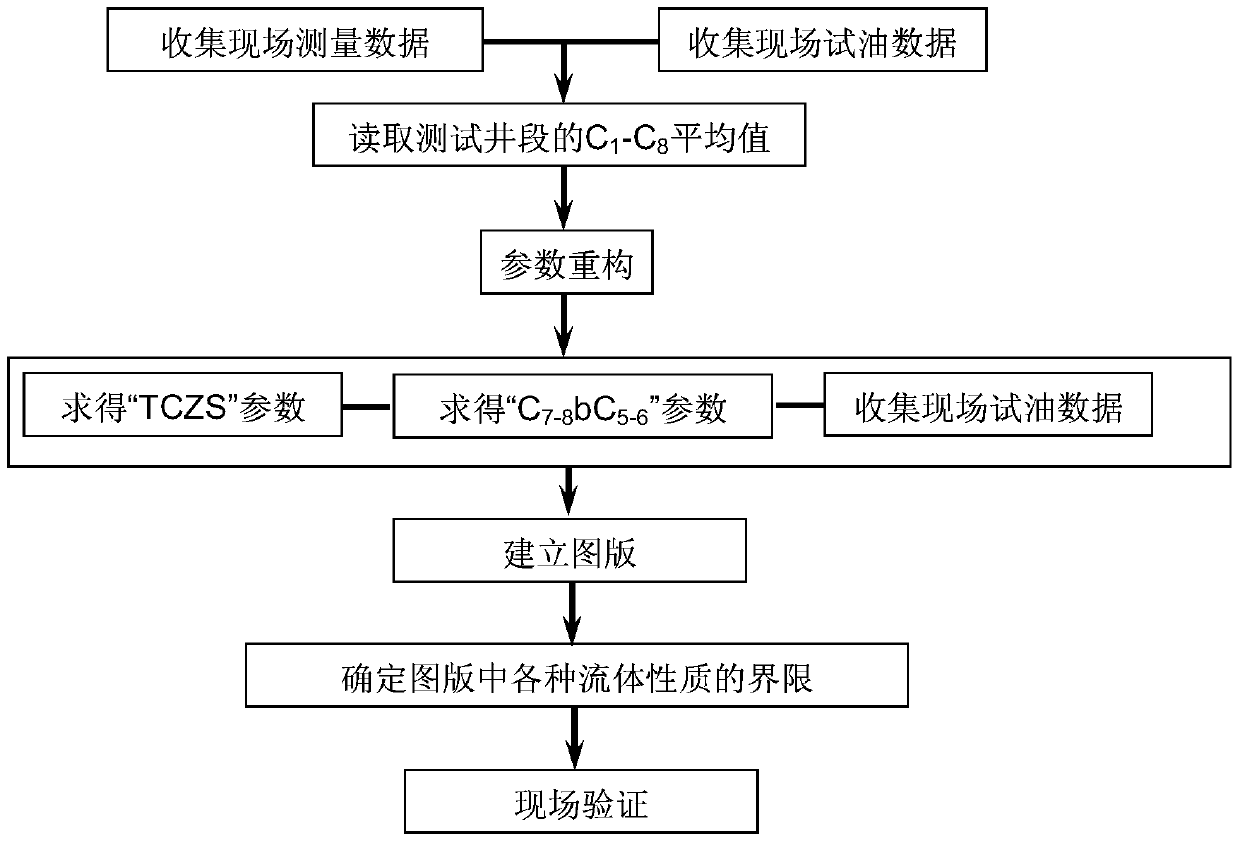

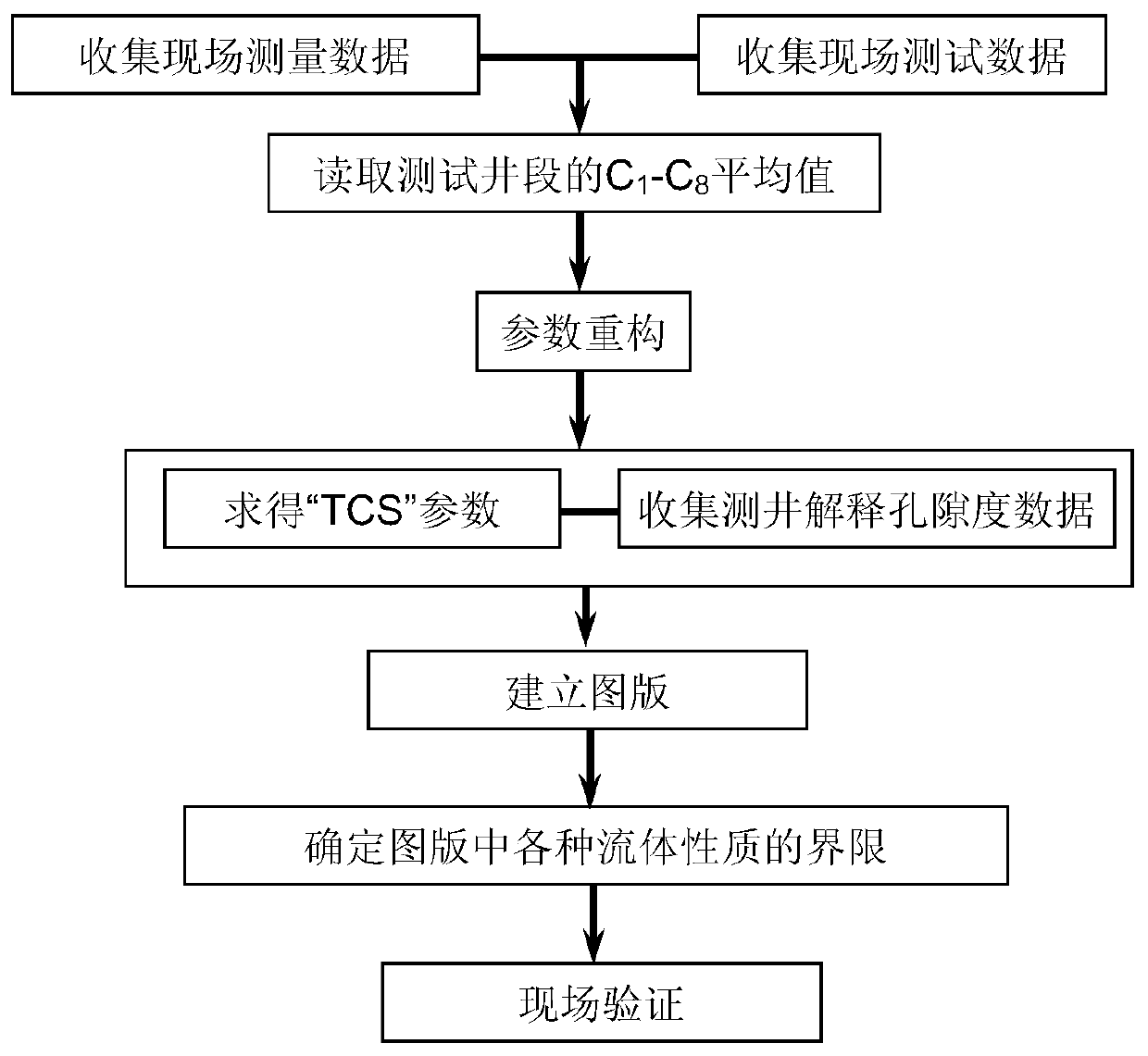

Gas logging oil-gas-water identification method based on parameter reconstruction

ActiveCN105156104AImprove efficiencyReduce the difficulty of identificationBorehole/well accessoriesPetrologyOil well

The invention discloses a gas logging oil-gas-water identification method based on parameter reconstruction. The method comprises the following steps: through average values of C1-C8 of an oil testing well section, establishing two reconstruction parameters of two FLAIR gas loggings, that is, a TCZS parameter and a C7-8bC5-6 parameter; then using the C7-8bC5-6 parameter as a x-coordinate, and the TCZS parameter as a y-coordinate, and field oil testing result data, establishing a plate, determining limits of various fluid properties in the plate, and finally verifying on site. The method solves problems of difficulty of depending on software identification and hardware developers, enriches existing technical means, and improves oil-gas-water layer identification efficiency of a well, reduces identification difficulty, and improves technical level of field staff.

Owner:CNOOC ENERGY TECH & SERVICES

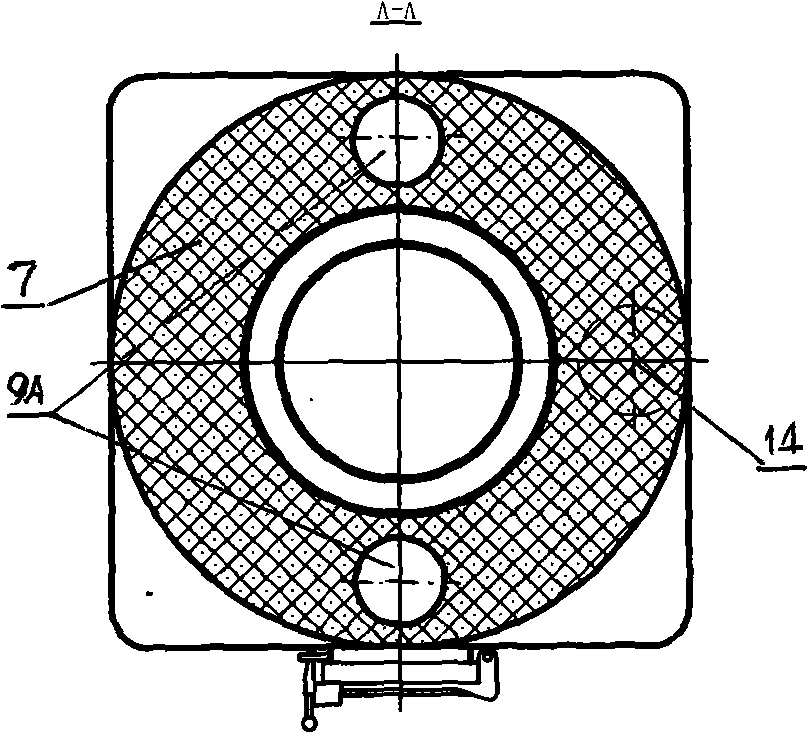

Heat pipe, manufacturing method of heat pipe and equipment comprising heat pipe

InactiveCN109764708AFlexible approachRich technical meansIndirect heat exchangersWaste productEnergy consumption

The invention discloses a heat pipe, a manufacturing method of the heat pipe and equipment comprising the heat pipe, mainly relates to a capillary core of the heat pipe and a manufacturing method of the capillary core, and belongs to the technical field of heat conduction. According to the manufacturing method, a positioning tool and a metal net are mainly used, metal powder is arranged and limited in a specific space position in a pipe shell, and the technical problems that in the sintering process in which a traditional method is adopted, the metal powder is bonded with a core rod, when thecore rod is pulled out after sintering, the capillary core is prone to damage, and even a waste product occurs, and the technical problems that core rod is used for separating the reducing atmospherefrom the metal powder, so that the reducing effect is poor, secondary sintering is generally needed, and the energy consumption and the thermal pollution are large can be comprehensively or correspondingly solved; and the technical situations that the capillary core of the sintered layer is damaged due to the deformation processes of bending, flattening and the like can be relieved or avoided, andthe process route in which bending is carried out first, and then sintering is carried out can be realized. The method is applied to manufacturing of the heat pipes (including hot columns and ultra-thin heat pipes). The heat pipe is applied to equipment or a device requiring heat transfer or heat dissipation through the heat pipe.

