Patents

Literature

36results about How to "Not easy to hook" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

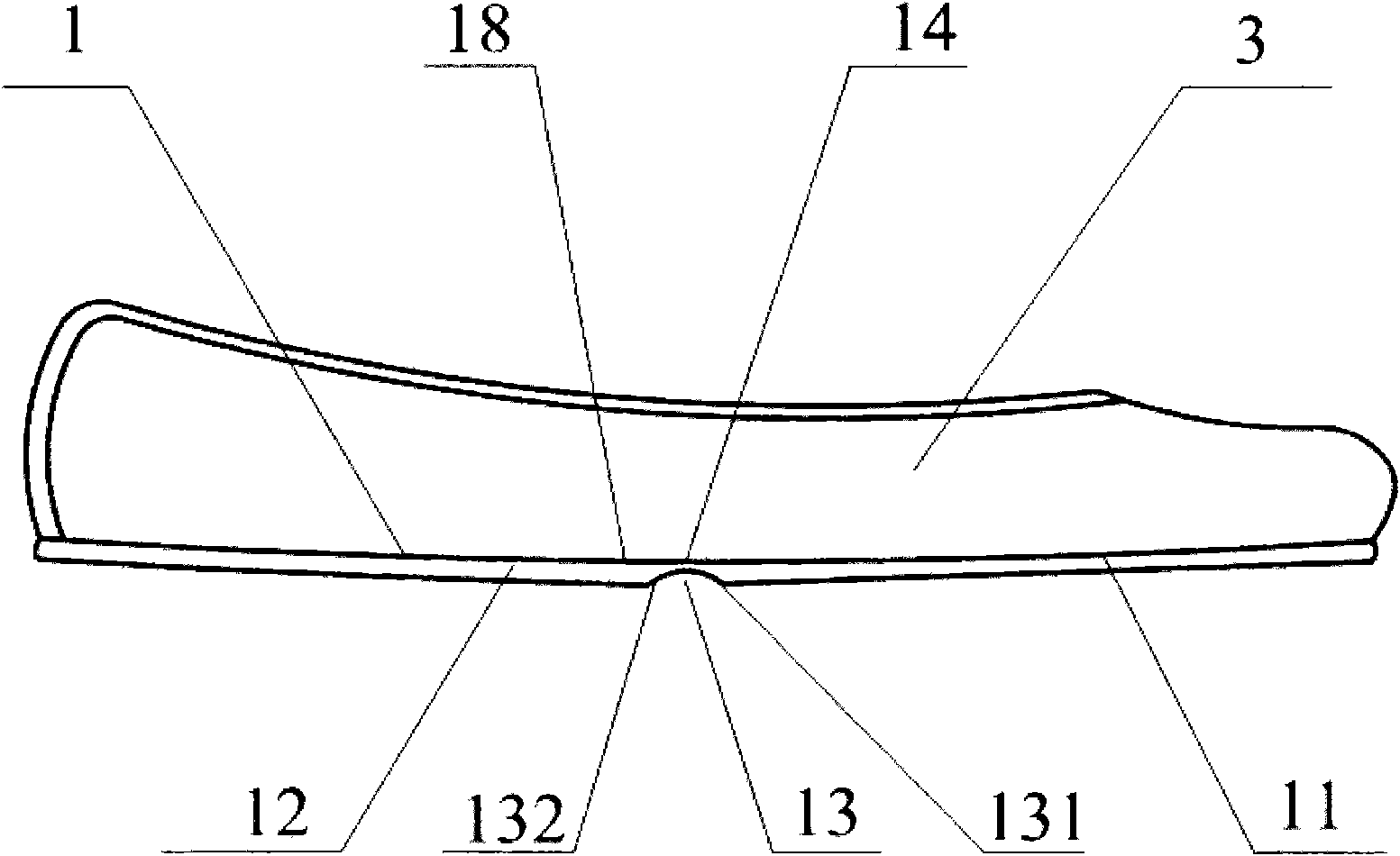

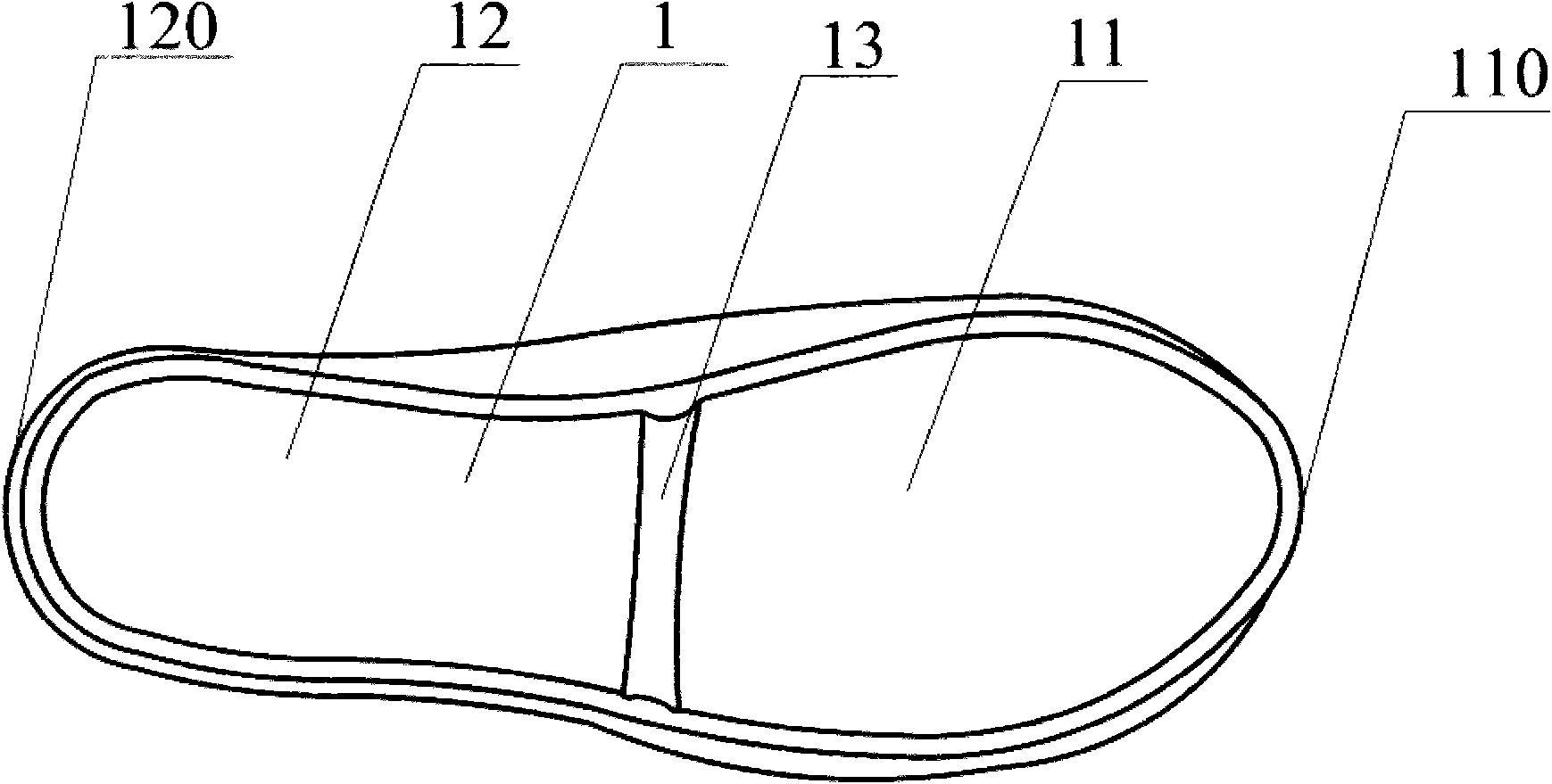

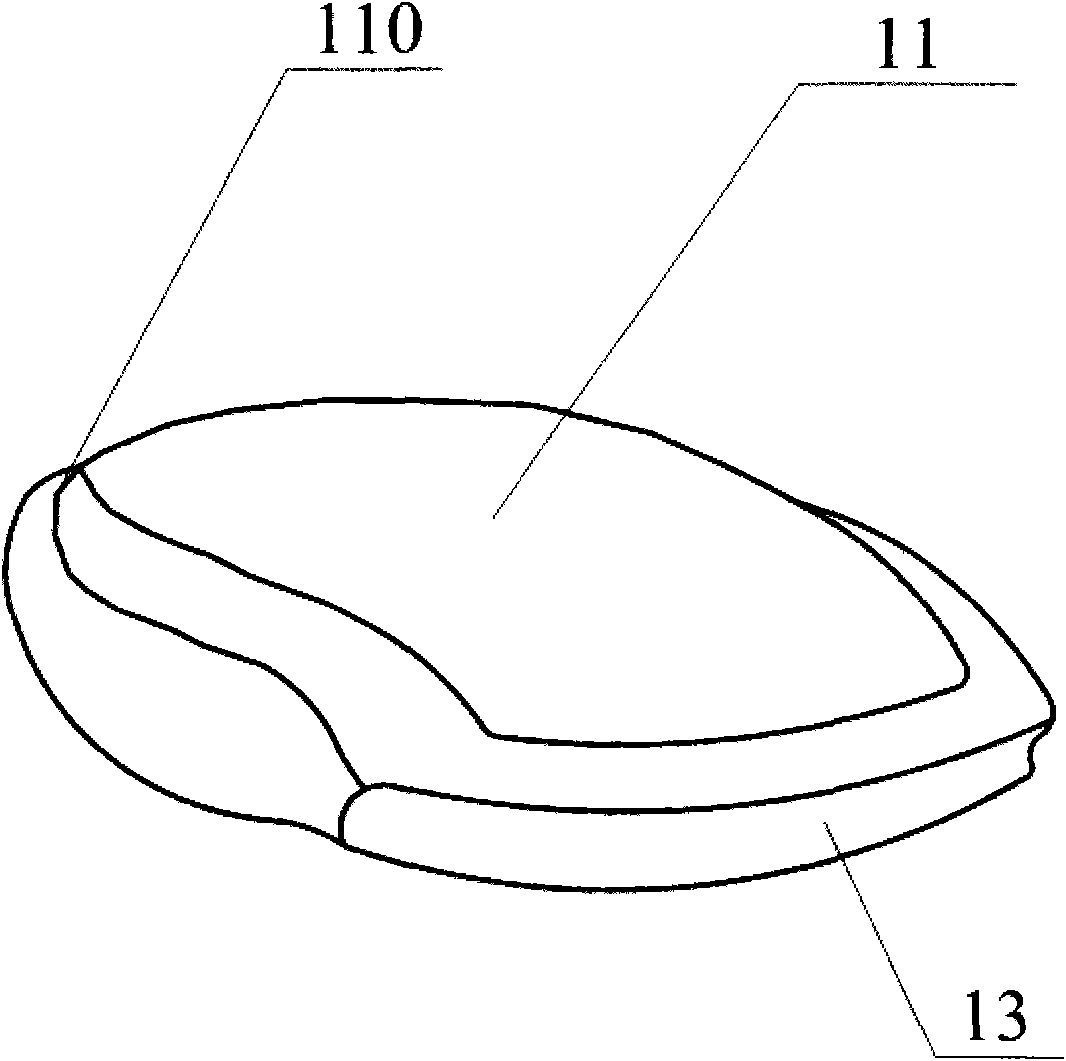

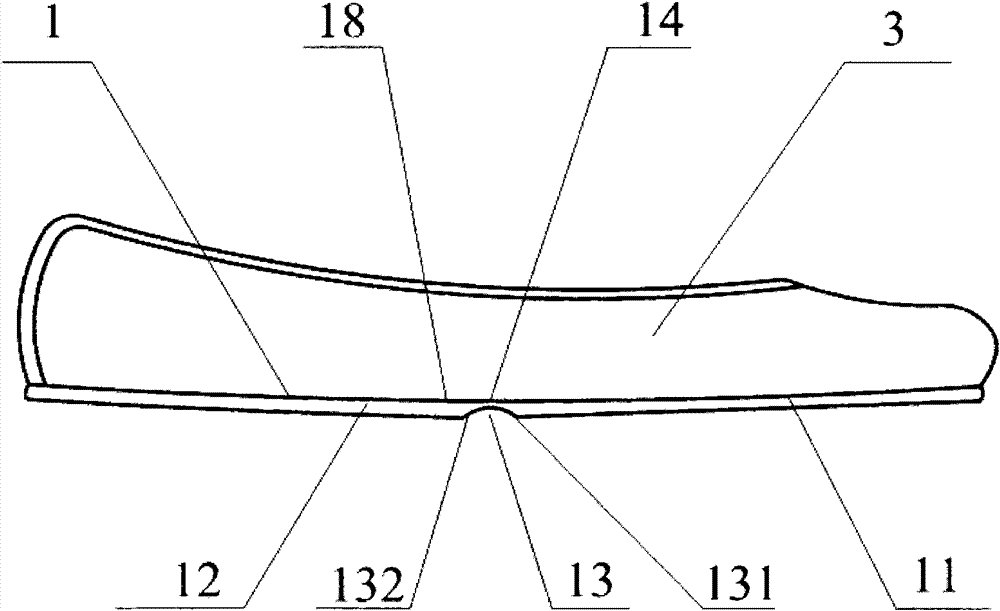

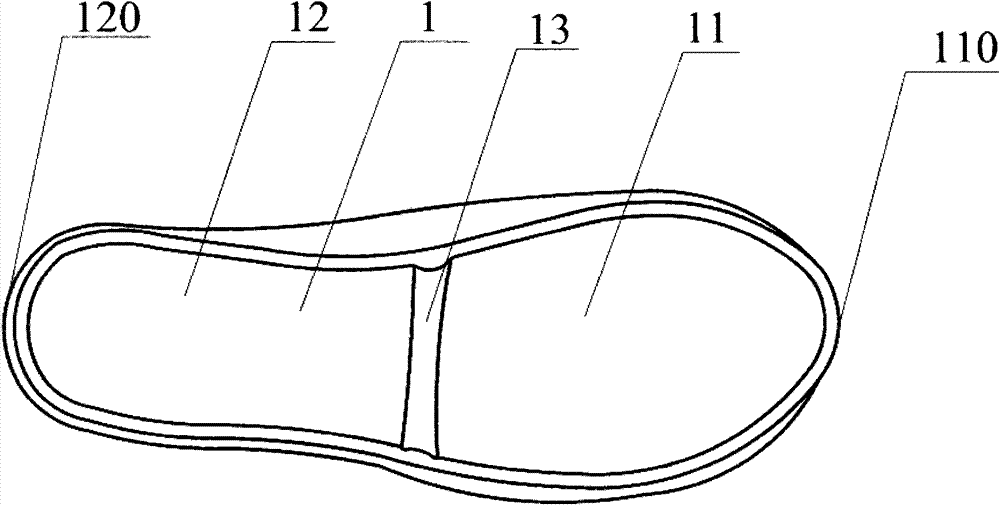

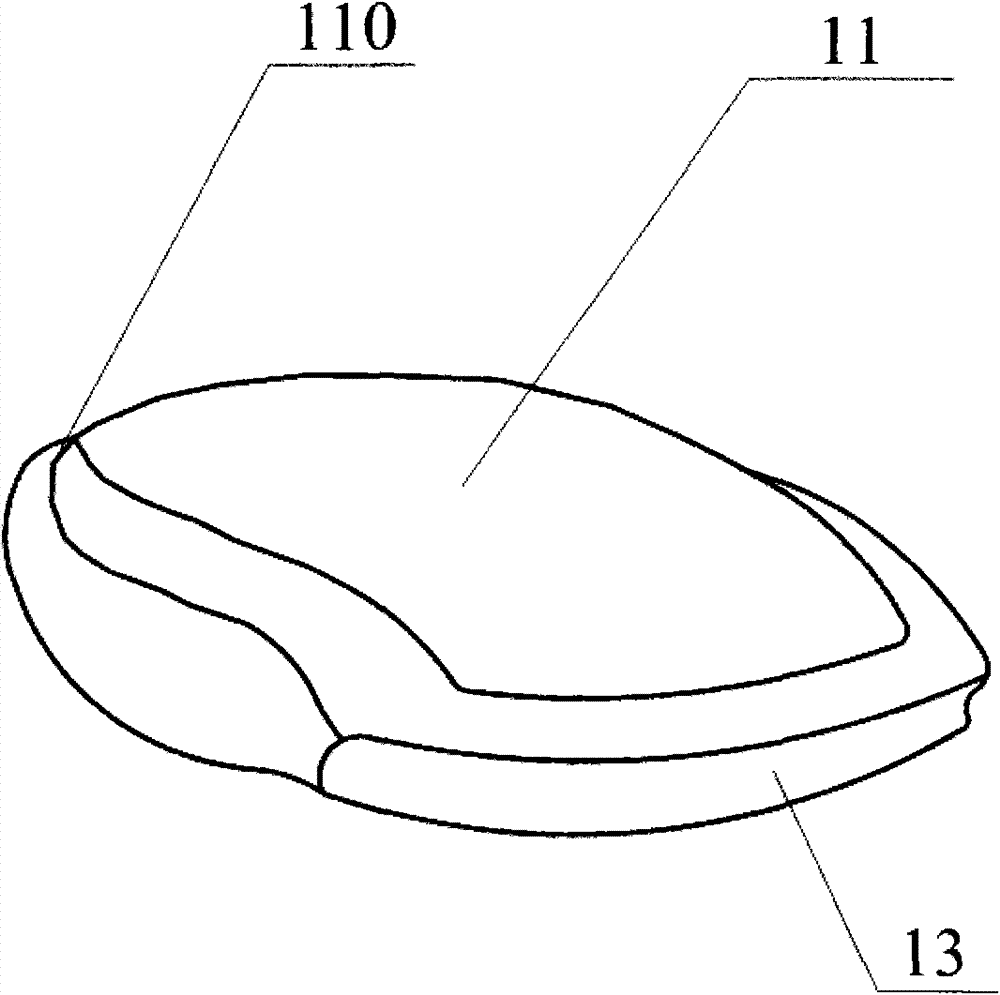

Fold-up shoe

Owner:浙江璐卡丝国际贸易有限公司

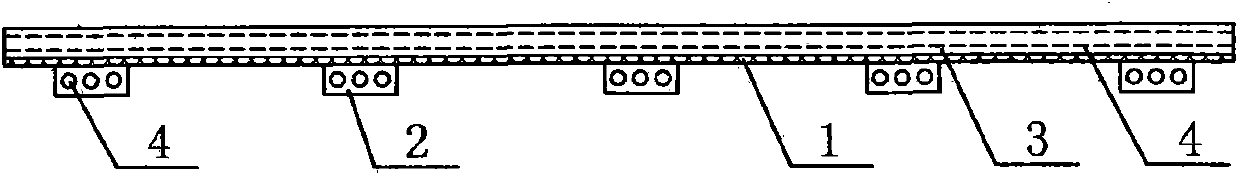

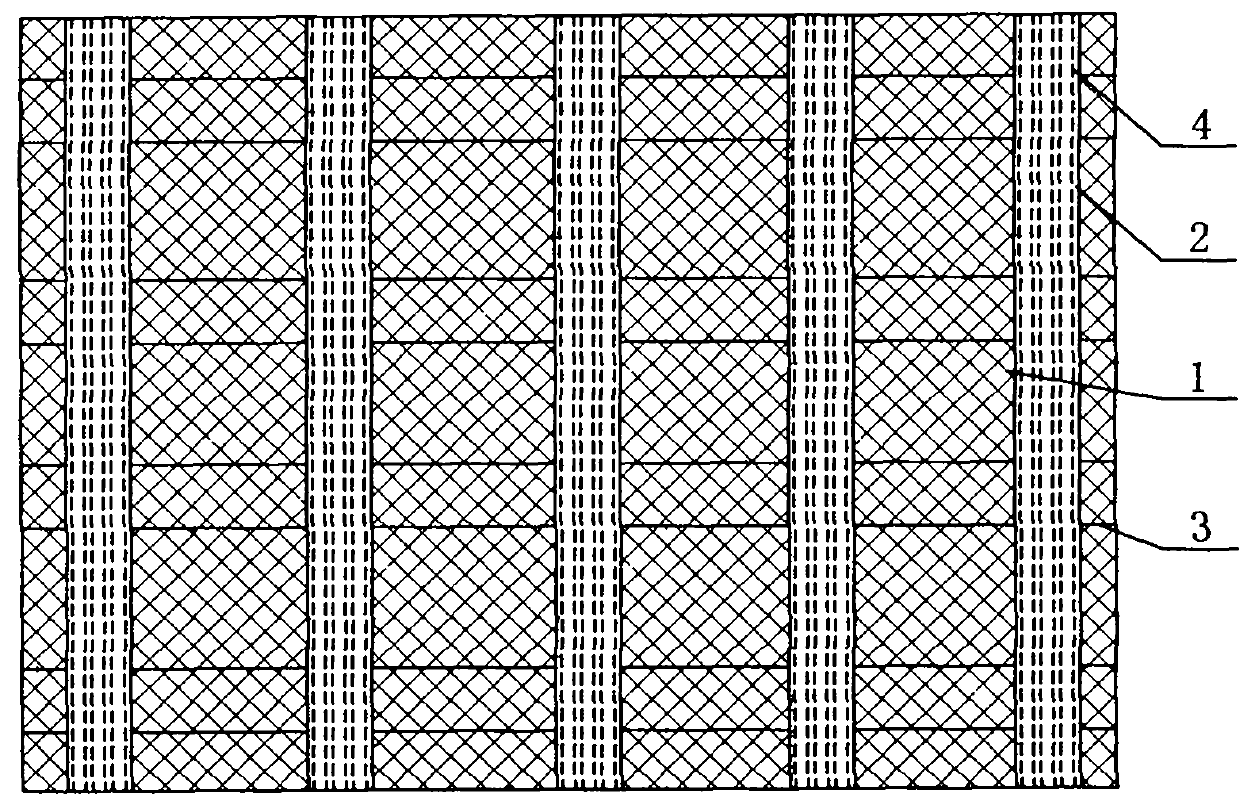

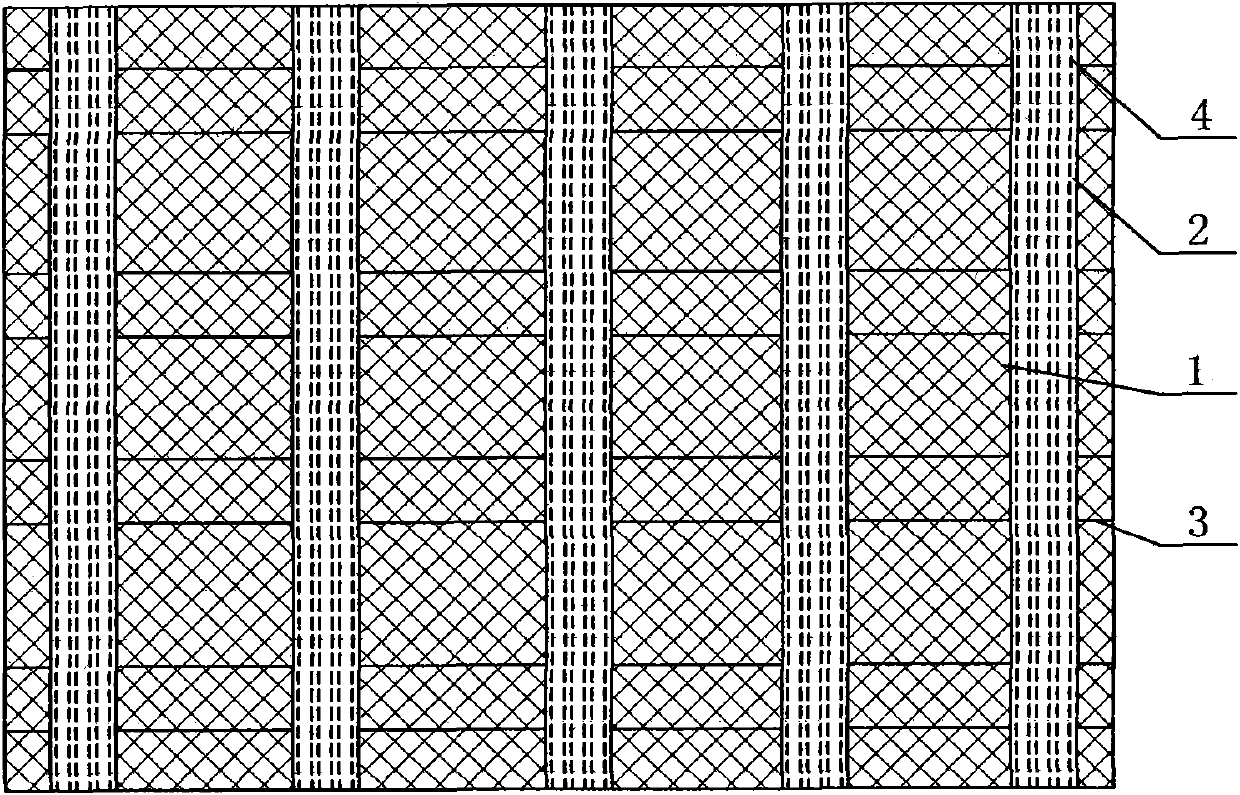

Safety protecting mesh

InactiveCN101906880AImprove protection strengthHigh strengthBuilding material handlingPolyesterFiber

The invention discloses a safety protecting mesh which comprises a plastic mesh. A plurality of plastic reinforced ribs I are arranged in parallel on one surface of the plastic mesh along the longitudinal direction, a plurality of plastic reinforced ribs II are arranged in parallel on the other surface of the plastic mesh along the transverse direction, and a plurality of glassfibers or polyester fibers are both embedded in each plastic reinforced rib I and each plastic reinforced rib II. After adopting the structure, the invention can enhance the using period and increase the reusability, also lower the failure ratio and the use cost, enhance the construction safety, is convenient for construction and operation, also remarkably strengthens the protection strength after being enclosed in the construction field, at a danger area or at the periphery of a building, has good anti-beaten capability and has the advantages of large vigor and obvious effect when resisting and buffering a heavy.

