Wire bending explorator

A technology of profiling and corner bending, which is applied in the field of profiling of double-wire ceramic splints on the wall and turned 90 degrees, which can solve the problems of low work efficiency, unsightly appearance, and easy hooking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

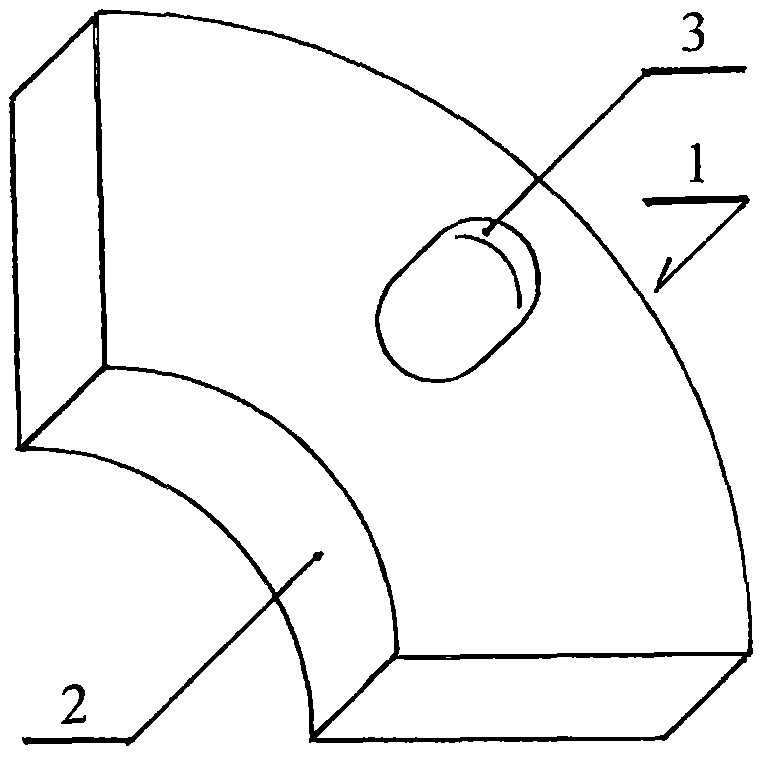

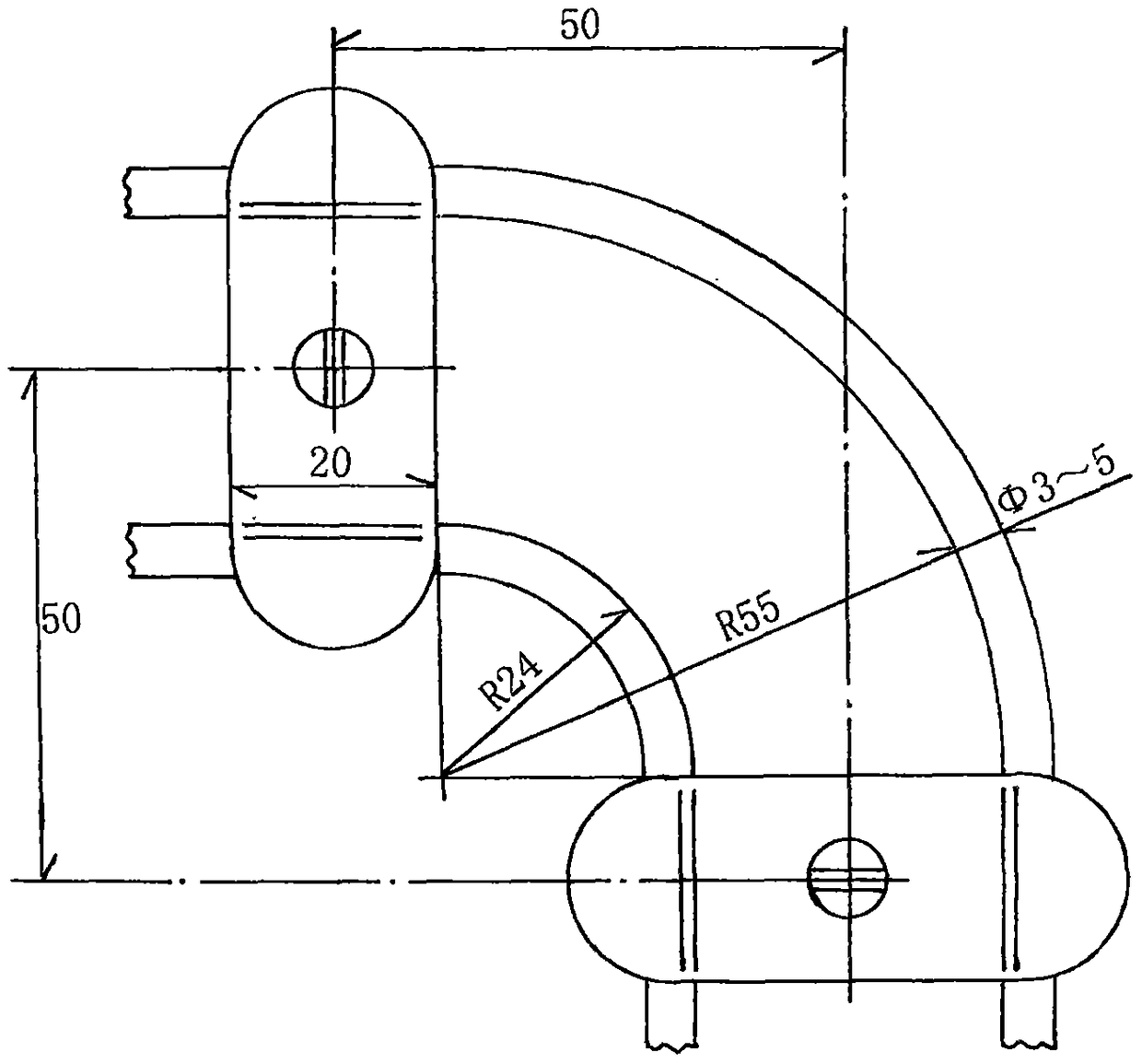

[0010] The line center distance of the double-line porcelain splint is 35mm. The laying technical data of the open wire of the porcelain splint turned 90 degrees, the distance between the fixed points of the two adjacent porcelain splints at the turn is 50mm ( figure 2 ). The wire makes a big arc turn, by figure 2 The fixed pitch of the porcelain splint shown is 50mm, the width of the porcelain splint is 20mm, and the diameter of the clamped wire is 3 to 5mm. After weighing the factors such as manufacturing and use, the geometric dimensions of the wire bending angle profile are determined: the radius of the convex arc edge 1 is 55mm, and the arc length is 77mm; The concave arc edge 2 has a radius of 24mm and an arc length of 34mm; both sides are planes with an included angle of 90 degrees; the thickness is 10mm. The grip button 3 is in the center and is in the shape of a hemispherical top column with a column diameter of 8mm and a height of 25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com