Owner:刘康

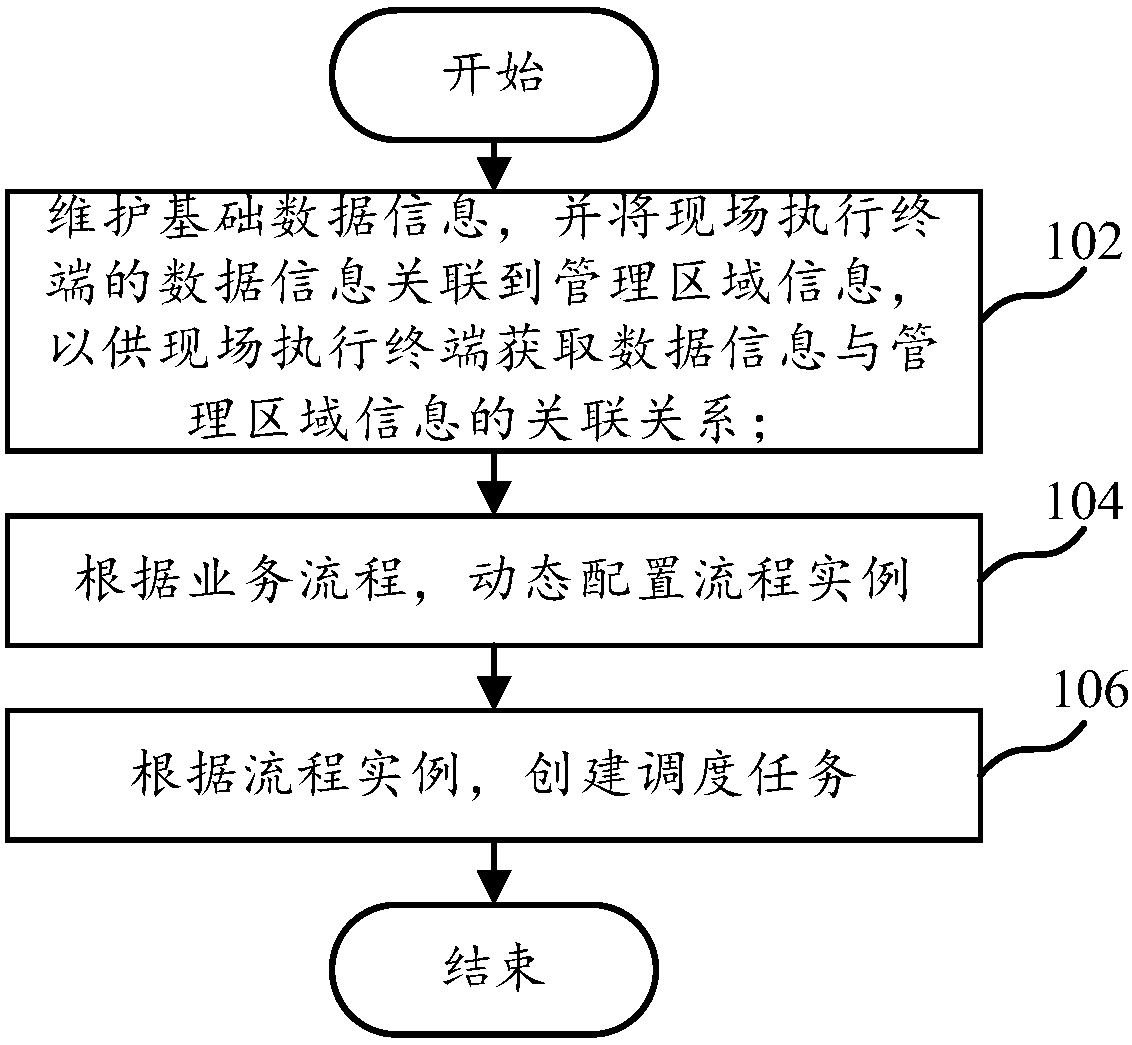

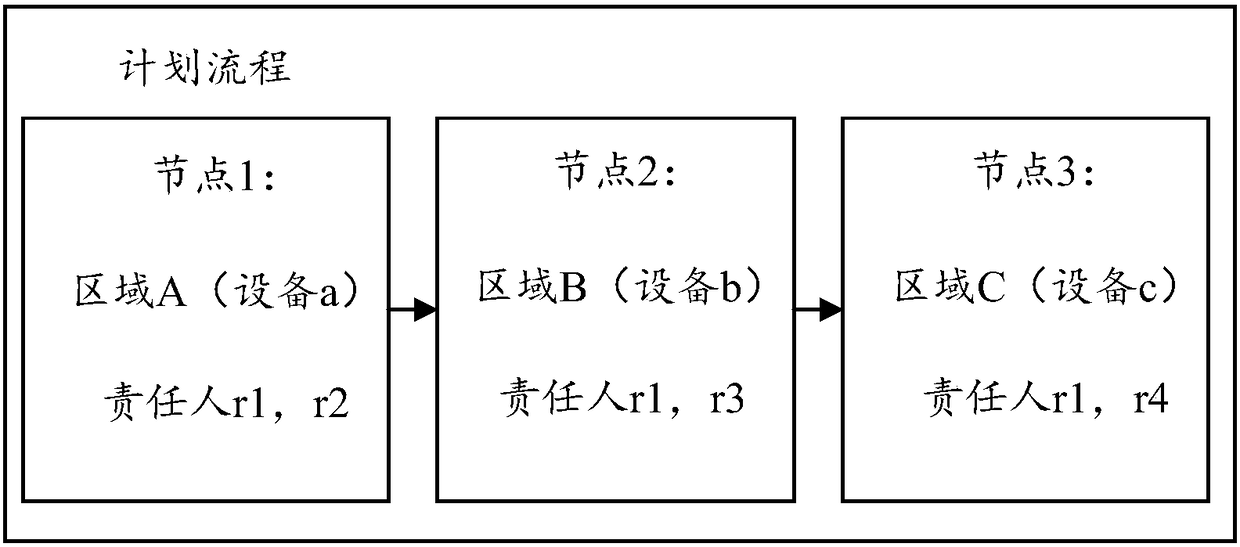

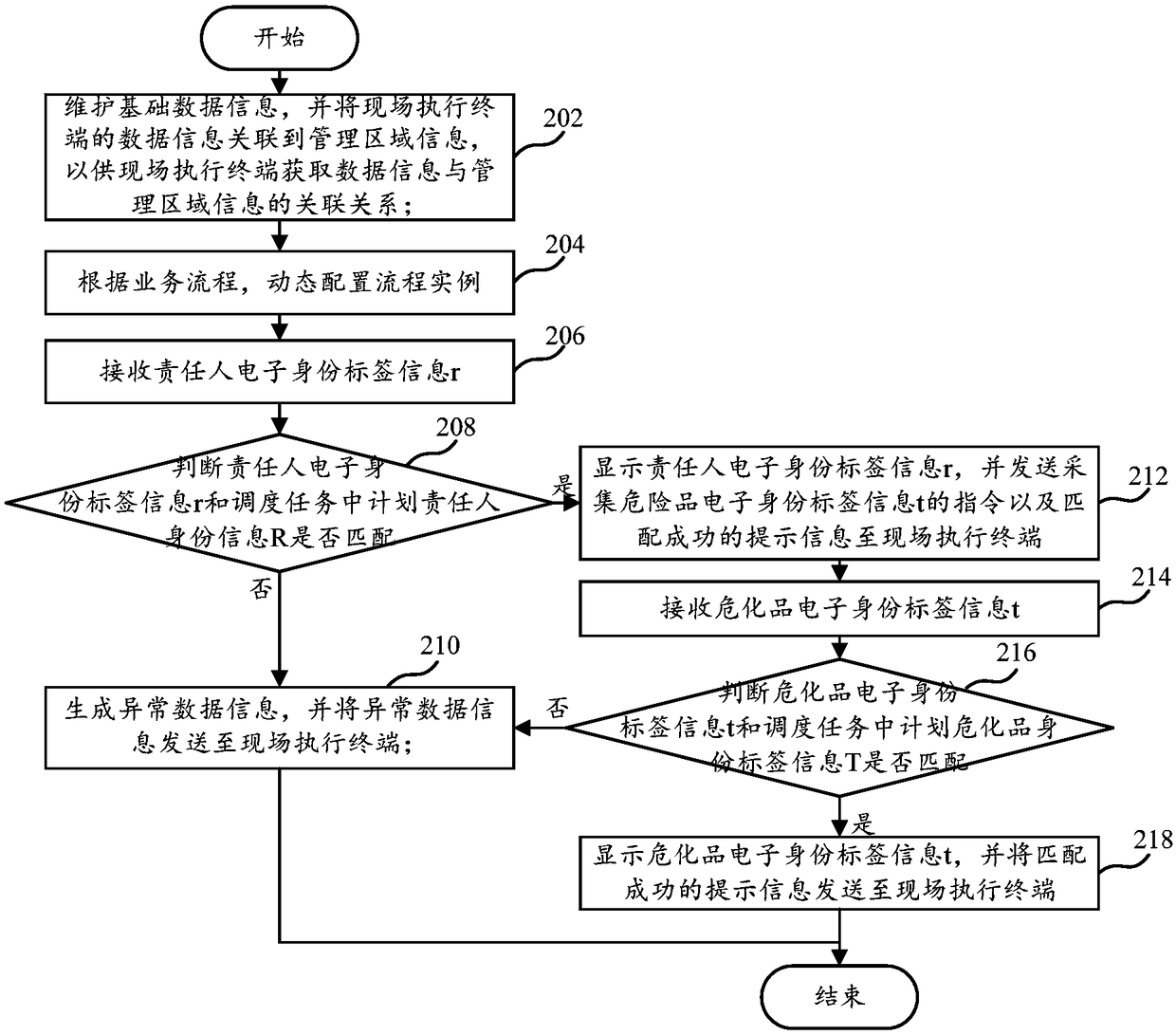

Process dynamic configuration-based hazardous chemical substance supervision method and system

InactiveCN108665125AEasy to useEasy to implementCo-operative working arrangementsResourcesProcess dynamicsData information

The invention provides a process dynamic configuration-based hazardous chemical substance supervision method and system. The process dynamic configuration-based hazardous chemical substance supervision method used for a business support platform of a server comprises the steps of maintaining basic data information, and associating data information of a field execution terminal to management regioninformation; according to a business process, dynamically configuring a process instance; and according to the process instance, creating a scheduling task. According to the process dynamic configuration-based hazardous chemical substance supervision method used for the business support platform of the server, provided by the invention, a specific execution process of a business scene is supervised; task execution is performed strictly according to process requirements of the scheduling task; and use and storage of hazardous chemical substances in a factory area are supervised in the whole process. Meanwhile, the field execution terminal communicates with the business support platform; the business support platforms check and approval on data in an actual execution process and a scheduling task plan; once abnormal problems occur, tracing is easy; and technical means of hazardous chemical substance supervision are perfected.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Method for controlling non-target species of degraded peat land and promoting dominant vegetation reconstruction

ActiveCN111328647AImprove survival rateEfficient reconstructionPlant cultivationCultivating equipmentsVegetationCarex

The invention discloses a method for controlling non-target species of a degraded peat land and promoting dominant vegetation reconstruction. The method comprises the following steps: (1) removing surface soil and performing raking; (2) obtaining Carex tato; (3) transplanting Carex tato; (4) performing water level control; (5) performing final-period management; and (6) performing overwintering protection. The method has the advantages that firstly, the reproduction of non-target species is effectively controlled and restored; the problems that abandoned peat land is large in soil volume, compact in soil and difficult in root system pricking of transplanted plants are solved, the survival rate of Carex tato is increased, and the survival rates of Carex tato of different sizes are all higher than 95%; and before transplanting, a large number of non-target species are effectively removed, and the reproductive capacity of weeds is weakened; secondly, different water level control measuresare taken at each growth stage of Carex tato to control the reproduction and growth of weeds, and the water level fluctuation can promote the reproduction of dominant species of Carex tato, and thirdly, the later-period management is more perfect, sexual reproduction of the weeds is blocked, rapid reproduction of the Carex tato is facilitated, and a stable Carex tato community is formed.

Owner:NORTHEAST NORMAL UNIVERSITY

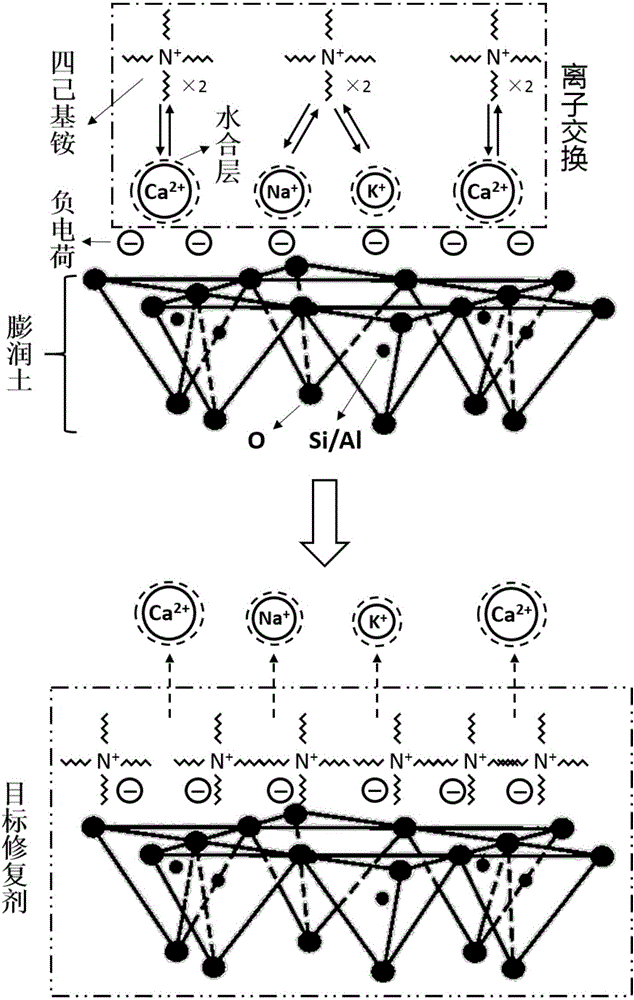

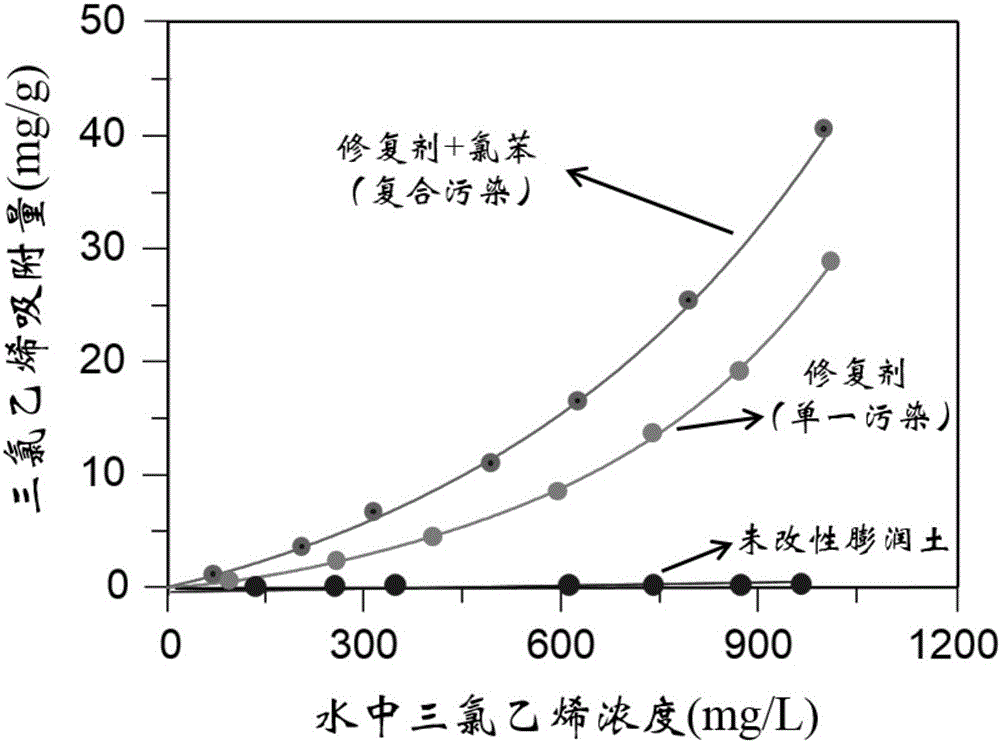

Preparation method for high-concentration compound organic pollution restoration agent

InactiveCN105126769AMeet governanceMeet needsOther chemical processesContaminated soil reclamationCompound organicHigh concentration

The invention provides a preparation method for a high-concentration compound organic pollution restoration agent. The preparation method includes the steps of preparing, optimizing and modifying sodium-type bentonite and forming modified bentonite. The preparation method is simple and economical, the prepared restoration agent has outstanding performance of adsorbing various organic pollutants and particularly existing high-concentration organic pollutants, is reliable in adsorption, stable in nature and environmentally friendly and is an economical high-practicability restoration agent. The restoration agent is particularly suitable for treating and restoring high-concentration compound organic pollution, for example, severe organic pollution soil, organic waste water and refuse landfill organic leachate.

Owner:宜兴市环境监测站

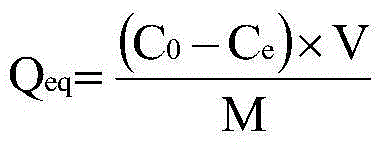

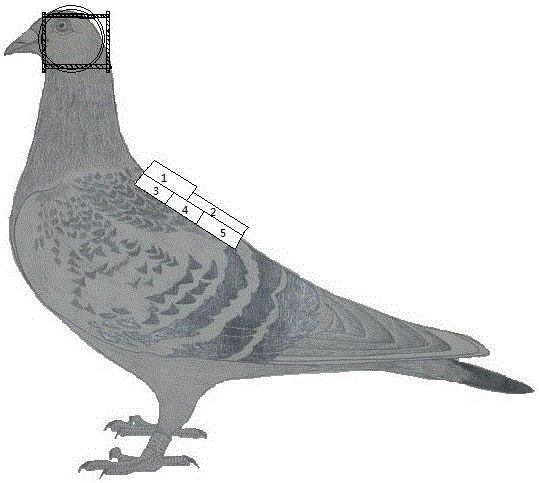

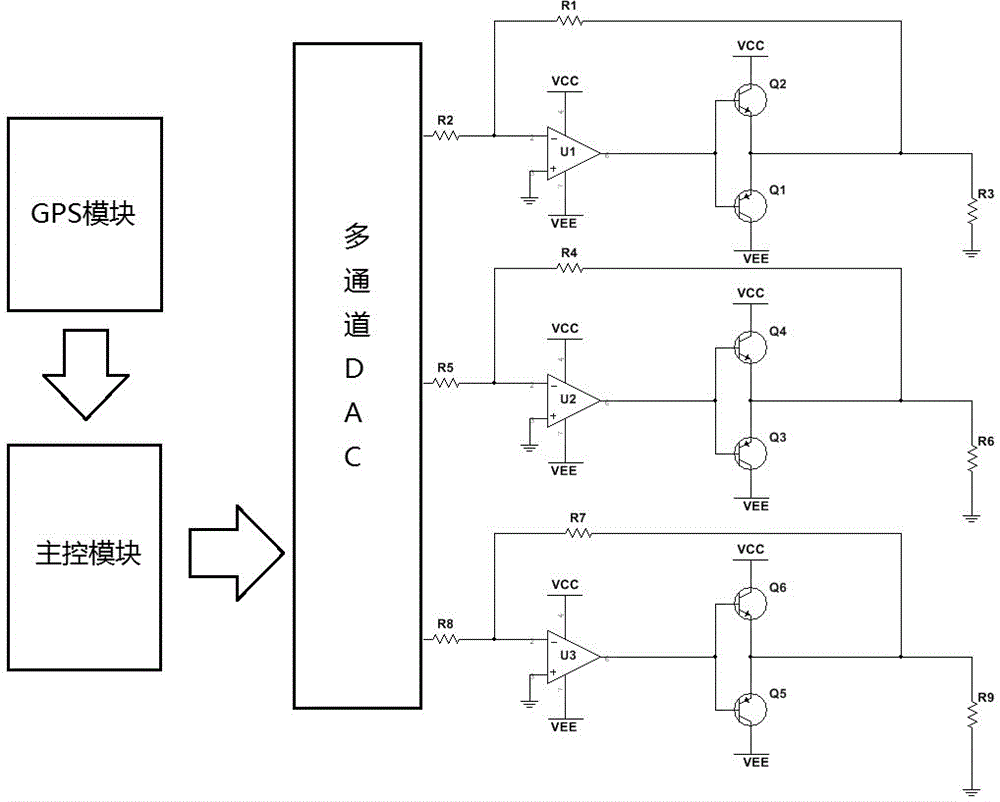

Three-axis magnetic field generating device and method for detecting birds for magnetic navigation orientation by aid of three-axis magnetic field generating device

InactiveCN106441284ARich technical meansNavigation by terrestrial meansPermanent magnetsComputer moduleSpatial direction