Owner:刘明志

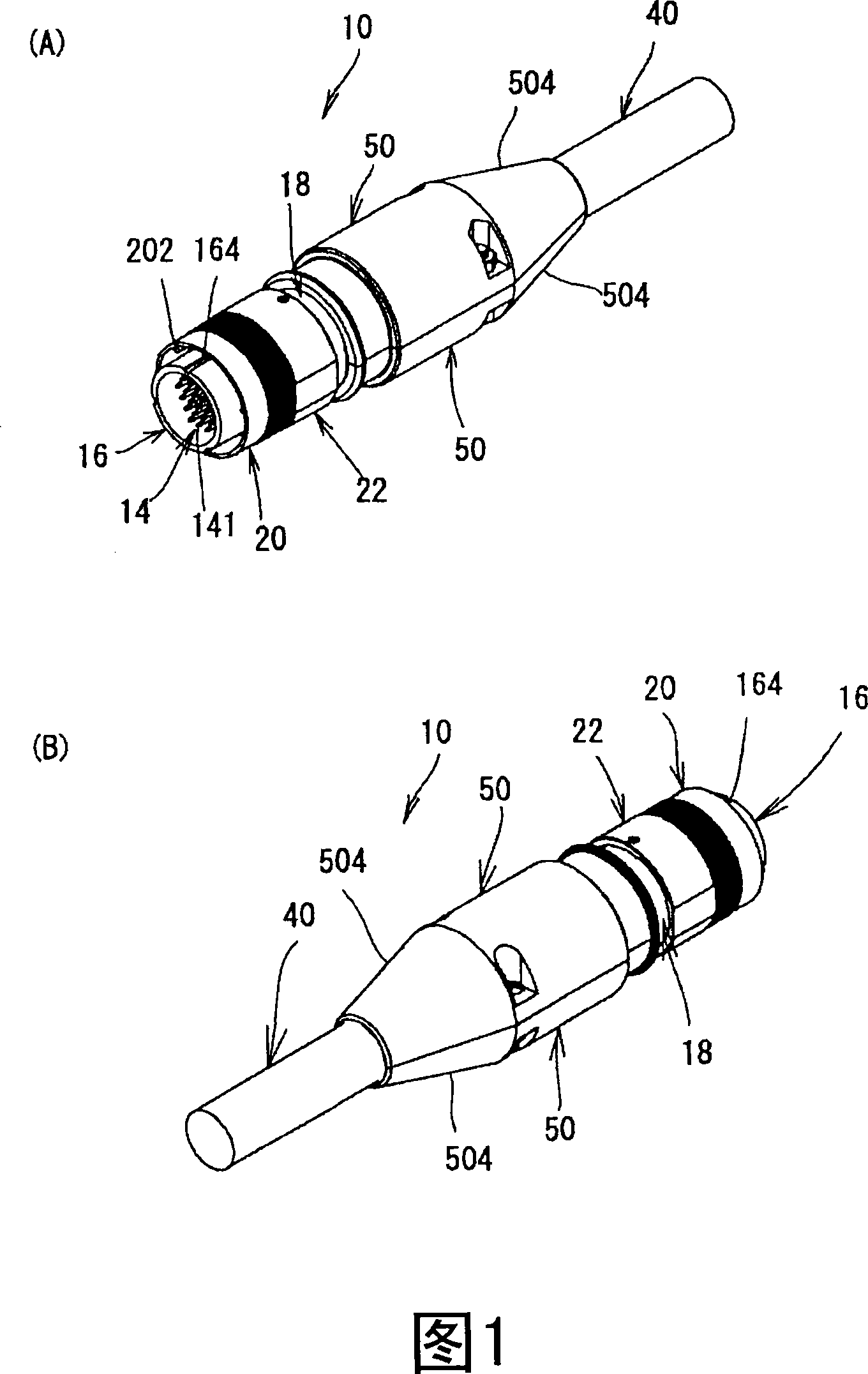

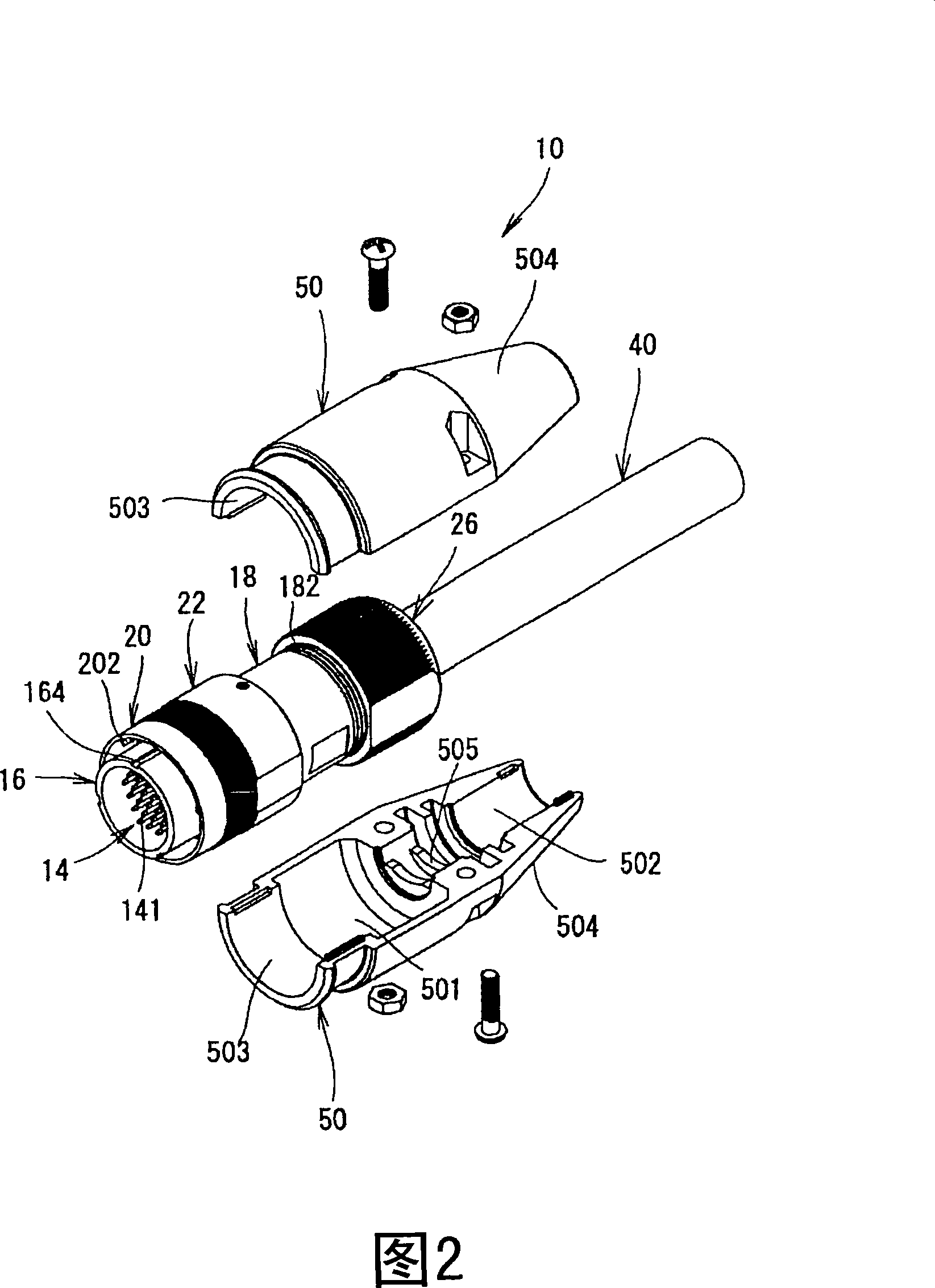

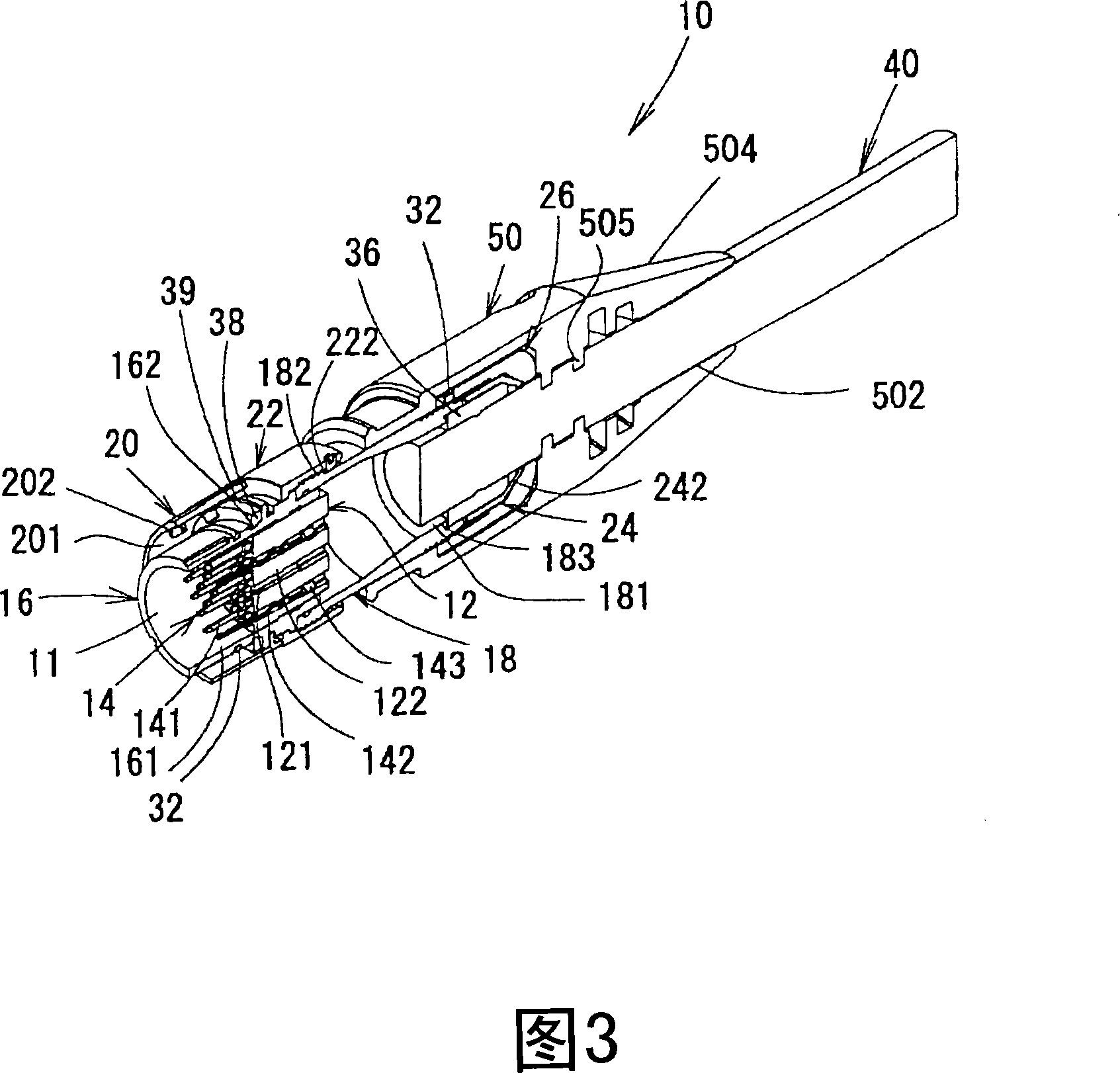

Electric connector

InactiveCN101237093AGood effectImprove retentionRelieving strain on wire connectionCouplingElectrical and Electronics engineering

The invention provides an electric connecter (10) which is hard to hang on the enclosures surrounding the industrial devices and an electronic device when a cable (40) is drew and improves retentiveness of the cable (40) and does not cause poor connection. In the electric connecter having a plurality of contacts (14), insulators (12), plug casings (16), coupling rings (20), rear casings (18), couplings (22), cable clamps (24) and clamp nuts (26), the connecter has a mounting unit (501) having a cable clamp (24), a cable insertion unit (502) where the cable (40) enters and is connected to the mounting unit (501). By arranging a conic section (504) on a periphery of a projection of the cable, or by arranging at least one projection (505) on the cable insertion unit (502) or by arranging both of the conic section (504) and the projection (505), two cover components (50) are mounted on the cable projection side of the mounting mechanism, thus the purpose of the invention can be realized.

Owner:DDK LTD +1

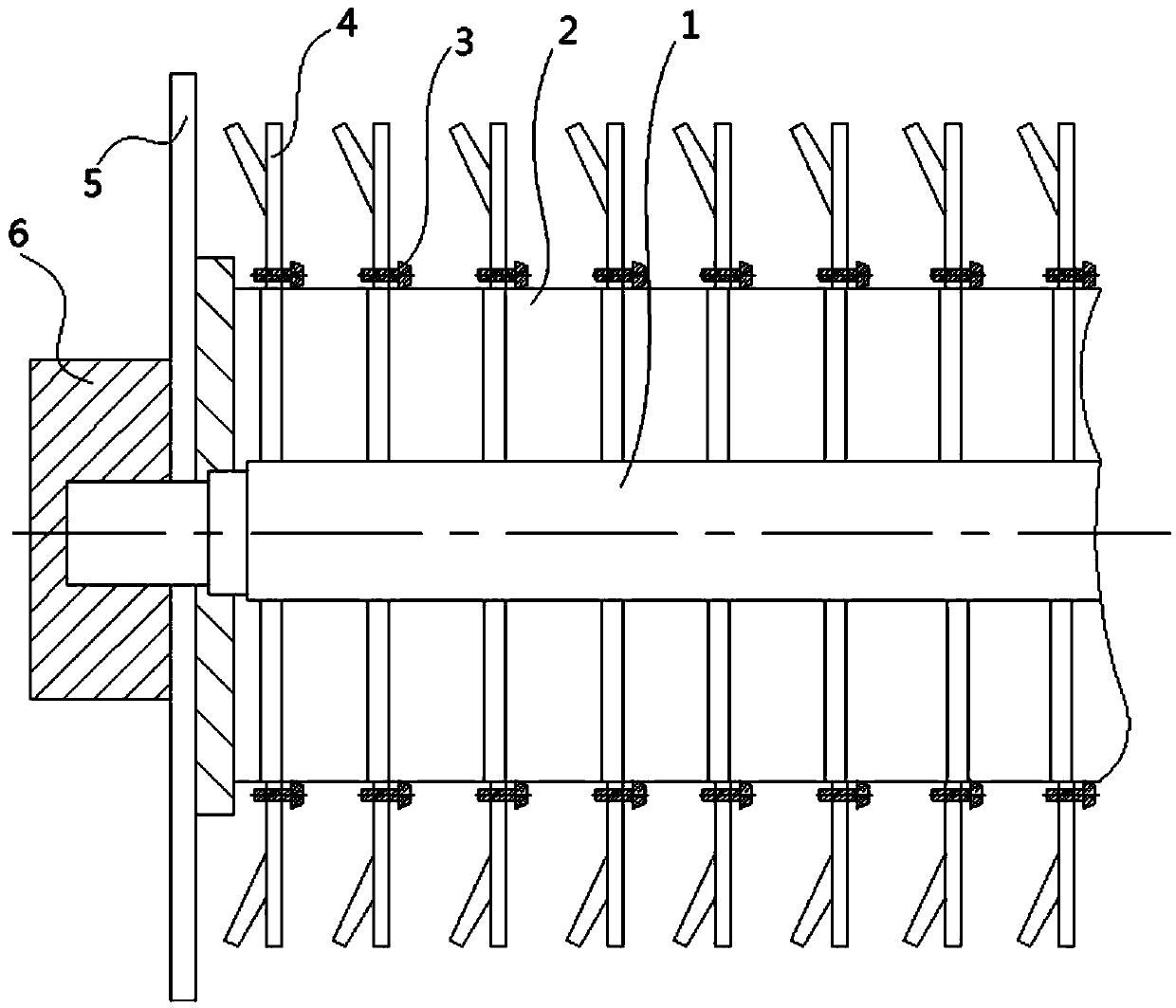

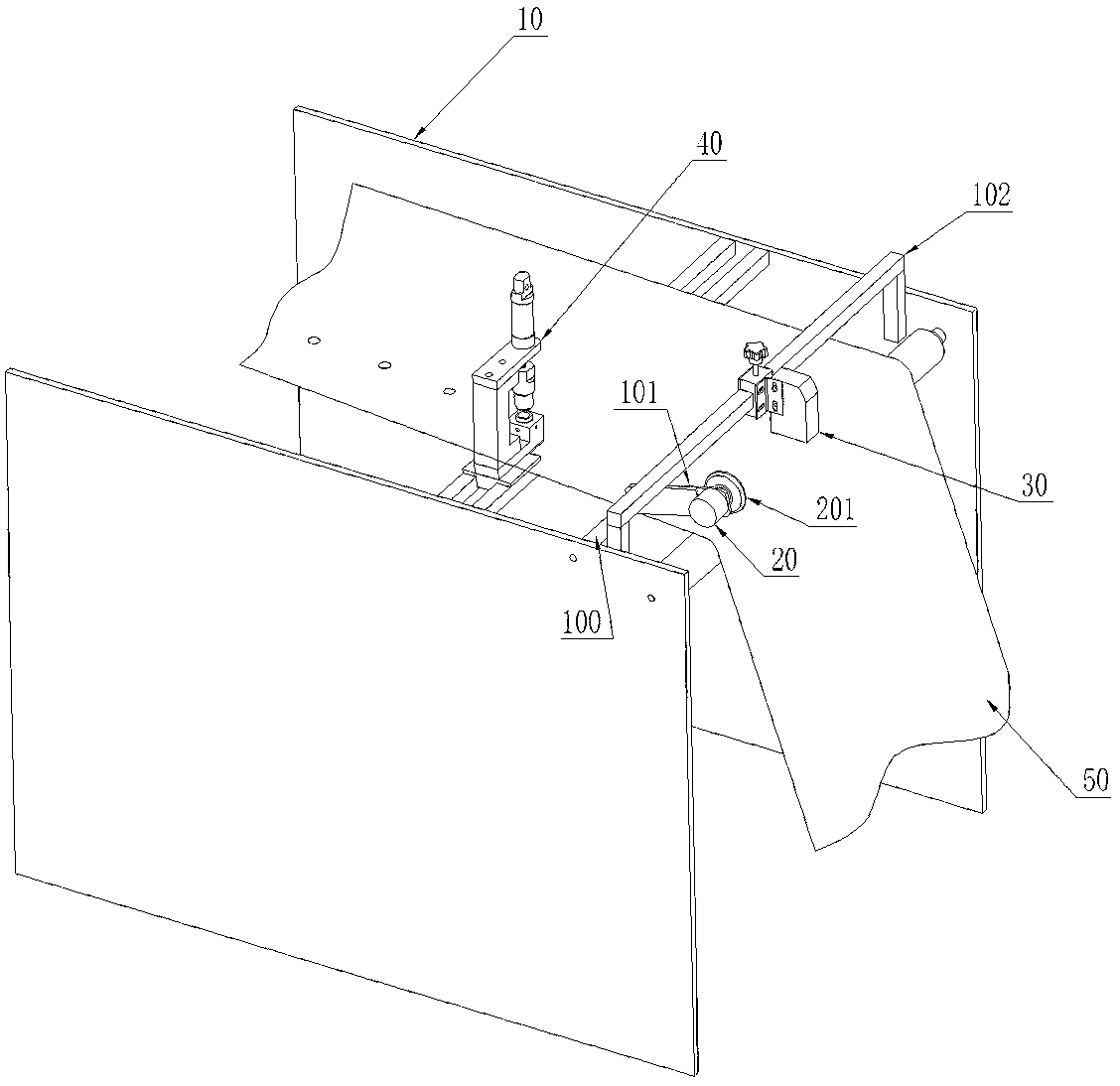

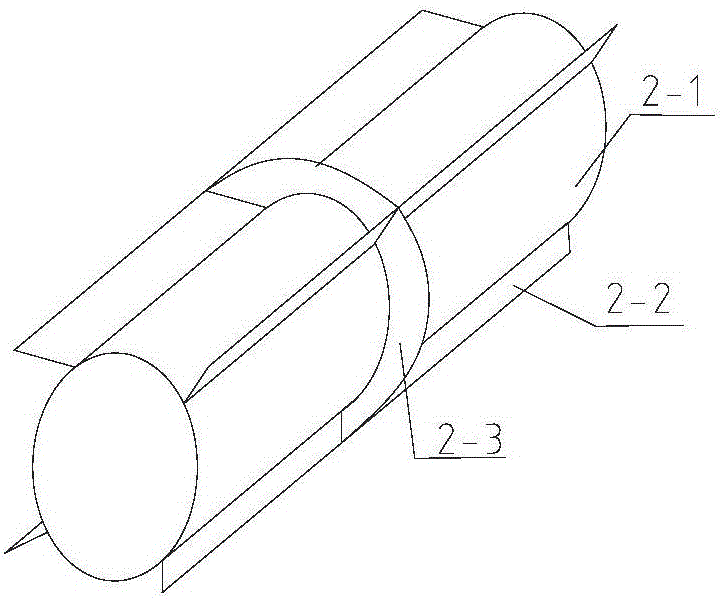

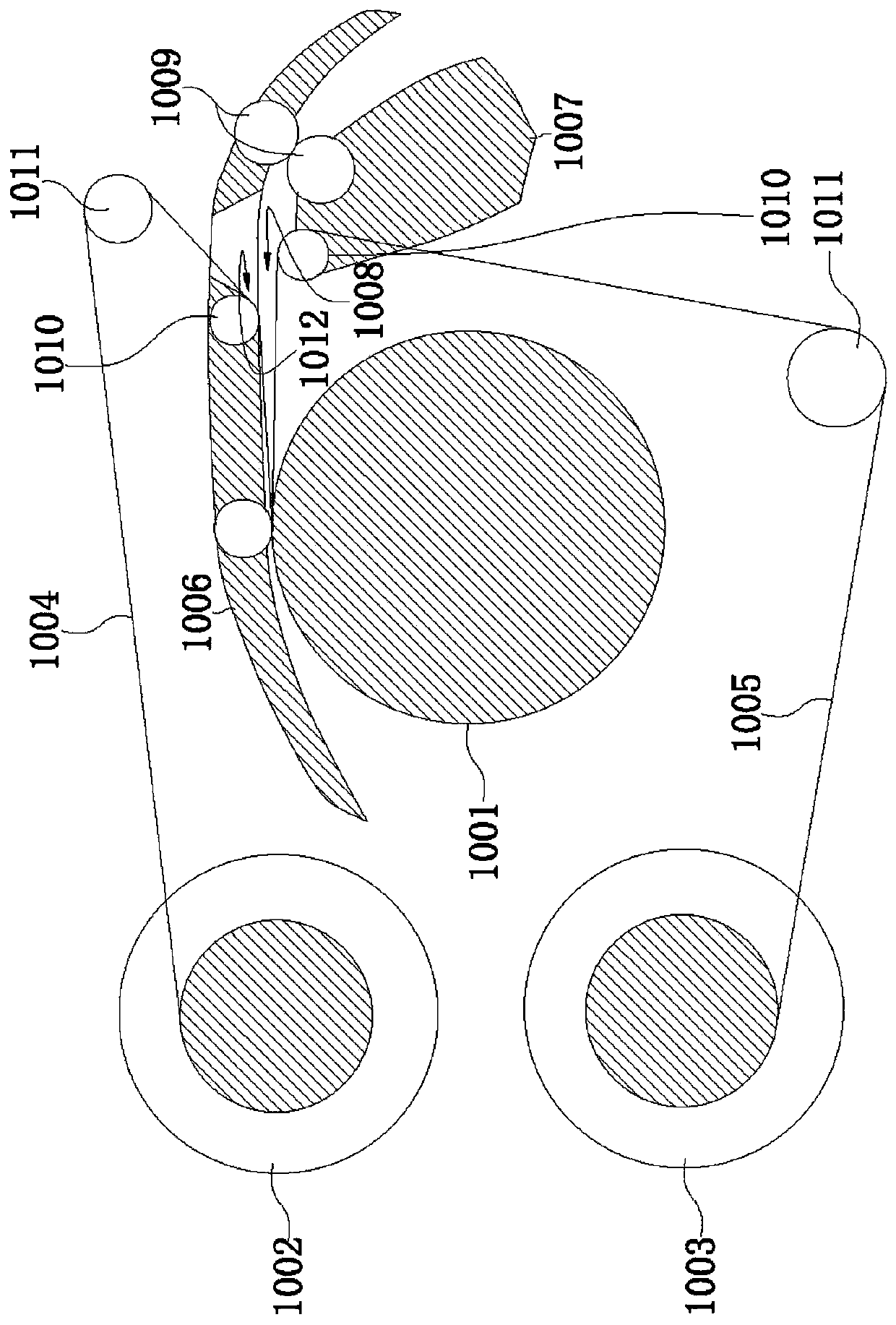

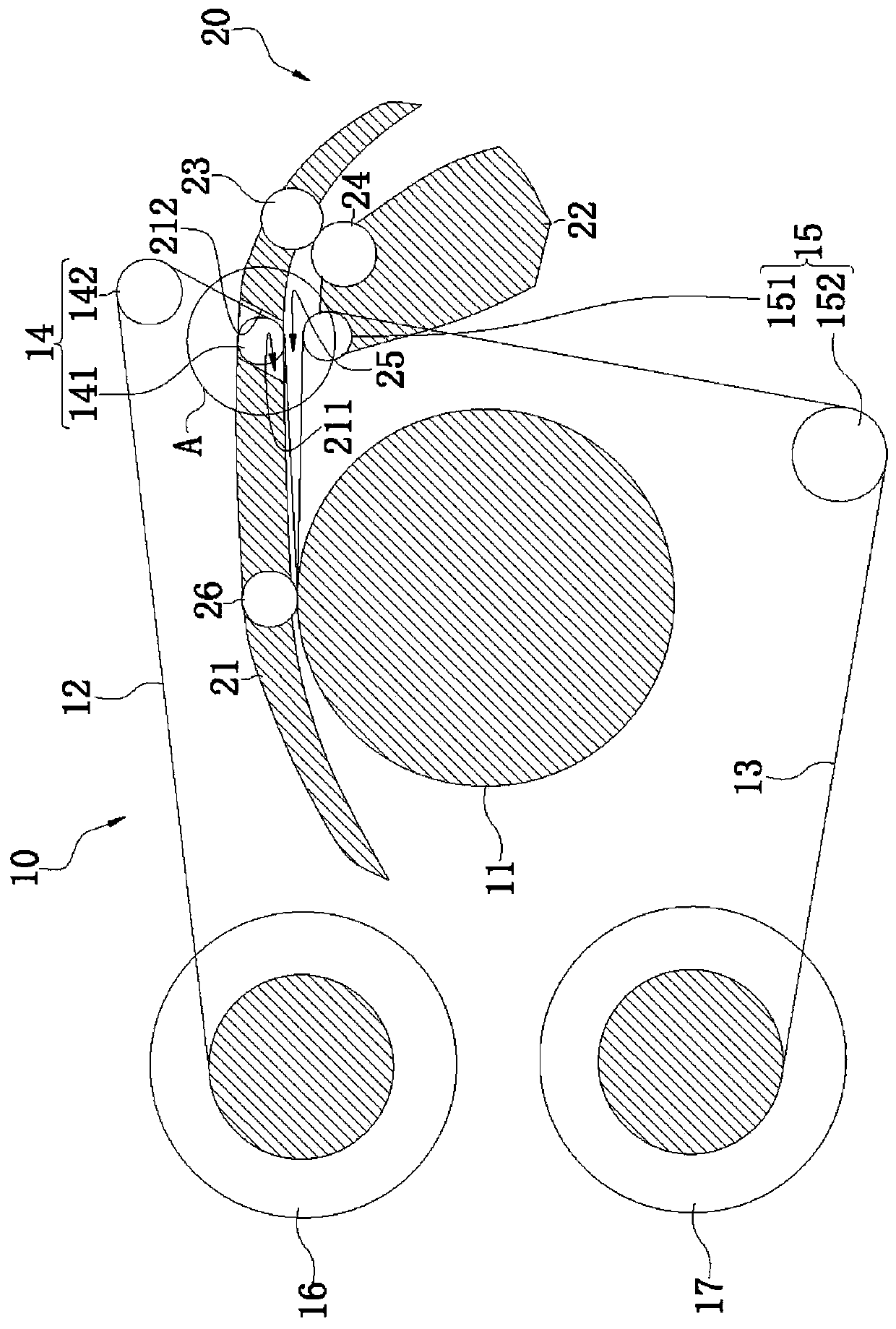

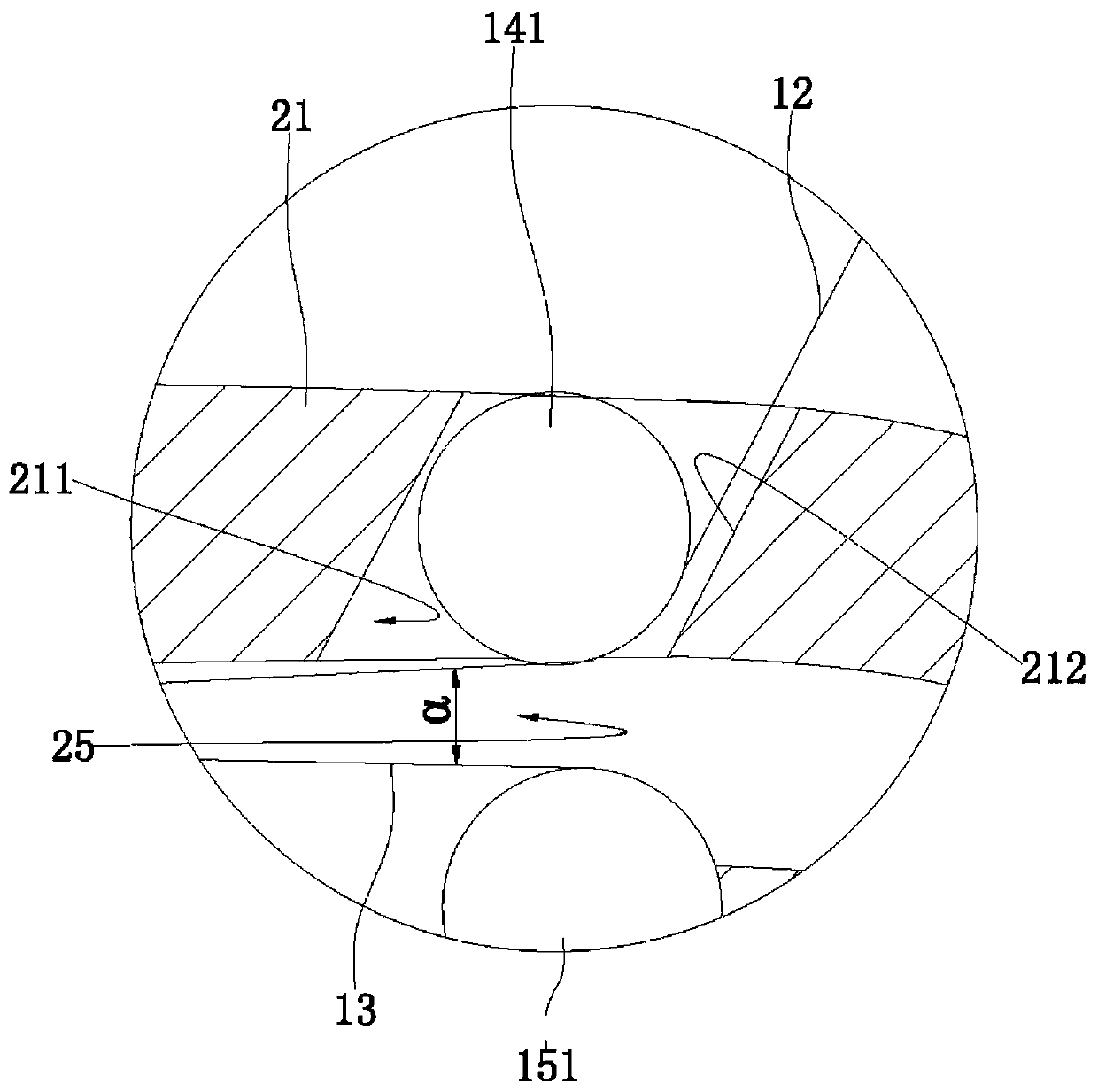

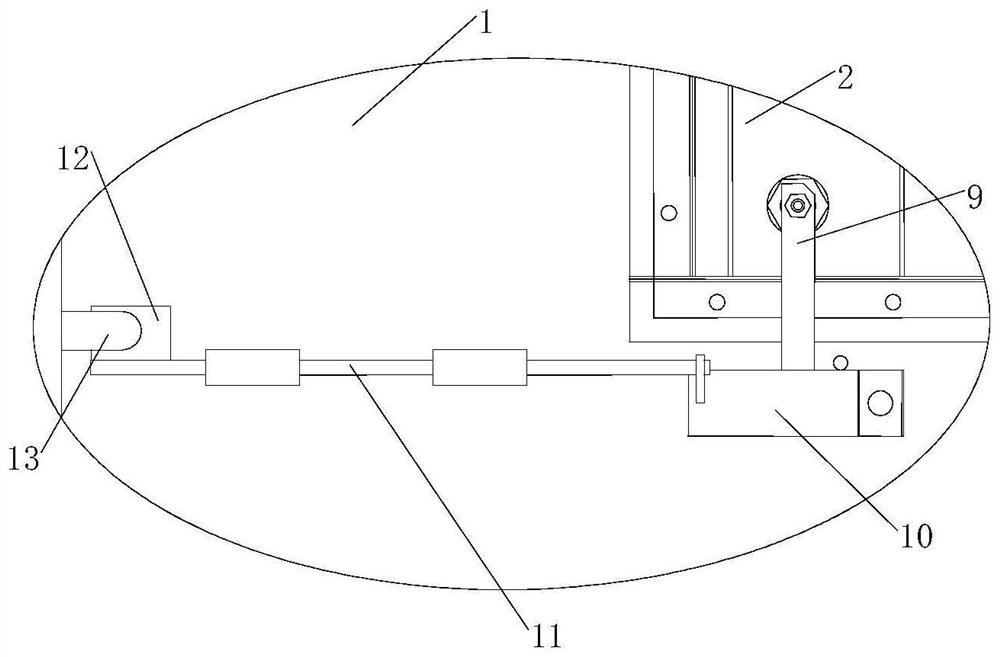

Beater device of disc cotton grabbing machine

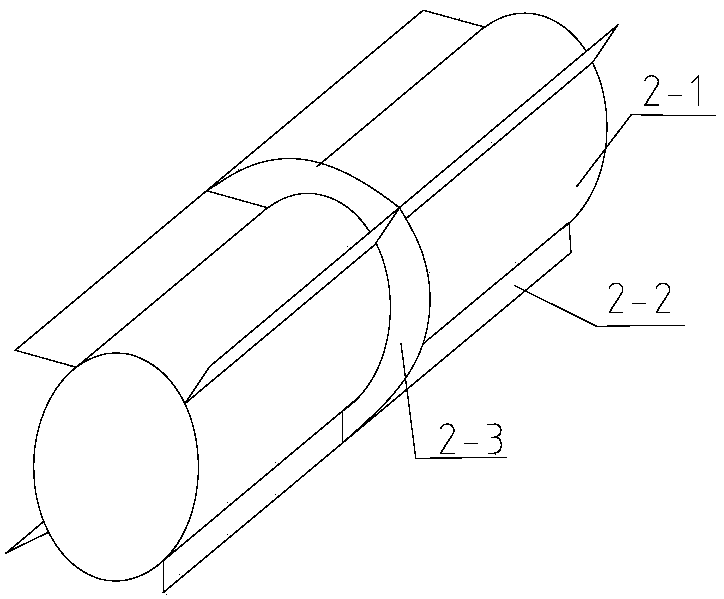

ActiveCN104805537AAvoid stickingNot easy to hookFibre breaking by beater armsFiberMechanical engineering

The invention discloses a beater device of a disc cotton grabbing machine. The beater device comprises a wallboard, a beater shaft, a beater frame and cutter blades, wherein a bearing seat is installed on the wallboard, the shaft-end part of the beater shaft is hinged into the bearing seat, the beater frame is in a cylindrical shape, the beater shaft is sleeved with the beater frame by virtue of a rotating bearing, and the beater frame is driven by an external drive device to rotate; the beater frame is provided with a fixed plate, cutter blades are uniformly welded on the fixed plate, two ends of the fixed plate are respectively connected with two adjusting bolts in a threading manner, and the adjusting bolts are fixed on the beater frame. The beater device has the characteristics that the beater cutter blades are unlikely to hook fibers, the extension length of the beater cutter blades can be adjusted, and the beater frame is unlikely to jam in the rotation process.

Owner:江苏坤泰环保科技有限公司

Punching machine capable of punching continuous conveying materials

InactiveCN102794791ANot easy to hookPlay the role of collecting the washed down wasteMetal working apparatusPunchingEngineering

The invention relates to a punching machine, and specifically relates to a punching machine capable of punching continuous conveying materials. The punching machine comprises a frame, a conveyer device for continuously conveying materials, a detecting device and a punching device and is characterized in that the punching device is provided with an air cylinder, wherein the detecting device is electrically connected with the air cylinder; the extensible piston rod of the air cylinder is connected with a punch head; the bottom surface of the punch head is arc-shaped; a tool holder is arranged below the punch head; the detecting device comprises a photoelectric detector and a coder; the air cylinder is operated by the signal given by the photoelectric detector or the coder. The punching machine designed in the invention uses the high-speed action of the air cylinder, and thus has less possibility of catching the punch head with the arc-shaped bottom surface, so that the materials can be directly punched without being stopped.

