A kind of warp knitted summer quilt fabric and preparation method thereof

A kind of fabric and warp knitting technology, applied in warp knitting, fabric surface trimming, knitting and other directions, can solve the problems of not being able to meet the requirements of lightness and softness of summer quilt fabrics, affecting the effect and use of cloth surface, insufficient air permeability and elasticity, etc. Achieve the effects of compact yarn body structure, overcoming the heavy feeling of chemical fiber and plastic, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw materials: the front comb is twisted polyamide filament, the denier is 40D, the number of holes is 12f, the twist is 15 pieces / 10cm, the monofilament cross-section is trilobal, and the back comb is polyethylene / polyamide composite sheath-core filament , the denier is 40D, the number of holes is 12f, the cross-sectional shape is circular, the core material is polyamide, and the mass ratio of the skin layer to the core layer is 4:6; polyamide filament and polyethylene, polyamide composite filament The mass ratio is 1.3:1.

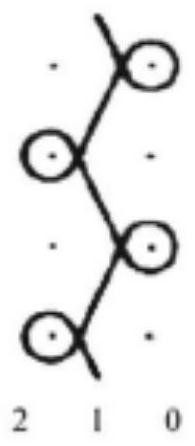

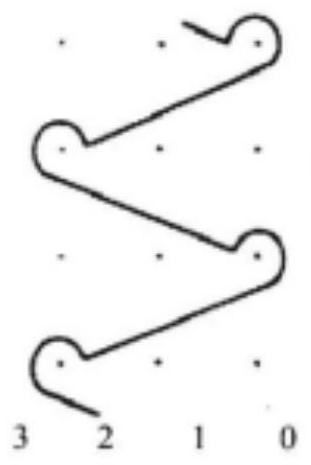

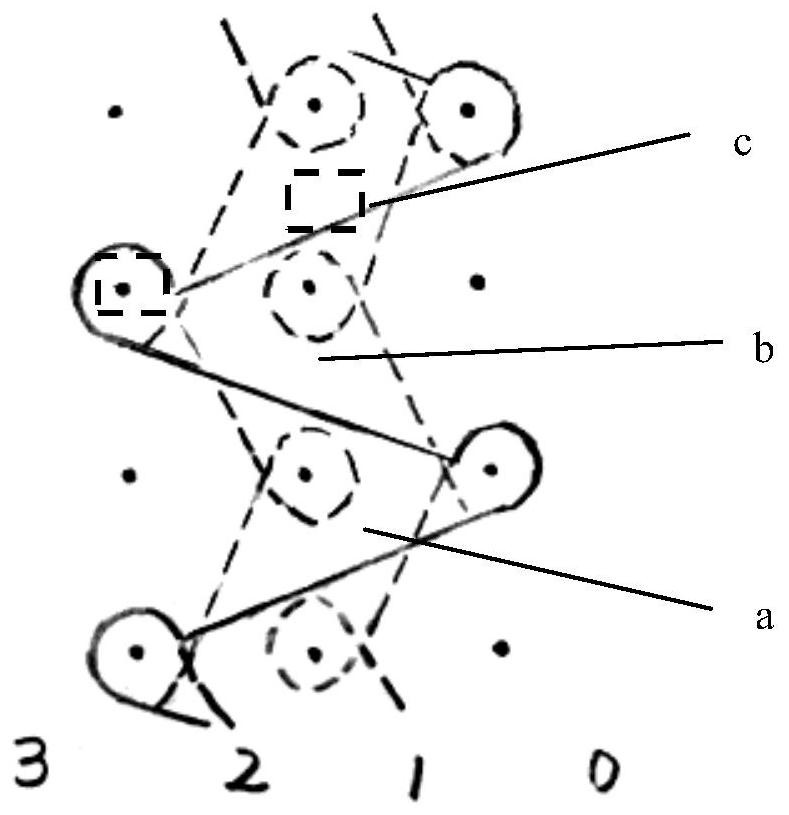

[0027] Tissue: front comb is open meridian oblique tissue, back comb is closed meridian flat tissue, such as Figure 1-3 as shown, image 3 In the middle, a-front comb; b-back comb; c-the intersection of front comb and back comb extension line, the movement track of the front comb is 3-2 / 0-1 / / , and the movement track of the back comb filament is 1 -2 / 1-0 / / .

[0028] Weave: Brushed front and back throughout.

[0029] Printing and dyeing: the gray...

Embodiment 2

[0031] Raw materials: the front comb is twisted polyamide filament, the denier is 60D, the number of holes is 36f, the twist is 10 pieces / 10cm, the monofilament cross-section is trilobal, and the back comb is polyethylene / polyamide composite sheath-core filament , the denier is 70D, the number of holes is 24f, the cross-sectional shape is circular, the core material is polyamide, and the mass ratio of the skin layer to the core layer is 5:5; polyamide filament and polyethylene, polyamide composite filament The mass ratio is 1.4:1.

[0032] Tissue: The front comb is an open warp oblique tissue, the back comb is a closed warp flat tissue, the movement trajectory of the front comb is 4-3 / 0-1 / / , and the movement trajectory of the back comb filament is 1-2 / 1-0 / / .

[0033] Weave: Brushed front and back throughout.

[0034] Printing and dyeing: the gray cloth is watered, printed or dyed, softened, and hot-pressed for setting. The temperature of the hot-pressing and setting treatme...

Embodiment 3

[0036] Raw materials: the front comb is twisted polyamide filament, the denier is 70D, the number of holes is 24f, the twist is 20 pieces / 10cm, the monofilament cross-section is trilobal, and the back comb is polyethylene / polyamide composite sheath-core filament , the denier is 55D, the number of holes is 36f, the cross-sectional shape is circular, the core material is polyamide, and the mass ratio of the skin layer to the core layer is 6:4; polyamide filament and polyethylene, polyamide composite filament The mass ratio is 1.6:1.

[0037]Weave: The front comb is an open warp weave, the back comb is a closed warp flat weave, the movement track of the front comb is 3-2 / 0-1 / / , and the movement track of the back comb is 1-2 / 1-0 / / .

[0038] Weave: Brushed front and back throughout.

[0039] Printing and dyeing: the gray cloth is watered, printed or dyed, softened, and hot-pressed for setting. The temperature of the hot-pressing and setting treatment process is 115°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com