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

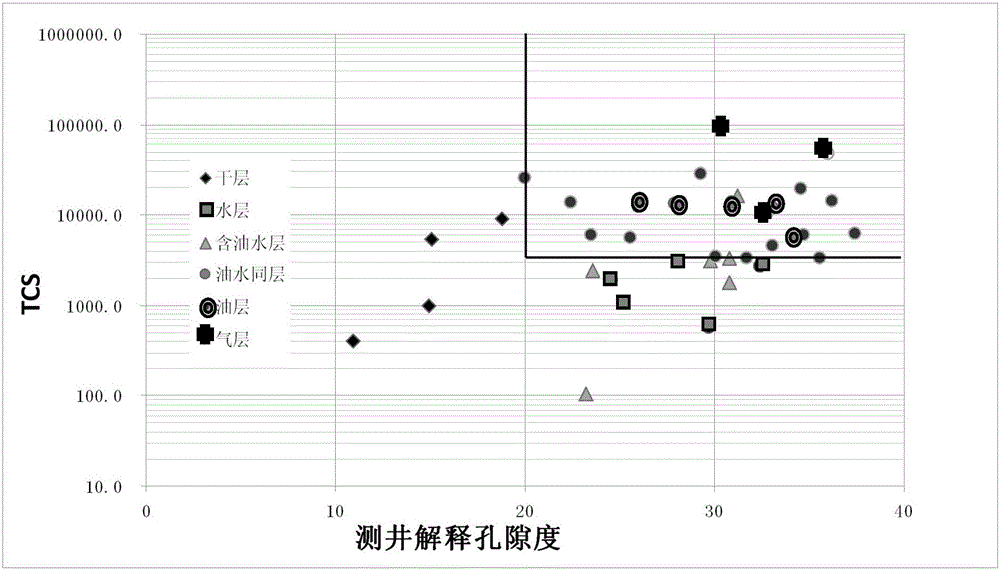

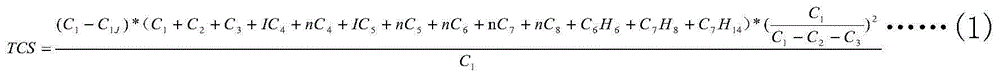

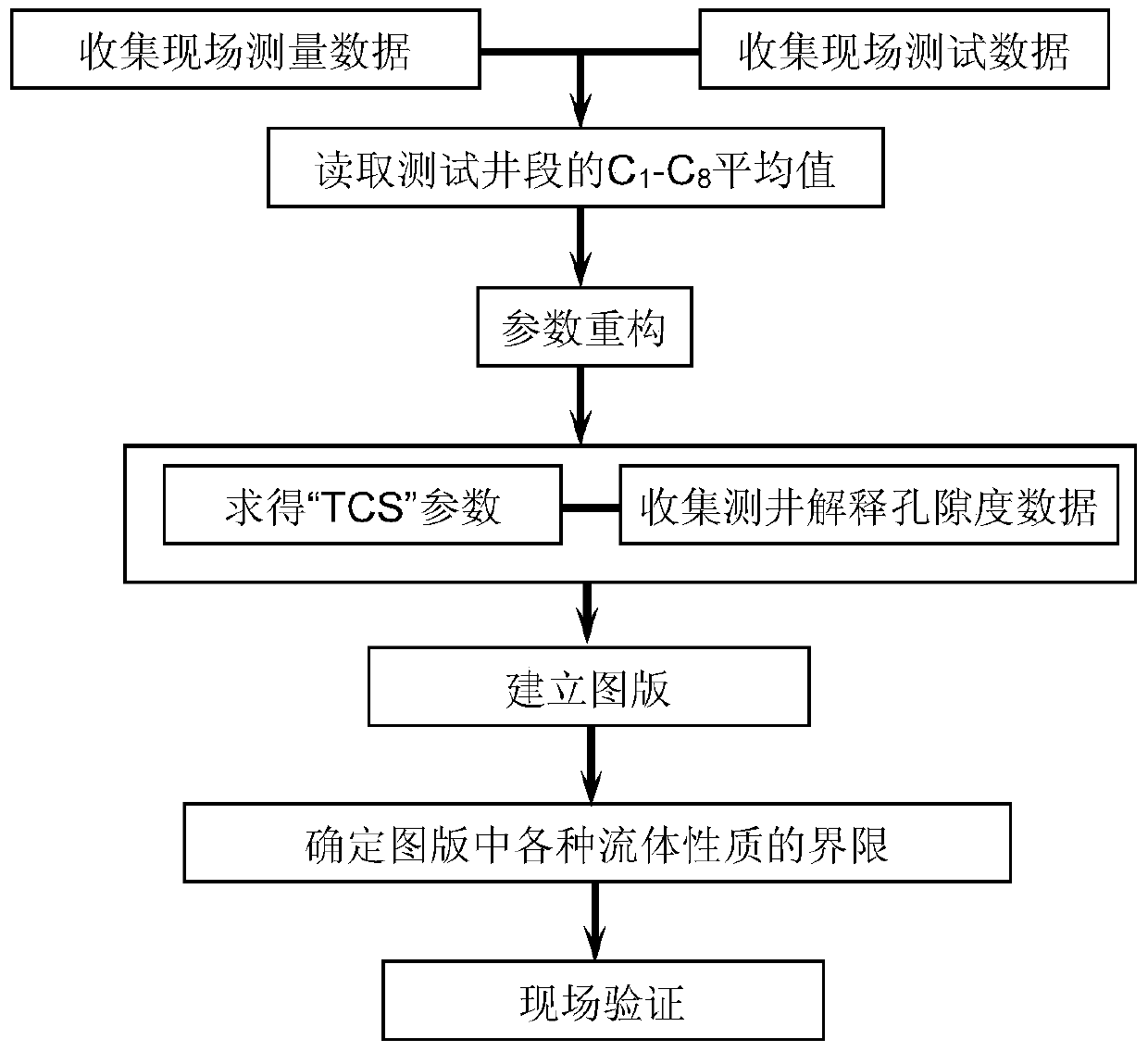

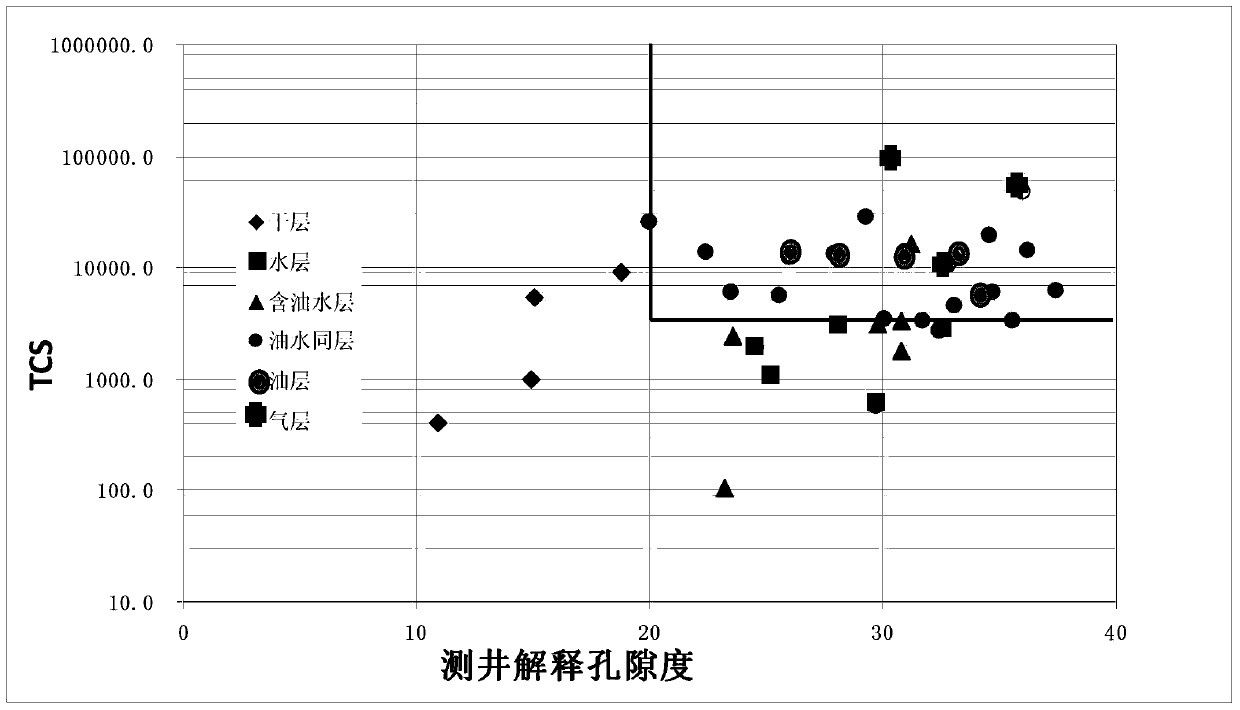

Method for oil-gas-water identification based on physical property and gas logging parameter intersection

ActiveCN105041305AResolve identifiabilitySolving difficult problems for hardware developersBorehole/well accessoriesPorosityWell logging

The invention discloses a method for oil-gas-water identification based on physical property and gas logging parameter intersection. The method comprises the following steps: reading the C1-C8 average of test well sections by collecting site gas logging data, well logging interpretation porosity data and oil testing data, performing parameter reconstruction, obtaining a TCS parameter, building a plate, determining limit of various fluid properties in the plate, performing on-site verification, and performing popularization and application in more wells on the site if no error occurs. The method solves the problem of immoderate reliance on software identification and hardware developers, enriches existing technical means, improves well drilling oil-gas-water layer identification efficiency, reduces identification difficulty, improves technical levels of field workers and also has the effect of promoting later-period oil-gas-water identification and instrument popularization.

Owner:CNOOC ENERGY TECH & SERVICES

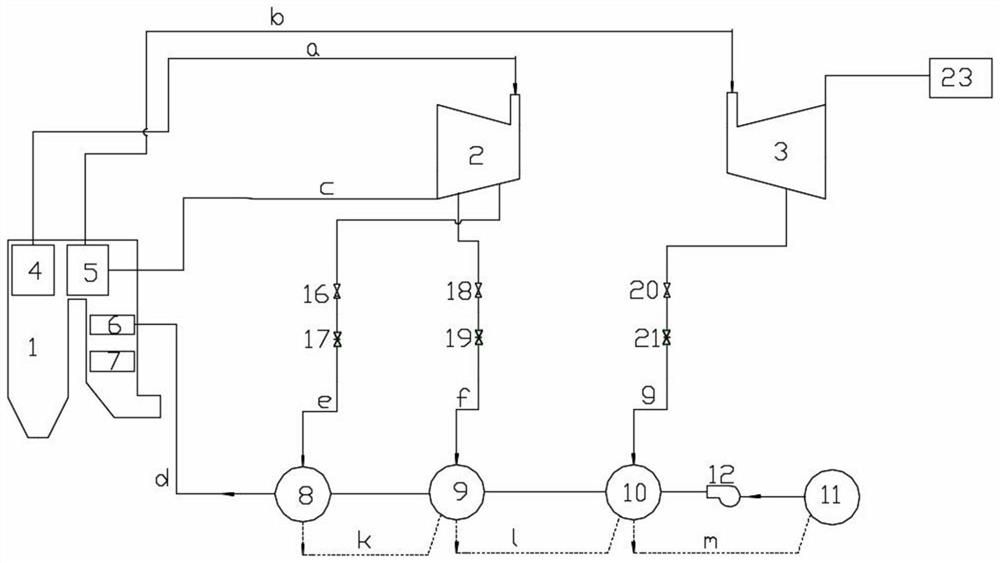

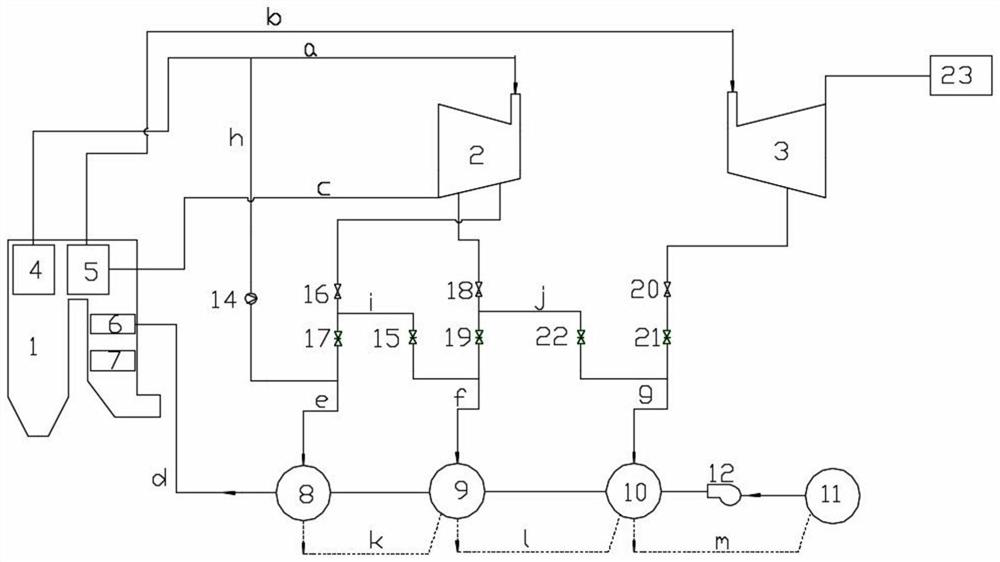

System for greatly increasing low-load feed water temperature of power station boiler

PendingCN113623634ASimple technologyRich technical meansLiquid degasificationFeed-water heatersSteam pressureEngineering

The invention discloses a system for greatly increasing the low-load feed water temperature of a power station boiler. A heating steam source is additionally arranged on a section of steam extraction pipeline of a first high-pressure heater of a unit regenerative system, and the steam source is taken from a superheated steam system or a main steam pipeline; a second-section external steam source pipeline is additionally arranged between a first-section steam extraction pipeline and a second-section steam extraction pipeline, and a third-section external steam source pipeline is additionally arranged between a second-section steam extraction pipeline and a third-section steam extraction pipeline. The temperature of feed water entering a boiler economizer is adjusted by adjusting the pressure of steam entering a first high-pressure heater, a second high-pressure heater and a third high-pressure heater, and finally the purpose of adjusting the temperature of flue gas at the inlet of an SCR reactor is achieved. According to the scheme, the technology is simple, a large amount of space is not occupied, moreover, only part of pipelines and valves need to be additionally arranged on an original system, and the problems that other low-load denitration technologies are limited in arrangement space, limited in temperature raising effect, high in investment, complex in system and the like are solved.

Owner:江苏慧峰仁和环保科技有限公司 +1

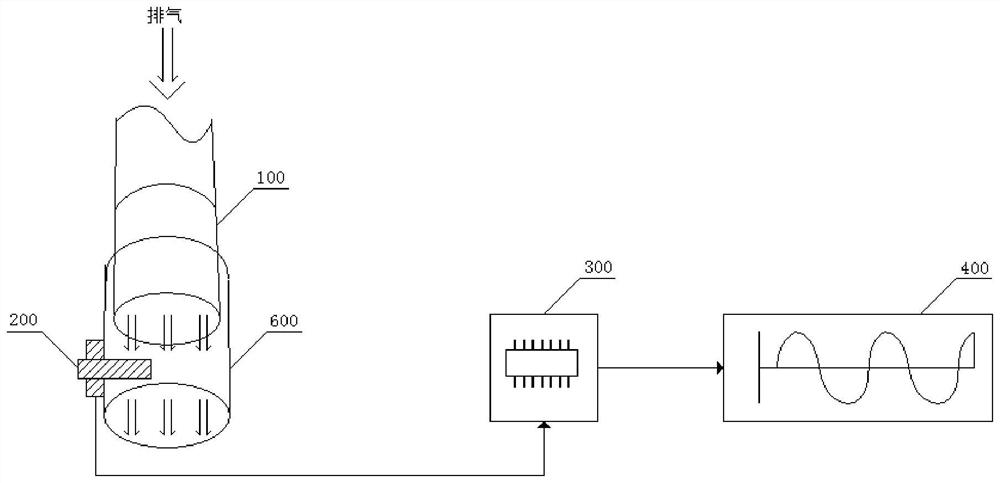

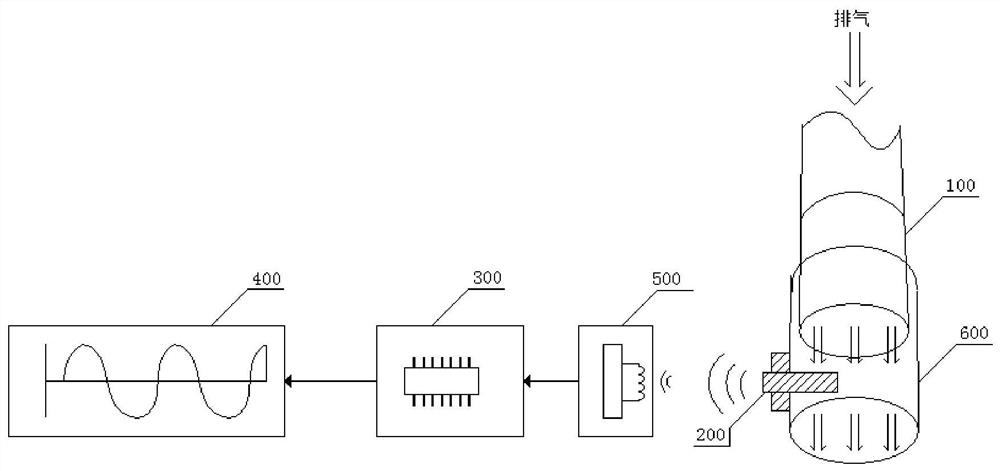

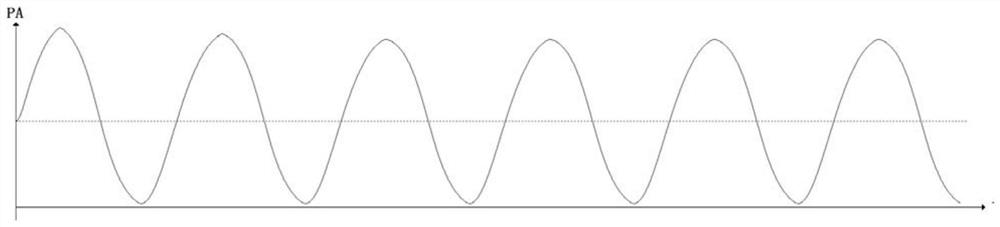

Engine exhaust pressure electronic waveform detection and identification method and system

ActiveCN112145270AAccurate detectionComprehensive detectionInternal combustion piston enginesEngine testingWaveform analysisWireless transmission

The invention relates to an engine exhaust pressure electronic waveform detection and identification method and system, and belongs to the technical field of automobile detection and maintenance equipment manufacture. The system comprises an exhaust pressure sensor, a data processing unit and a display unit, the exhaust pressure sensor is connected with the data processing unit, the exhaust pressure sensor is used for transmitting electronic signals output by the exhaust pressure sensor to the data processing unit, and the data processing unit performs operation processing according to the engine exhaust pressure electronic waveform detection and recognition method; and the data processing unit is further connected with the display unit and used for displaying an operation result through the display unit in a terminal mode, the displayed information is used for analyzing operation characteristics, engine performance or fault causes of an engine, and sensor signals can be subjected to wireless transmission, cloud processing, APP diagnosis and the like. According to the engine exhaust pressure electronic waveform detection and identification method and system, quantitative detectionand waveform analysis are carried out on exhaust pressure waves, the performance of the engine is effectively, accurately and comprehensively detected and diagnosed, and the technical level of automobile maintenance operation is improved.