Owner:浙江超伟机械有限公司

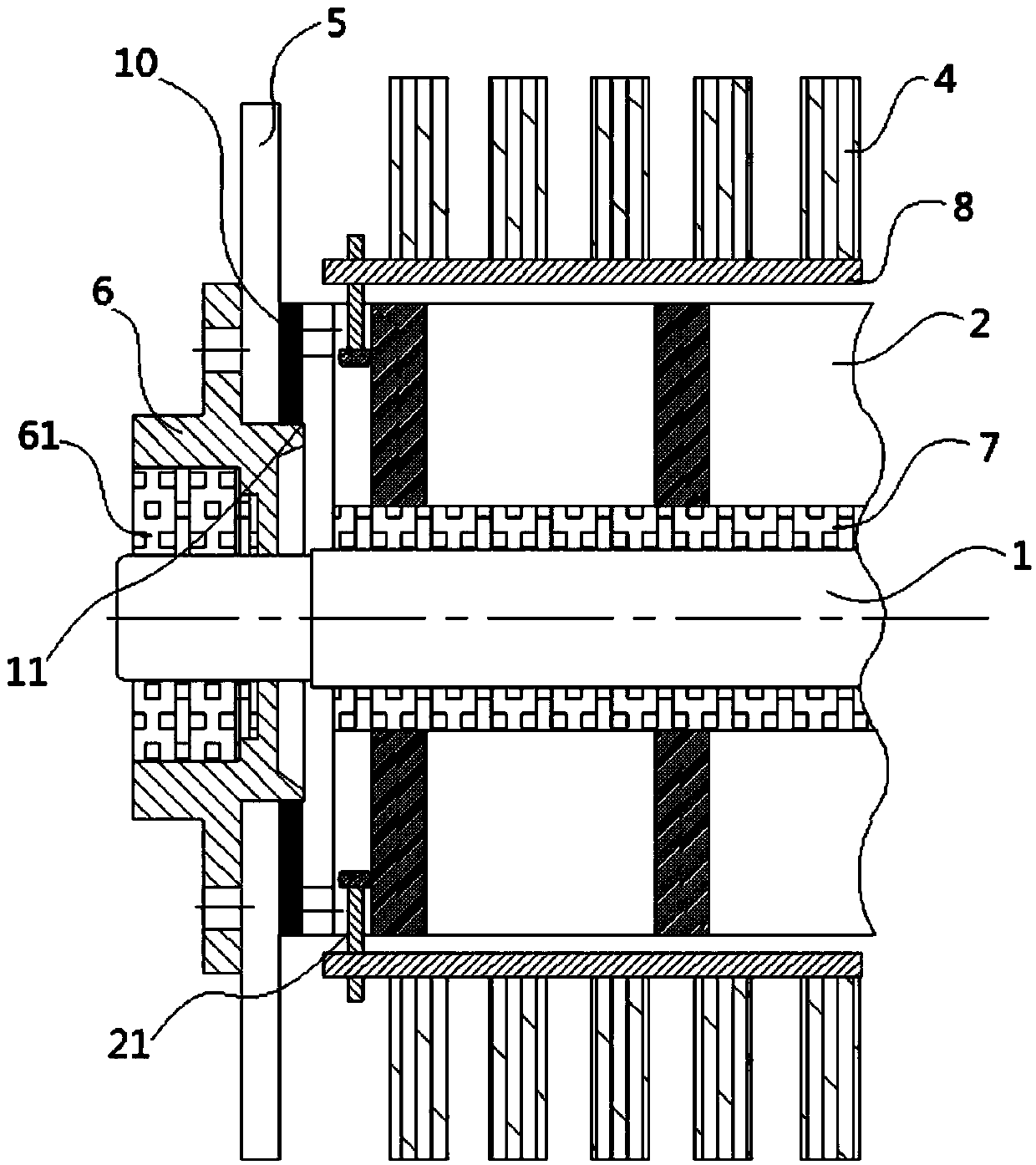

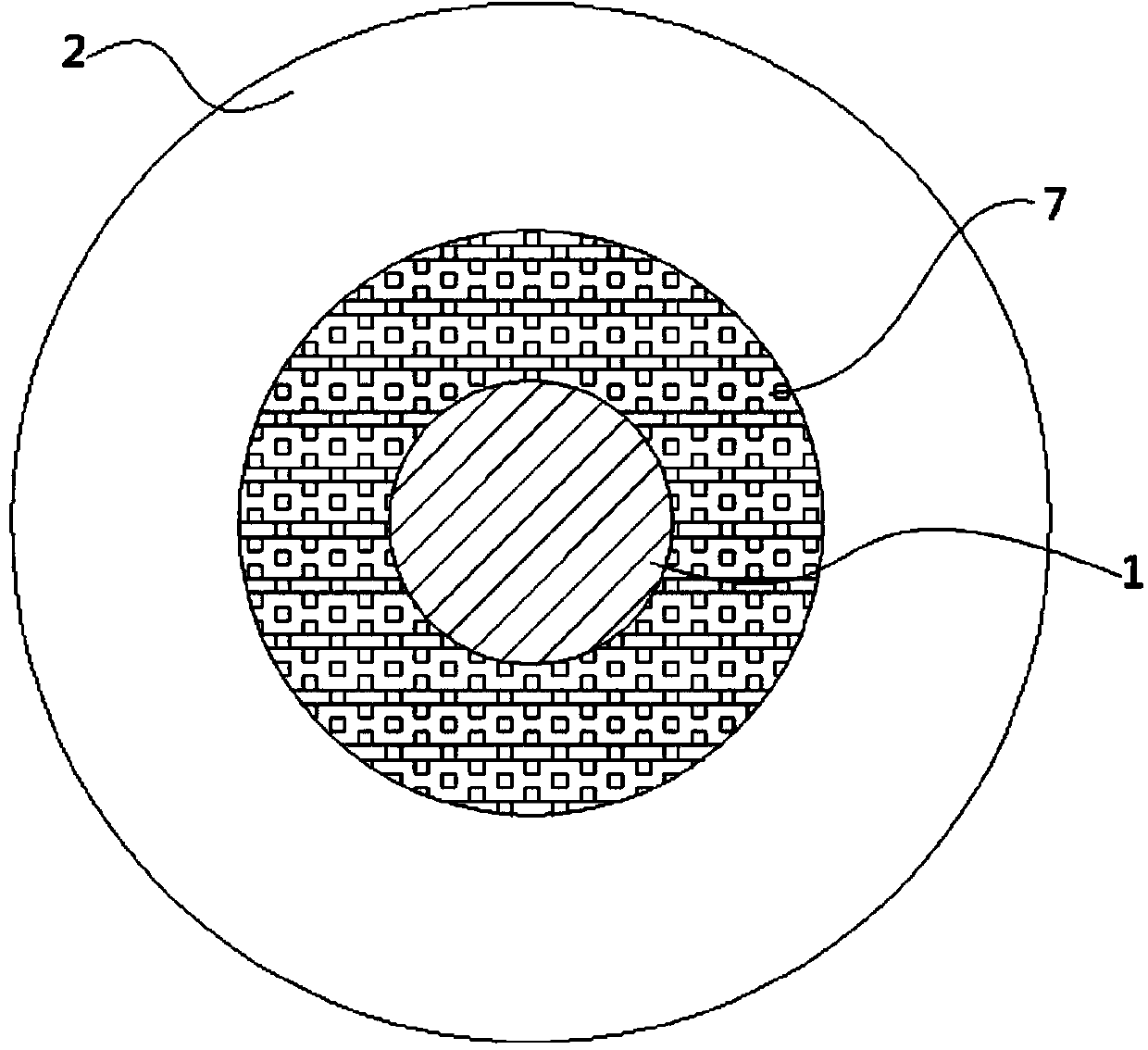

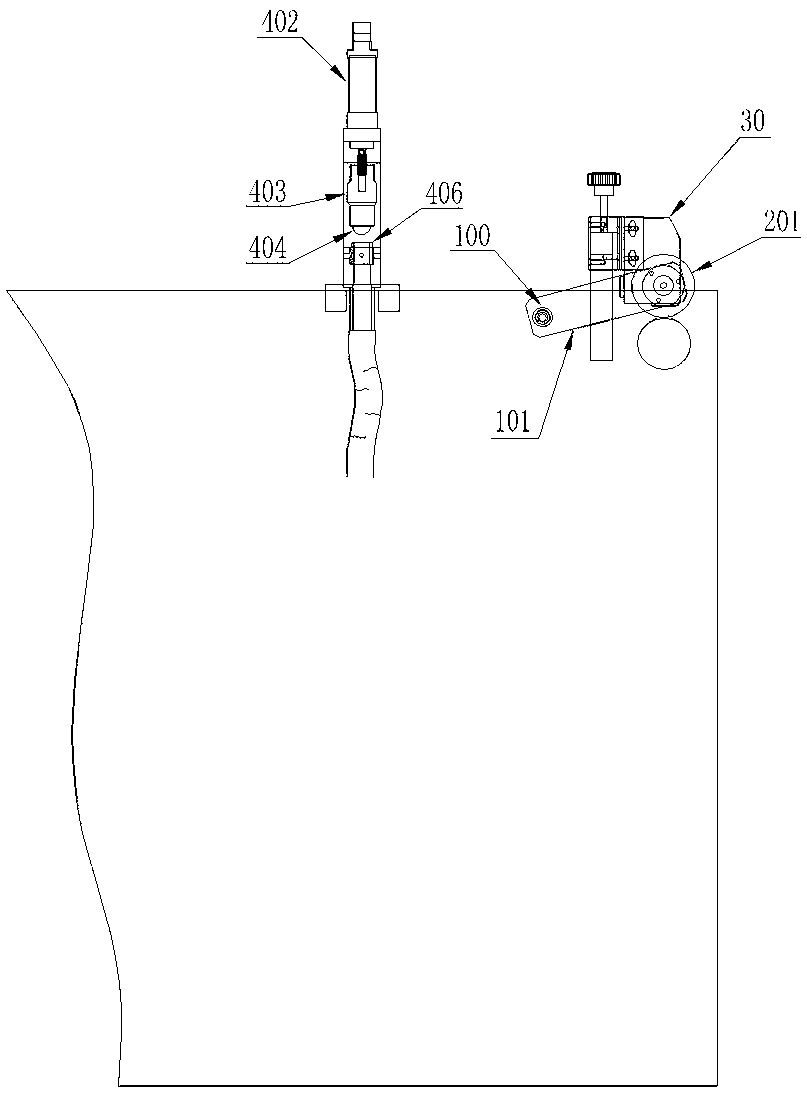

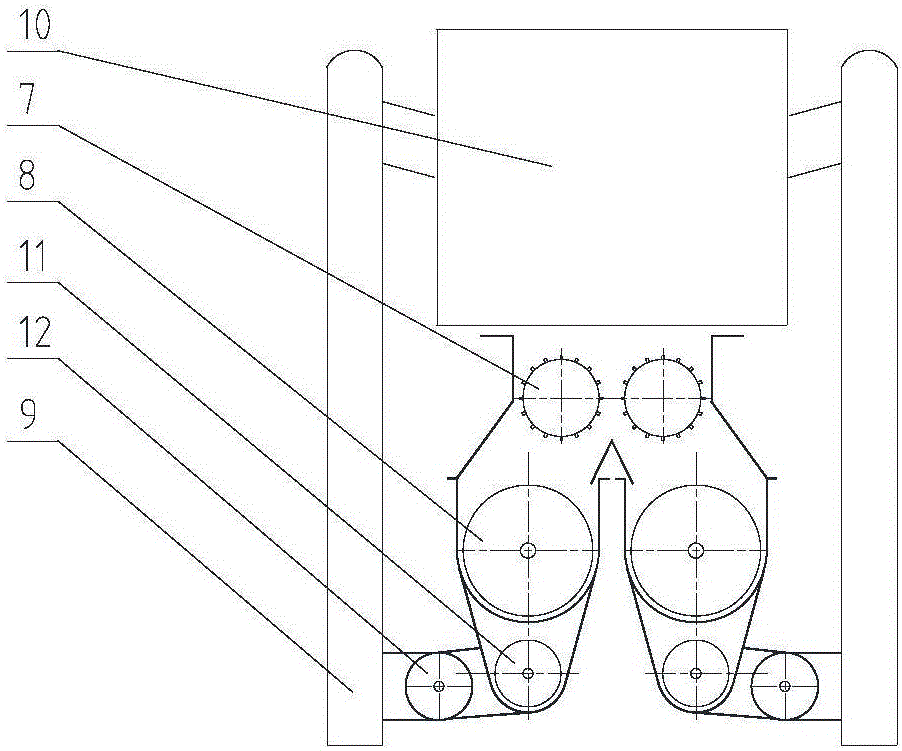

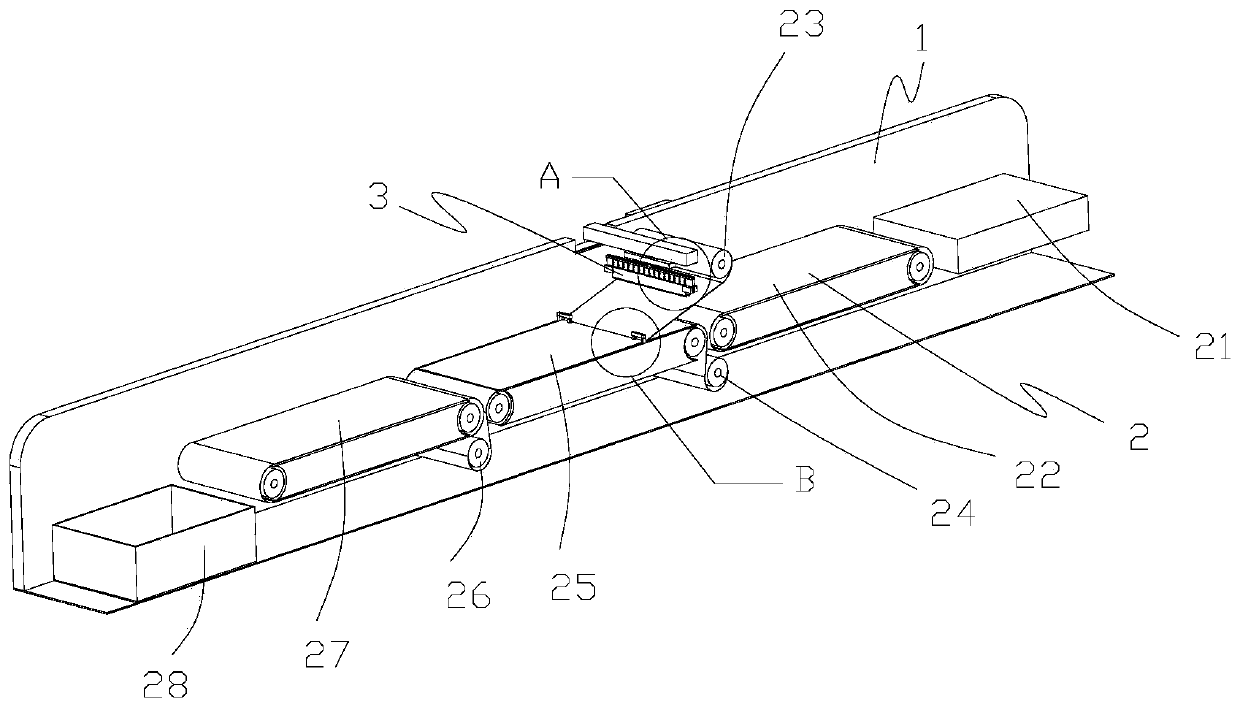

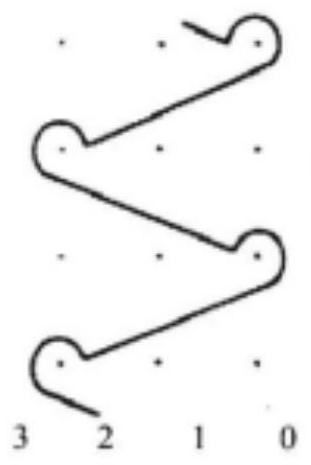

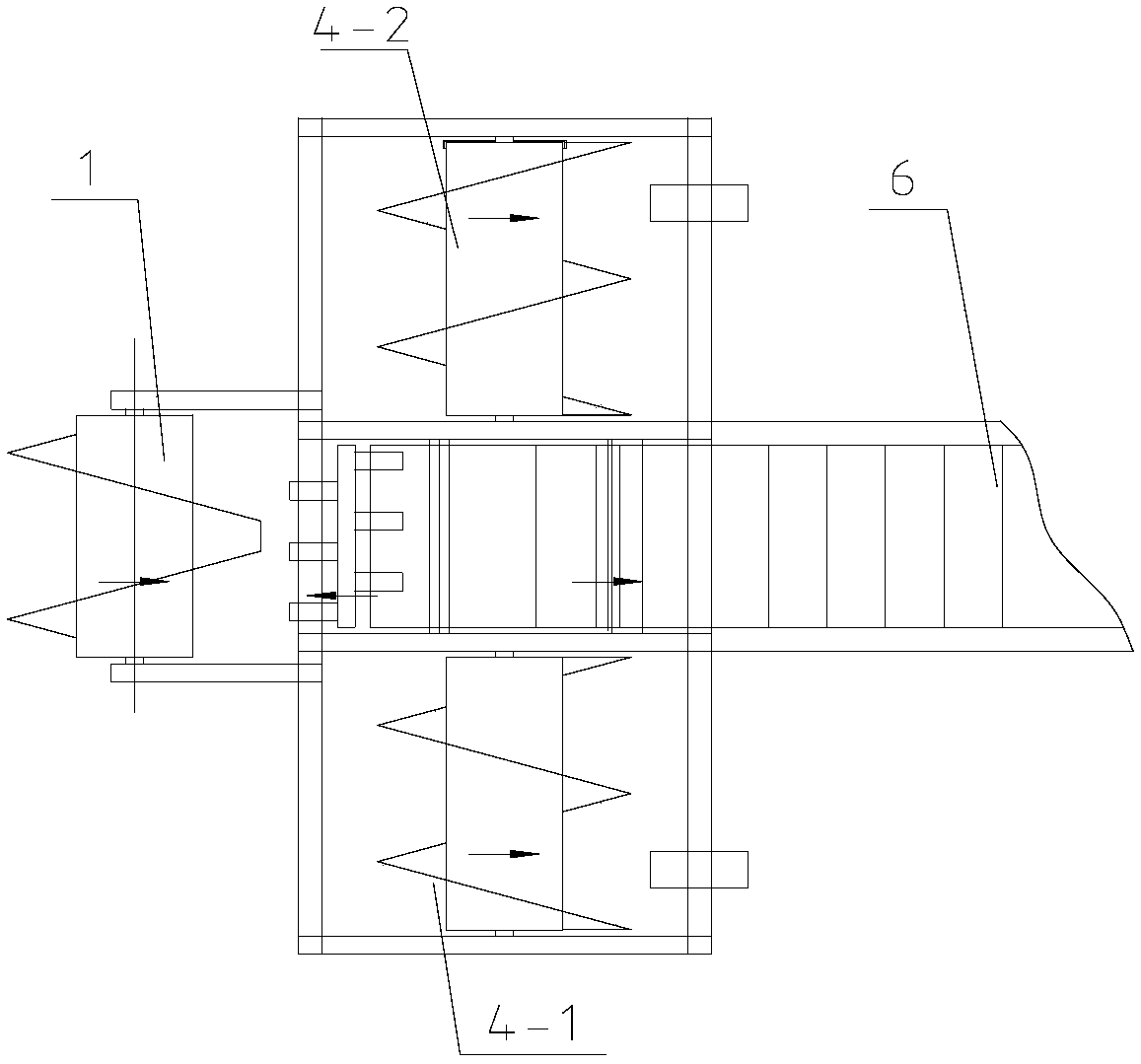

Paper money storing and delivering device and paper money automatic transaction device

ActiveCN106023429AReduce spacingNot easy to hookCoin/currency accepting devicesPulp and paper industryFinancial transaction

The invention relates to the technical field of bank equipment, and particularly relates to a paper money storing and delivering device and a paper money automatic transaction device. The paper money storing and delivering device comprises a paper money coiling mechanism and a paper money guiding mechanism. The paper money coiling mechanism comprises a roller on which an upper coiling tape and a lower coiling tape coil, an upper guide part and a lower guide part. The paper money guiding mechanism comprises an upper guide member, a lower guide member, and an upper clamping roller and a lower clamping roller which are respectively arranged on the upper guide member and the lower guide member. The upper guide part comprises a first upper tape roller. The upper guide member is provided with a tape through hole. The first upper tape roller is arranged in the tape through hole. The lower guide part comprises a first lower tape roller which is arranged on the lower guide member and corresponding to the first upper tape roller. The upper coiling tape is arranged on the first upper tape roller and penetrates through the tape through hole. The lower coiling tape is arranged on the first lower tape roller, and a paper money conveying path is formed between the lower coiling tape and the upper coiling tape. According to the paper money storing and delivering device, paper money with coiled parts can be normally stored without tearing.

Owner:SHENZHEN YIHUA COMP +2

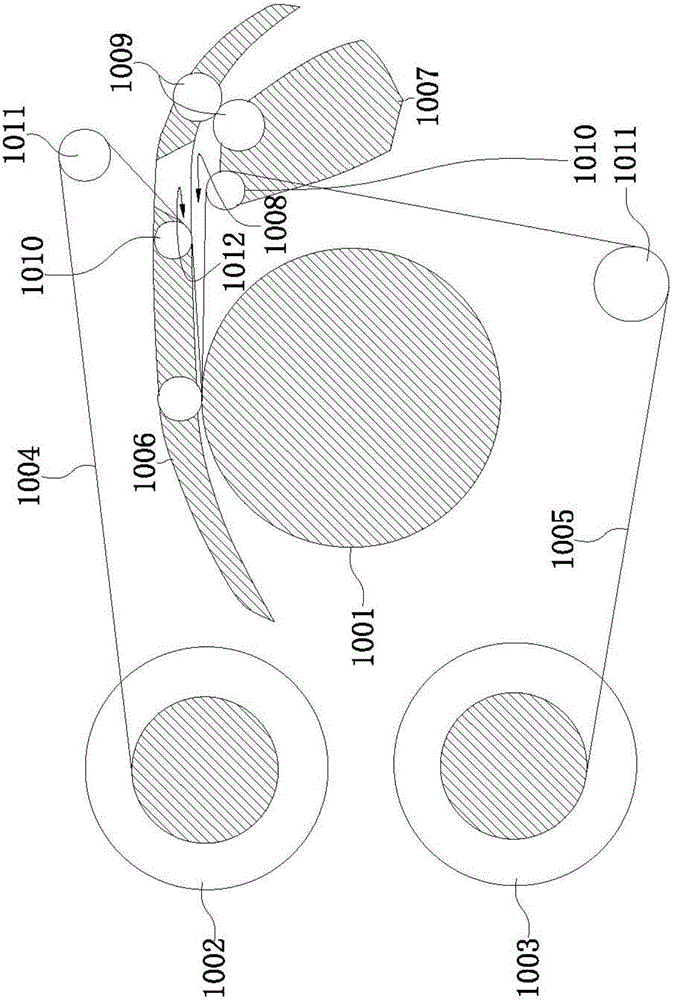

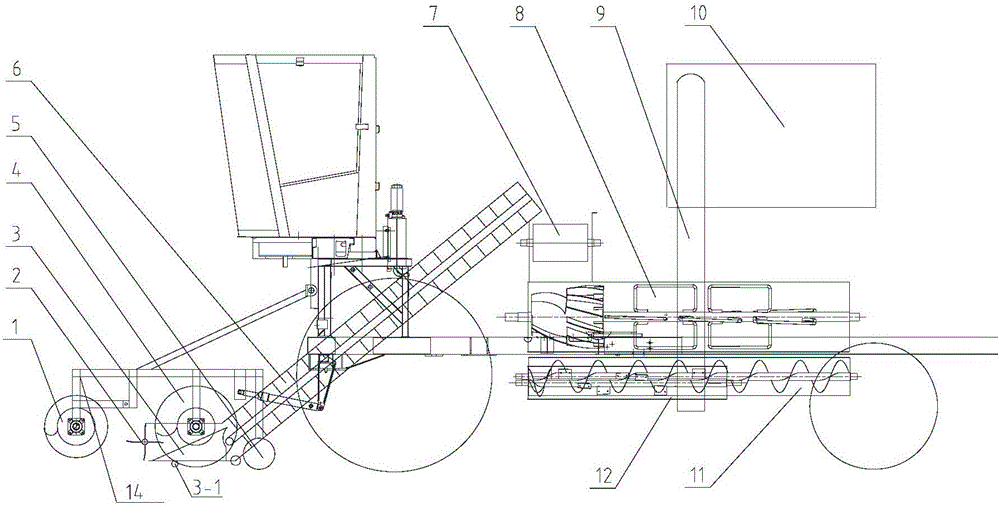

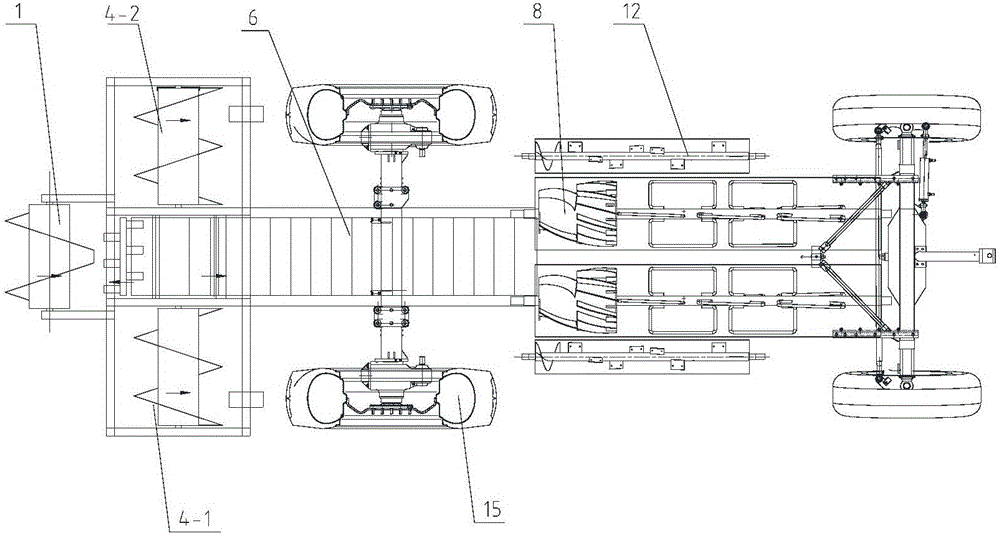

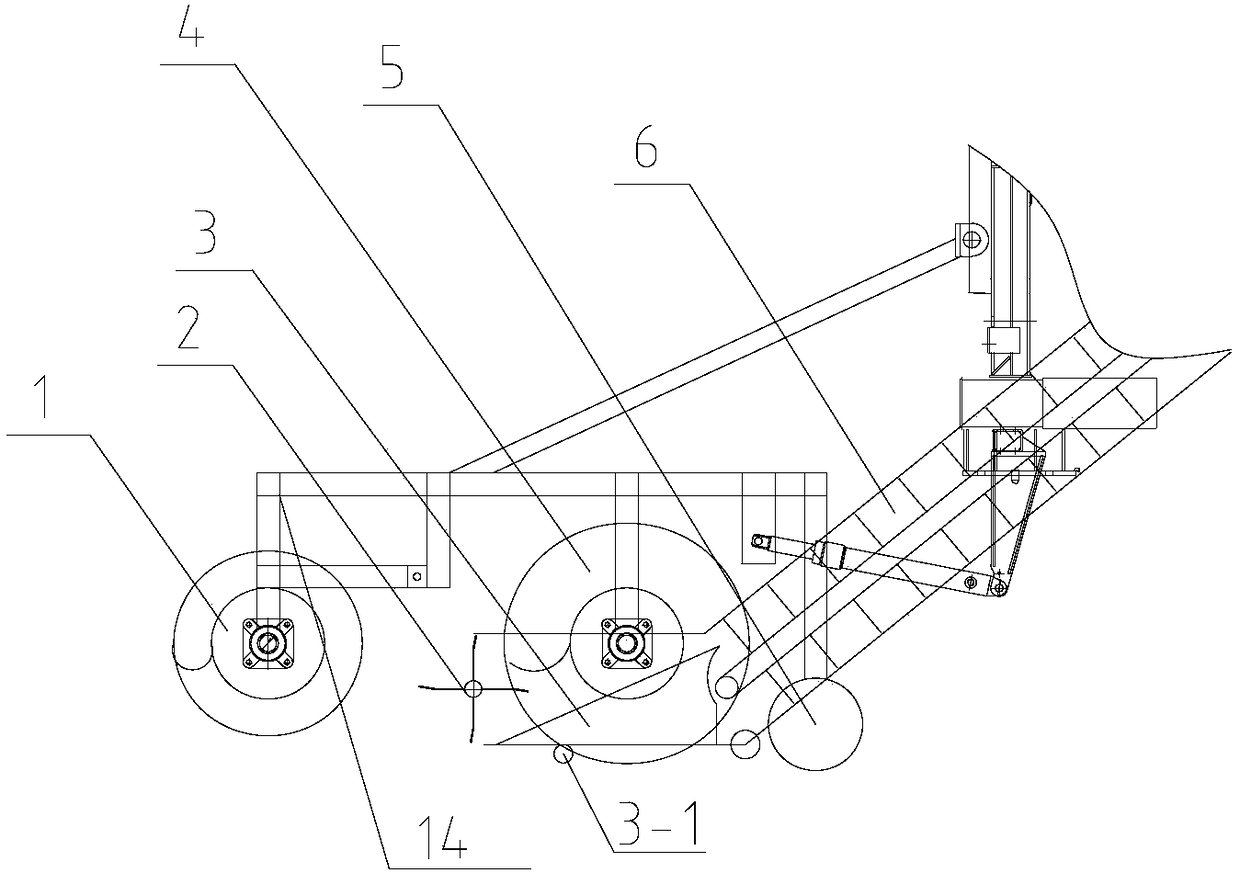

Seedling-watermelon harvester

ActiveCN105993375AIssues such as reducing lossesImprove work efficiencyMowersThreshersEngineeringMelon (food)

The invention relates to a seedling-watermelon harvester which comprises a picking table, a seed taking device and a conveying device. The conveying device conveys seeding-watermelons collected by the picking table to the seed taking device. A front row of augers of the picking table are arranged in the middle right in the front of a machine frame so that the seeding-watermelons can be pushed to the two sides, and a rear row of augers are divided into two groups which are located on the two sides of the machine frame respectively and used for pushing the seeding-watermelons to the middle. A seeding-watermelon collecting shovel conveys the seeding-watermelons pushed by a seeding-watermelon pushing wheel to the conveying device on the rear side. The seed taking device breaks the seeding-watermelons through pressing rollers in pairs, and the broken seeding-watermelons are divided into two groups and fall into two different melon ladle separators respectively, melon seeds and melon pulp separated out by the melon ladle separators are sent into a melon pulp separator, and the seeds are separated out by the melon pulp separator and conveyed into a seed box through a perpendicular auger. The problems of grass twining, vine removing, seed leaking and other problems in the seedling-watermelon harvesting link can be solved, and meanwhile the defect that seedling-watermelon high-efficiency harvesting is not matched with low-efficiency seeding taking can be overcome.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

