Goaf air leakage flow field fixed-time and fixed-point measuring device, and using and measuring method

A technology of measuring device and timing device, applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc., can solve the unresolved method, theoretical basis and basic data acquisition means of goaf flow field parameters , Can not meet the fine gas control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

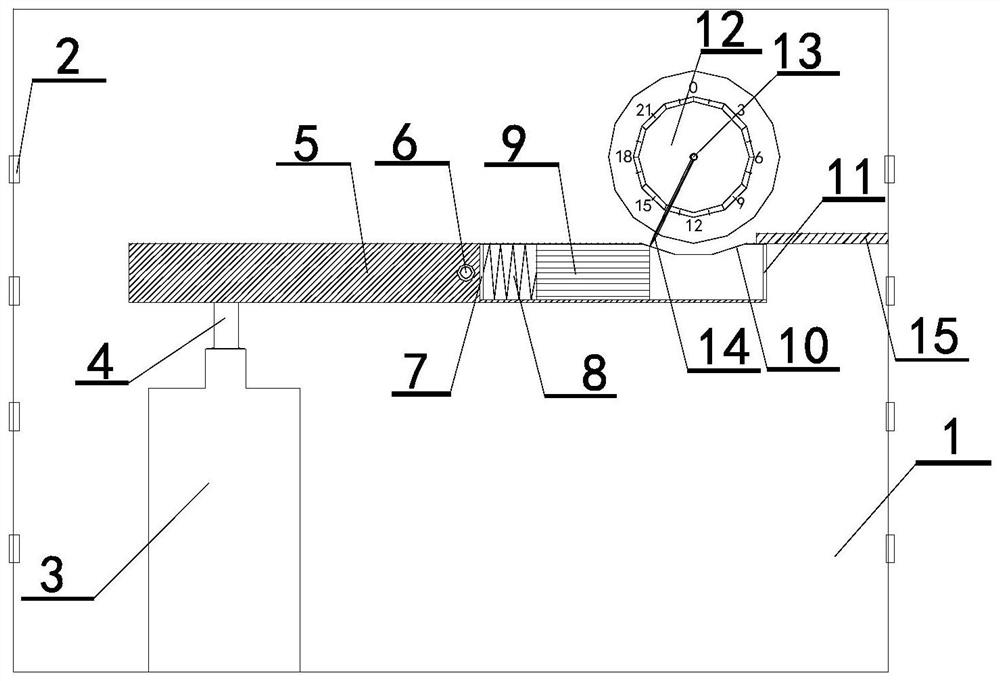

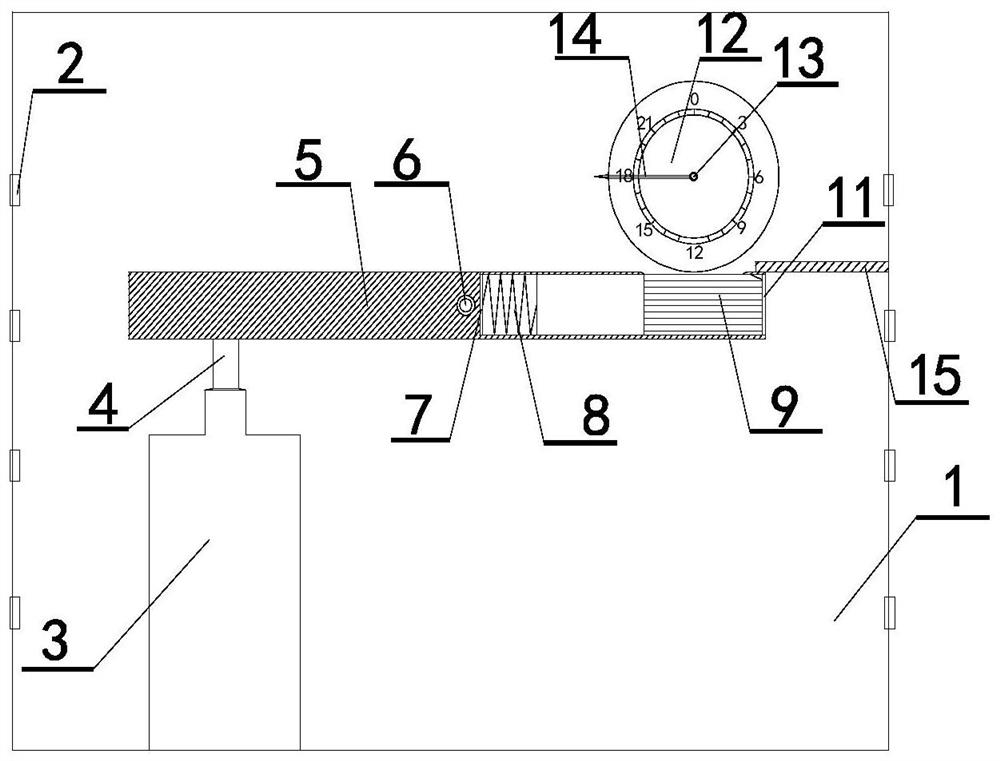

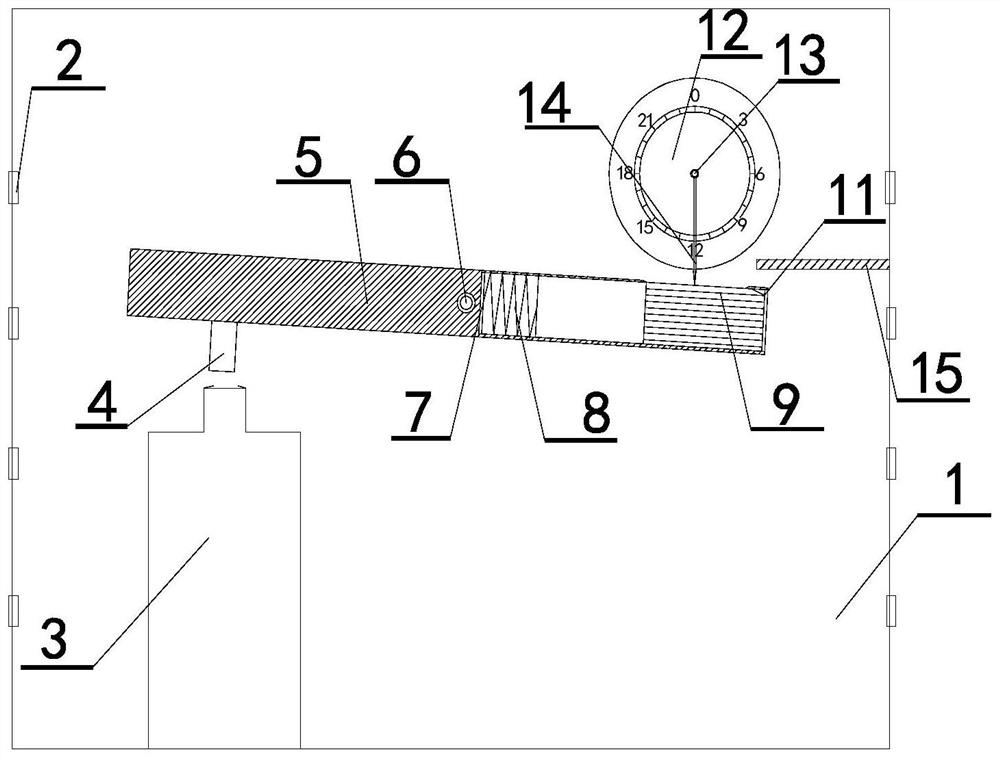

[0031] Such as Figure 1-Figure 3 As shown, the timing and fixed-point measurement device 16 of the goaf air leakage flow field proposed in this embodiment includes a box body 1, and a tracer gas bottle 3, a bottle stopper 4, a lever 5, and a lever support shaft arranged inside the box body 1. 6. The slider 9, the slider baffle 11 and the timing device 12, wherein the box body 1 is provided with a release hole 2, the lever support shaft 6 is connected to the middle section of the lever 5, and the lever 5 is rotatably connected to the lever 5 through the support shaft of the lever 5. Inside the box 1, the top of the tracer gas bottle 3 has a bottle mouth, and the tracer gas bottle 3 is arranged below the first side of the lever 5, and the first side of the lever 5 corresponds to the bottle stopper 4 at the mouth of the tracer gas bottle 3; the lever 5 The second side has a built-in slideway, and the end of the slideway close to the lever support shaft 6 is provided with a sprin...

Embodiment 2

[0037] The method for using the timing and fixed-point measuring device 16 of the air leakage flow field in the goaf proposed in this embodiment uses the timing and fixed-point measuring device 16 for the air leakage flow field in the goaf proposed in Embodiment 1, and the method is as follows:

[0038] The timing and fixed-point measurement device 16 of the air leakage flow field in the goaf is debugged, the bottle stopper 4 of the tracer gas bottle 3 is tightly plugged, the pointer 14 of the timing device is located at the bottom end of the toggle opening 10, and the lever 5 is in a balanced state, which is Timing device 12 is in untimed state, as figure 1 shown.

[0039] Tighten the clockwork of the timing device 12 to time the measuring device, the pointer 14 of the timing device leaves the toggle opening 10, under the push of the spring 8, the slide block 9 slides to the right, the toggle opening 10 is blocked by the slide block 9, and the lever 5 is still in a balanced ...

Embodiment 3

[0042] The timing and fixed-point measurement method for the goaf air leakage flow field proposed in this embodiment uses the timing and fixed-point measurement device 16 for the goaf air leakage flow field proposed in Embodiment 1.

[0043] Such as Figure 4-Figure 6 As shown, when the underground working face of the coal mine is in the mining process, the timed and fixed-point measurement device 16 for the air leakage flow field in the goaf is placed at the tail position behind the hydraulic support of the coal mining face 18, and is placed in the coal mine underground along the direction of the coal mining face 18. When the working face is in the mining process, the timed and fixed-point measurement device 16 of the air leakage flow field in the goaf is placed at the tail position behind the hydraulic support of the coal mining face 18. The distance between the strike direction of the coal working face 18 and the rear tail is Y, such as Figure 4 As shown, where X can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com