Owner:广东唯普汽车科技股份有限公司

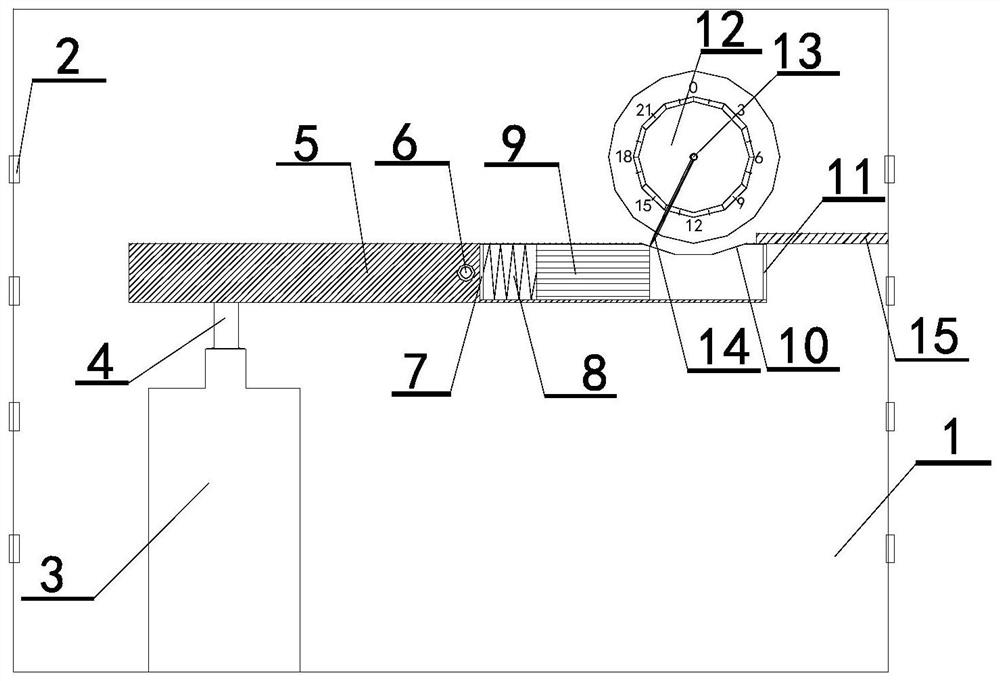

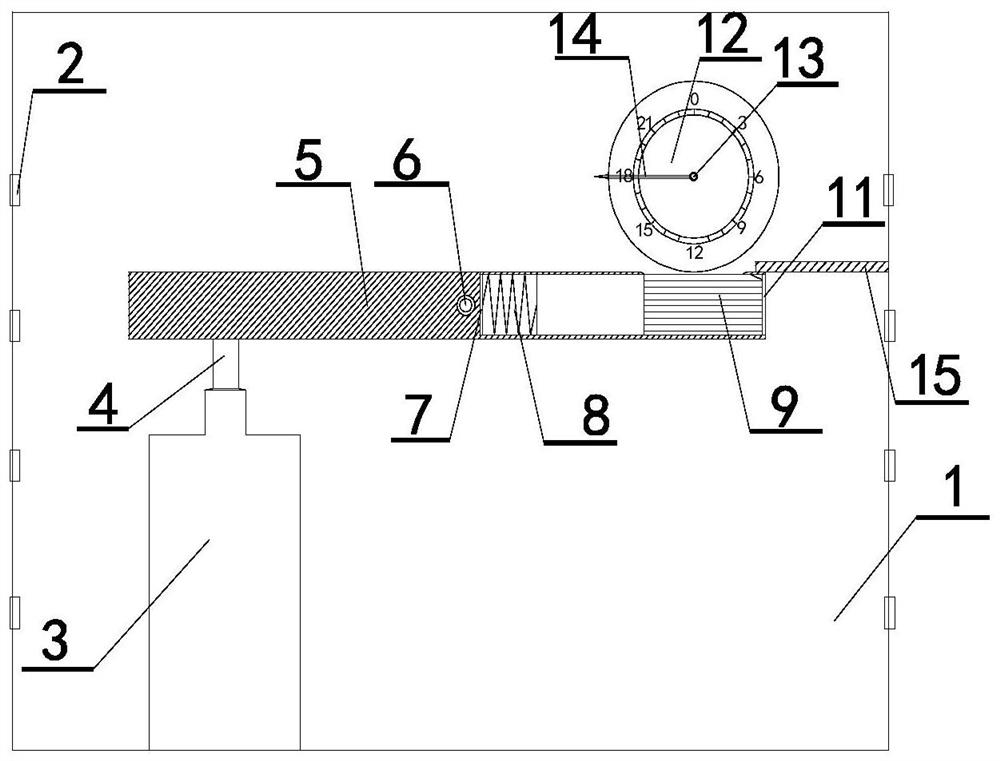

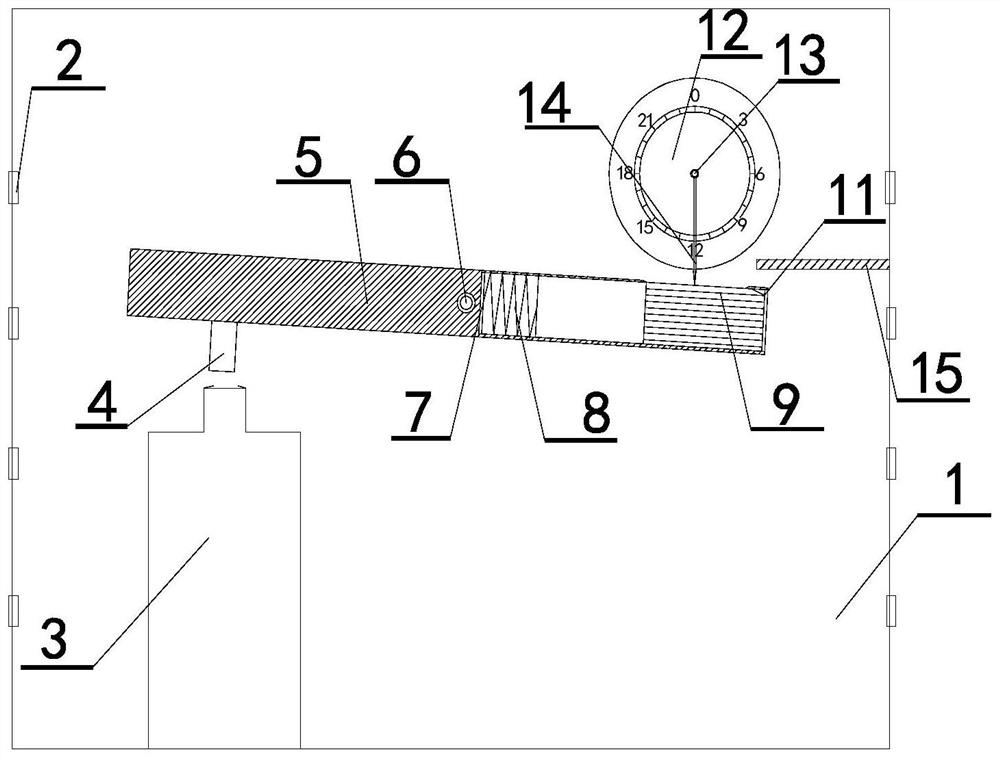

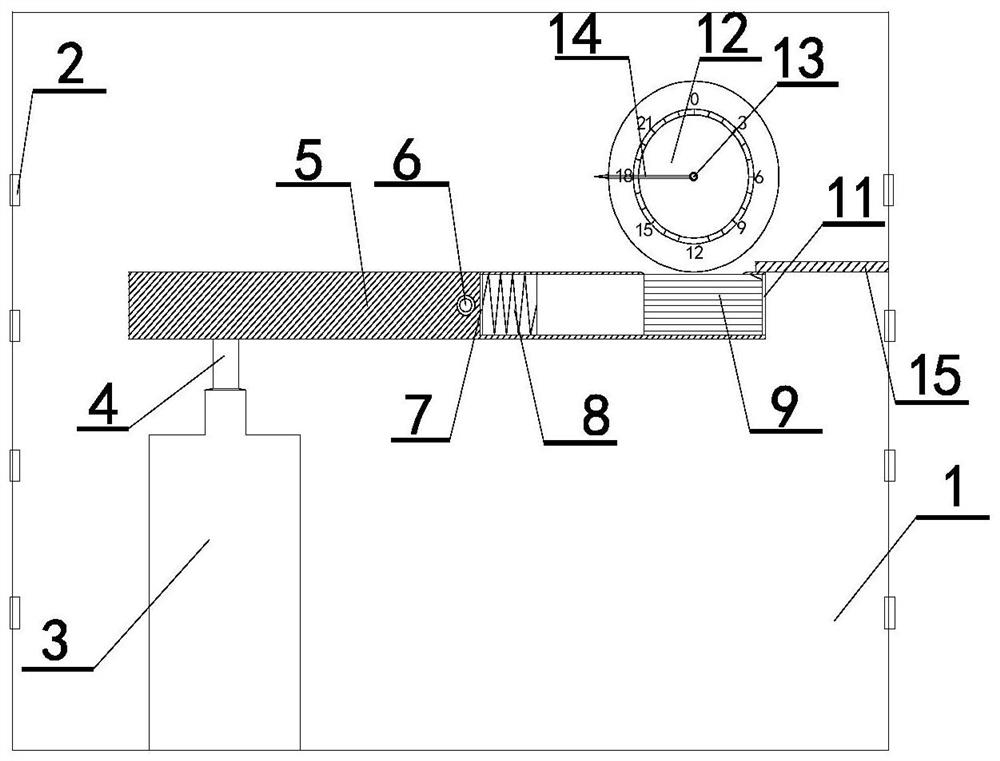

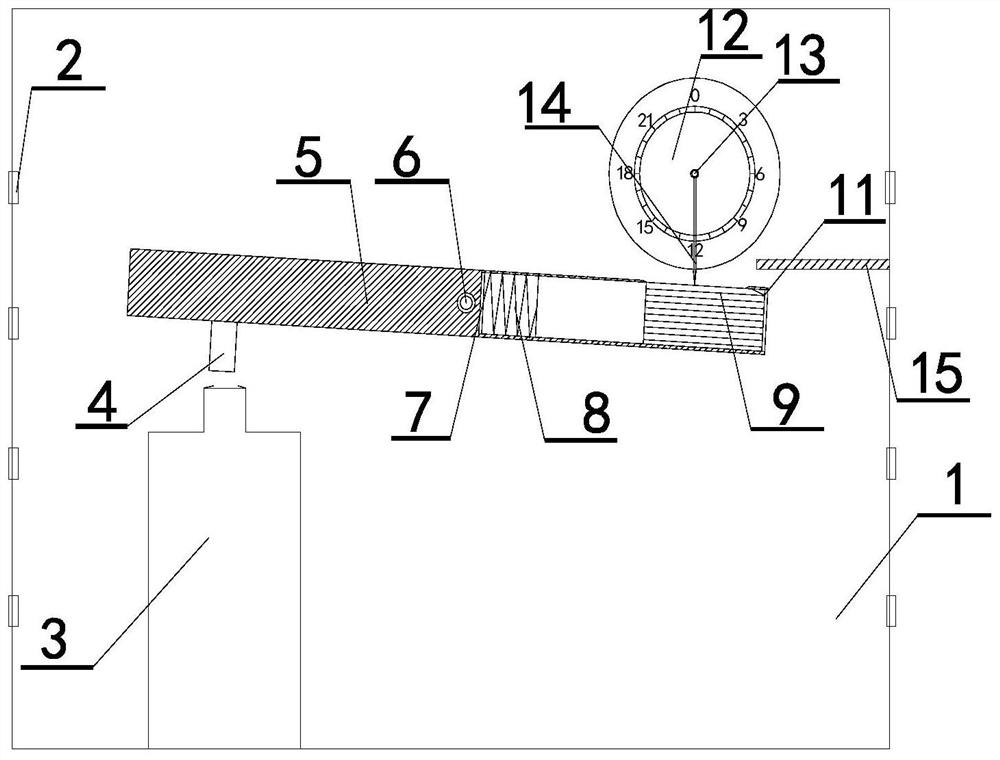

Goaf air leakage flow field fixed-time and fixed-point measuring device, and using and measuring method

ActiveCN111811771AAccurately get the flow stateSolve measurement problemsHydrodynamic testingClassical mechanicsBottle

The invention relates to a goaf air leakage flow field measuring technology, in particular to a goaf air leakage flow field fixed-time and fixed-point measuring device. The goaf air leakage flow fieldfixed-time and fixed-point measuring device comprises a box body, wherein a lever is rotatably connected in the box body through a lever supporting shaft rod, and a bottle plug is arranged on the first side, corresponding to a bottle opening of a tracer gas bottle, of the lever; a slideway is arranged in the second side of the lever; a spring is arranged at the end, close to the lever supportingshaft rod, of the slideway; a sliding block is arranged in the slideway, and a poking opening is formed in the top part of one side, away from the lever supporting shaft rod, of the slideway; and a timing device is arranged above the second side of the lever, the timing device is provided with a timing device shaft rod capable of being driven by the timing device to rotate, a timing device pointeris installed on the timing device shaft rod, the timing device shaft rod is opposite to the poking opening, and a moving path at the free tail end of the timing device pointer enters the poking opening forcibly. The goaf air leakage flow field fixed-time and fixed-point measuring device can complete goaf air leakage flow field measurement. The invention further provides a using method of the goafair leakage flow field fixed-time and fixed-point measuring device and a goaf air leakage flow field fixed-time and fixed-point measuring method.

Owner:CCTEG SHENYANG RES INST

Preparation method of fermented germinated brown rice milk beverage

ActiveCN102952663BRich technical means for deep processingRich technical meansAlcoholic beverage preparationAmylaseHydrolysate