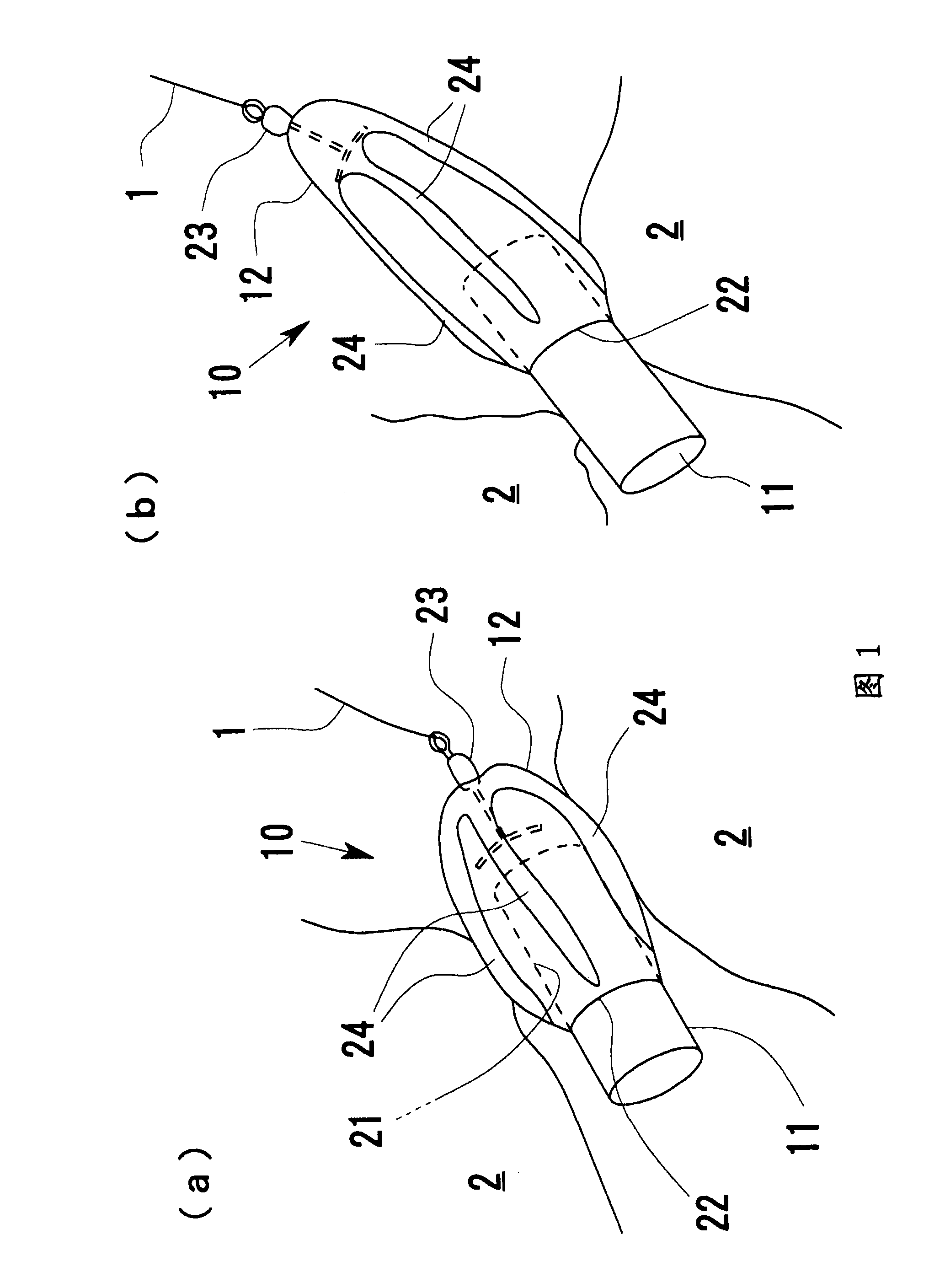

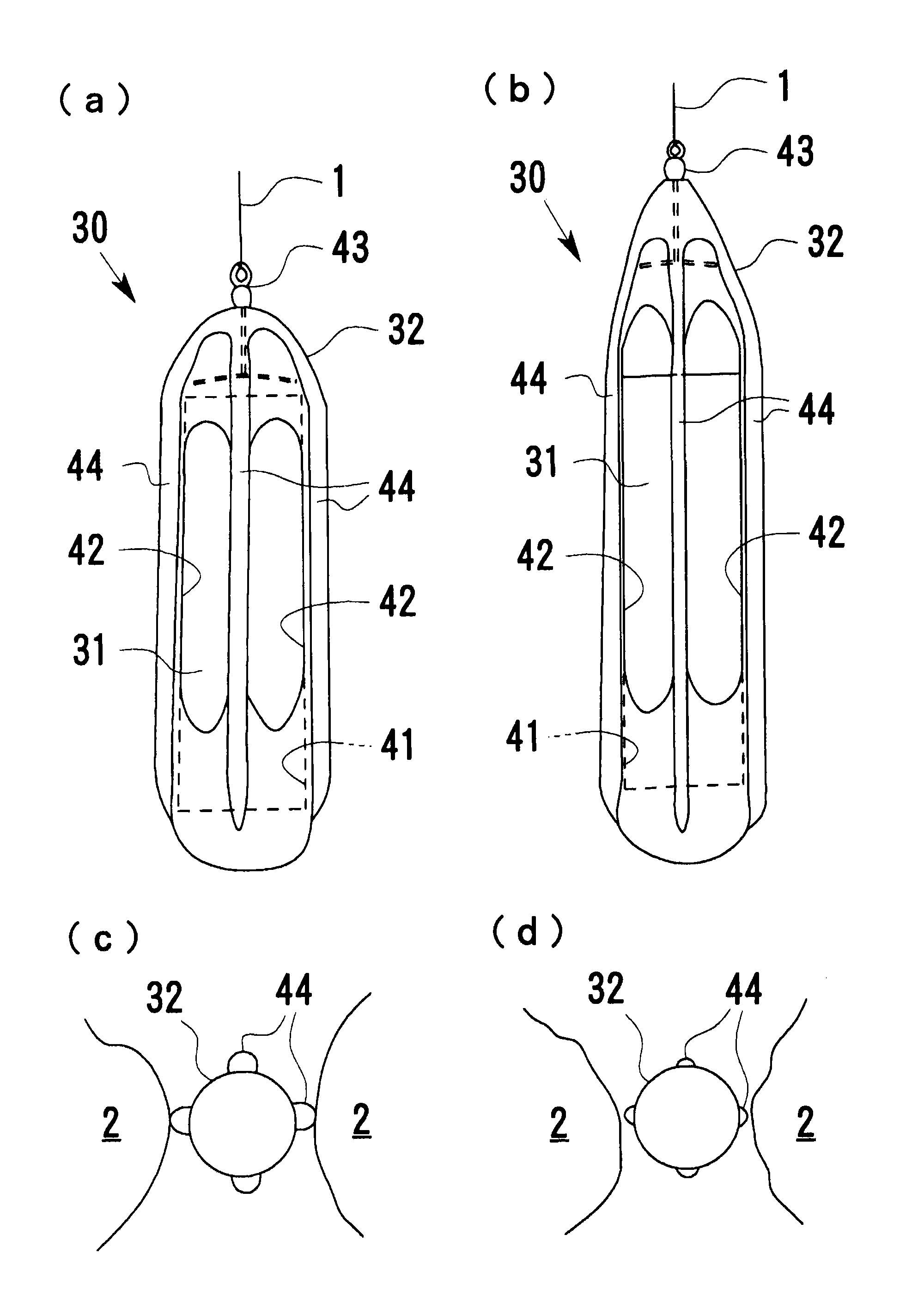

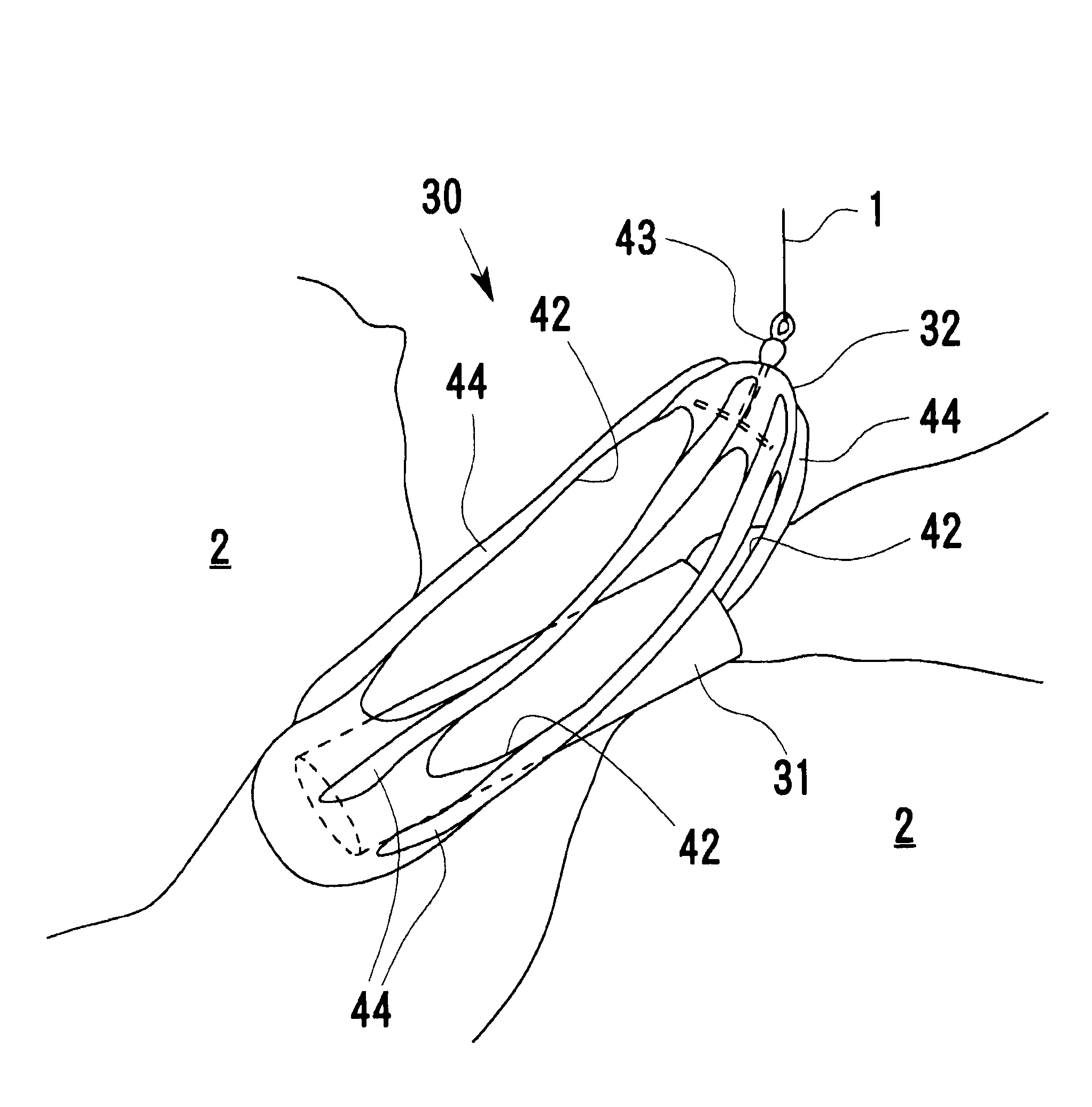

Fishing drop for fishing

The present invention provides a weight for fishing, which is hard to cause hang and has non harmful effects to peripheral living beings even though being remained in undersea. A holder is made of rubber having elasticity, comprising a storage chamber (21) for storing a ferreous spindle (11) and a thread fixed part (23) for fixing fishing threads (1). The holder (12) has an opening (22) through which the spindle (11) is inserted and removed from the storage chamber (21). The holder (12) holds the spindle (11) in the storage chamber (21) by own elastic force. In addition, the holder (12) may discharge the spindle (11) outside the storage chamber (21) from the opening (22) when the holder is subjected to a force against the elastic force.

Owner:内馆英一

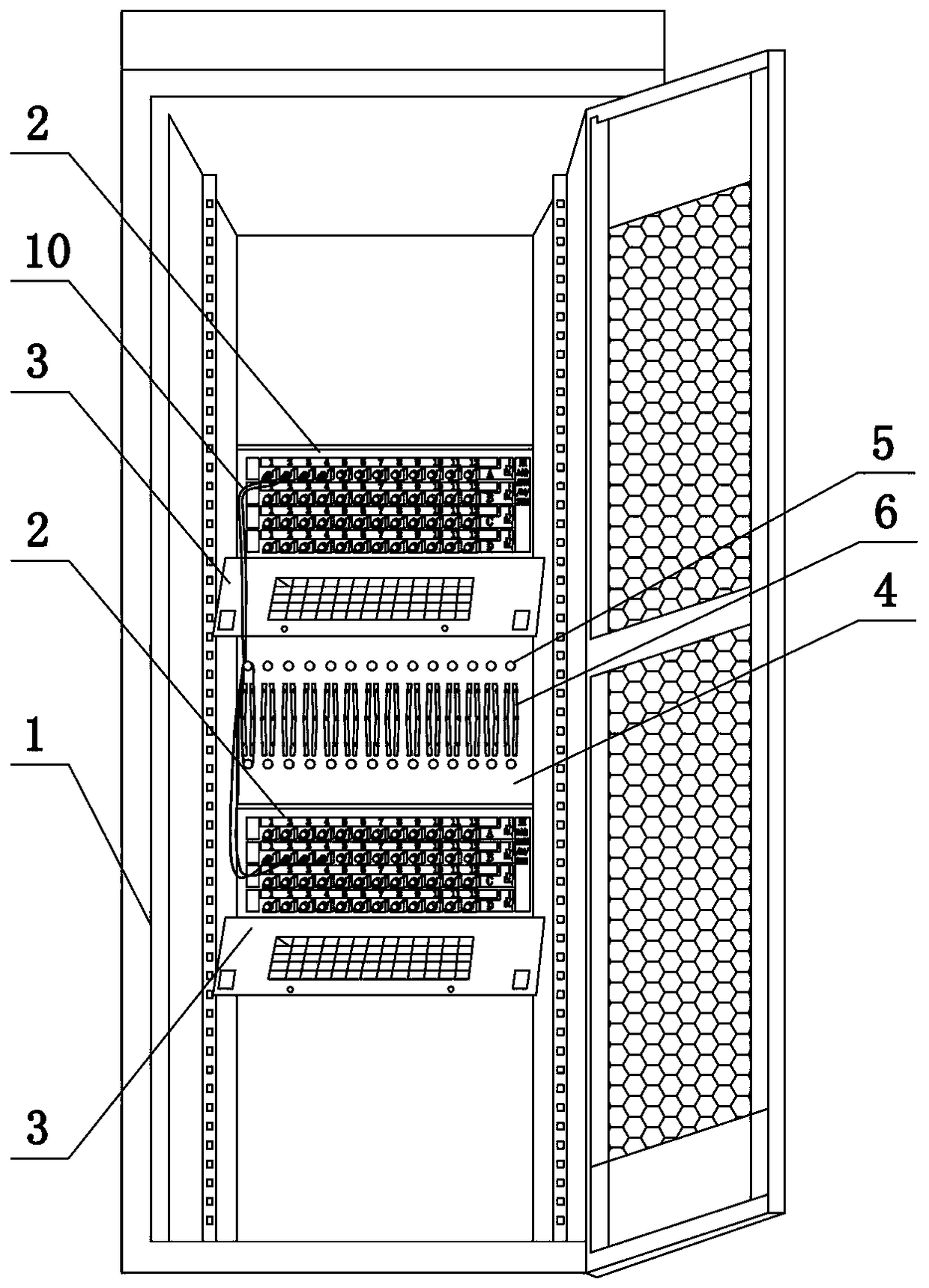

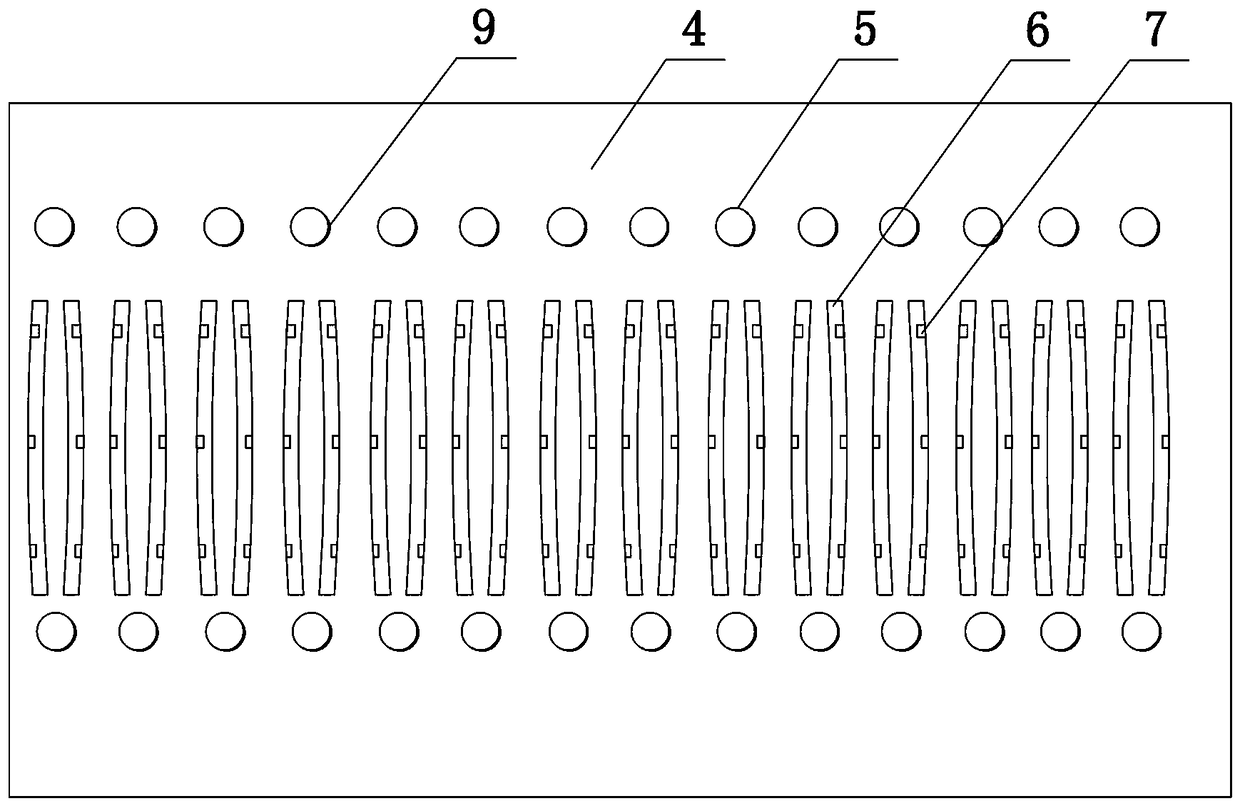

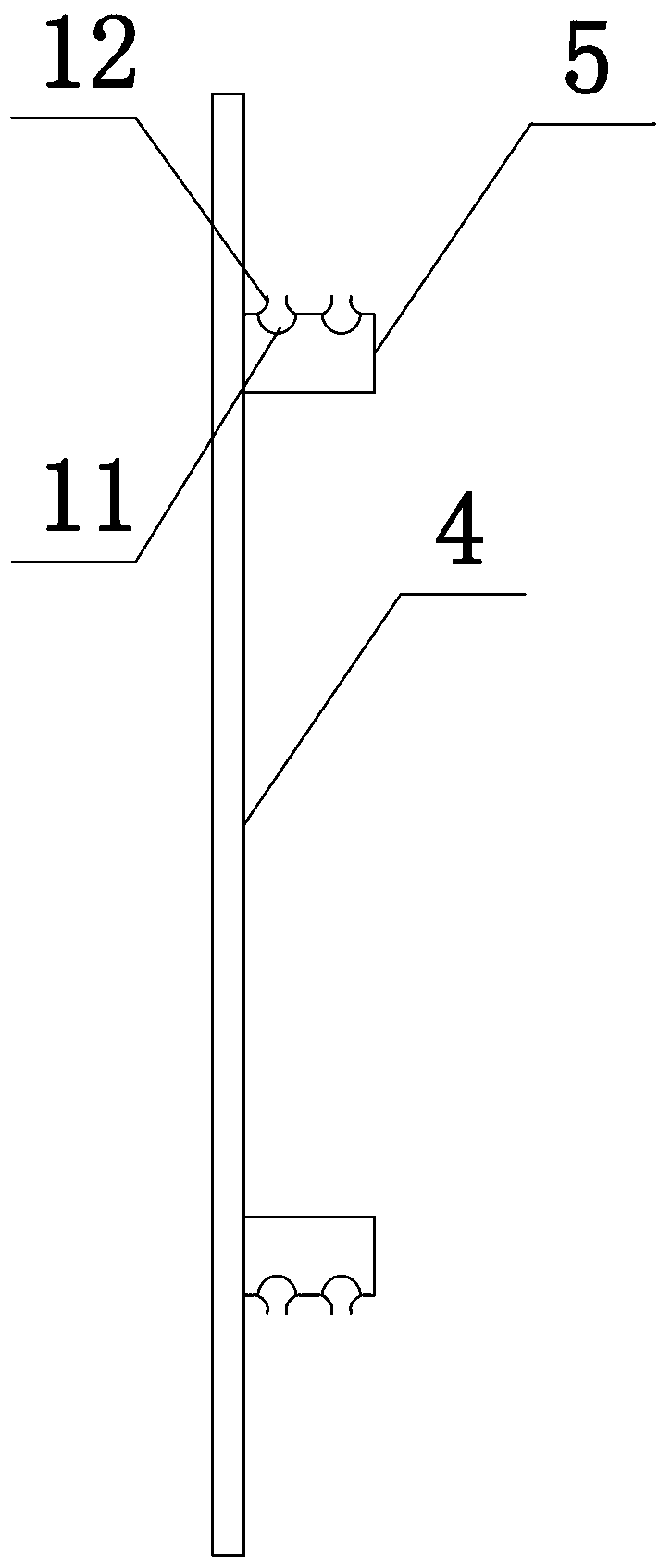

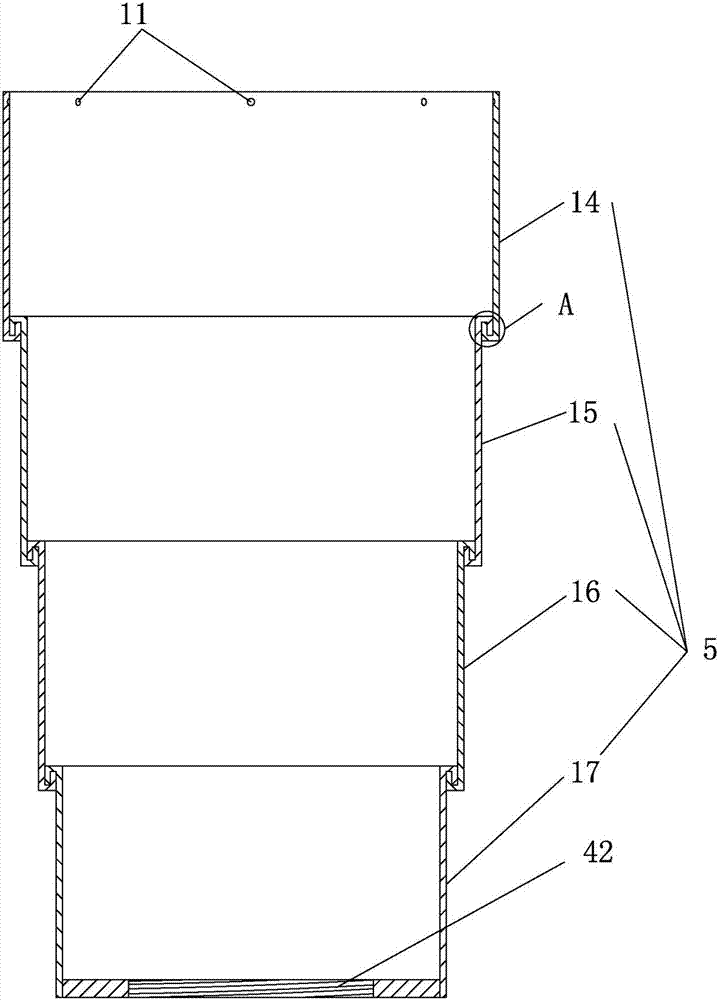

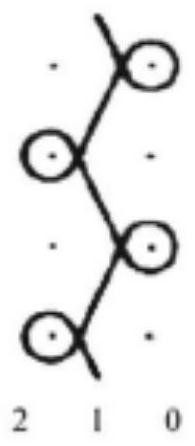

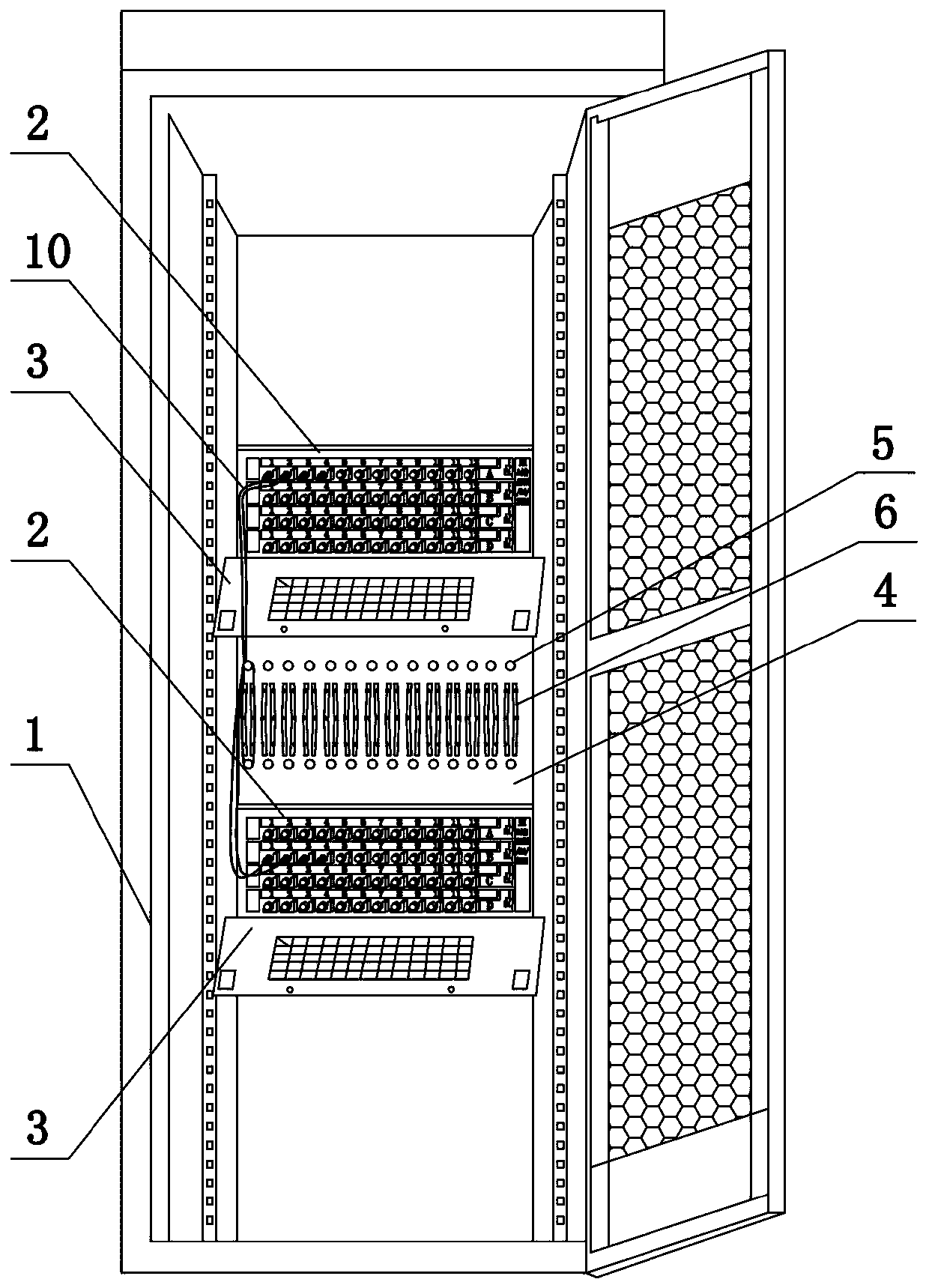

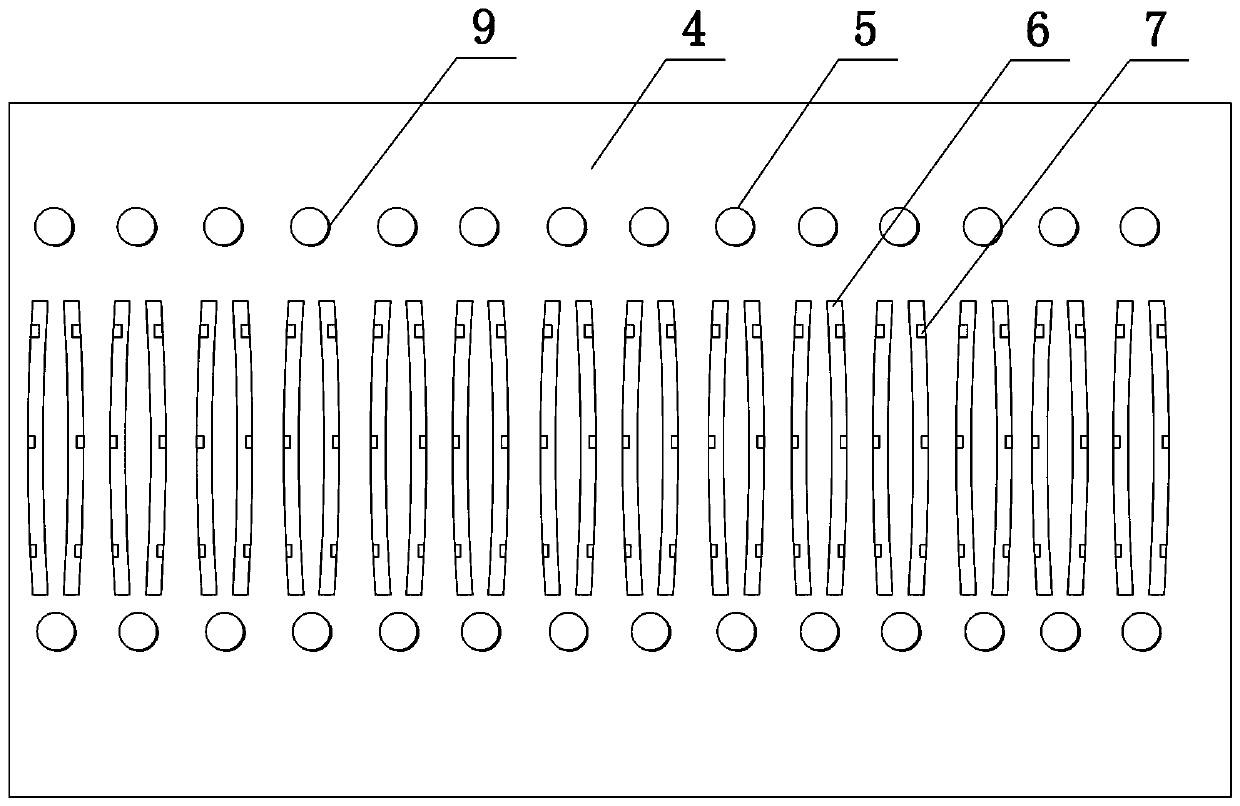

Optical fiber distribution cabinet

ActiveCN109116498AEasy and reasonable windingEasy to troubleshootFibre mechanical structuresDistribution frameSpecial design

The invention belongs to the technical field of communication equipment, in particular to an optical fiber distribution cabinet. The cabinet comprises a cabinet body and a plurality of distribution frames in the cabinet body. A winding mechanism is disposed between the adjacent distribution frames. Each winding mechanism comprises a winding plate, a plurality of winding posts on the winding plate,a plurality of wire sorting grooves disposed on the winding plate, wherein the winding posts are arranged in two rows and multiple columns, and the wire sorting grooves are located between two columns of winding posts. Through the special design of the winding mechanisms, each two winding posts arranged at the top and bottom are set as one group, and the same group of optical fibers are wound around the same group of winding posts, thereby facilitating the reasonable winding of the remaining optical fibers, facilitating the fault inspection, greatly improving the searching speed, and shortening the fault processing time.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

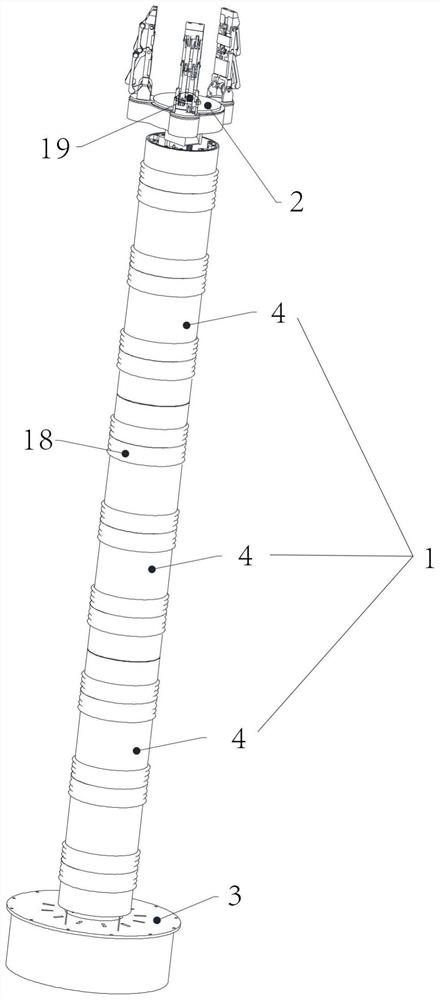

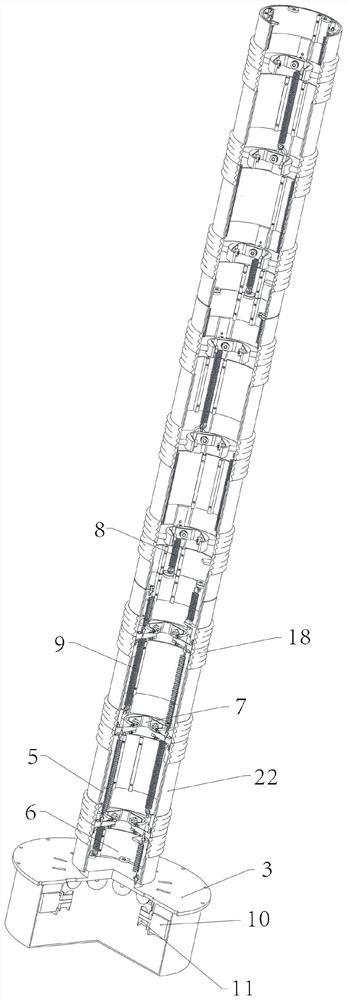

Rigid-flexible coupling hyper-redundant intelligent sensing mechanical arm and using method thereof

PendingCN114227660AModularity hasStrong adaptability to space environmentProgramme-controlled manipulatorJointsControl engineeringElectric machinery

The rigid-flexible coupling hyper-redundant intelligent sensing mechanical arm comprises a mechanical arm body, an operation device and a driving mechanism are arranged at the front end and the rear end of the mechanical arm body respectively, and the mechanical arm body is formed by sequentially connecting a plurality of bending units; each bending unit comprises a plurality of middle sections connected in sequence, base sections are arranged at the two ends of each middle section, the base sections and the middle sections are of hollow cylindrical structures, the base sections and the middle sections are movably connected through cross hinges, and every two adjacent middle sections are movably connected through cross hinges; the driving mechanism comprises a plurality of driving motors, reels are arranged on rotating shafts of the driving motors, a plurality of tendon ropes are arranged in the bending unit, one ends of the tendon ropes are fixed to the front end of the bending unit, and the other ends of the tendon ropes are connected with the reels respectively. The mechanical arm has the advantages of modularization, super-redundancy self-adaption, high space environment adaptability, measurable tail end pose, perceptible external contact and the like, and can be used for capturing and grabbing non-cooperative and cooperative targets and internal investigation of complex cavities.

