Electric dust cleaner

A vacuum cleaner and electric technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of preventing the removal of paper packaging bags, dust spreading in the dust collection room, and installation, etc., to achieve the effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

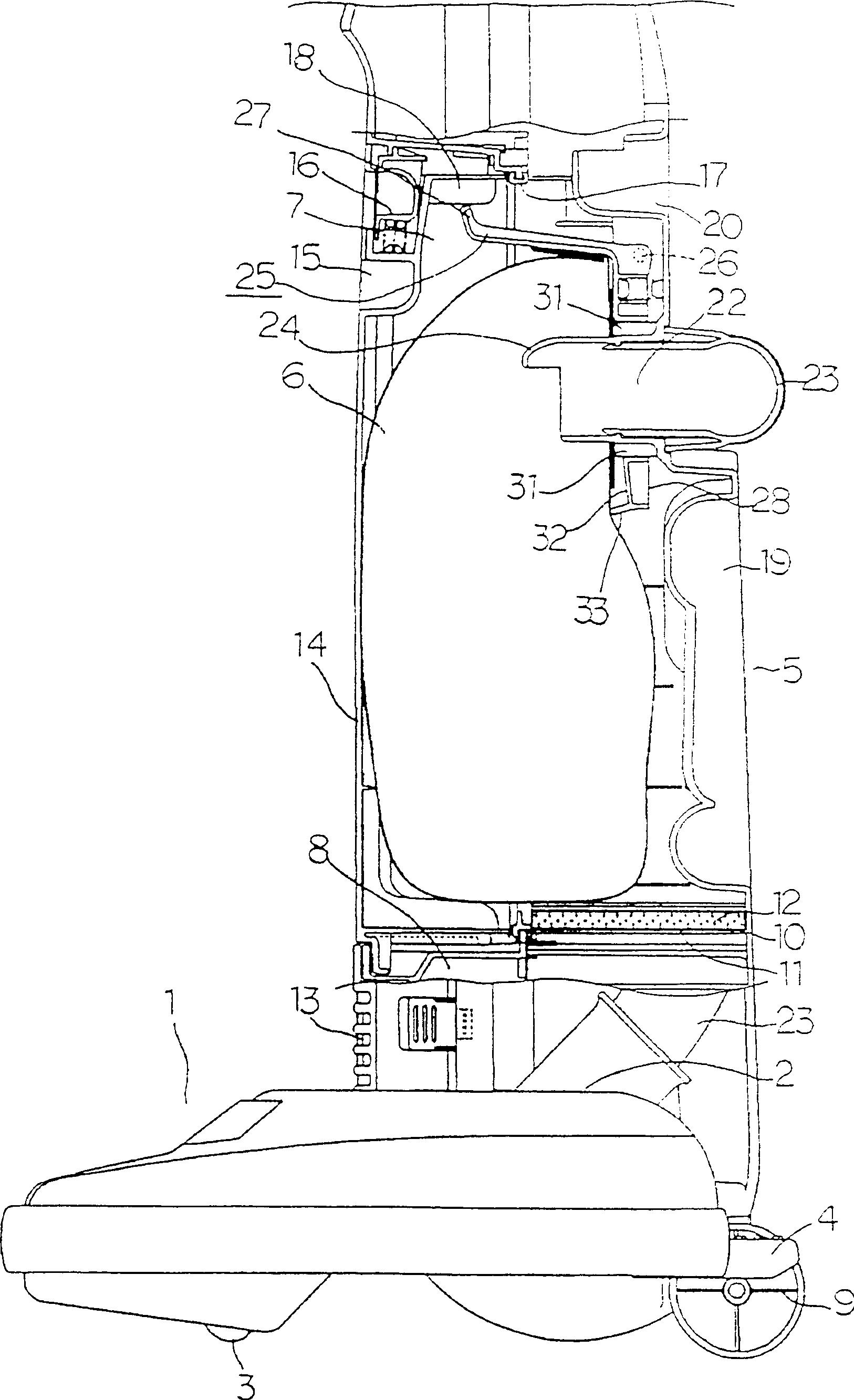

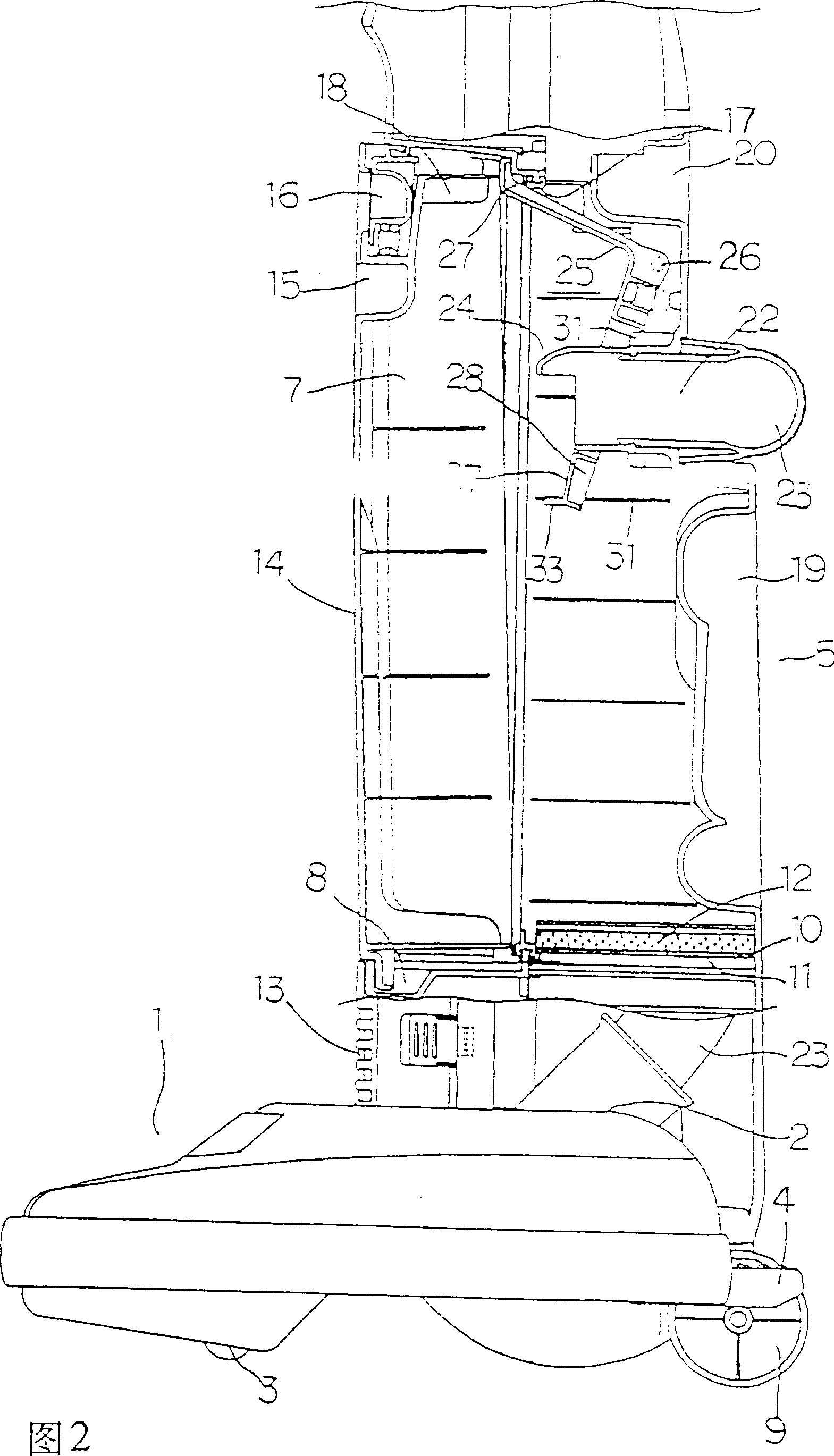

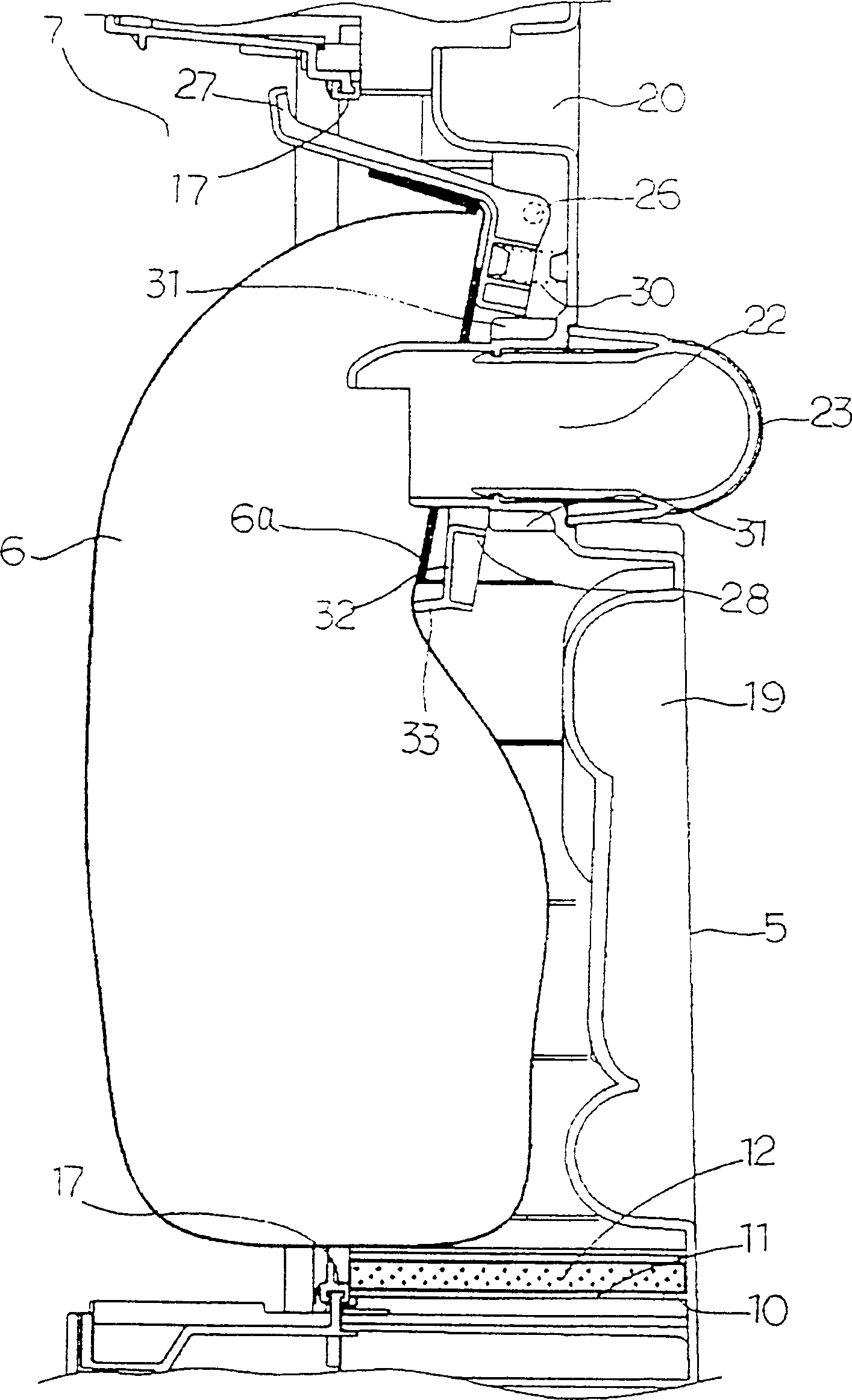

[0054] Based on the vertical electric vacuum cleaner shown in the figure, an embodiment of the present invention is described in detail as follows. Reference Figure 1~10 , 1 is the suction device body, the bottom surface of which has an opening, and a rotating brush facing the opening (not shown) is built in. The aforementioned rotary brush is connected to the rotary shaft of the electric blower built under the main body 5 described later, and constitutes a rotary drive.

[0055]The upper part of the suction device body 1 is formed with a connection port 2 communicating with the opening and connected with a hose 23 described later. 3 is a pair of left and right wheels arranged in front of the suction device body 1. 4 is a foot pedal. Step on the foot pedal 4 and operate to release the locking of the standing state of the suction device main body 1 of the main body 5 as described later, and the main body 5 can be tilted toward the suction device main body 1 described above.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com