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

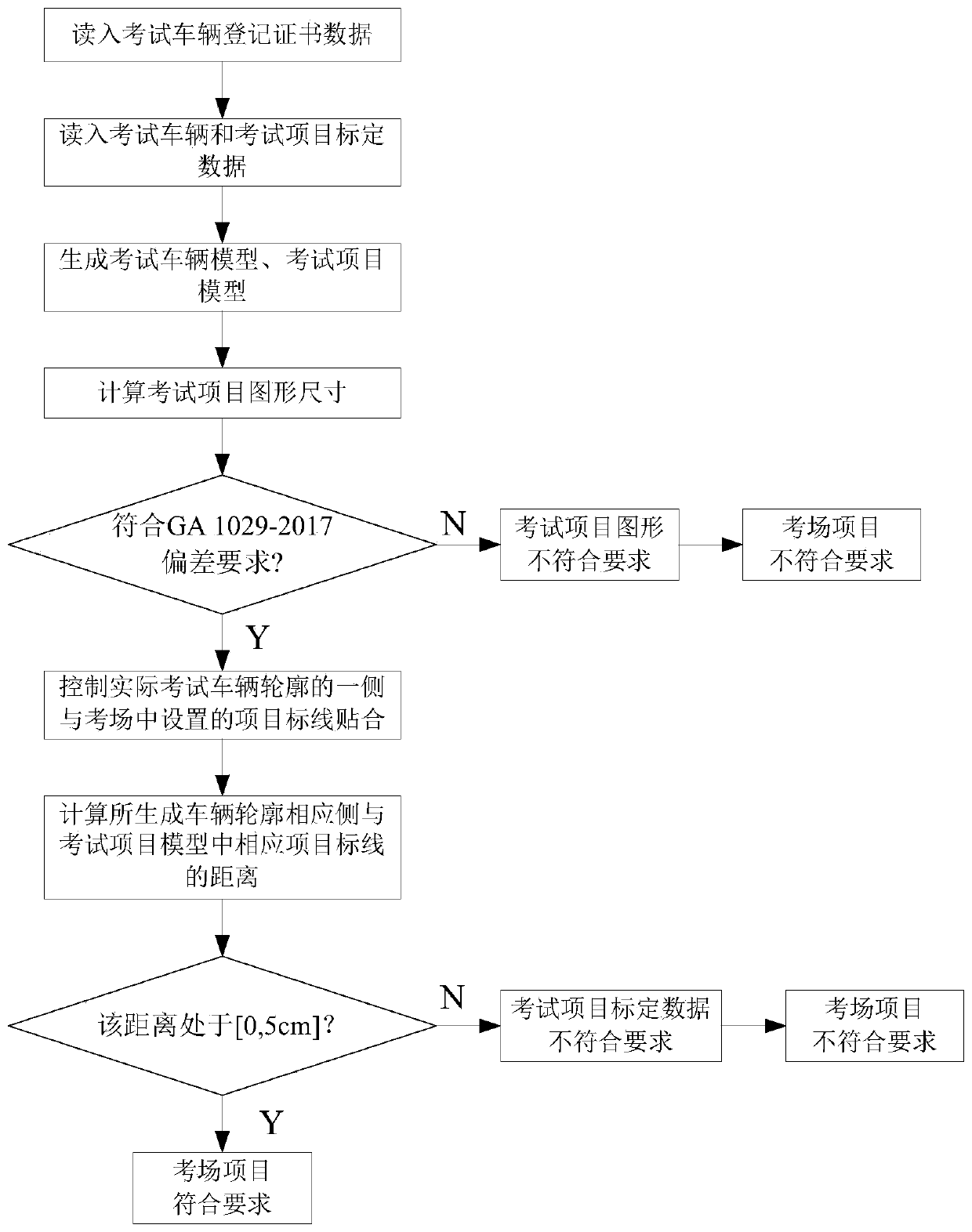

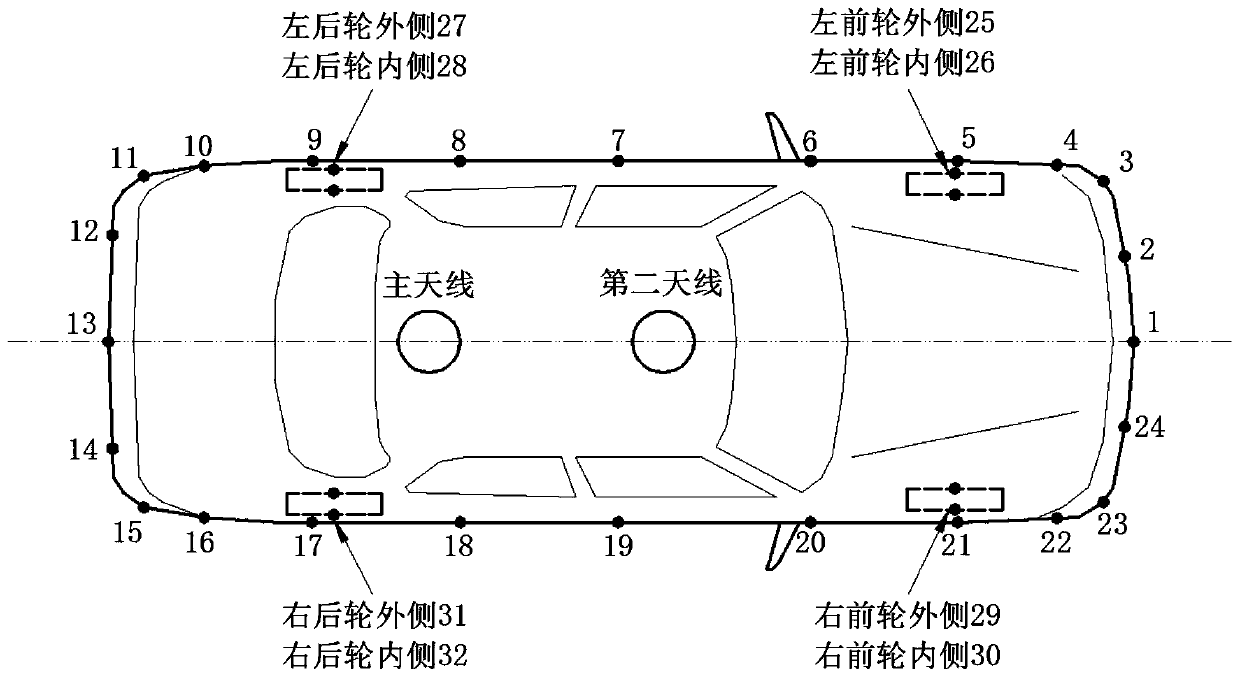

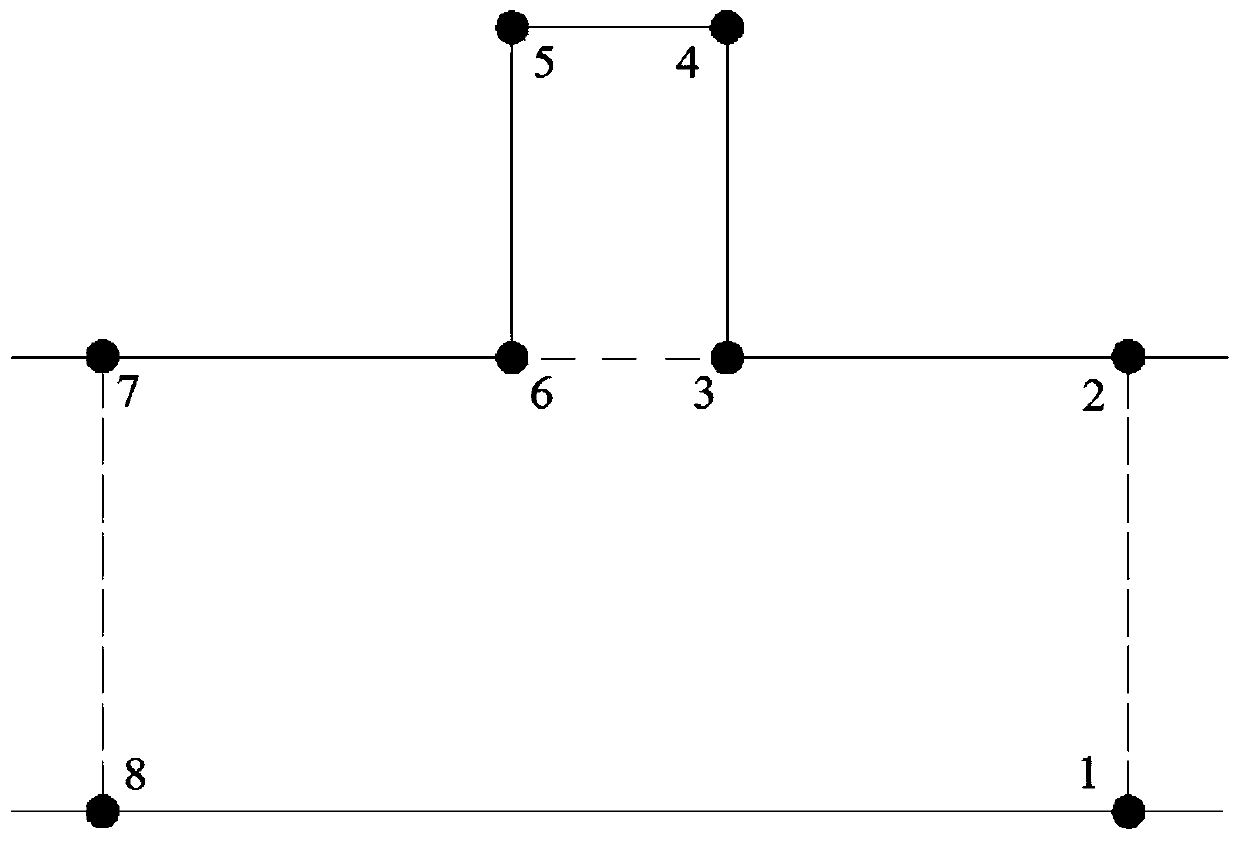

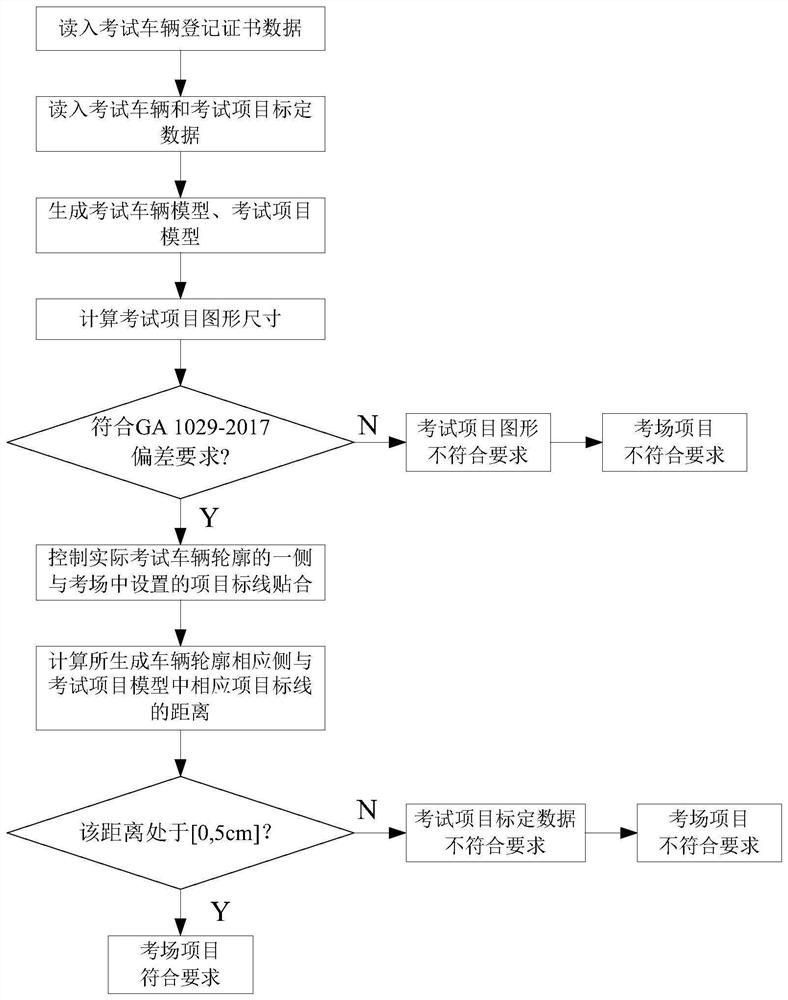

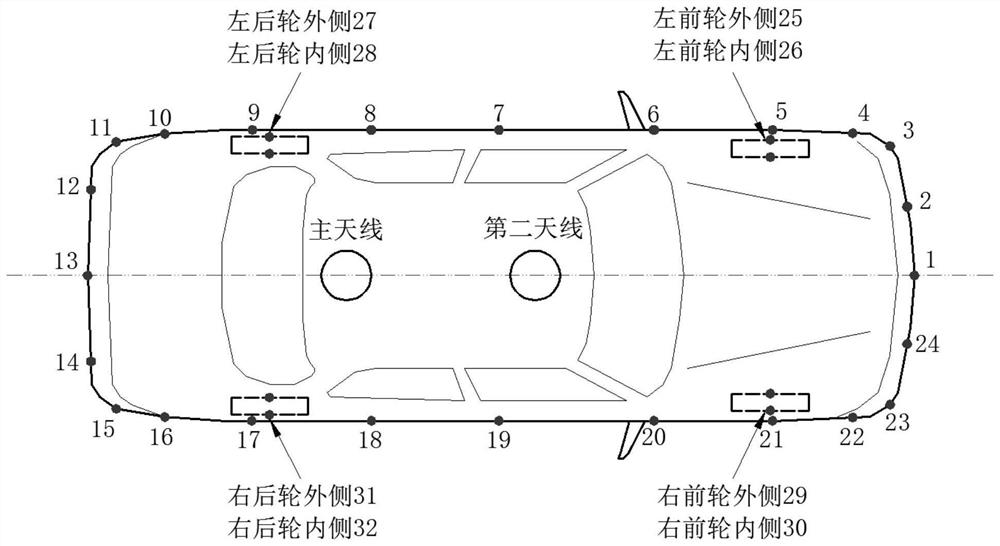

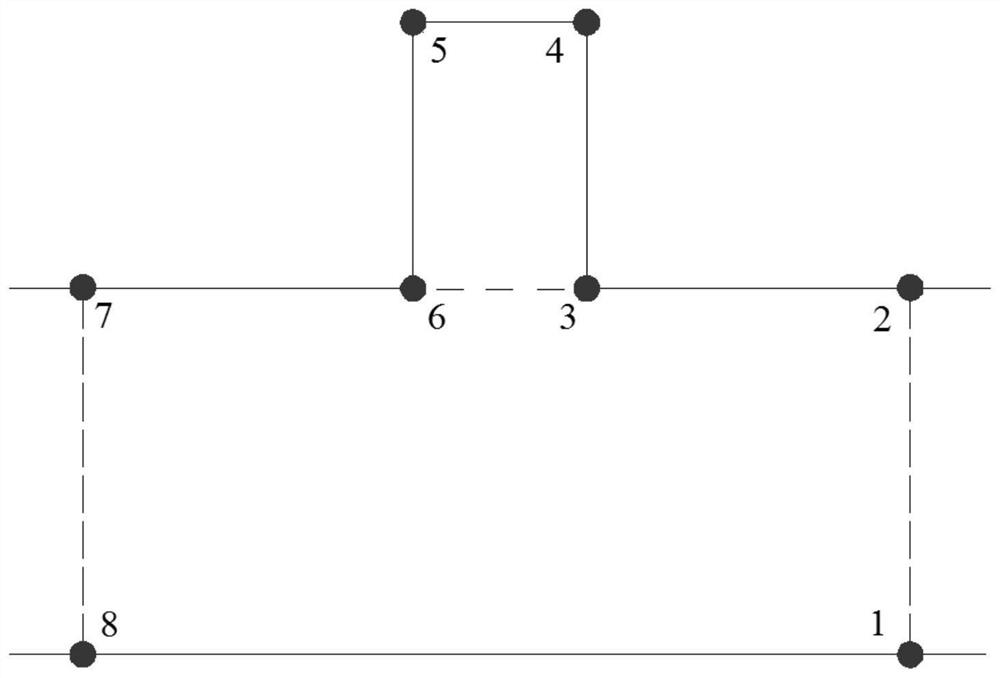

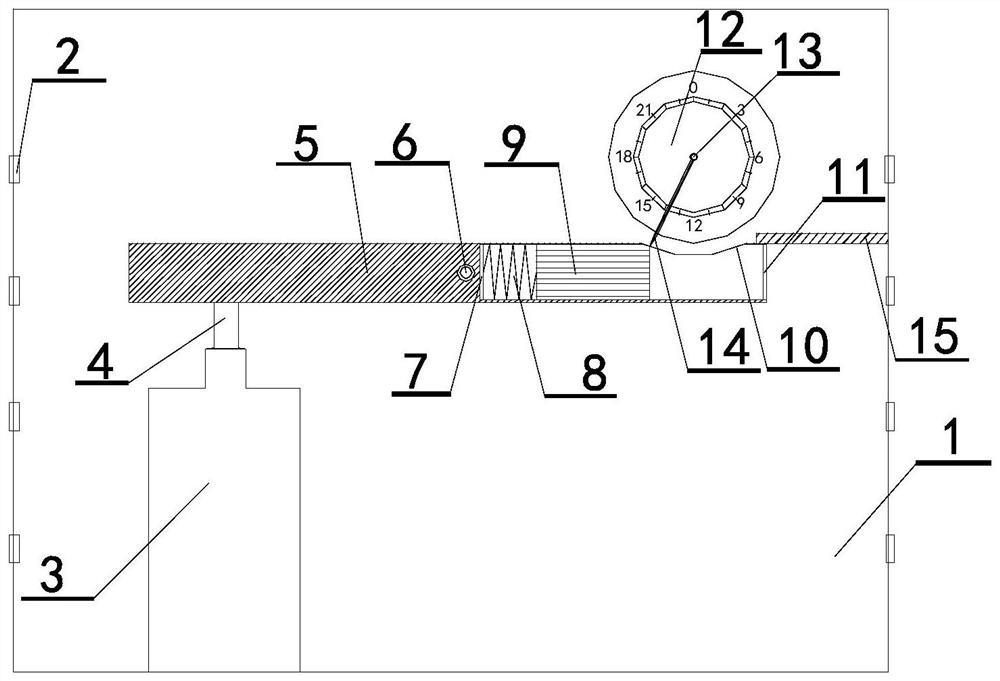

Motor vehicle driver examination item rapid rechecking method based on satellite positioning

ActiveCN111564088ARich technical meansPromote the standardization of examinationsImage analysisCharacter and pattern recognitionSimulationEngineering

The invention provides a motor vehicle driver examination item rapid rechecking method based on satellite positioning. The motor vehicle driver examination item rapid rechecking method comprises the following steps: acquiring examination vehicle registration certificate data and examination vehicle and examination item calibration data of an examination room to generate an examination vehicle model and an examination item model; through the generated examination item model, calculating an examination item graph size by utilizing the item graph characteristics; judging the graphic size compliance of the examination item according to the first judgment condition; controlling one side of the contour of an actual examination vehicle to be attached to an item marking line arranged in the examination room; calculating and generating a vehicle contour according to the received satellite positioning data of the actual examination vehicle; calculating the distance between the corresponding side of the generated vehicle contour and the corresponding item marked line in the examination item model; and judging the conformity of the examination item calibration data according to the calculateddistance and a second judgment condition. According to the invention, the compliance of the graphic size of the examination item set in the examination room of the motor vehicle driver and whether the calibration data meet the requirements can be rechecked.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY

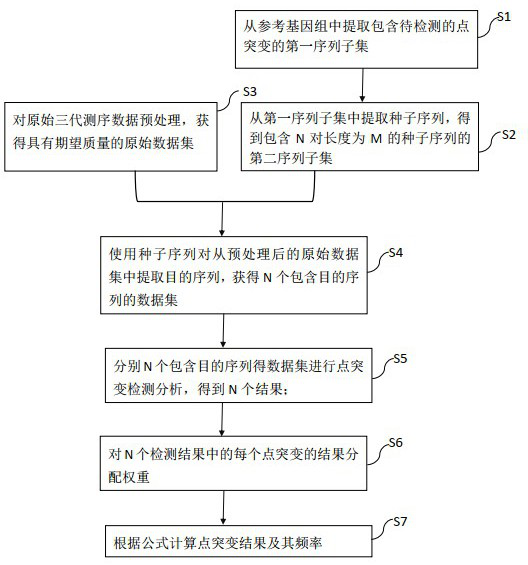

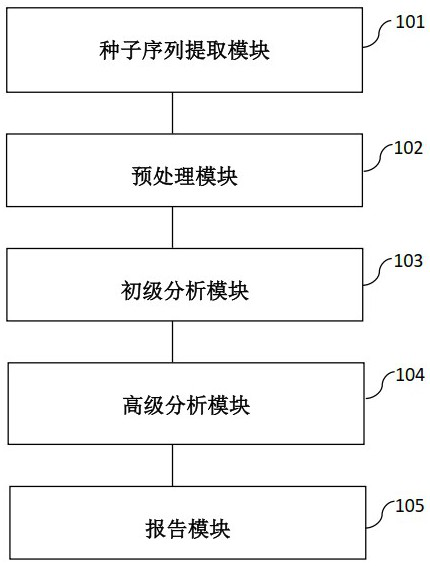

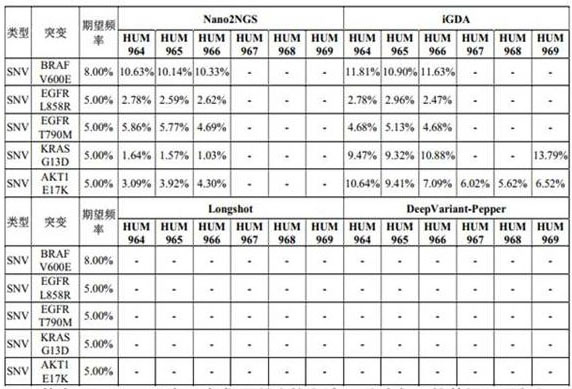

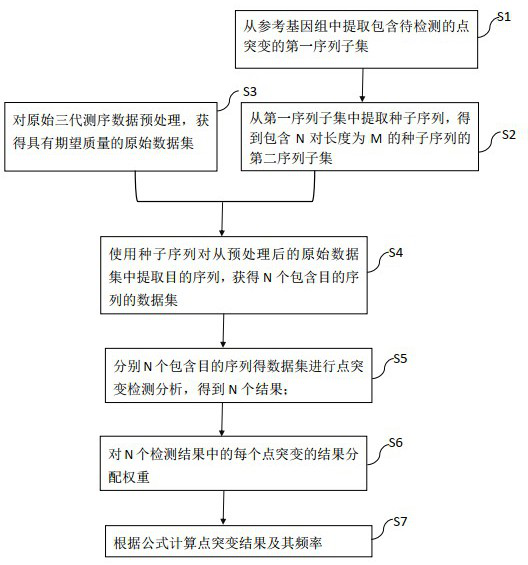

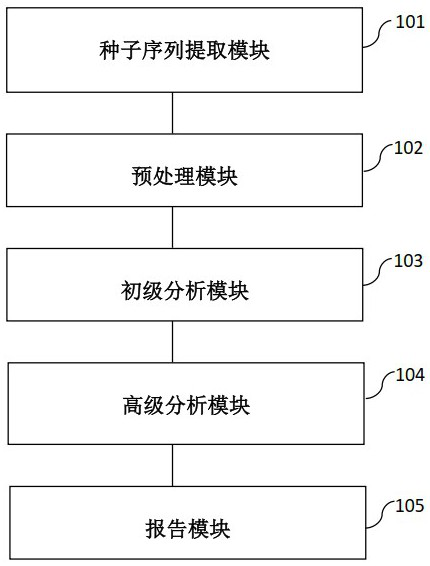

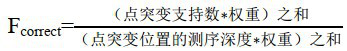

Analysis method and device for detecting point mutation based on third-generation sequencing data