Owner:BEIJING INST OF SPACECRAFT SYST ENG +1

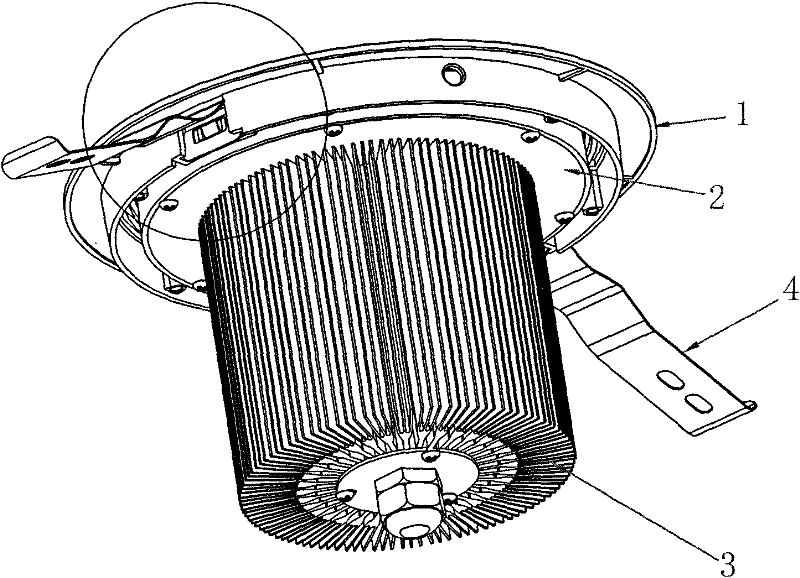

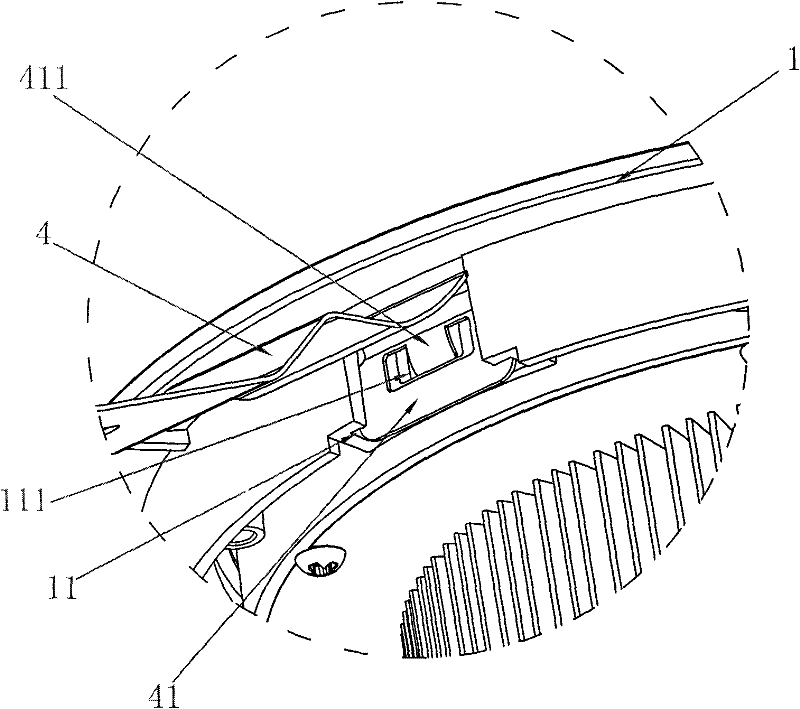

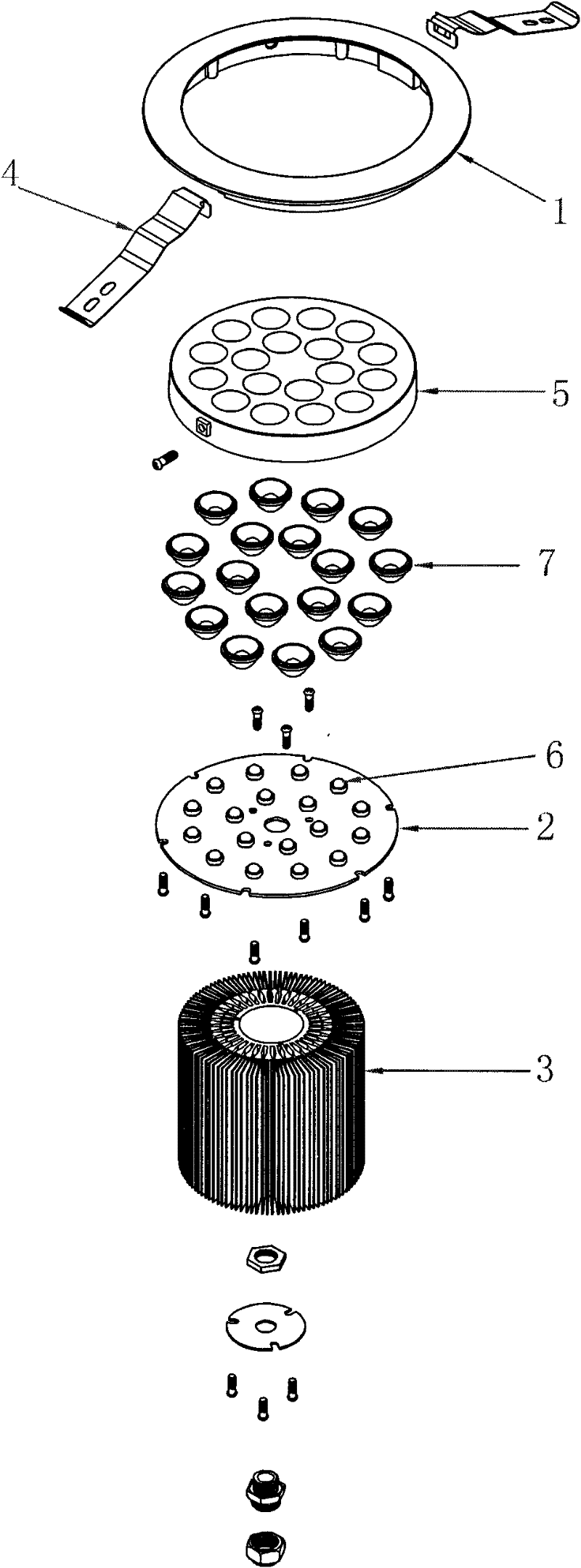

Ceiling lamp

InactiveCN101749614AAchieve positioningNot easy to hookLight fasteningsFixed installationEngineeringHeat spreader

The invention discloses a ceiling lamp, which comprises a case, an aluminum base plate, a heat radiator and a leaf spring. The invention is characterized in that the side wall of the case is provided with a leaf spring installation groove position, the side wall of the leaf spring installation groove position is provided with a recessed position, one end of the leaf spring is provided with an inserting plate accommodated in the installation groove position, and a buckle position matched with the recessed position is arranged on the insertion plate. The dismounting of the leaf spring does not need the use of a special tool, and the effects of simplicity and convenience are realized. In addition, the leaf spring consists of three sections of anti-slip dropping plates, and the ceiling lamp has triple anti-slip protection, so the installation of the ceiling lamp is firmer and safer.

Owner:伍志坚

Multifunctional umbrella

The invention relates to living articles, and discloses a multifunctional umbrella. The multifunctional umbrella comprises an umbrella handle and a holding part which comprises an upper holding segment, a lower holding segment and a connecting segment, the upper holding segment is located on the upper portion of the connecting segment, and the lower holding segment is located on the lower portion of the connecting segment; the lower portion of the umbrella handle is sleeved with a telescopic hose used as an umbrella cover, and the upper end of the telescopic hose is provided with two opposite compaction pieces; locating grooves are formed in the peripheral surface of the upper portion of the umbrella handle, an installing tank is arranged in each locating groove, a return spring is arranged inside each installing tank, a clamping tenon is arranged at an outlet of each installing tank, and one end of each return spring abuts against the corresponding clamping tenon. The multifunctional umbrella can be shared by two persons conveniently, the bodies of the two persons are not prone to make contact with each other, and the two persons can use the umbrella stably and are not prone to get wet; the umbrella and water droplets on the umbrella can be conveniently stored, and operation is easy, convenient and rapid.

Owner:YUZHONGNIAO FUJIAN OUTDOOR PROD

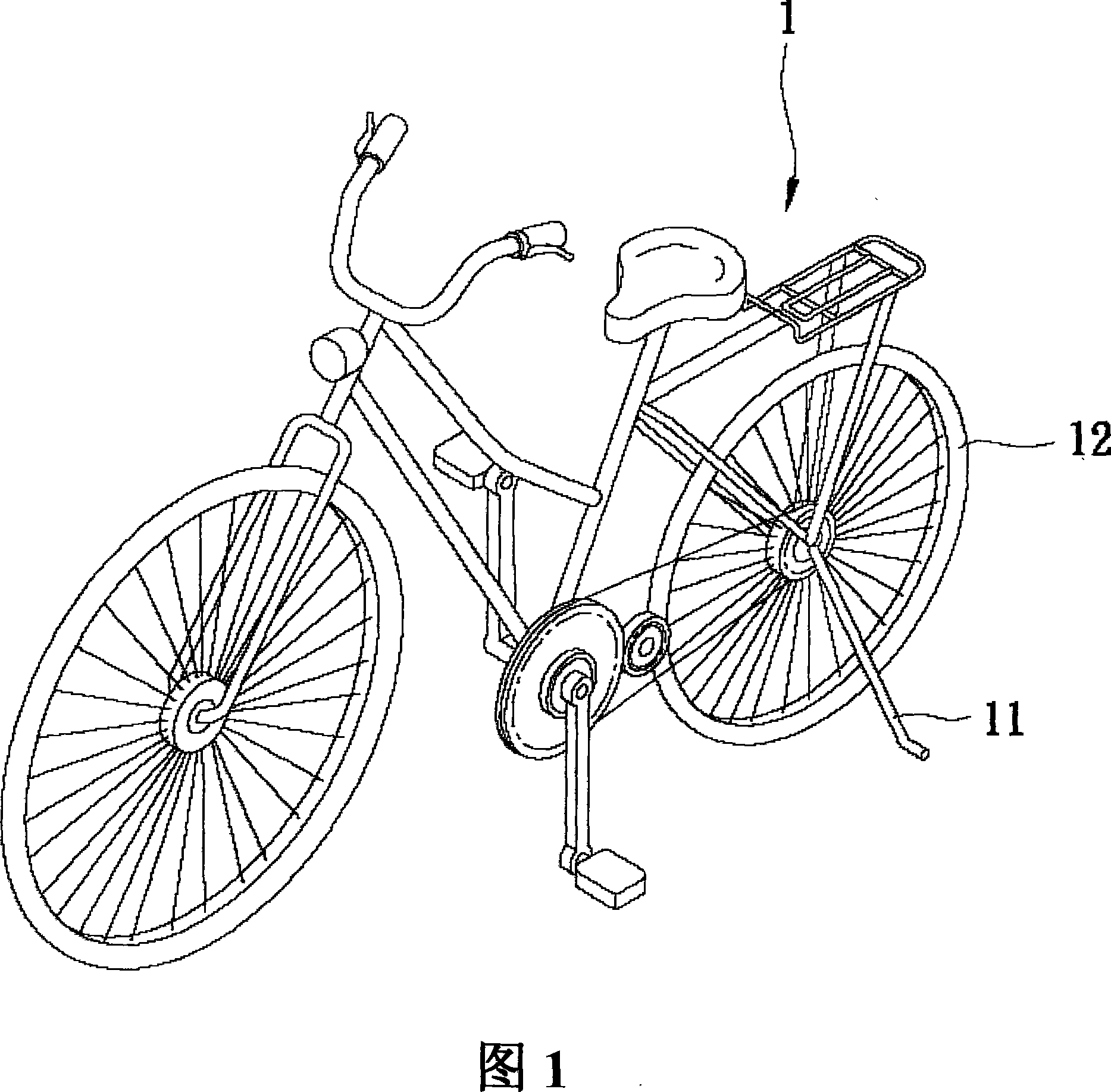

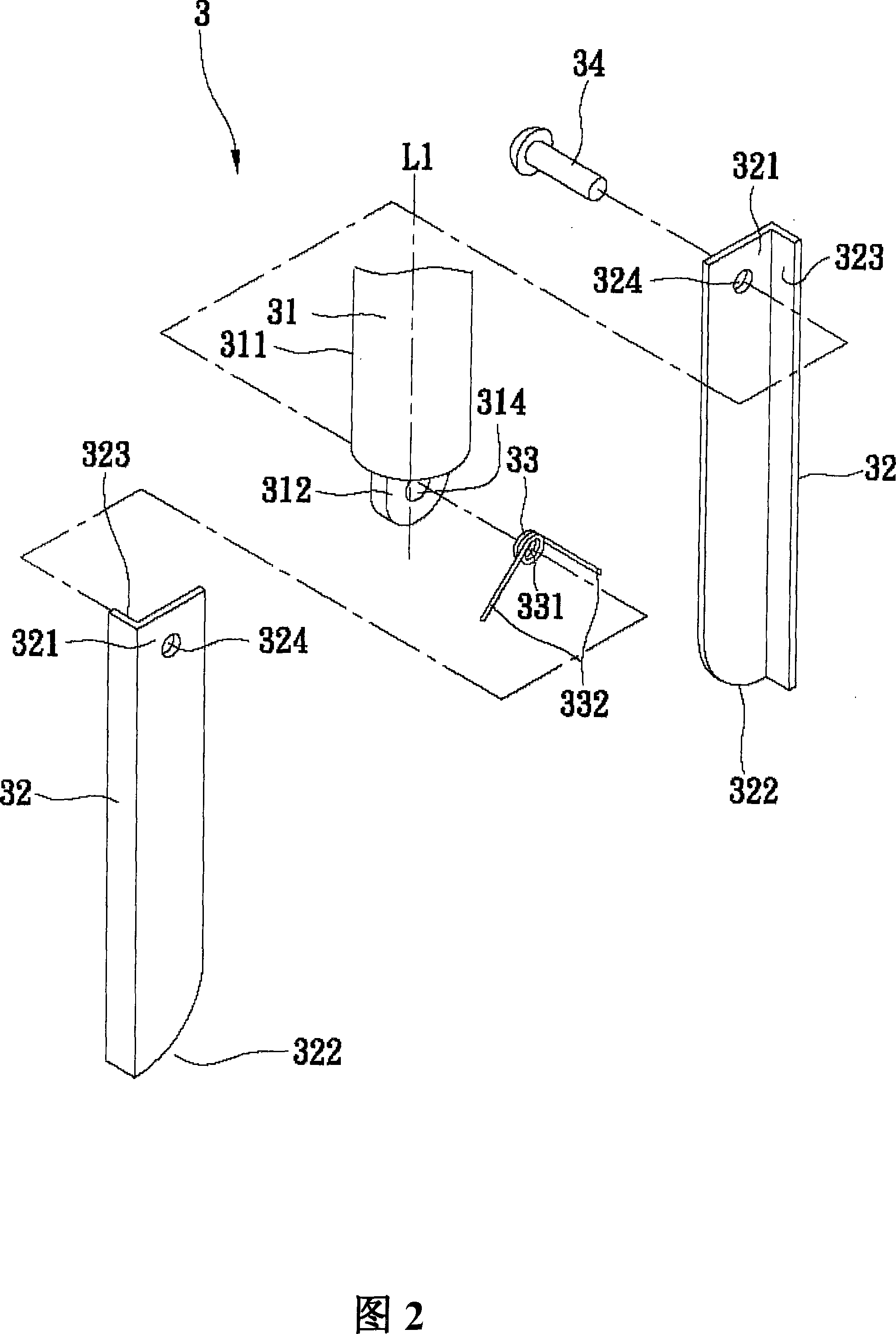

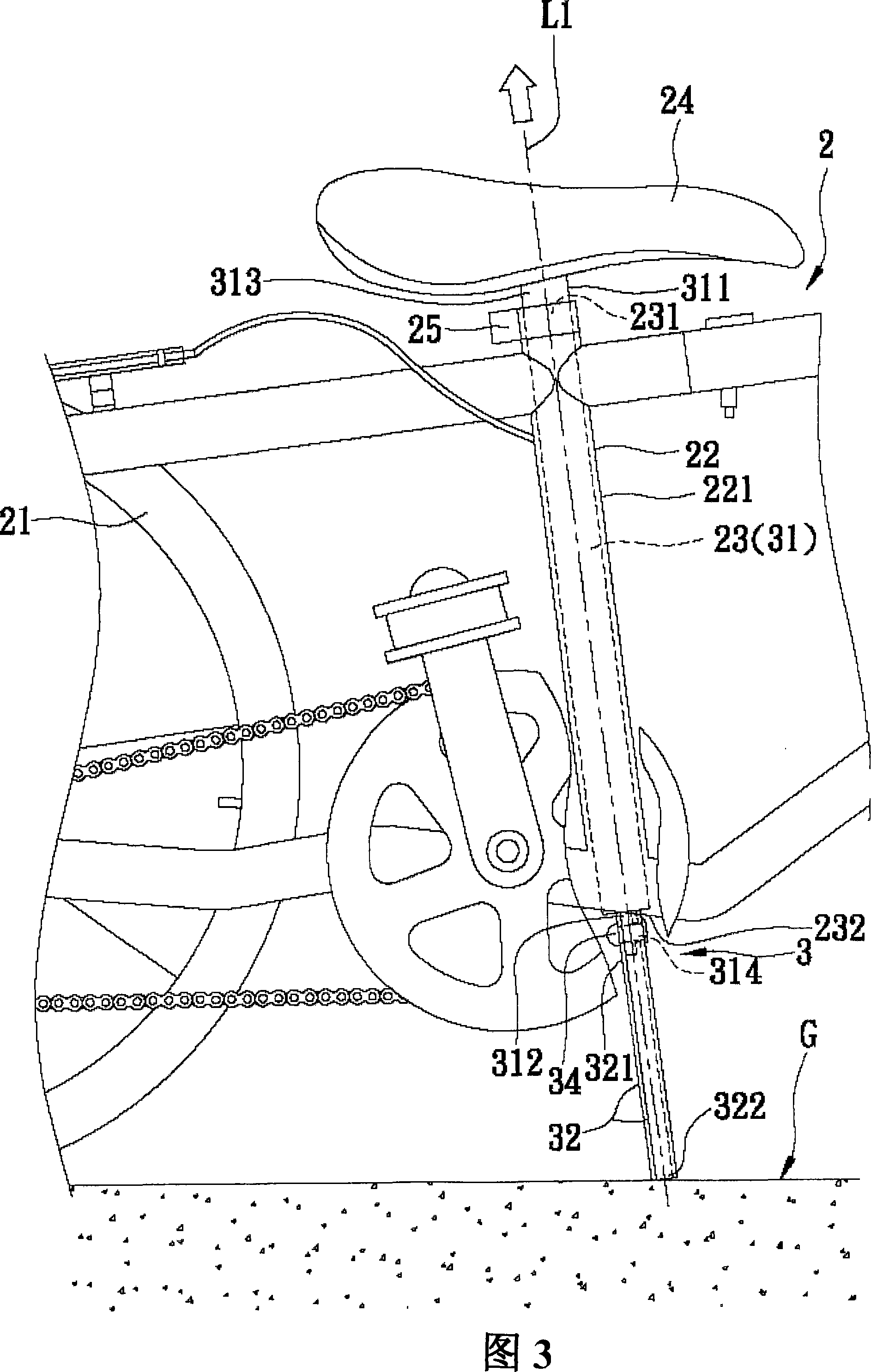

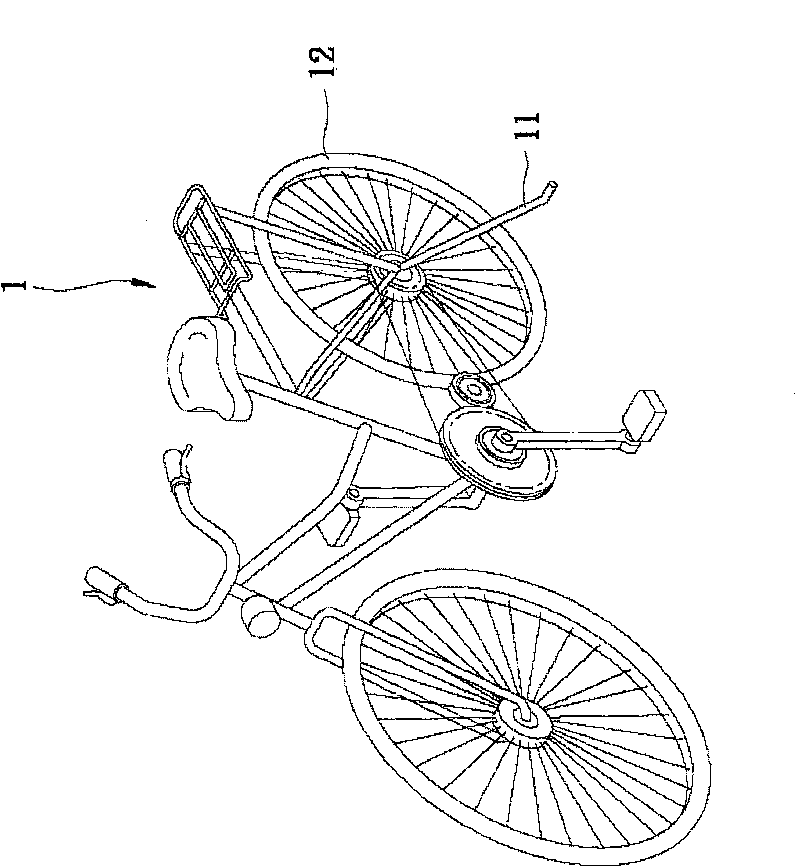

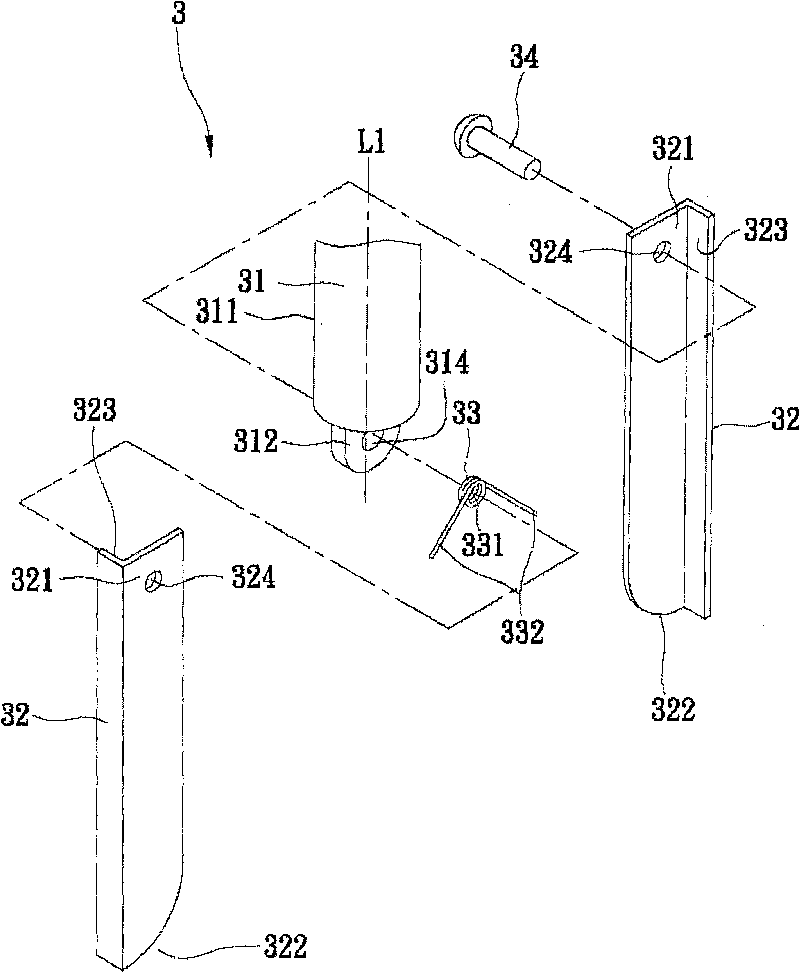

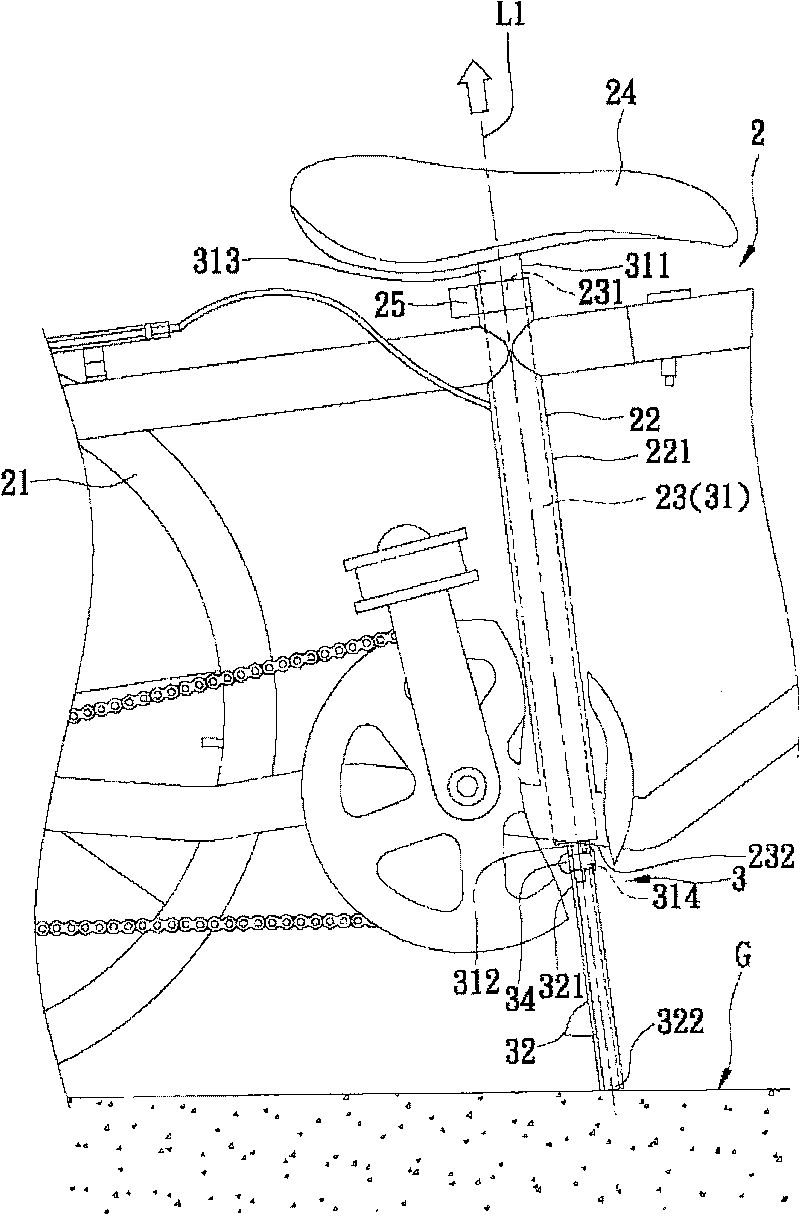

Concealed jiffy stand

The hidden bicycle stand capable of being held telescopically in some holding chamber includes one push rod, two support members, and one separating assembly. The push rod capable of moving inside the holding chamber has one pivot unit, each of the support members has one end pivoted to the pivot unit and one other end for supporting, and the separating assembly can drive the support members for the supporting ends to separate each other. The hidden bicycle stand has less influence on the rider and the pedestrian, small occupied space and capacity of making the bicycle simple and goodly.

Owner:GIANT TIANJIN CO LTD

Automatic packaging machine

InactiveCN111409889ANot easy to hookGuaranteed flatnessWrappingWrapper twisting/gatheringStructural engineeringPlastic packaging

The invention discloses an automatic packaging machine which comprises a rack, a conveying device arranged on the side wall of the front surface of the rack and a trimming device arranged above the conveying device. The trimming device comprises a translation mechanism and a pressing mechanism; the pressing mechanism comprises a pressing driving part, a T-shaped plate arranged below the pressing driving part, a fusing strip arranged below the T-shaped plate and two pressing assemblies arranged on the left side wall and the right side wall of the T-shaped plate correspondingly; and each pressing assembly comprises two clamping blocks arranged at the two ends of the same side wall of the T-shaped plate correspondingly, a movable plate arranged between the two clamping blocks, a plurality ofelastic pieces arranged between the upper wall of the movable plate and the T-shaped plate and a flat film roller arranged on the lower wall of the movable plate. Articles to be packaged are firstly extruded and then packaged through the trimming device, so that plastic packaging films are saved, and the packaging cost is reduced.