ActiveCN114005489ARich technical meansSolve the current situation of insufficient mutation accuracyProteomicsGenomicsData setAlgorithm

The invention provides an analysis method and device for detecting point mutation based on third-generation sequencing data. The analysis method comprises the following steps: 1) extracting a first sequence subset containing to-be-detected point mutation; 2) extracting a seed sequence from the first sequence subset to obtain a second sequence subset; 3) obtaining an original data set with expected quality; 4) using the seed sequence pair of the second sequence subset to obtain N data sets containing target sequences; 5) carrying out point mutation detection analysis on the N data sets containing the target sequence; 6) allocating a weight W to the result of each point mutation in the N detection results; and 7) calculating a point mutation result and frequency thereof according to a formula. The invention further provides a device for detecting point mutation based on third-generation sequencing data. By using the method provided by the invention, the problem of false negative caused by low comparison rate due to random indel or relatively high sequencing error is effectively avoided from the aspect of data features, and meanwhile, the false positive result can be more effectively controlled.

Owner:QITAN TECH LTD CHENGDU

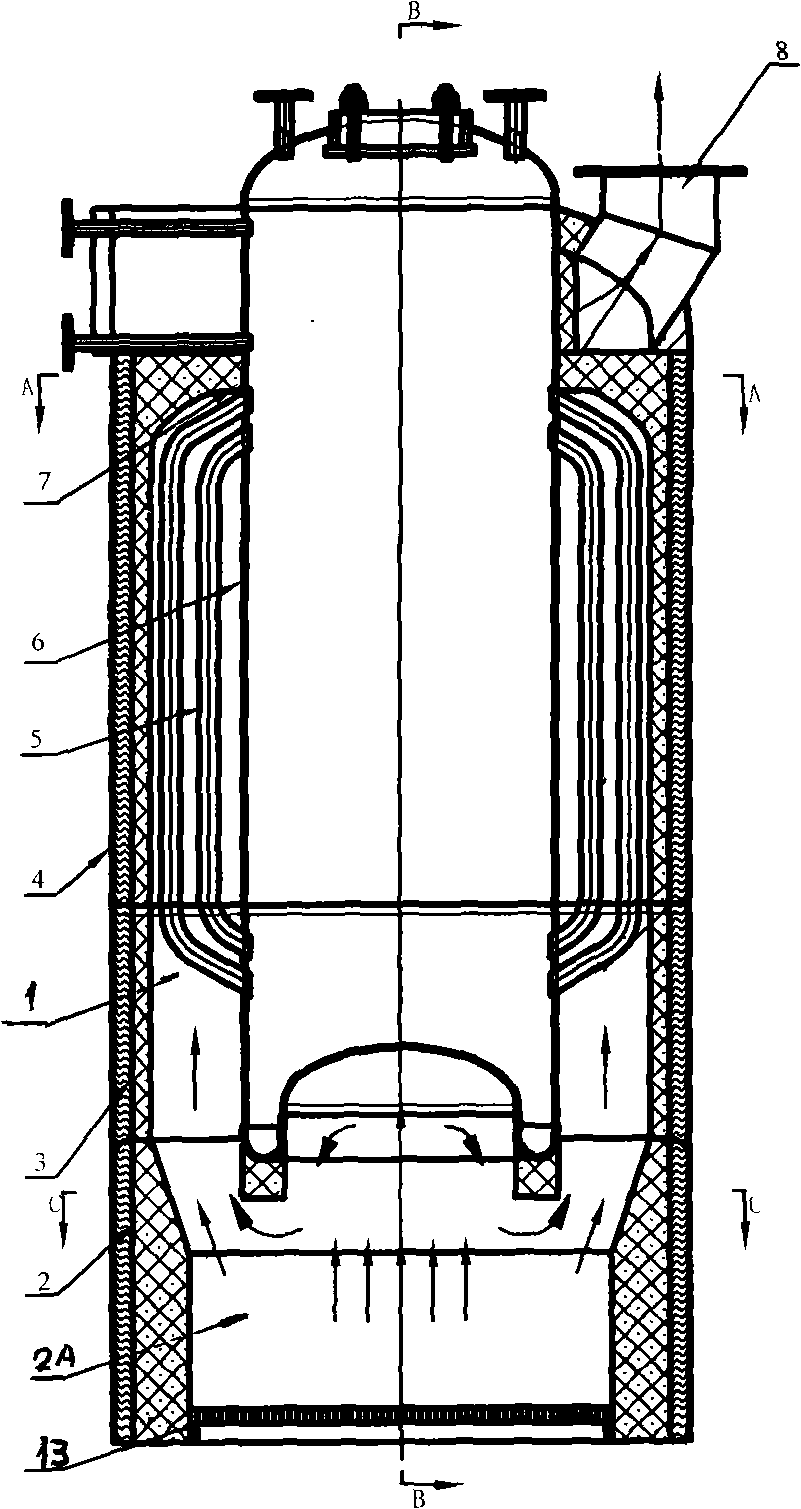

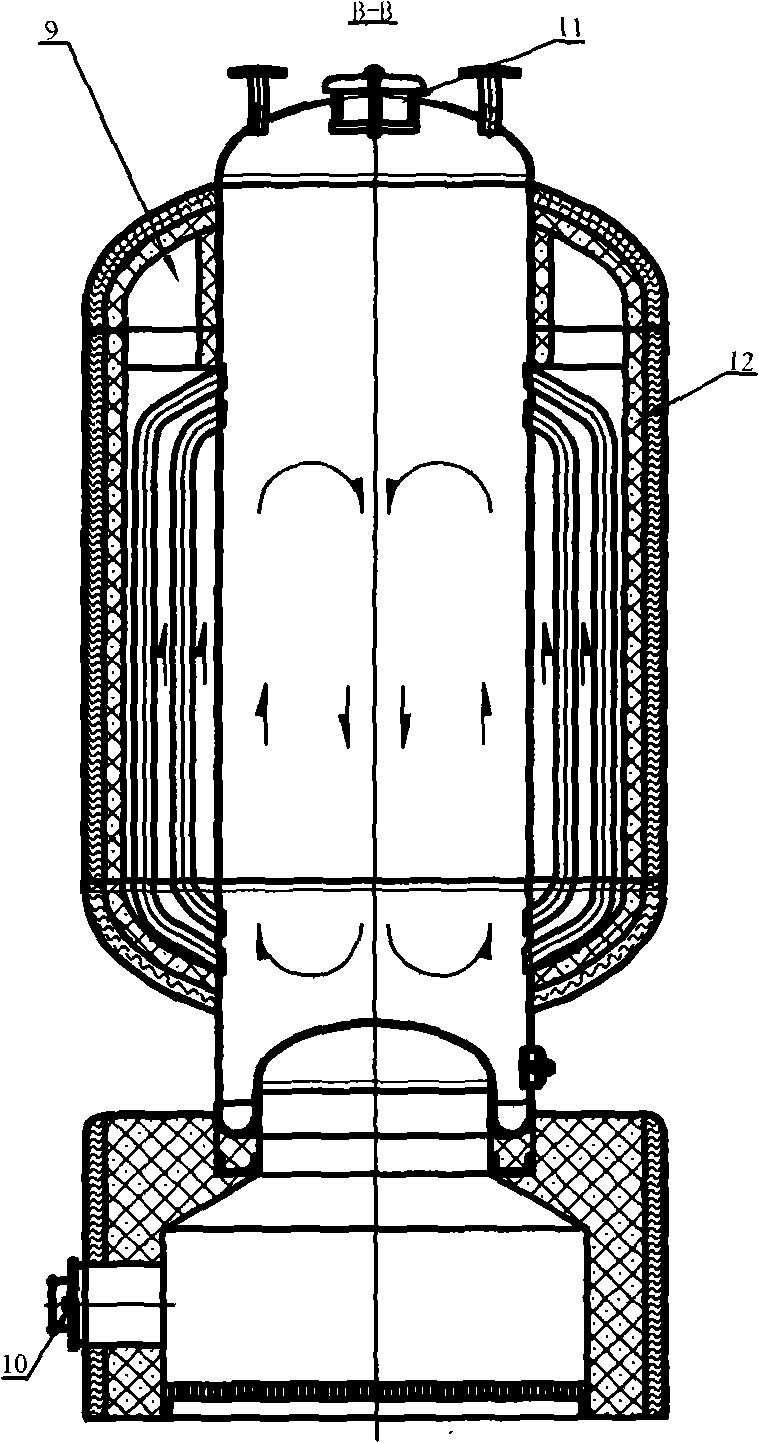

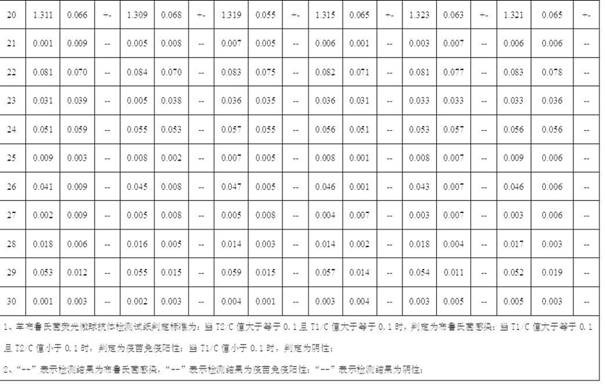

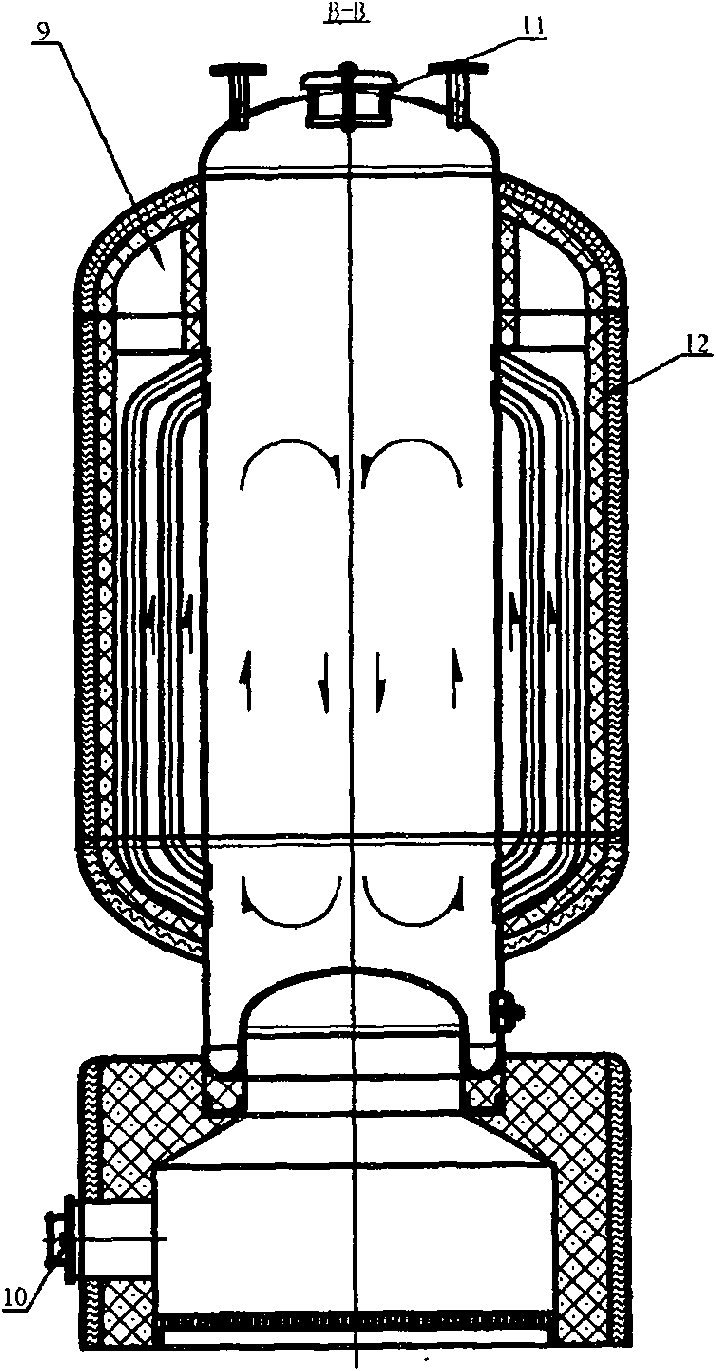

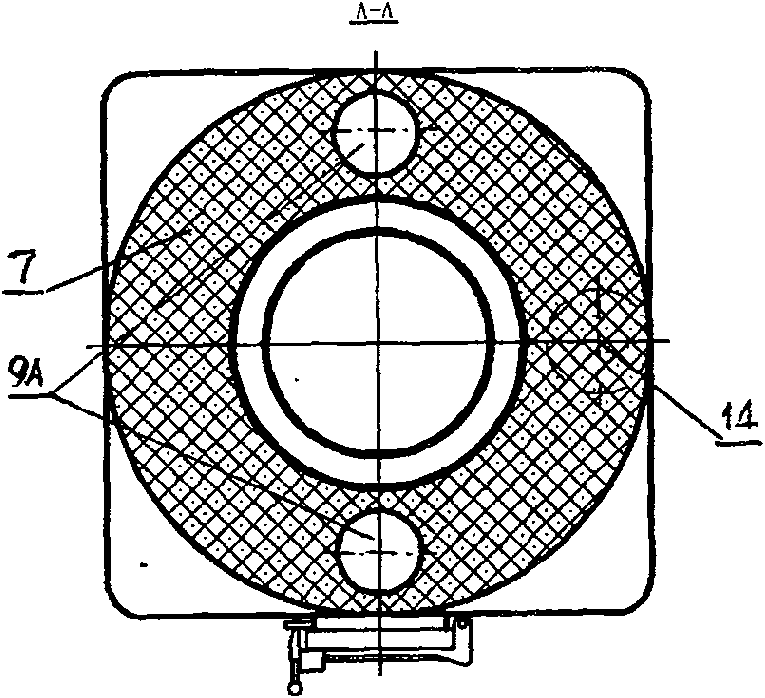

Miniature energy-saving consumption-reducing vertical bearing boiler

The invention relates to an improved design of a vertical pressure boiler with small size, energy saving and consumption reduction. The design structure comprises a water tank of the boiler and a combustion chamber on the upper part of the water tank. The key improvements of a flue which is used for communicating the combustion chamber with a chimney port are as follows: first, the water tank is reformed into a vertical pressure vessel; second, the vertical pressure vessel is located on the upper part of the combustion chamber formed by an outer sheath and compound refractory materials, the periphery of the vertical pressure vessel is provided with an insulation casing, a flue gas channel is formed between the insulation casing and the pressure vessel, and a chimney interface is arranged on the lateral side of the upper end of the insulation casing; third, rib shaped tubes are evenly distributed between the upper section and the lower section, and on the periphery of the vertical pressure vessel; fourth, an upper flue gas damping separator and a lower flue gas damping separator are separately arranged between the flue gas channel and the combustion chamber, the flue gas channel and the flue gas vent.