Owner:卢月望

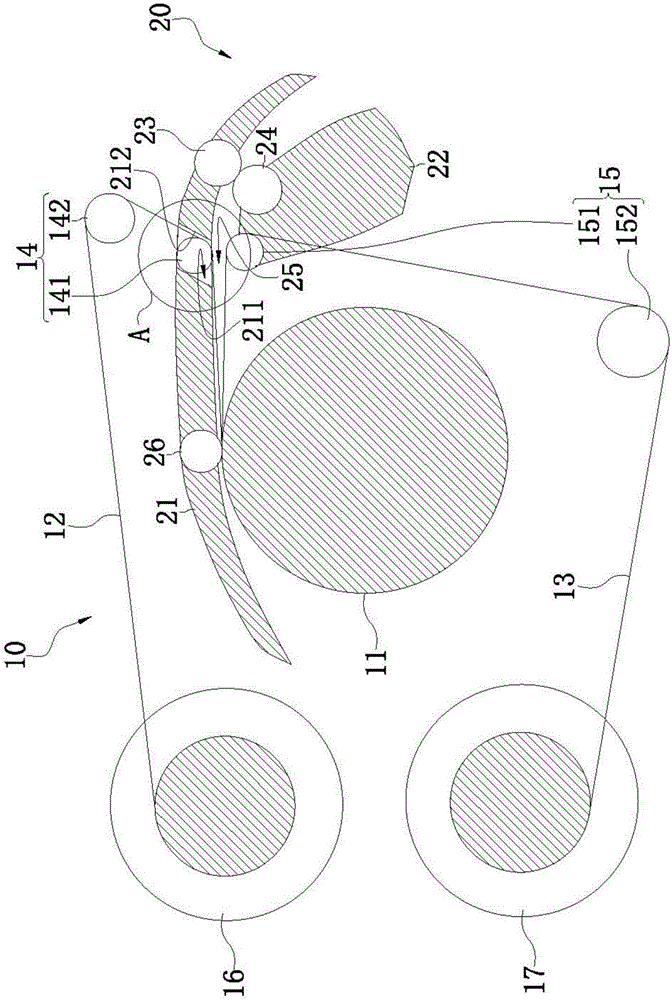

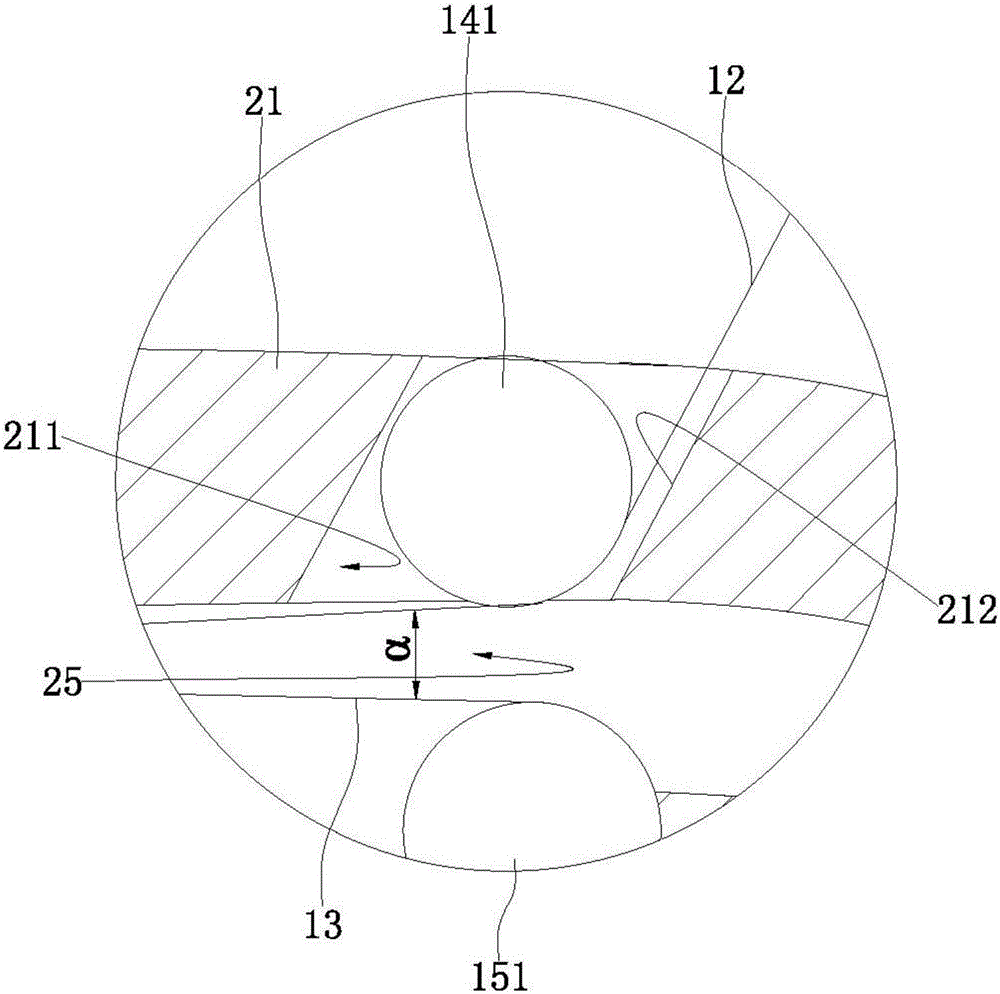

Picking platform of seed-watermelon harvester

The invention relates to a picking platform of a seed-watermelon harvester. The picking platform of the seed-watermelon harvester comprises a frame, front-row augers, rear-row augers, a seed-watermelon poking wheel and a seed-watermelon collecting shovel; the front-row augers are arranged in the middle position right ahead of the frame to push the seed-watermelons towards two sides; the rear-row augers comprise a left rear-row auger and a right rear-row auger arranged at two sides of the frame, which push the seed-watermelons towards the middle position; the seed-watermelon poking wheel is arranged right behind the front-row augers and located between the left rear-row auger and the right rear-row auger. The seed-watermelon poking wheel is hinged to the frame and a plurality of seed-watermelon poking plates are fixed around the seed-watermelon poking wheel; the rear of the seed-watermelon poking wheel is provided with the seed-watermelon collecting shovel for conveying the pushed seed-watermelons by the seed-watermelon poking wheel to a conveyor. The seed-watermelon collecting shovel is wedge-shaped and hinged to the frame. A roller is arranged at the bottom of the seed-watermelon collecting shovel. The picking platform can solve the grass-winding, vine-removing and melon-missing problems in the harvesting process of the seed-watermelons.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

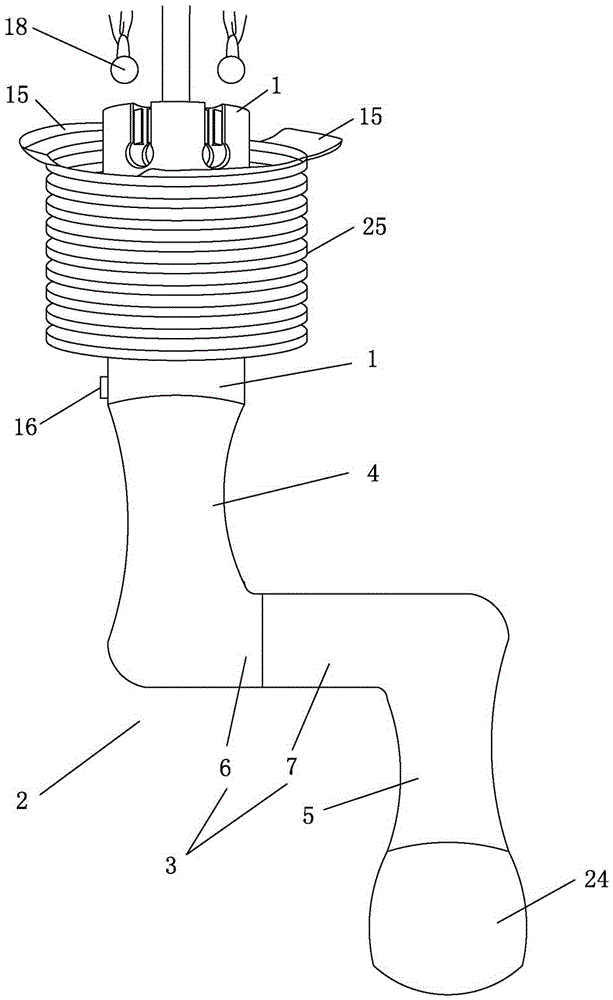

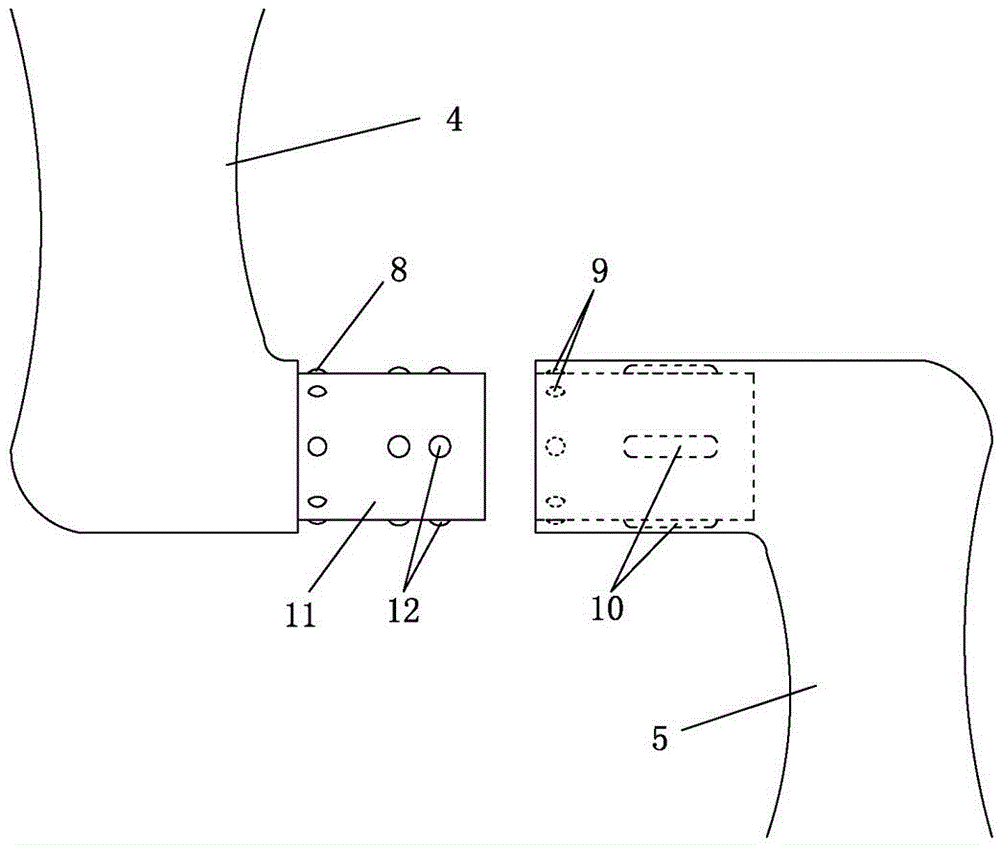

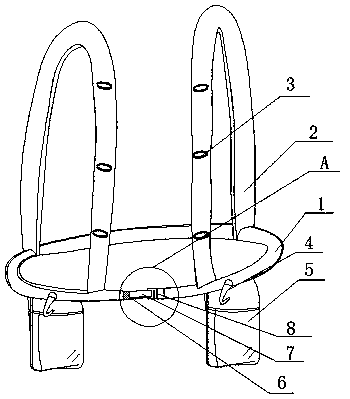

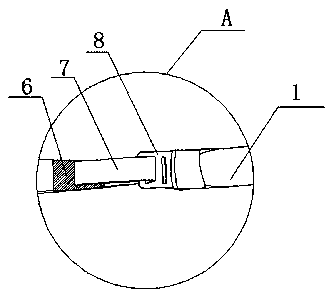

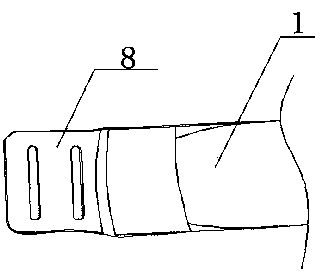

Portable drainage device fixing belt

PendingCN109771713APrevent slippageReduce unplanned extubation ratesCatheterSuction devicesCatheterEngineering

The invention discloses a portable drainage device fixing belt, which structurally comprises a waist fixing belt, a strap, a catheter fixing ring, a hook, a transparent observation bag, an elastic belt, a magic tape and a buckle, wherein the outer side of the top of the waist fixing belt is sewn with the strap, the catheter fixing ring is fixed at the middle side of the front part of the strap, the hook is arranged at the front part of the waist fixing belt, and the transparent observation bag is fixed at the front side of the bottom of the waist fixing belt. By arranging a drainage bag in thetransparent observation bag, a patient with the drainage bag can move out of the bed with holding the drainage bag in a hand; the hook on the waist fixing belt can effectively fix the drainage bag; the catheter fixing ring is arranged on the strap, a drainage pipe can be prevented from slipping off, the drainage situation can be observed, so that the exposed part of the drainage pipe is guaranteed and is not easy to drag, therefore the purpose of protecting the drainage pipe is achieved, the unplanned pipe pulling rate of drainage pipe is effectively reduced.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

portable umbrella

InactiveCN105852350BReduce dropLess likely to be unstableWalking sticksEngineeringMechanical engineering

The invention relates to articles of daily use and discloses a portable umbrella. The portable umbrella comprises an upper nest, an umbrella stem, an accommodating casing and an umbrella handle, wherein the accommodating casing is formed by at least two sections of annular cylinders through sealing and clamping, the annular cylinder at the innermost section is connected with the umbrella stem, and the annular cylinder at the outermost section is buckled and locked with the upper nest; the umbrella handle comprises a C-shaped section and a movable section, an annular structure is defined by the movable section and the C-shaped section, the C-shaped section comprises a connecting part provided with bulges and a rotating part provided with grooves, and the rotating part and the connecting part realize positioning through matching of the bulges and the grooves. The portable umbrella is provided with the folding type accommodating casing, and the accommodating casing is used for accommodating the umbrella, occupies small space, is pulled up and matched with the upper nest to accommodate the umbrella inside when in use, is sealed to guarantee that rainwater cannot leak and wet floors or bags and the like, and is simple and convenient to operate; by means of the umbrella handle with the annular structure, people can reply messages by a mobile phone urgently while holding the umbrella, contact points of the umbrella handle and the wall can be increased through rotation of the rotating part, and accordingly, the umbrella is enabled to lean against the wall stably.

Owner:YUZHONGNIAO FUJIAN OUTDOOR PROD

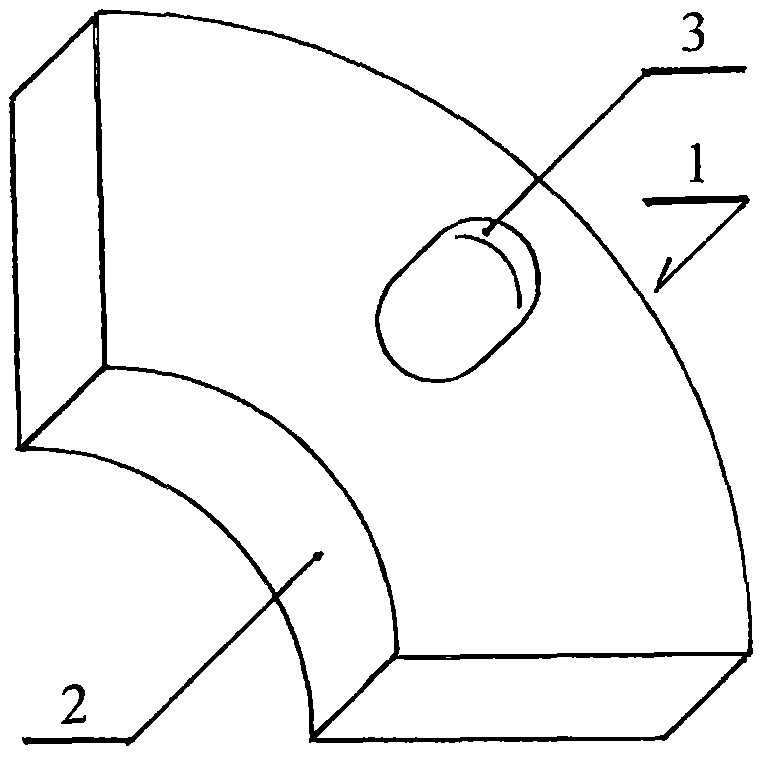

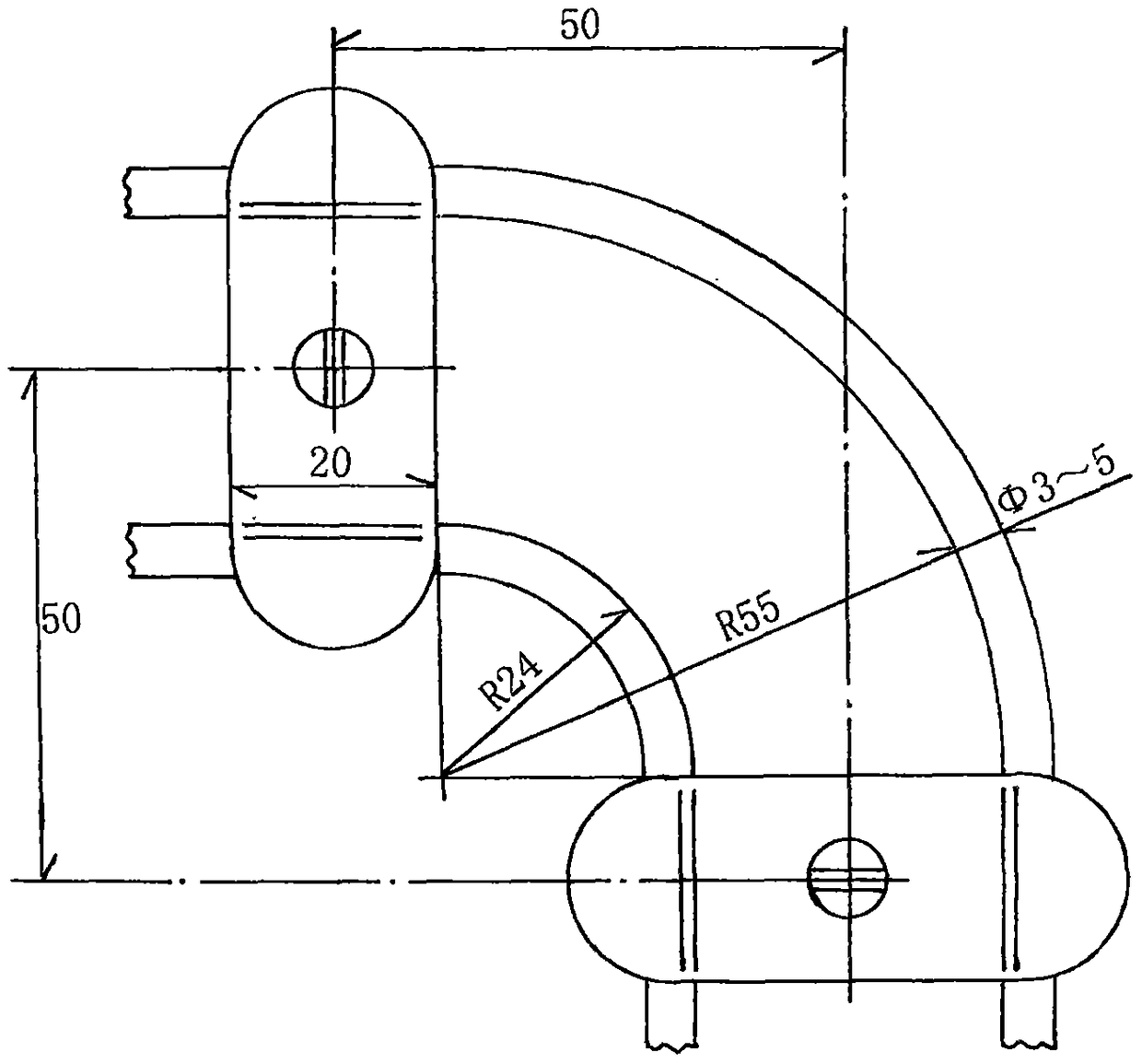

Wire bending explorator

InactiveCN108856559ASmall deformation under external tension and internal pressureHigh wiring efficiencyInsulation layerEngineering

The invention relates to a wire bending explorator and discloses the explorator for rotating laid wires of a double-wire porcelain clamping plate by 90 degrees. The wire bending explorator is a folding fan sector-shaped plate like explorator and comprises a convex arc side 1 and a concave arc side 2, and an upper plate face is provided with a holding knob 3. During wire bending, the holding knob 3is hold with one hand, one wire is attached to the convex arc side 1 with the other hand, the other wire is attracted to the concave arc side 2, and the two wires are bent into 90-degree great circular arcs. Insulation layers slightly deform due to external pulling and internal pressing, and the service life is benefited; the wire laying working efficiency is high; the circular arcs are attractive; and hooking is not prone to being caused. The wire bending explorator is used for wall wire laying.

Owner:武洋

A kind of warp knitted summer quilt fabric and preparation method thereof

ActiveCN111501191BCompact structureStable structureWarp knittingHeating/cooling textile fabricsPolymer sciencePolyamide

The invention discloses a warp-knitted summer quilt fabric and a preparation method thereof. The fabric is a warp-knitted fabric made of polyamide filaments for front combing and polyethylene and polyamide composite filaments for rear combing. Polyamide filaments and The mass ratio of polyethylene and polyamide composite filaments is 1.3-1.6:1, and the preparation method of the fabric is provided. The fabric of the present invention is cool and comfortable to the touch, breathable, bright in luster, and has anti-snagging and anti-drilling properties at the same time Advantages of the invention, the preparation method of the present invention has the advantages of high production efficiency, short process and low cost.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

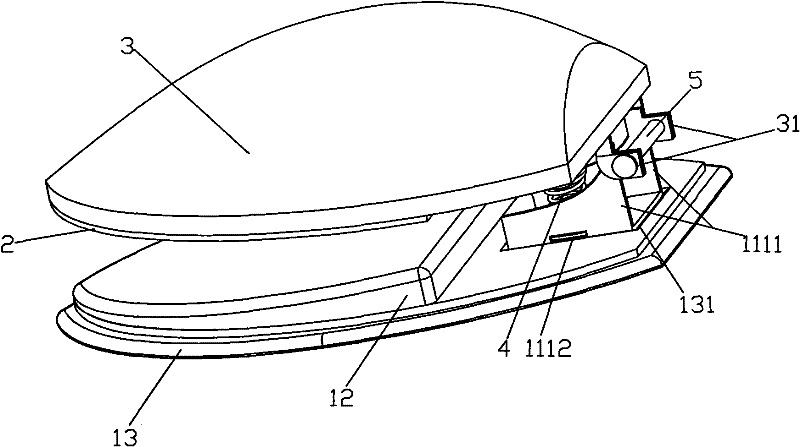

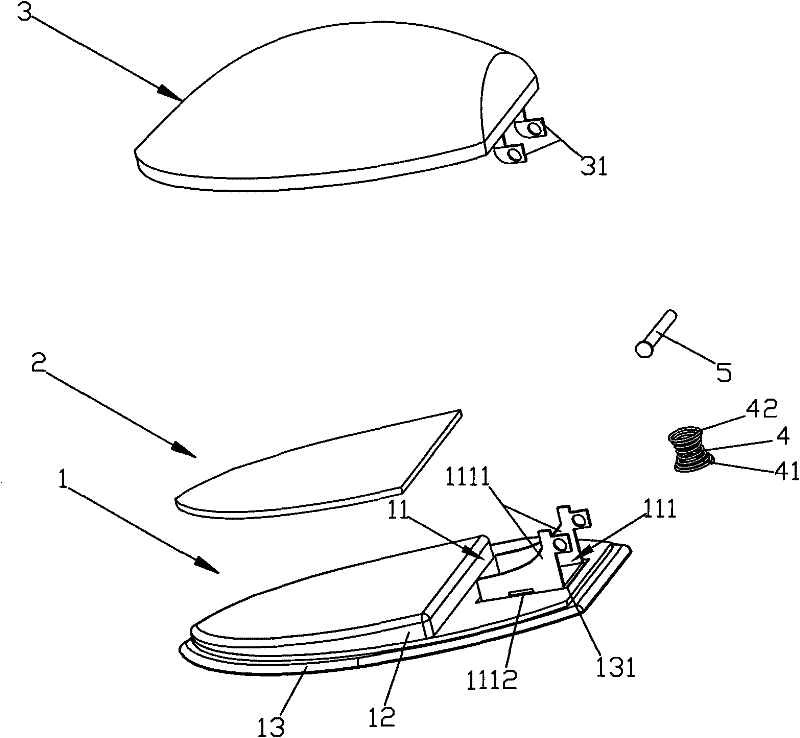

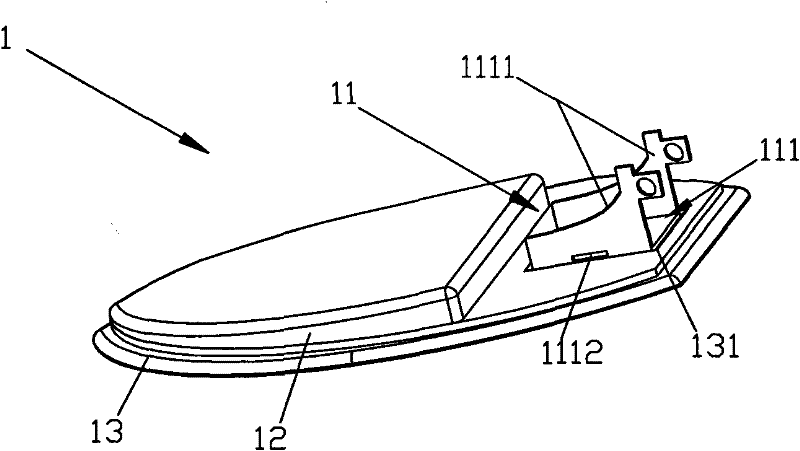

Improved iron

InactiveCN101701421BImprove the safety of useReduce volumeHand ironTextiles and paperMetallurgyOn board

The invention relates to an improved iron which comprises an iron main body and an ironing board, wherein the ironing board is assembled below the iron main body, a heating element for heating the ironing board is arranged in the iron main body, the improved iron further comprises an additional board matched with the iron main body, and the additional board and the iron main body can be connectedby rotating up and down. The invention designs the unique improved iron, when in use, the improved iron can be operated without the ironing board, and the ironing can also be directly carried out on wearing clothes, so that the convenience is significant when going out for business or travelling of people; and the additional board matched with a base can improve the safety of the use of the iron,the temperature on the surface of the ironing board below the iron main body is very high during the operation process, and the additional board can play the role of blocking the ironing board, so that even the operation of a user is improper, the user can not be easily burnt by the ironing board.

Owner:福建省南安市同盛体育器材有限公司

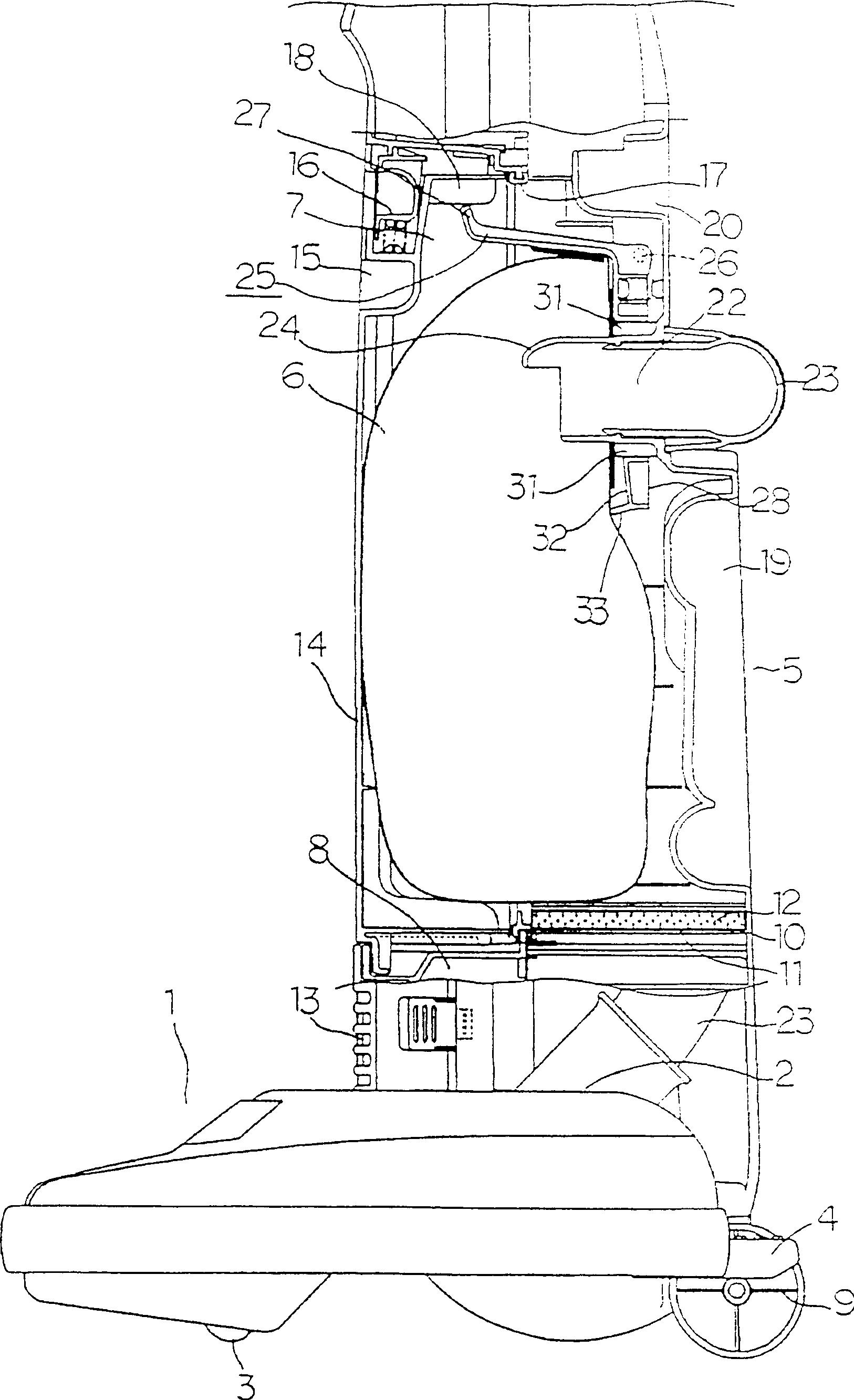

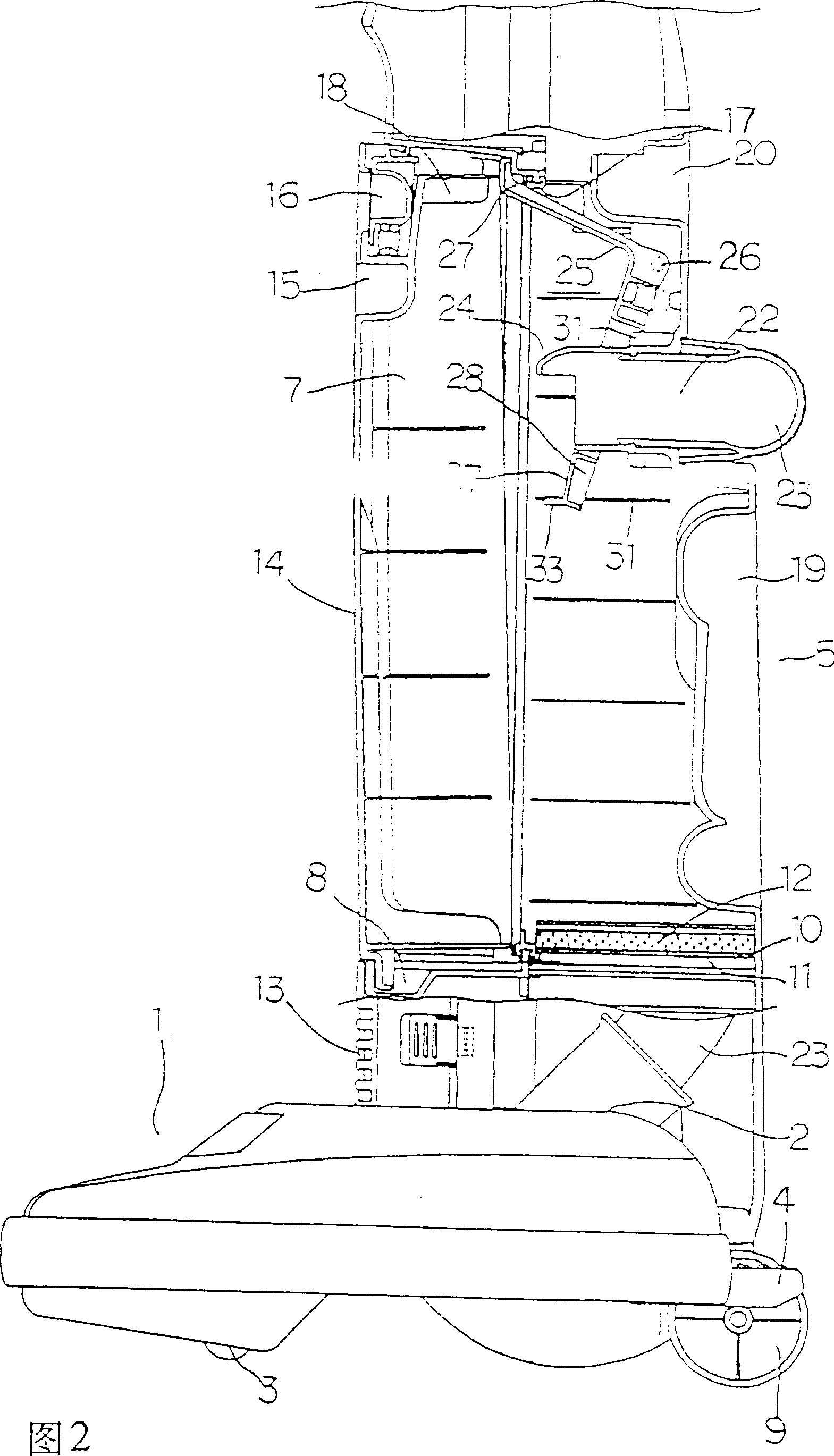

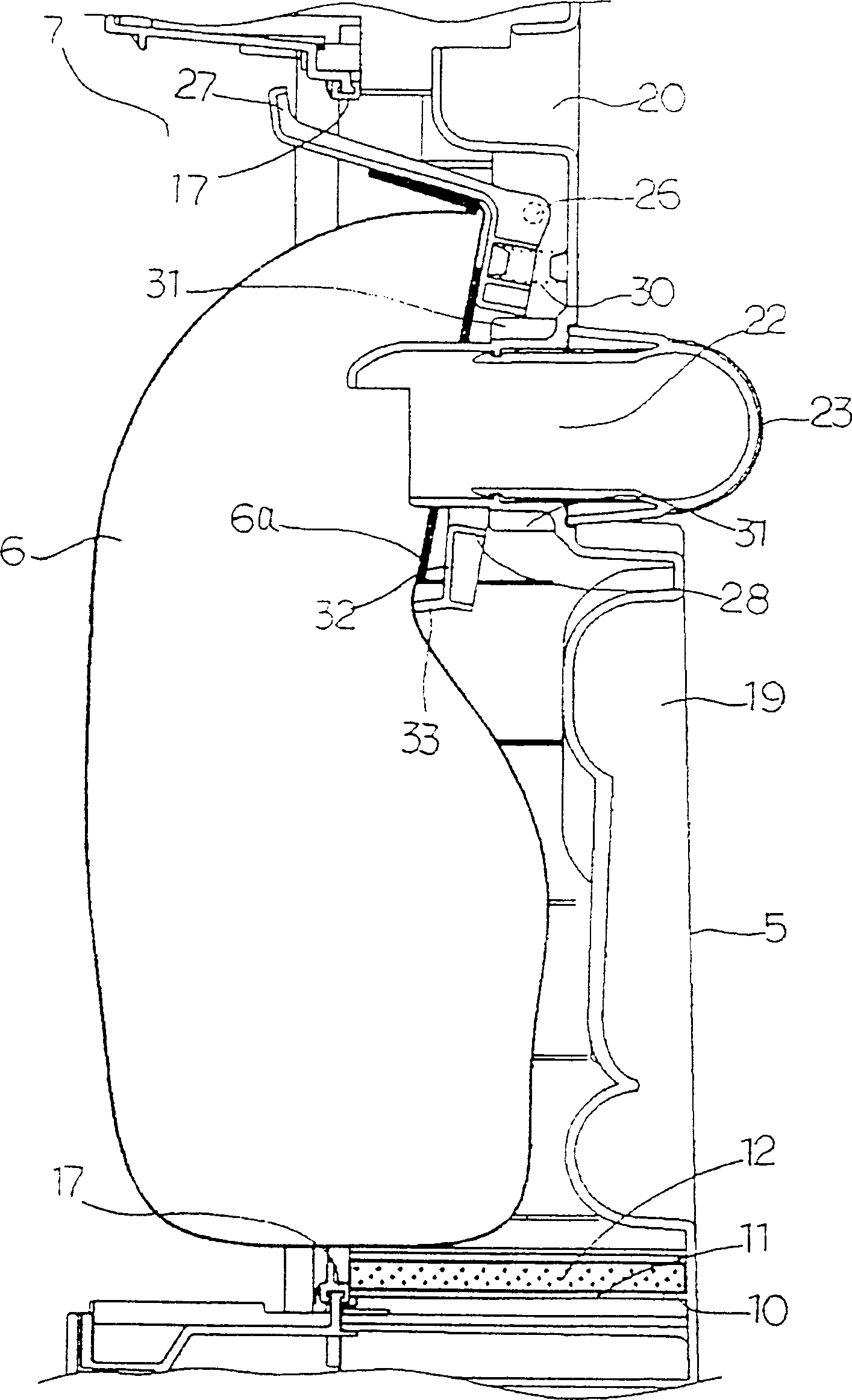

Electric dust cleaner

The invention relates to an electric vacuum cleaner, a rod 25 is hinged freely between the air suction opening 22 of the dust collection chamber 7 and the opening of the dust suction chamber 7, one end of the rod 25 is arranged at the flange of the opening of the dust collection chamber 7,simultaneously the other end of the dust collection chamber 7 is approximate to the air suction opening 22, the opening plate 6a of a dust collection bag 6 is arranged at the air suction opening 22 so as to revolve the rod 25, so that one end of the rod 25 is ejected in the dust collection chamber 7 to form an upright electric vacuum cleaner. When the dust collection bag is not arranged, the rod is arranged at the flange of the opening of the dust collection chamber, at the time the dust collection cover is incapable to be arranged, thereby preventing the mistaken use of electric vacuum cleaner positively, when the dust collection bag is intended to be replaced, one end of the rod is pressed, the other end of the rod moves upwardly to push the opening plate of the dust collection bag, thereby removing the dust collection bag easily so as to improve operation.