Owner:陈社庭

A Method for Recognition of Oil, Gas and Water in Gas Logging Based on Parameter Reconstruction

ActiveCN105156104BSolve problemsEnrich existing technical meansBorehole/well accessoriesSoil scienceWell drilling

Owner:CNOOC ENERGY TECH & SERVICES

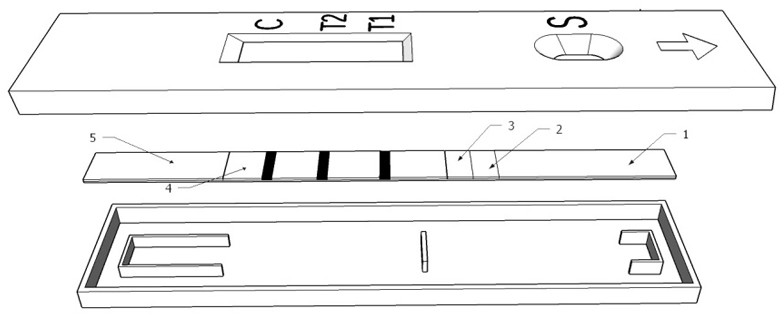

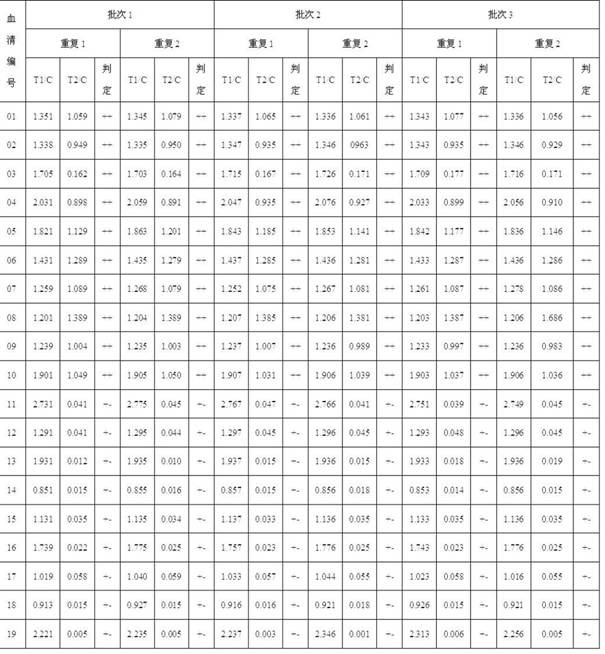

A kind of brucella antibody serological differential diagnosis test paper

ActiveCN109541206BFast waySimple methodBiological material analysisBiological testingAntigenAntiendomysial antibodies

Owner:洛阳现代生物技术研究院有限公司

Miniature energy-saving consumption-reducing vertical bearing boiler

The invention relates to an improved design of a vertical pressure boiler with small size, energy saving and consumption reduction. The design structure comprises a water tank of the boiler and a combustion chamber on the upper part of the water tank. The key improvements of a flue which is used for communicating the combustion chamber with a chimney port are as follows: first, the water tank is reformed into a vertical pressure vessel; second, the vertical pressure vessel is located on the upper part of the combustion chamber formed by an outer sheath and compound refractory materials, the periphery of the vertical pressure vessel is provided with an insulation casing, a flue gas channel is formed between the insulation casing and the pressure vessel, and a chimney interface is arranged on the lateral side of the upper end of the insulation casing; third, rib shaped tubes are evenly distributed between the upper section and the lower section, and on the periphery of the vertical pressure vessel; fourth, an upper flue gas damping separator and a lower flue gas damping separator are separately arranged between the flue gas channel and the combustion chamber, the flue gas channel and the flue gas vent.

Owner:陈社庭

A kind of warp knitted summer quilt fabric and preparation method thereof

ActiveCN111501191BCompact structureStable structureWarp knittingHeating/cooling textile fabricsPolymer sciencePolyamide

The invention discloses a warp-knitted summer quilt fabric and a preparation method thereof. The fabric is a warp-knitted fabric made of polyamide filaments for front combing and polyethylene and polyamide composite filaments for rear combing. Polyamide filaments and The mass ratio of polyethylene and polyamide composite filaments is 1.3-1.6:1, and the preparation method of the fabric is provided. The fabric of the present invention is cool and comfortable to the touch, breathable, bright in luster, and has anti-snagging and anti-drilling properties at the same time Advantages of the invention, the preparation method of the present invention has the advantages of high production efficiency, short process and low cost.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Analysis method and device for detecting point mutations based on third-generation sequencing data

ActiveCN114005489BRich technical meansSolve the current situation of insufficient mutation accuracyProteomicsGenomicsData setGenetics

The invention provides an analysis method and device for detecting point mutations based on three-generation sequencing data. The analysis method of the present invention includes: 1) extracting the first sequence subset containing the point mutation to be detected; 2) extracting the seed sequence from the first sequence subset to obtain the second sequence subset; 3) obtaining the original sequence subset with expected quality Data set; 4) Use the seed sequence pairs of the second sequence subset to obtain N data sets containing the target sequence; 5) Perform point mutation detection and analysis on the N data sets containing the target sequence; 6) Analyze the N detection results The result of each point mutation in is assigned a weight W; 7) Calculate the point mutation result and its frequency according to the formula. The invention also provides a device for detecting point mutations based on three-generation sequencing data. Using the method of the present invention not only effectively avoids the problem of false negatives caused by low alignment rates caused by random indels or high sequencing errors from the perspective of data characteristics, but also can more effectively control the results of false positives.

Owner:QITAN TECH LTD CHENGDU

A fast review method for motor vehicle driver test items based on satellite positioning

ActiveCN111564088BRich technical meansPromote the standardization of examinationsImage analysisCharacter and pattern recognitionGraphicsTest room

The present invention provides a method for quickly reviewing test items of motor vehicle drivers based on satellite positioning. The test item model, using the item graphic features to calculate the test item graphic size; judge the compliance of the test item graphic size according to the first judgment condition; control the side of the actual test vehicle outline to fit the item marking line set in the test room; Receive the satellite positioning data of the actual test vehicle, calculate and generate the vehicle outline; calculate the distance between the corresponding side of the generated vehicle outline and the corresponding item marking line in the test item model; check the conformity of the test item calibration data according to the calculated distance and the second judgment condition Make a judgment. The invention can check whether the compliance of the graphic size of the test items set in the test room of the motor vehicle driver and whether the calibration data meet the requirements.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY

Timing and fixed-point measurement device for air leakage flow field in goaf and its use and measurement method

ActiveCN111811771BAccurately get the flow stateSolve measurement problemsHydrodynamic testingEngineeringAtmospheric sciences

The invention relates to a goaf air leakage flow field measurement technology, a timing and fixed-point measurement device for the goaf air leakage flow field, wherein the lever is rotatably connected in the box through the lever support shaft, and the first side of the lever corresponds to the mouth of the tracer gas bottle There is a bottle stopper; the second side of the lever has a built-in slideway, and the end of the slideway close to the lever support shaft is provided with a spring, the slider is placed in the slideway, and the top of the slideway away from the lever support shaft has a toggle opening; The timing device is placed above the second side of the lever. The timing device has a timing device shaft that can be driven and rotated by the timing device. The timing device pointer is installed on the timing device shaft. The timing device shaft is opposite to the toggle opening. The movement path of the free end enters the toggle opening. The device can complete the measurement of the air leakage flow field in the goaf. The invention also proposes a method for using the device for timing and fixed-point measurement of the air leakage flow field in the goaf, and a method for timing and fixed-point measurement of the air leakage flow field in the goaf.

Owner:CCTEG SHENYANG RES INST

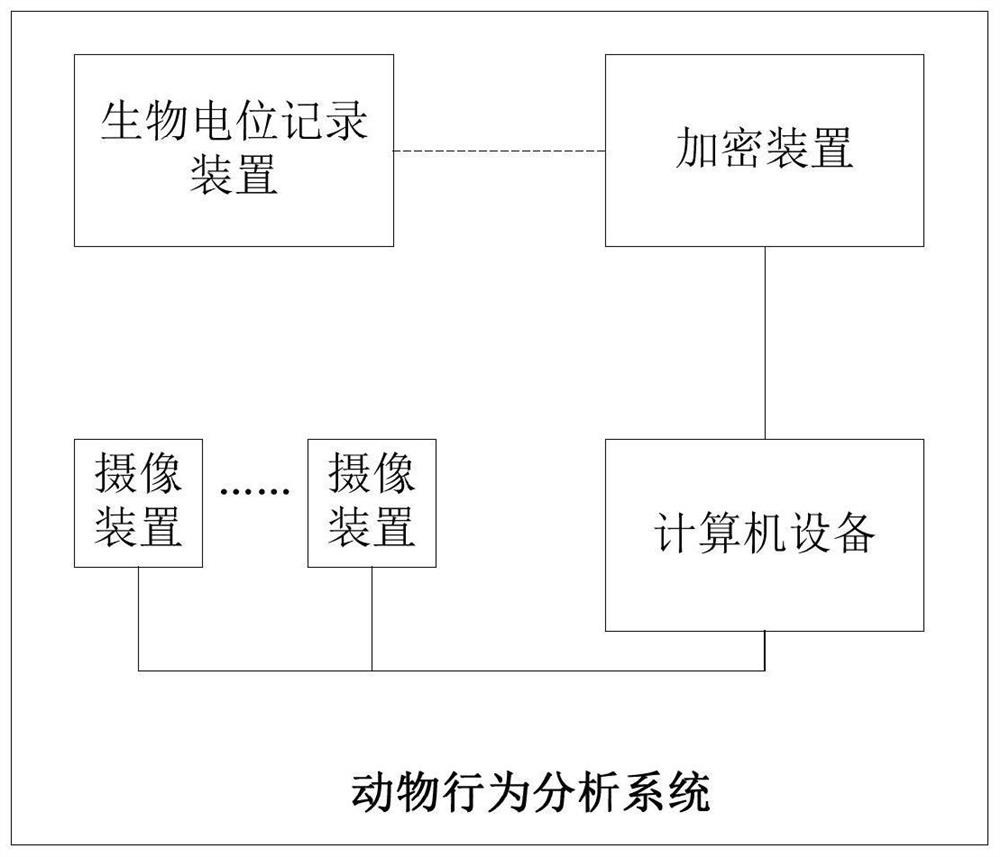

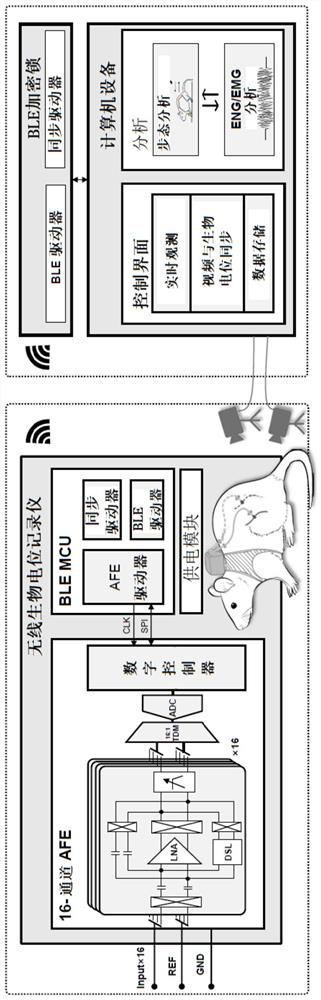

Animal behavior analysis system and method

ActiveCN114793947AImprove accuracyRich technical meansOther apparatusComputer hardwareAnimal science

The invention discloses an animal behavior analysis system and method. The system comprises computer equipment, a biopotential recording device, an encryption device and at least one camera device, wherein the encryption device and the at least one camera device are respectively connected with the computer equipment; the biopotential recording device is in communication connection with the encryption device; the biopotential recording device is used for collecting a bioelectric signal of a target animal and sending the bioelectric signal to the encryption device; the encryption device is used for encrypting the bio-electricity signal to obtain an encrypted electric signal; the at least one camera device is used for shooting a video for a target animal; and the computer equipment is used for performing animal behavior analysis in combination with the encrypted electric signal and the video. According to the animal behavior analysis system, animal behavior analysis can be carried out by combining the bio-electricity signals obtained by the bio-potential recording device and the videos shot by the camera device, the technical means are more diversified, bio-electricity signal analysis accurately corresponding to animal behaviors can be achieved, and the accuracy of animal behavior analysis results is high.

Owner:TSINGHUA UNIV +1

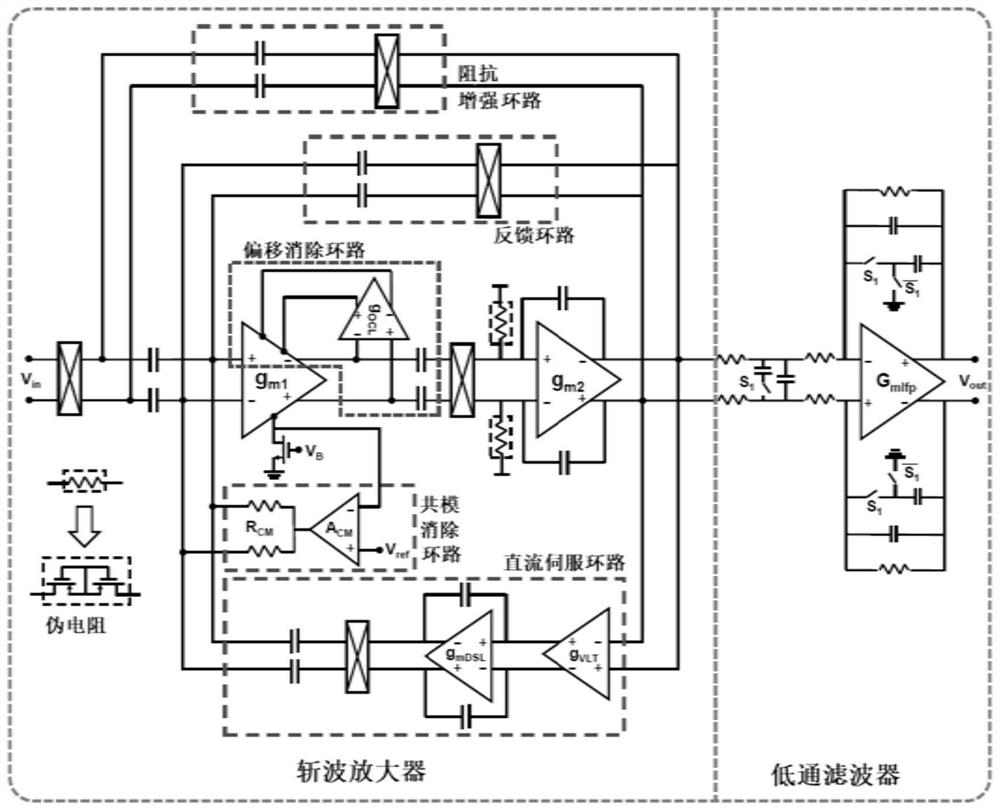

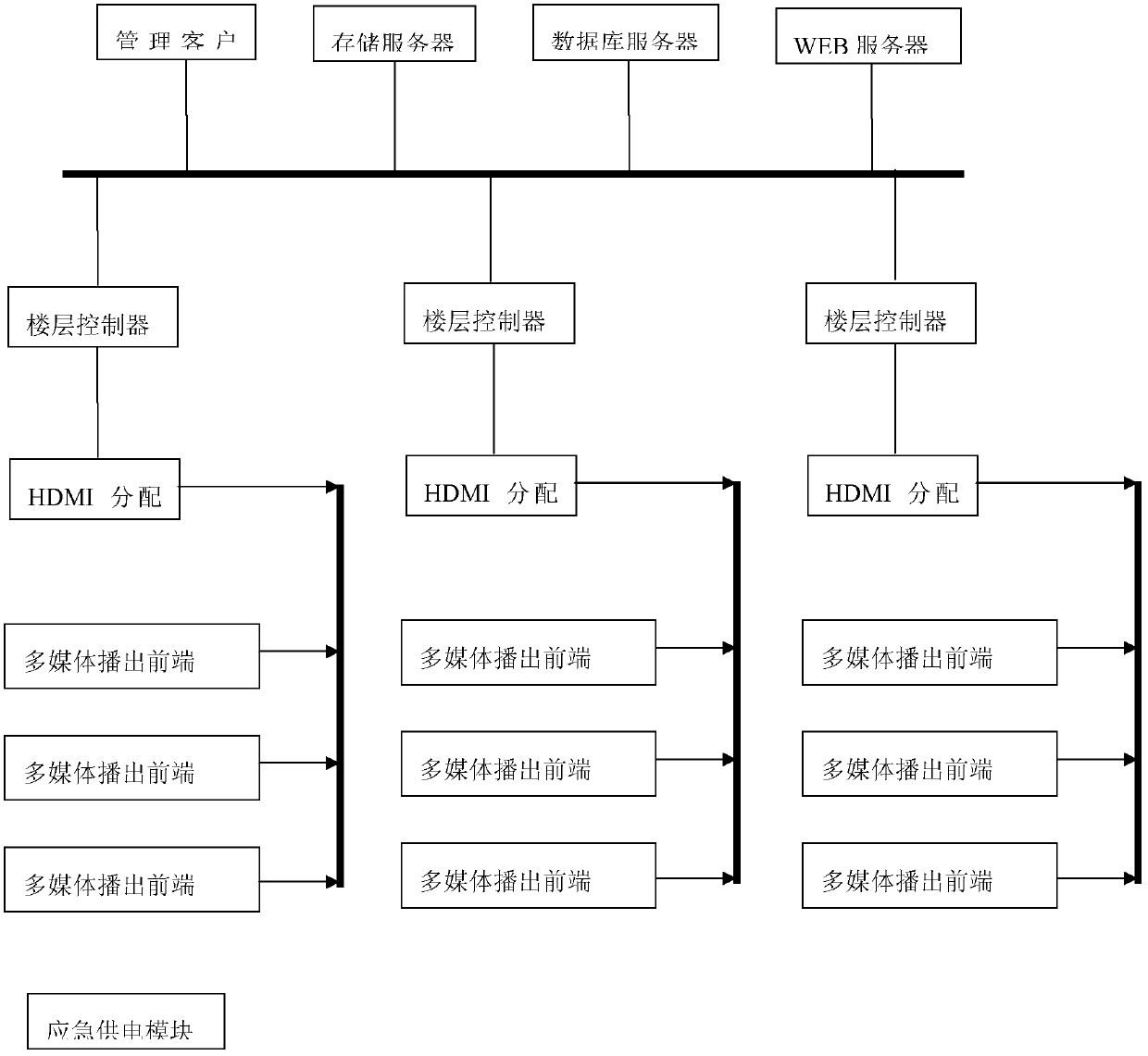

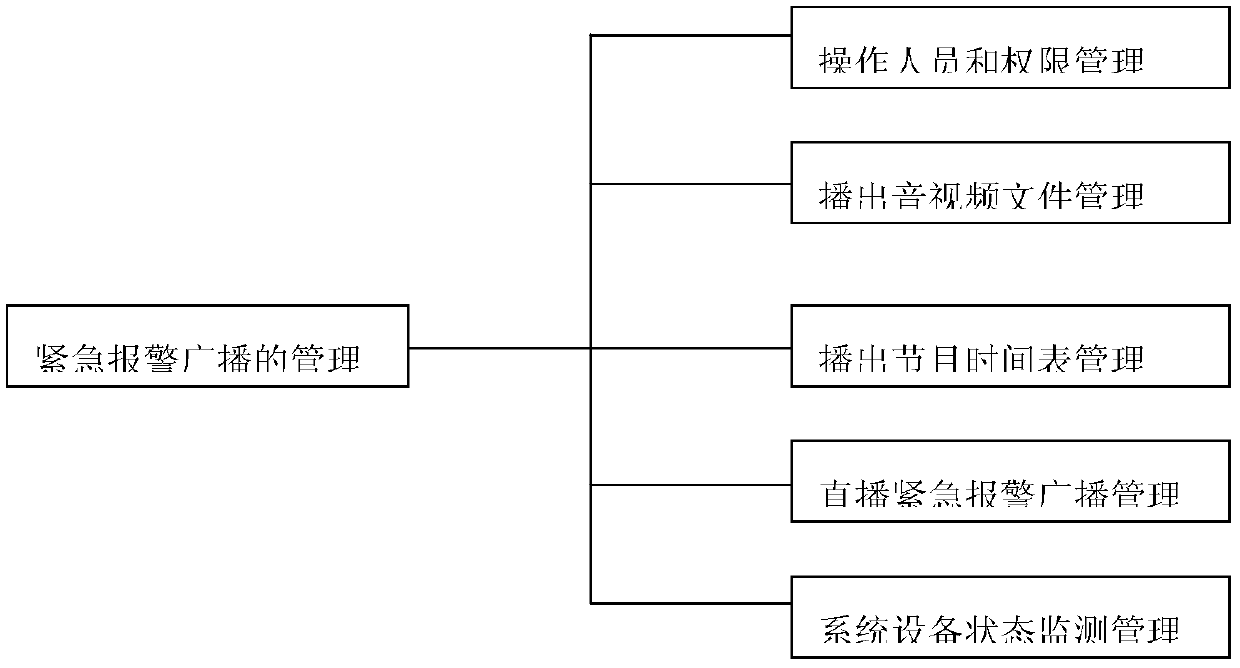

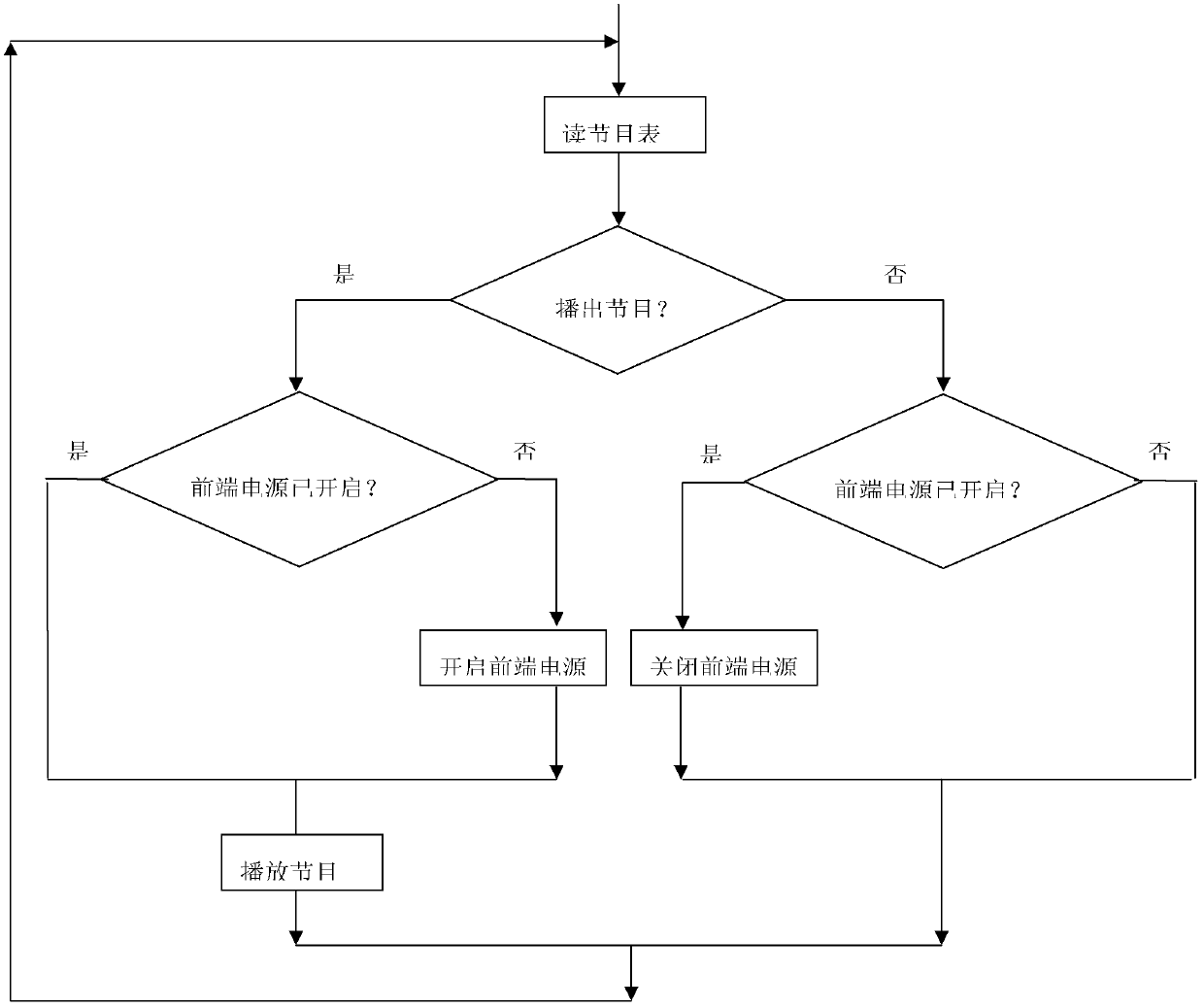

Disaster warning emergency public broadcasting system taking into account hearing-impaired people

ActiveCN102684803BEasy to manageFunction increaseBroadcast specific applicationsAlarmsPublic address systemWeb service

Owner:广东二十四小时科技有限公司

A Comprehensive Analysis Method of Paleofluid Geochemistry

ActiveCN105572131BRich technical meansReliable research resultsRaman scatteringFormation fluidOil and natural gas

The invention discloses a comprehensive analysis method for paleo-fluid geochemistry and mainly aims to solve the problems of single tracing method, strong subjectivity of interpretation process, untight combination of a formed reservoir and geological background and low credibility of obtained achievements in the existing method. According to the comprehensive analysis method disclosed by the invention, the defects of single tracing method, low argument credibility, strong subjectivity of interpretation process, untight combination of the geological background and unreliable obtained achievements in an existing isotope geochemical tracing technique in research on formation fluid movement and oil and gas reservoir formation are overcome; the comprehensive analysis method has important significance for pushing application of fluid geochemistry tracing in oil and natural gas reservoir formation research.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

A method for identifying oil, gas and water based on the intersection of physical properties and gas logging parameters

ActiveCN105041305BSolve problemsEnrich existing technical meansBorehole/well accessoriesPorosityWell logging

The invention discloses a method for oil-gas-water identification based on physical property and gas logging parameter intersection. The method comprises the following steps: reading the C1-C8 average of test well sections by collecting site gas logging data, well logging interpretation porosity data and oil testing data, performing parameter reconstruction, obtaining a TCS parameter, building a plate, determining limit of various fluid properties in the plate, performing on-site verification, and performing popularization and application in more wells on the site if no error occurs. The method solves the problem of immoderate reliance on software identification and hardware developers, enriches existing technical means, improves well drilling oil-gas-water layer identification efficiency, reduces identification difficulty, improves technical levels of field workers and also has the effect of promoting later-period oil-gas-water identification and instrument popularization.

Owner:CNOOC ENERGY TECH & SERVICES

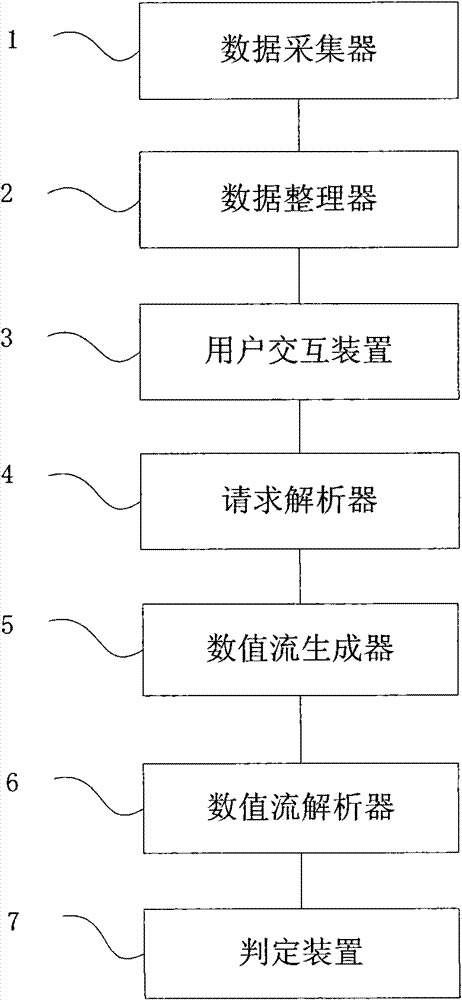

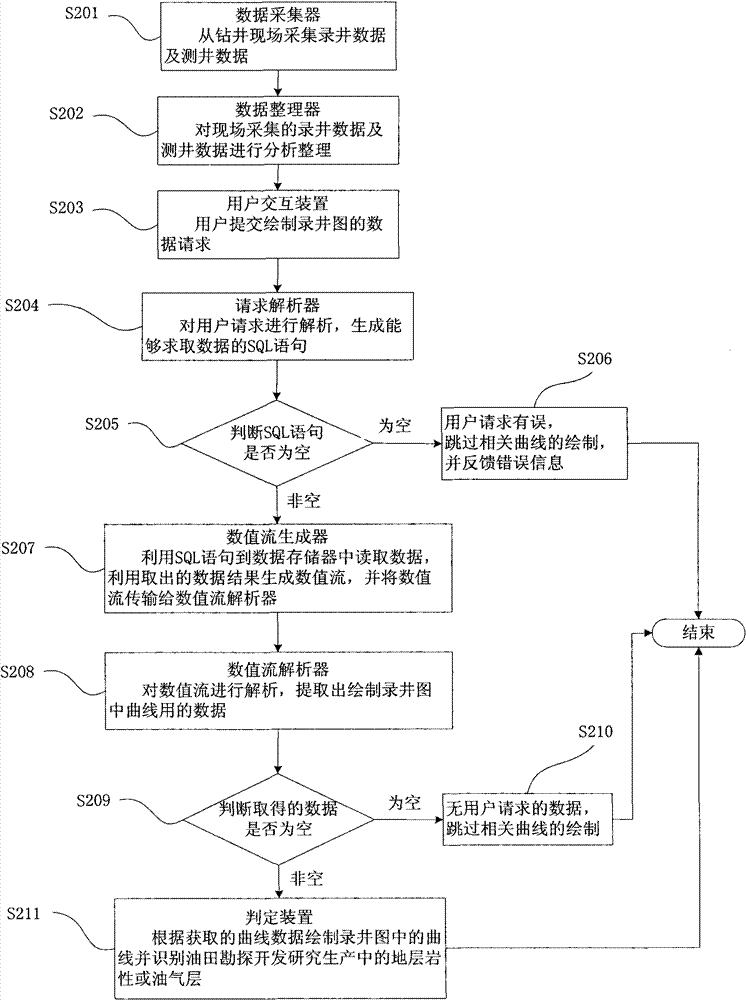

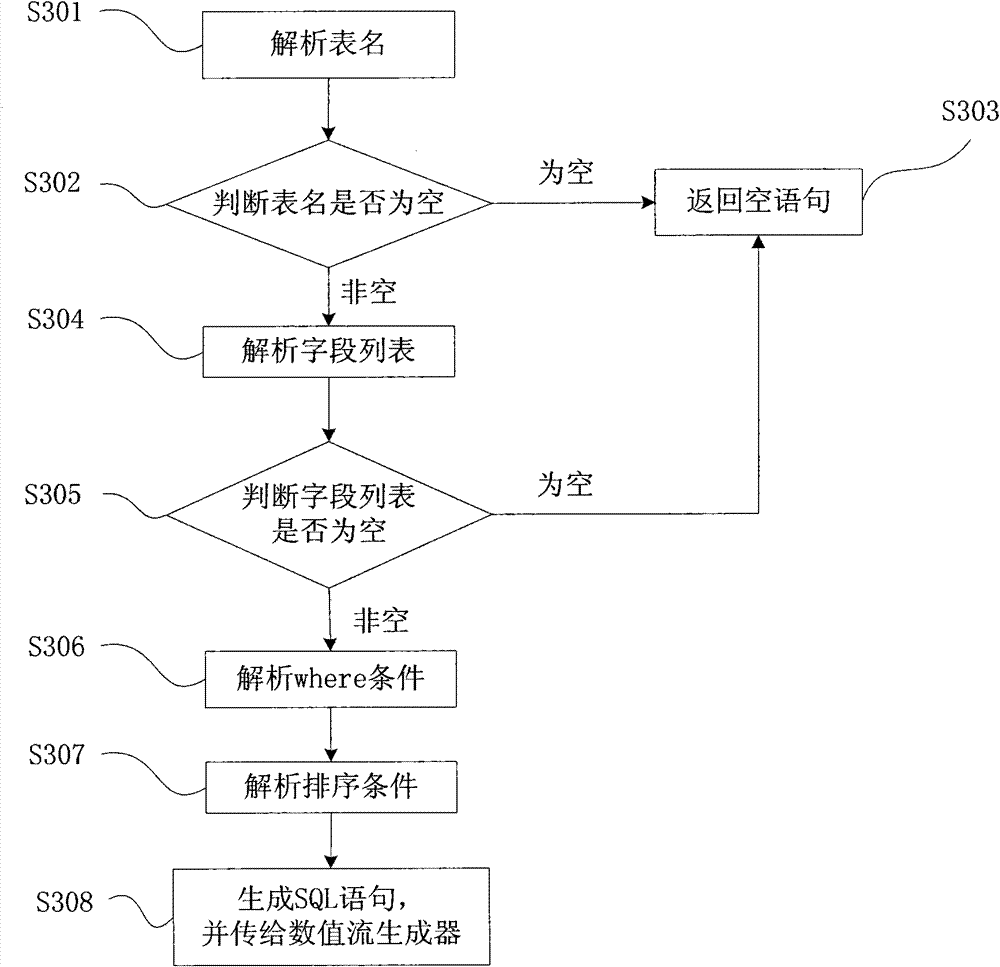

Method and device for transmitting and analyzing numerical flow of curve data in logging system

ActiveCN101781986BRich technical meansImprove transmission efficiencySurveyConstructionsLithologyData acquisition

The invention relates to a method and a device for transmitting and analyzing numerical flow of curve data. The method comprises the following steps: acquiring data; sorting the data; receiving a request; analyzing the request submitted by a user, and generating an SQL sentence capable of calculating data from a data storage; calculating the data by using the SQL sentence, generating the numerical flow by using the acquired data result and transmitting the numerical flow; analyzing the numerical flow, and acquiring the curve data used in drawing a logging map; and drawing a curve in the logging map according to the acquired curve data and identifying formation lithology or hydrocarbon reservoir in scientific research and production for oil filed exploration and development. The device fortransmitting and analyzing the numerical flow of the curve data comprises a data acquisition unit, a data storage unit, a user interaction device, a request analyzer, a numerical flow generator, a numerical flow analyzer and a judging device. Through the method and the device for transmitting and analyzing the numerical flow of the curve data, the data processing capability and accuracy are improved greatly.

Owner:PETROCHINA CO LTD

A screening method for 108 over-the-counter drugs in veterinary preparations

ActiveCN107202839BPromote healthy developmentRich technical meansComponent separationHigh-Throughput Screening MethodsMedicine

The invention discloses a screening method for 122 nonprescription drugs in veterinary medicine preparations. The screening method comprises the following steps specifically: preparation of a standard working solution, analysis pretreatment of a sample to be measured, establishment and qualitative analysis of a database and the like. Through a constructed high-throughput screening and qualitative detection platform, the detection of a single compound is developed into simultaneous detection of various compounds in the field, and compared with the prior art, the technical means for detecting various compounds in one substance is more perfect, so that the cost is greatly reduced, and the work efficiency is greatly improved. The method plays an important role in veterinary medicine illegal addition and bacterial drug resistance plan implemented in the department of agriculture. Sample detection is carried out in provincial animal product quality detection center of our country, and through incomplete statistics, ten thousands of samples are popularized and applied.

Owner:河南省兽药饲料监察所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com