Owner:SANYO ELECTRIC CO LTD

Picking table of melon harvester

ActiveCN106385981BIssues such as reducing lossesImprove work efficiencyMowersPicking devicesEngineeringMelon (food)

The invention relates to a picking platform of a seed-watermelon harvester. The picking platform of the seed-watermelon harvester comprises a frame, front-row augers, rear-row augers, a seed-watermelon poking wheel and a seed-watermelon collecting shovel; the front-row augers are arranged in the middle position right ahead of the frame to push the seed-watermelons towards two sides; the rear-row augers comprise a left rear-row auger and a right rear-row auger arranged at two sides of the frame, which push the seed-watermelons towards the middle position; the seed-watermelon poking wheel is arranged right behind the front-row augers and located between the left rear-row auger and the right rear-row auger. The seed-watermelon poking wheel is hinged to the frame and a plurality of seed-watermelon poking plates are fixed around the seed-watermelon poking wheel; the rear of the seed-watermelon poking wheel is provided with the seed-watermelon collecting shovel for conveying the pushed seed-watermelons by the seed-watermelon poking wheel to a conveyor. The seed-watermelon collecting shovel is wedge-shaped and hinged to the frame. A roller is arranged at the bottom of the seed-watermelon collecting shovel. The picking platform can solve the grass-winding, vine-removing and melon-missing problems in the harvesting process of the seed-watermelons.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Concealed jiffy stand

The hidden bicycle stand capable of being held telescopically in some holding chamber includes one push rod, two support members, and one separating assembly. The push rod capable of moving inside theholding chamber has one pivot unit, each of the support members has one end pivoted to the pivot unit and one other end for supporting, and the separating assembly can drive the support members for the supporting ends to separate each other. The hidden bicycle stand has less influence on the rider and the pedestrian, small occupied space and capacity of making the bicycle simple and goodly.

Owner:GIANT TIANJIN CO LTD

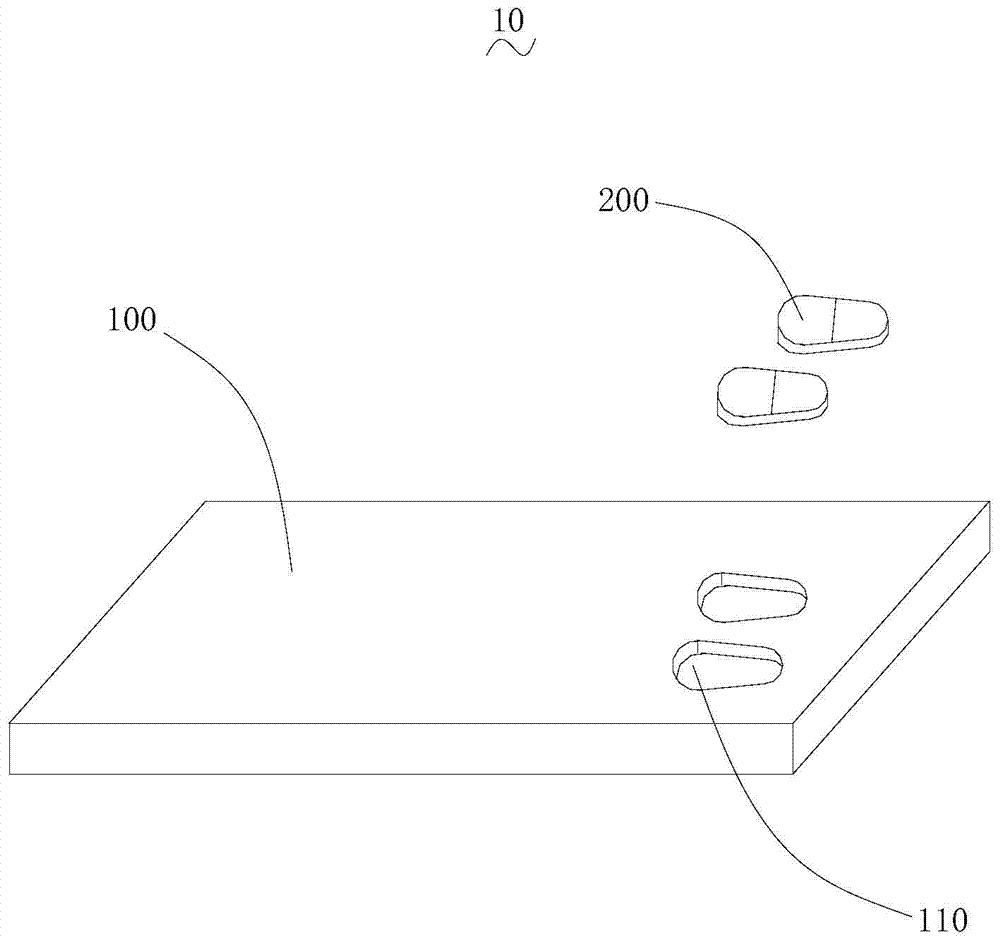

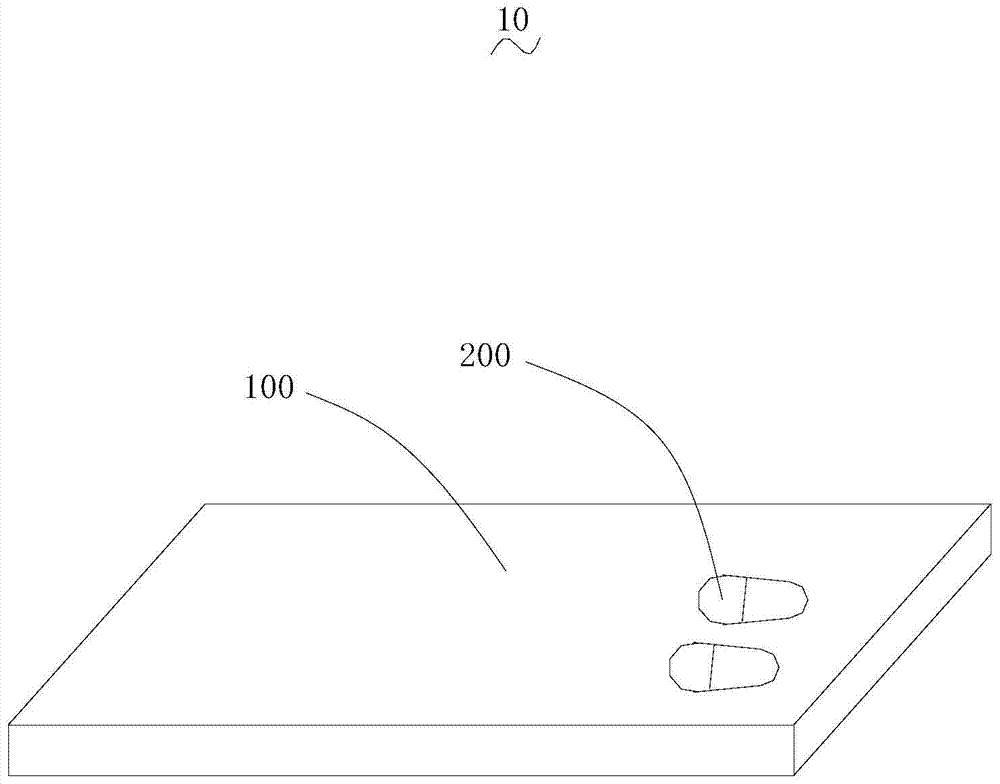

Mat device

The invention relates to a floor mat device, comprising: a body, slippers and a charger, the body is provided with a number of grooves matching the slippers; a heater is arranged in the slippers, and the heater has a connection end, the The slippers are accommodated in the groove; the charger is arranged in the body, the charger has a plug-in end, and the plug-in end abuts and is electrically connected to the connection end of the heater, so that the charger can provide power for the heater of the slippers. The above-mentioned floor mat device and the groove make the placement of the slippers more orderly, do not occupy other space, make full use of the accommodation space, and save the accommodation space. And make the place where the floor mat device is used more tidy. In addition, the heater inside the slippers can be connected with the charger inside the body, which can heat the slippers in winter, making the user more comfortable to wear.

Owner:姚健军

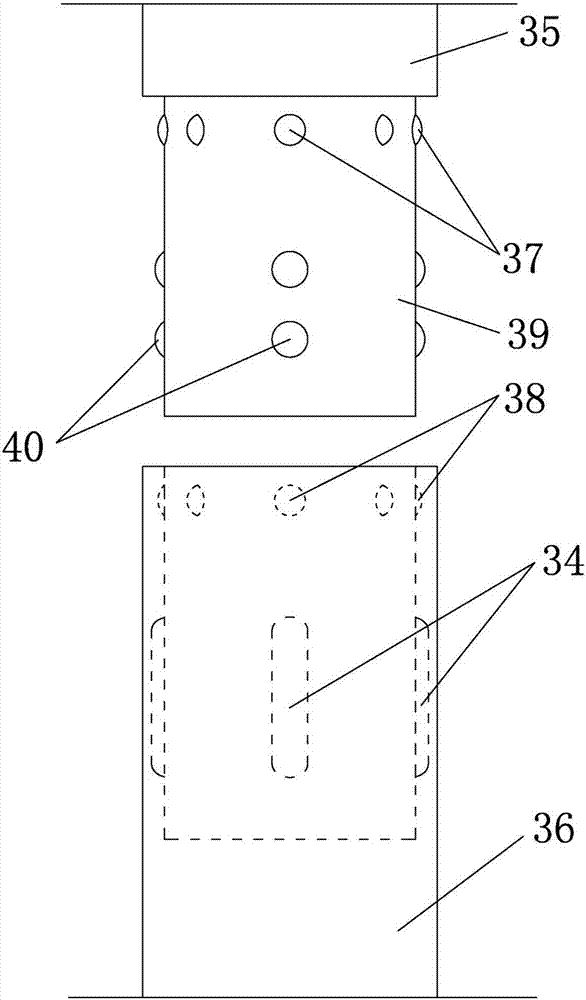

Banknote storage and delivery device and banknote automatic transaction device

ActiveCN106023429BReduce spacingNot easy to hookCoin/currency accepting devicesEngineeringFinancial transaction

The invention relates to the technical field of bank equipment, and particularly relates to a paper money storing and delivering device and a paper money automatic transaction device. The paper money storing and delivering device comprises a paper money coiling mechanism and a paper money guiding mechanism. The paper money coiling mechanism comprises a roller on which an upper coiling tape and a lower coiling tape coil, an upper guide part and a lower guide part. The paper money guiding mechanism comprises an upper guide member, a lower guide member, and an upper clamping roller and a lower clamping roller which are respectively arranged on the upper guide member and the lower guide member. The upper guide part comprises a first upper tape roller. The upper guide member is provided with a tape through hole. The first upper tape roller is arranged in the tape through hole. The lower guide part comprises a first lower tape roller which is arranged on the lower guide member and corresponding to the first upper tape roller. The upper coiling tape is arranged on the first upper tape roller and penetrates through the tape through hole. The lower coiling tape is arranged on the first lower tape roller, and a paper money conveying path is formed between the lower coiling tape and the upper coiling tape. According to the paper money storing and delivering device, paper money with coiled parts can be normally stored without tearing.

Owner:SHENZHEN YIHUA COMP +2

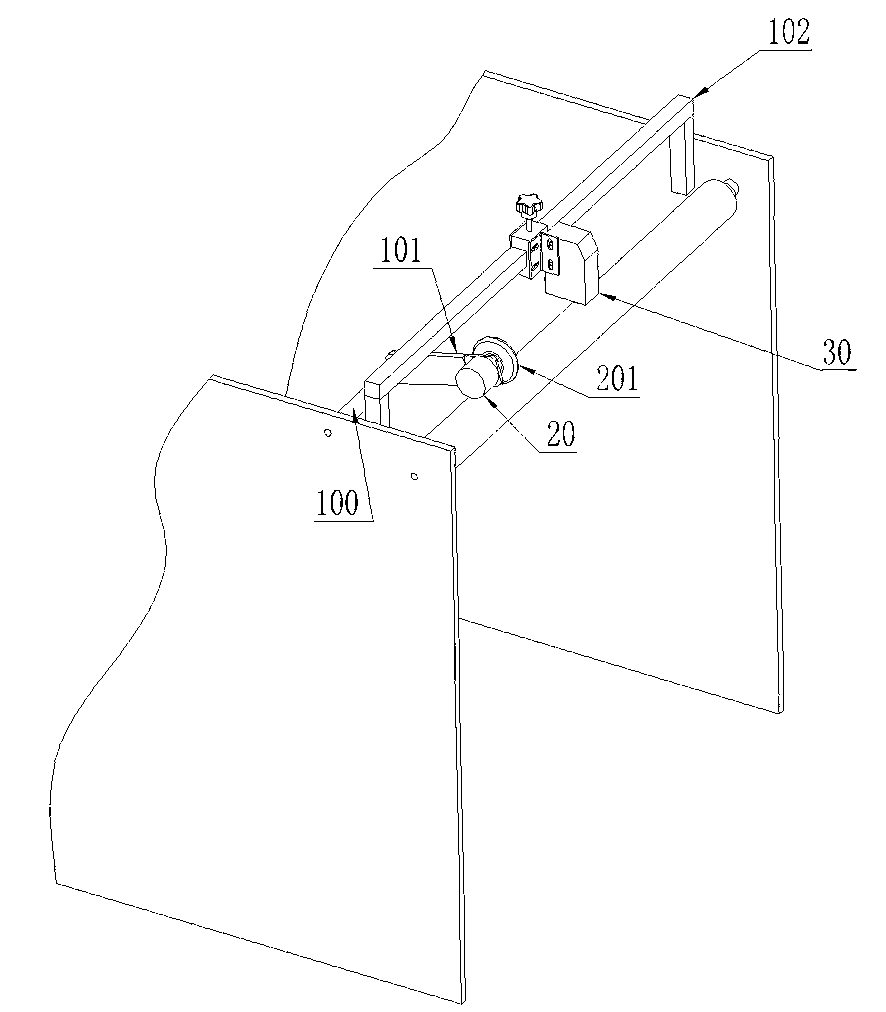

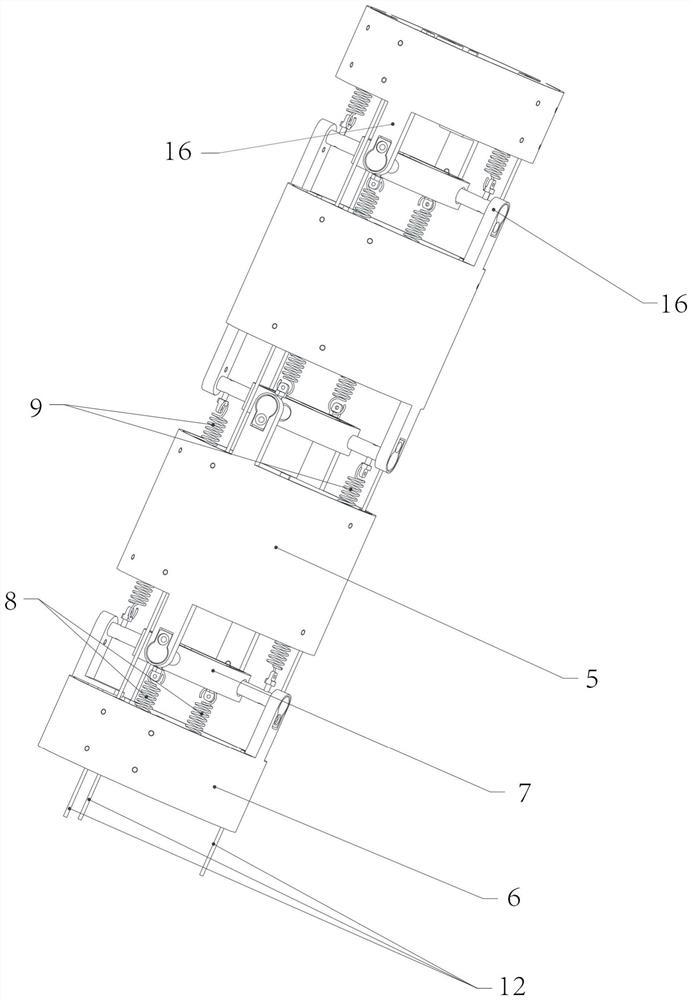

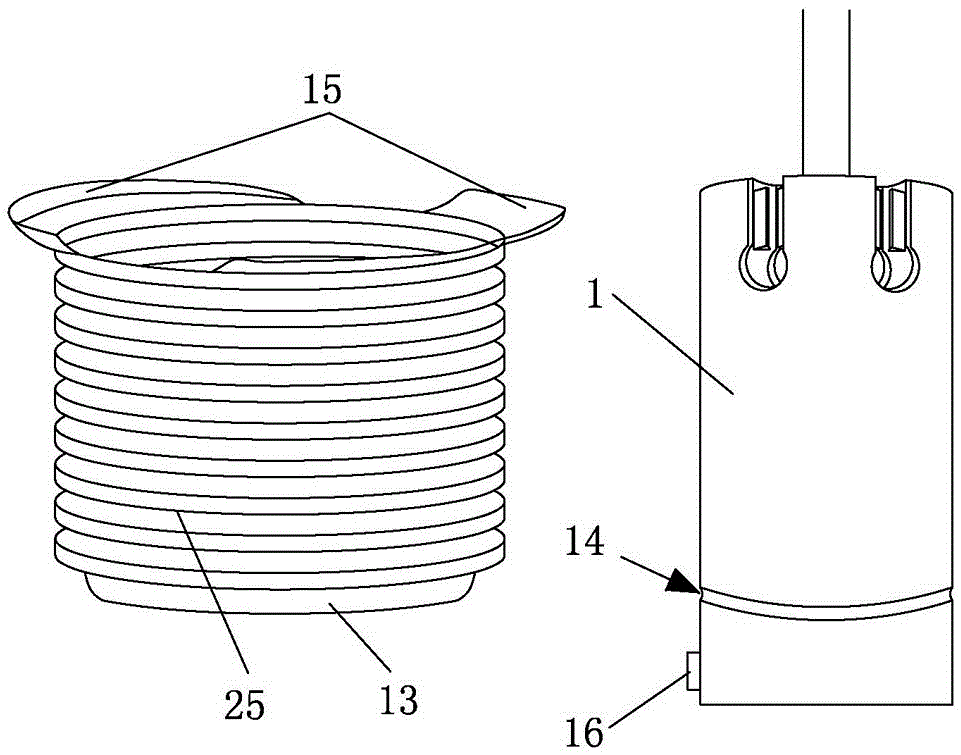

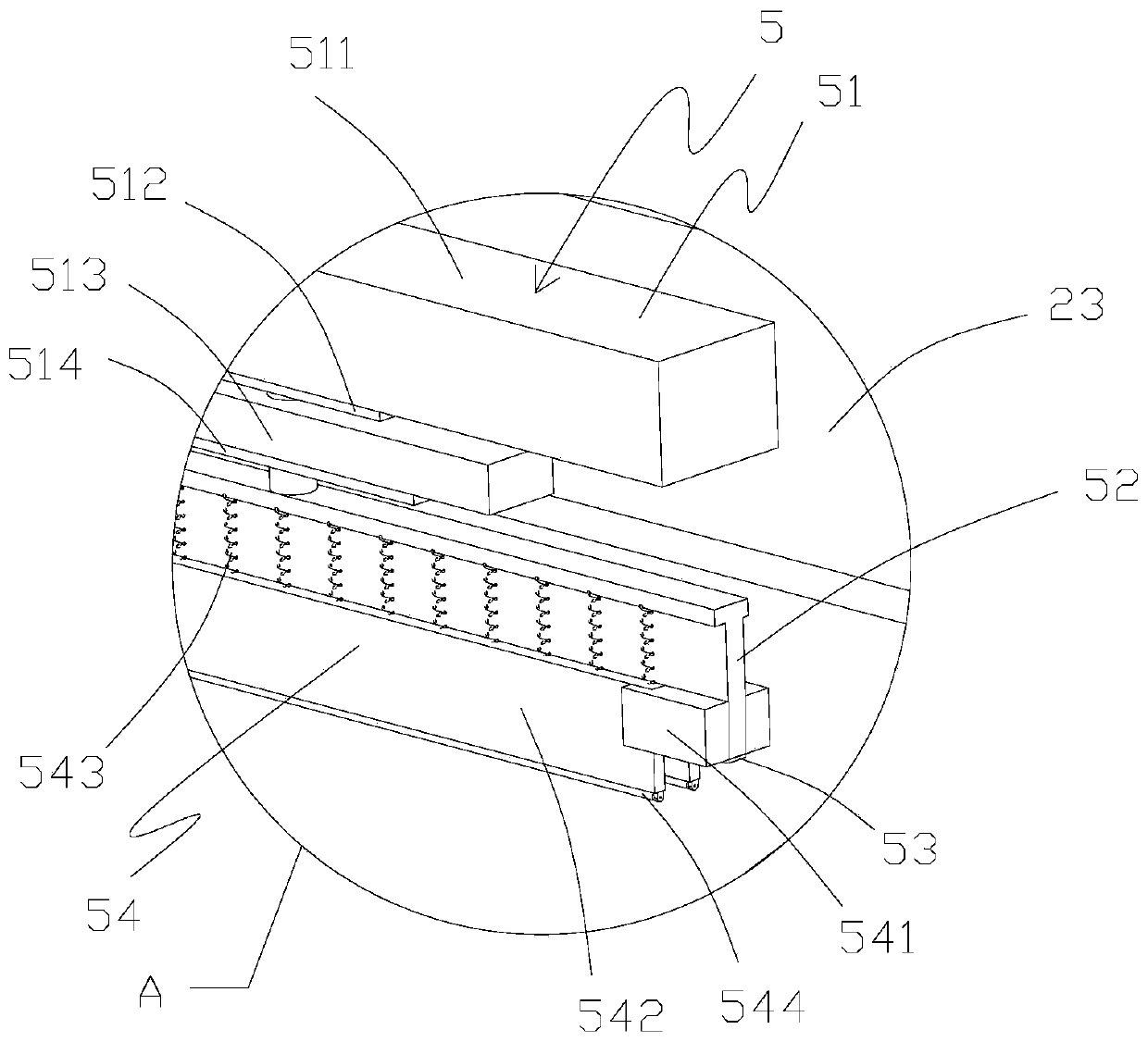

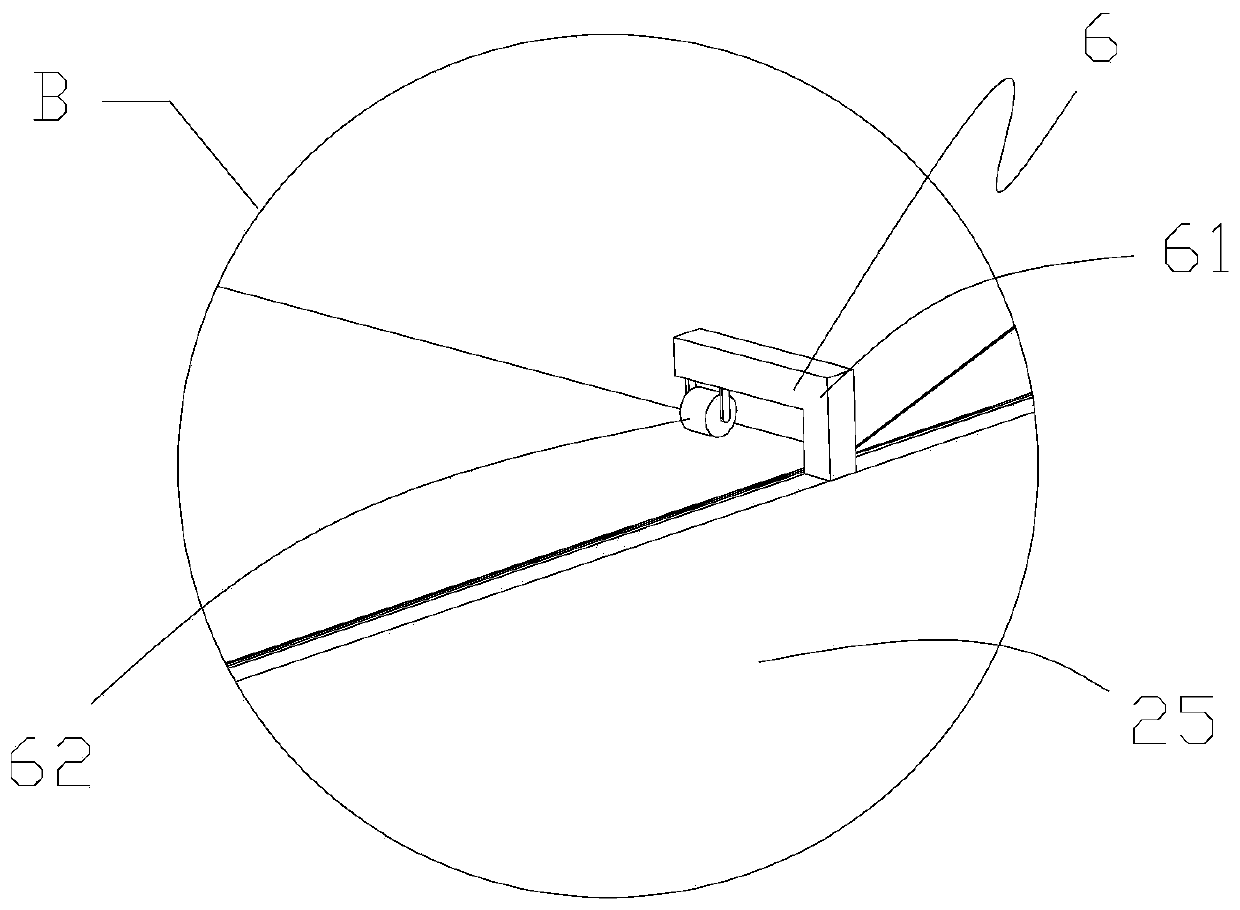

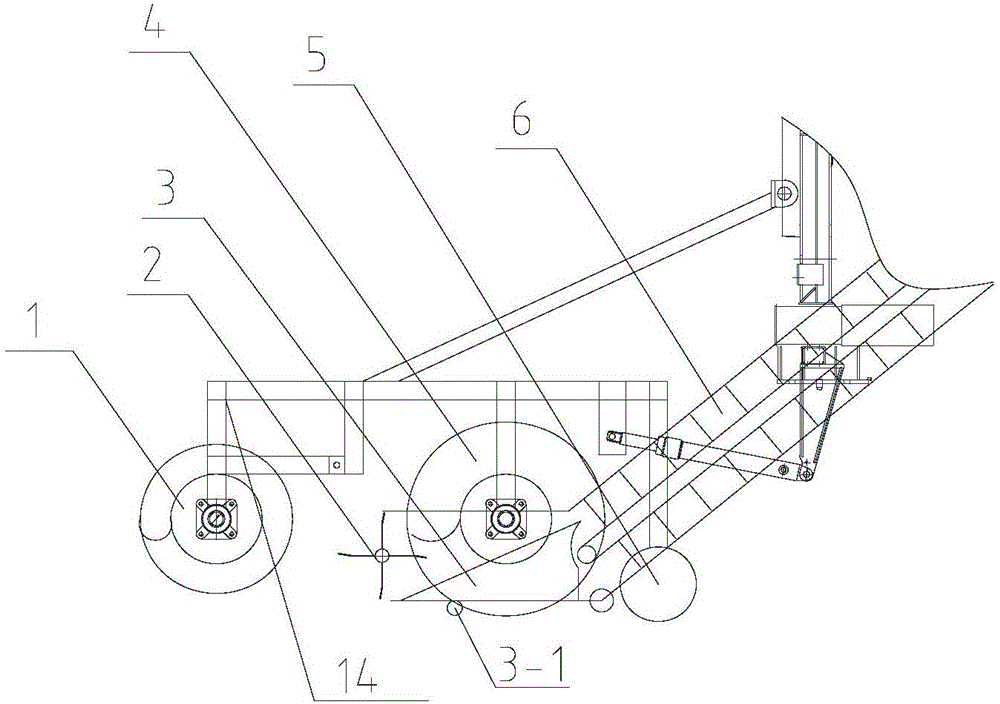

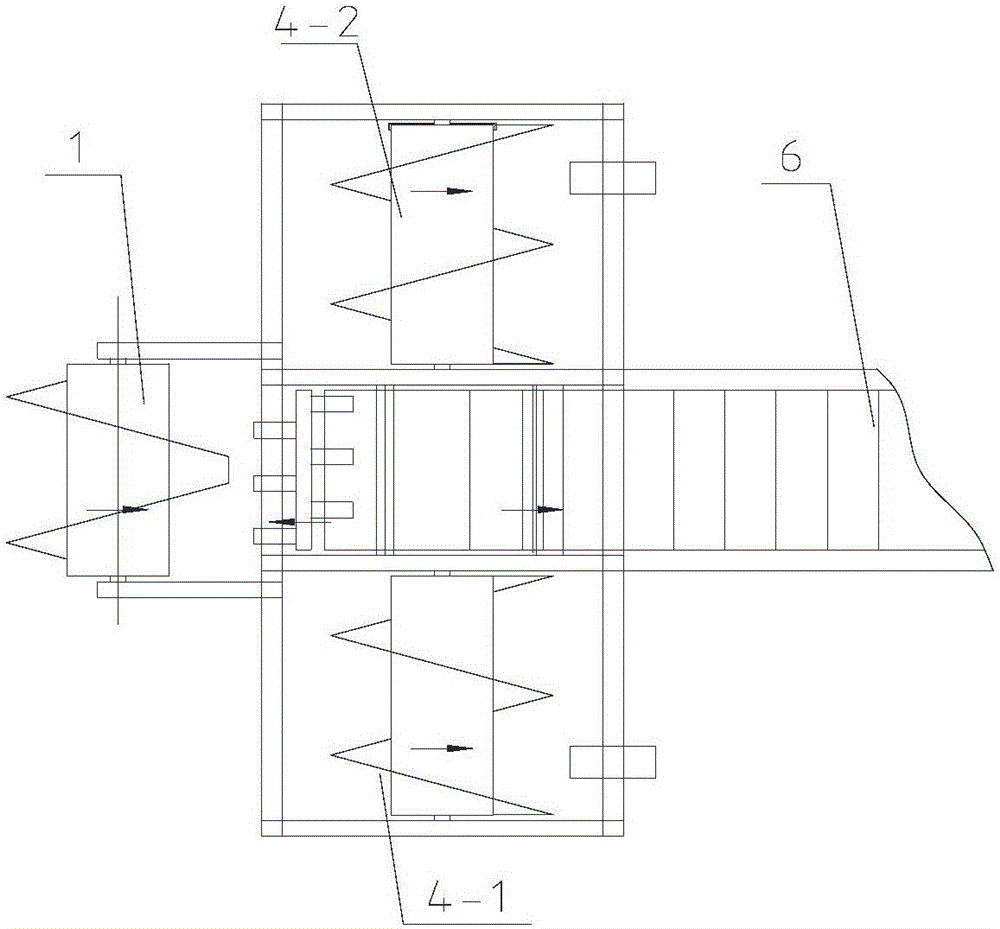

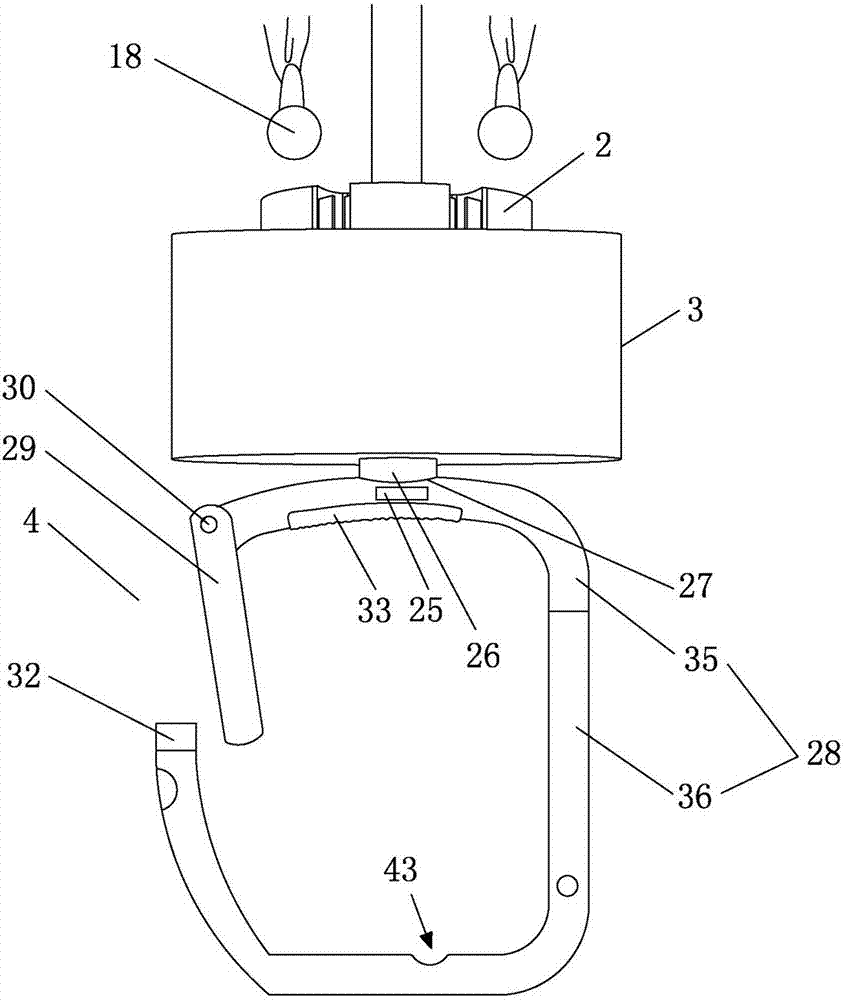

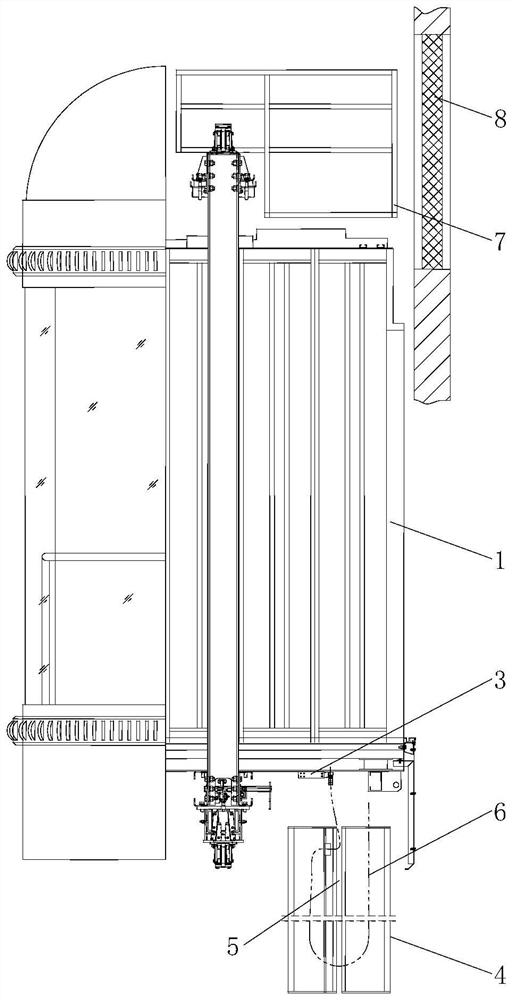

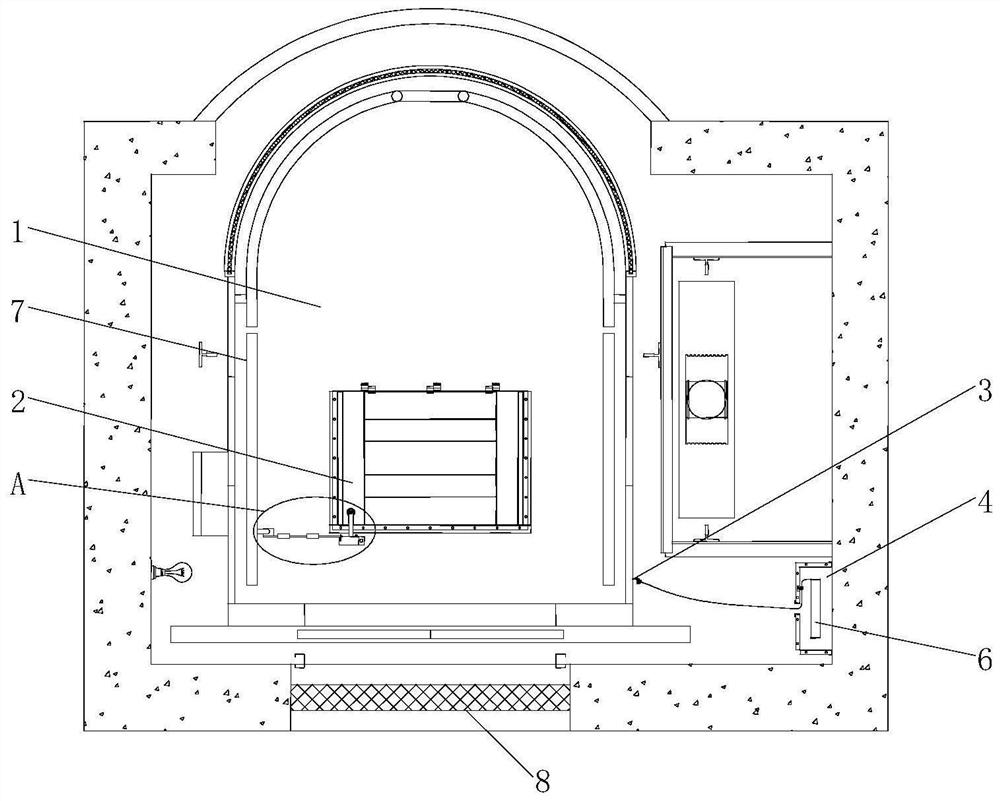

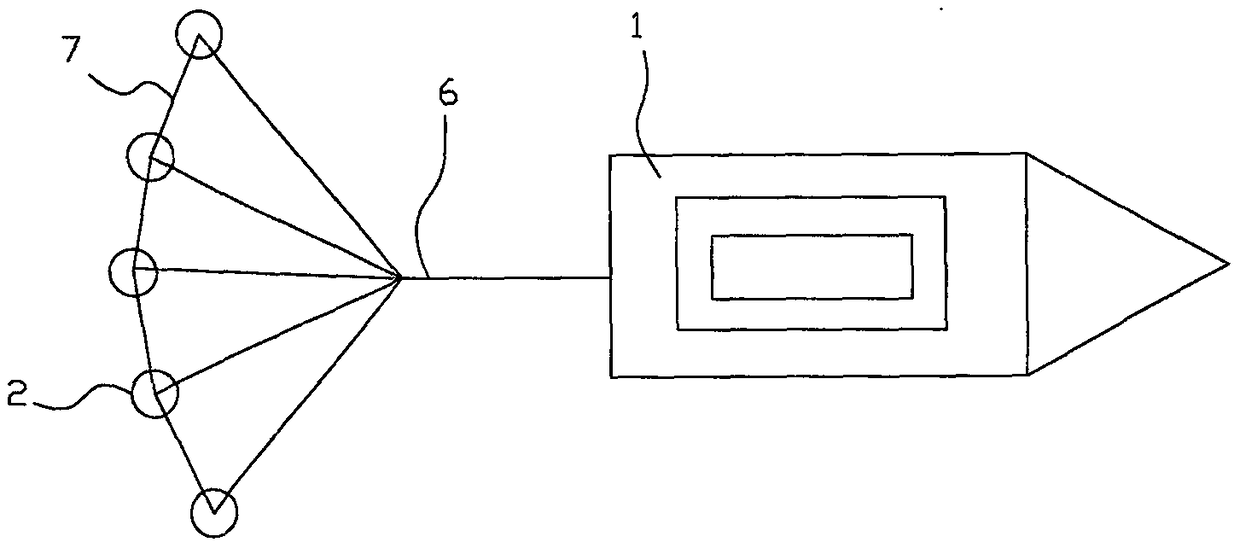

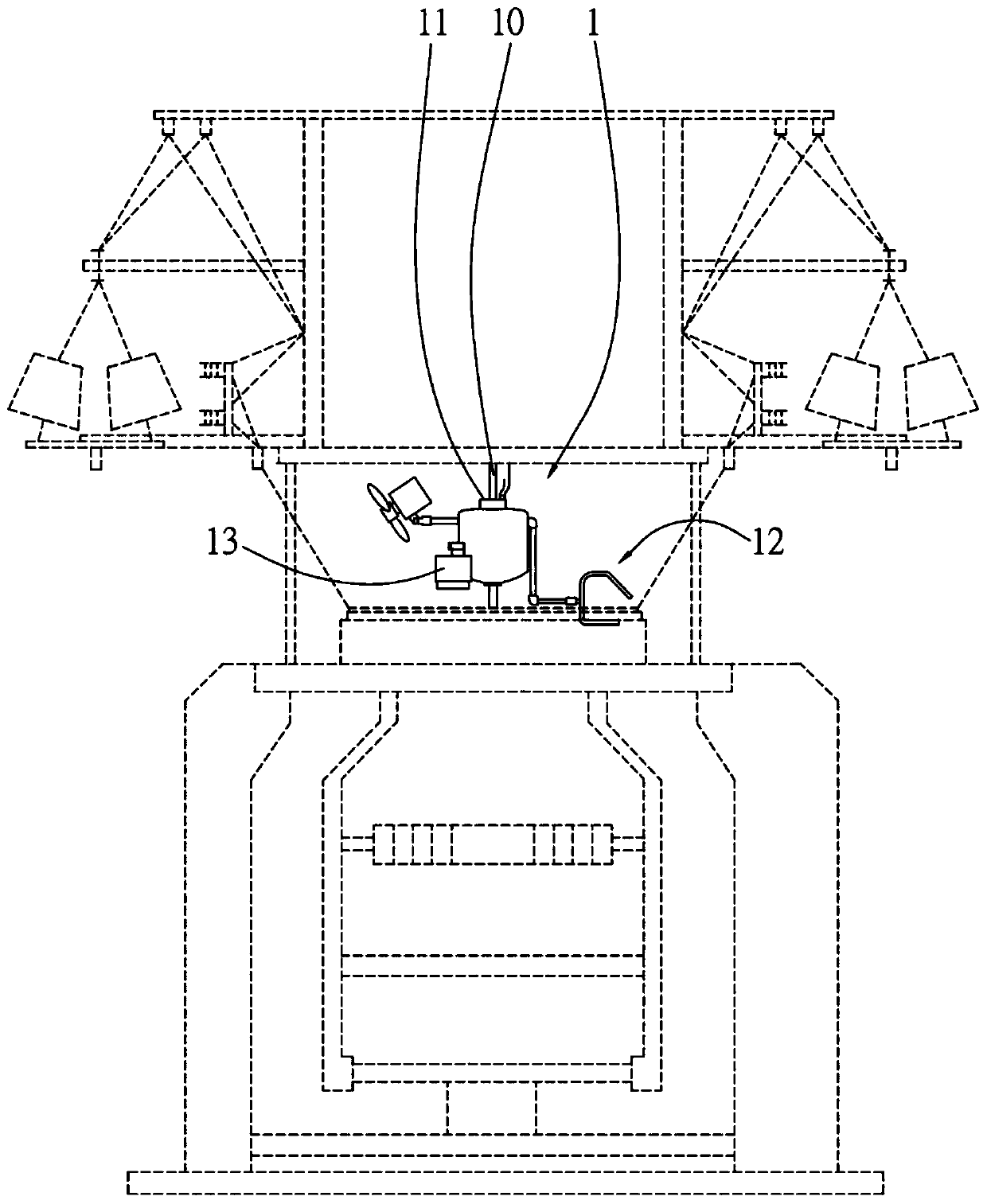

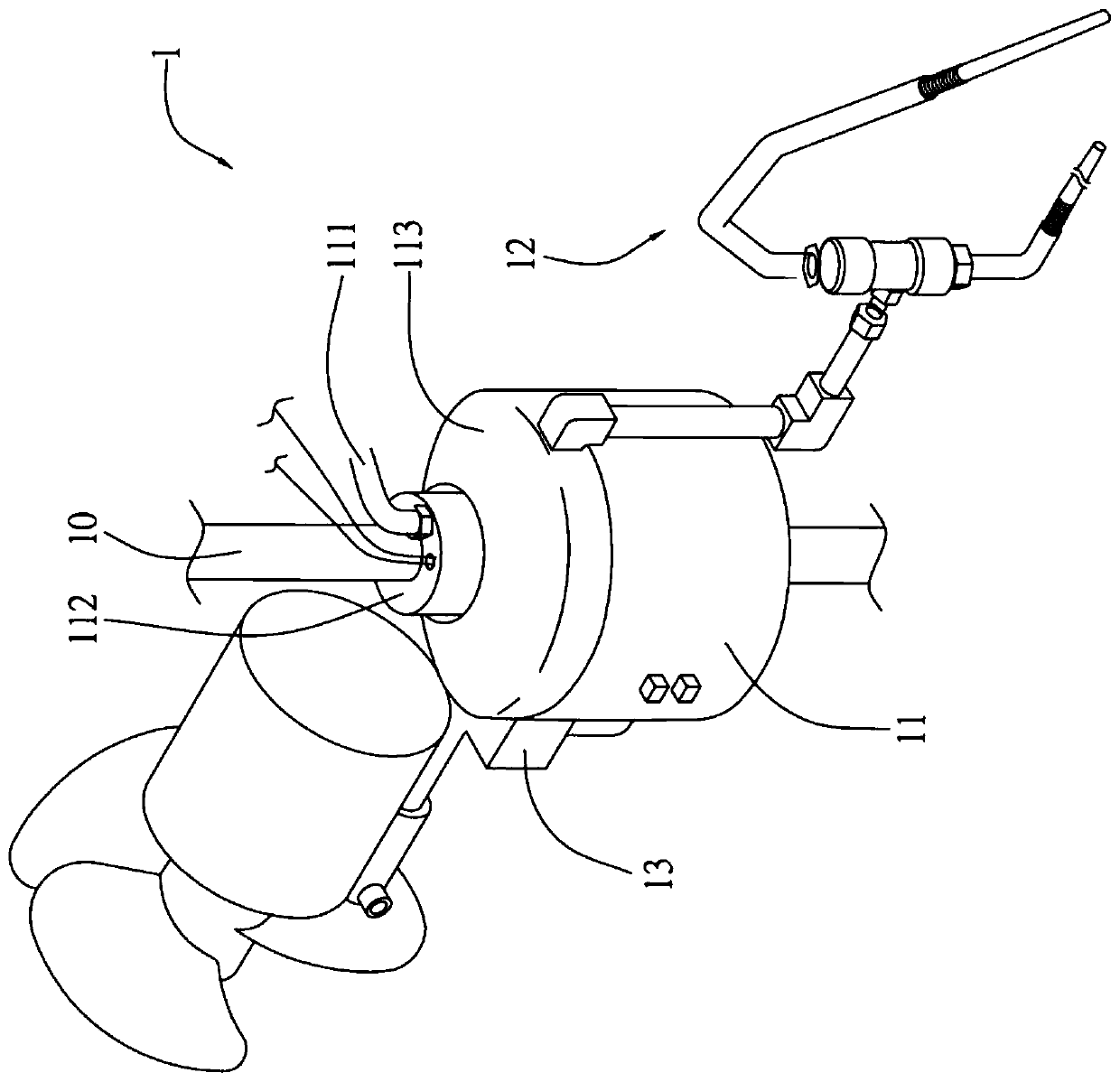

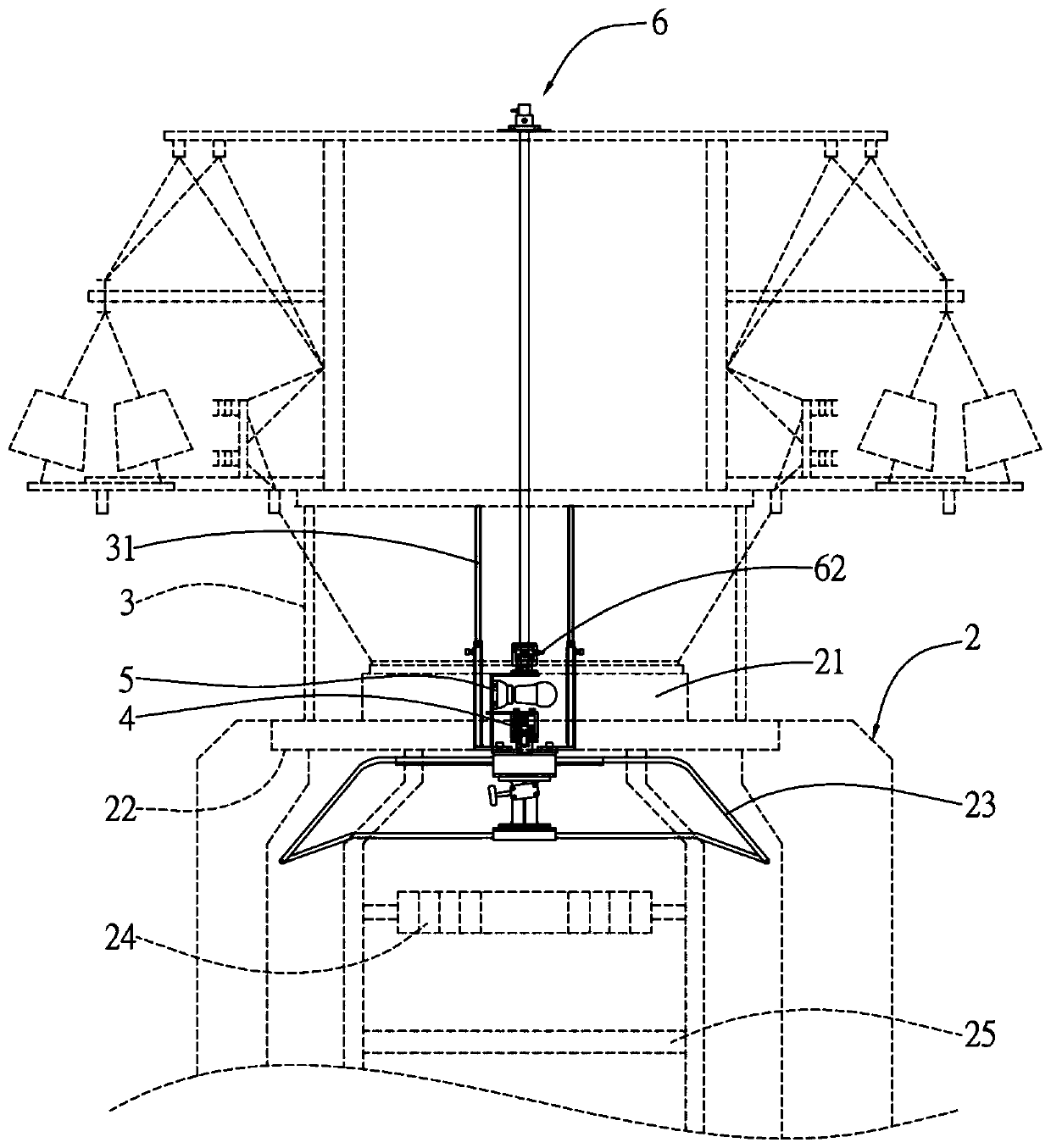

Marine sightseeing passenger elevator

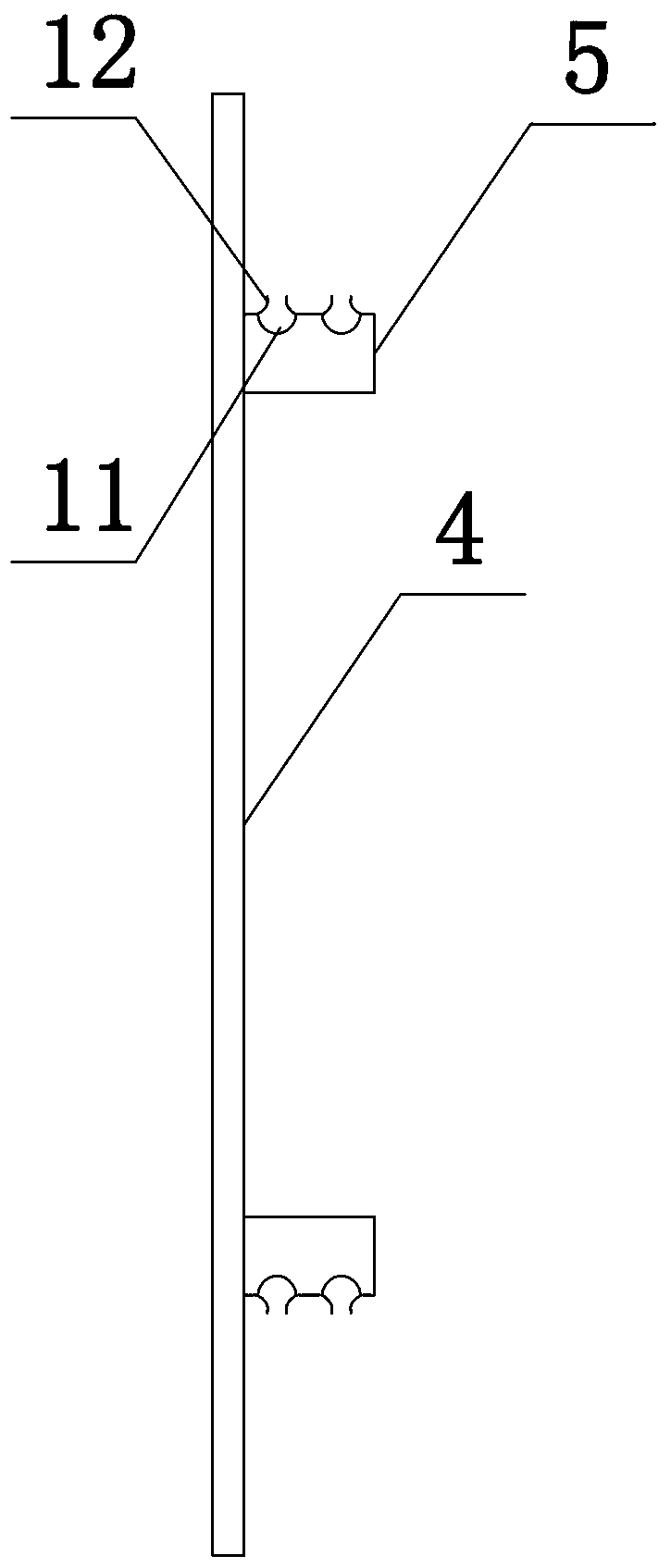

PendingCN114455432AGuaranteed running stabilityPrevent slipping outElevatorsBuilding liftsMarine engineeringEmergency encounter

The marine sightseeing passenger elevator comprises an elevator shaft, a sightseeing elevator car (1) is connected into the elevator shaft, an elevator safety window (2) is arranged at the top of the sightseeing elevator car (1), a cable fixing assembly (3) is connected to the side wall of the sightseeing elevator car (1), a cable protection plate set (4) is connected to one side of the elevator shaft, and a wiring groove (5) is formed in the cable protection plate set (4). A traveling cable (6) falling in a U shape is arranged in the cable protection plate set (4), one end of the traveling cable (6) extends to the outer side of the cable protection plate set (4) through the wiring groove (5) and is connected with the cable fixing assembly (3), and the other end of the traveling cable (6) extends to the top of the cable protection plate set (4). The traveling cable limiting device can limit the traveling cable in the elevator shaft, facilitates evacuation of passengers in the sightseeing elevator car in emergency, and has the advantages that safety is high, and the traveling cable is not prone to hooking.

Owner:SICHER ELEVATOR

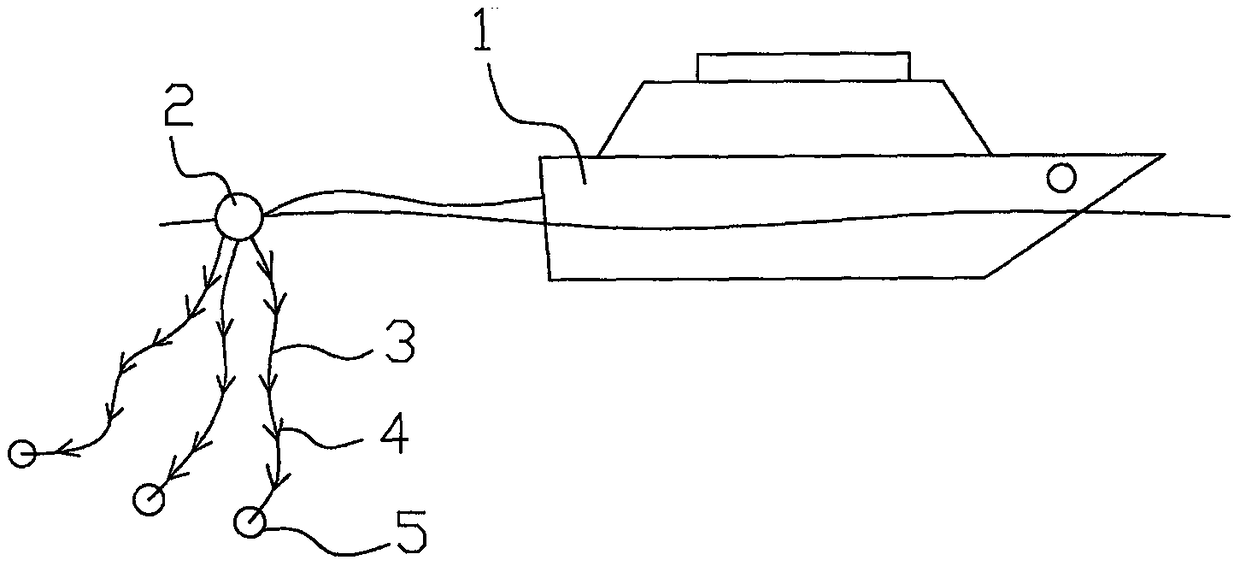

Fishing vessel

The invention discloses a fishing vessel. The fishing vessel comprises a vessel body and a plurality of floating balls. The floating balls are connected through connecting rods in sequence, the floating balls are connected with the vessel body through pull ropes, steel wire ropes are fixed to the floating balls, hooks are installed on the steel wire ropes, and lead blocks are fixed to the tail ends, away from the floating balls, of the steel wire ropes.

Owner:陈昊

Fold-up shoe

Owner:浙江璐卡丝国际贸易有限公司

An optical fiber distribution cabinet

ActiveCN109116498BEasy and reasonable windingEasy to troubleshootFibre mechanical structuresDistribution frameWinding machine

The invention belongs to the technical field of communication equipment, in particular to an optical fiber distribution cabinet. The cabinet comprises a cabinet body and a plurality of distribution frames in the cabinet body. A winding mechanism is disposed between the adjacent distribution frames. Each winding mechanism comprises a winding plate, a plurality of winding posts on the winding plate,a plurality of wire sorting grooves disposed on the winding plate, wherein the winding posts are arranged in two rows and multiple columns, and the wire sorting grooves are located between two columns of winding posts. Through the special design of the winding mechanisms, each two winding posts arranged at the top and bottom are set as one group, and the same group of optical fibers are wound around the same group of winding posts, thereby facilitating the reasonable winding of the remaining optical fibers, facilitating the fault inspection, greatly improving the searching speed, and shortening the fault processing time.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

Flocculent-yarn blowing and heat dissipation improved structure for circular knitting machine

The invention discloses a flocculent-yarn blowing and heat dissipation improved structure for a circular knitting machine. The improved structure mainly includes a machine table, fixing assemblies, ahydrargyrum base, a monitoring device and a flocculent-yarn blowing and heat dissipation structure body; the symmetrical fixing assembles are fixedly inserted into the outer edge of an upper needle hole of the machine table, the hydrargyrum base is clamped at the position close to the center of the upper needle hole, the monitoring device is arranged above the hydrargyrum base, a first lamp is fixedly assembled on the inner side of a first side edge of one side of a supporting frame of the monitoring device, and the flocculent-yarn blowing and heat dissipation structure body is locked and combined, towards the top surface, with a second side edge of the other side of the supporting frame. By blowing away flocculent yarn to prevent yarn from piling up to form cotton balls, a yarn needle isnot easily entangled, and increasing of the defect rate of the cloth is reduced; meanwhile, by monitoring outage through a checking light, knitting signals when the yarn is knitted are controlled so that noise cannot be generated, and thus it is further achieved that a power supply is not subjected to abnormal efficacy; therefore, the tension is adjusted, and meanwhile the thickness of the cloth is adjusted to be suitable for the tightness of rolling, so that the flocculent-yarn blowing and heat dissipation improved structure for the circular knitting machine is formed.

Owner:泳立(厦门)机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com