Process dynamic configuration-based hazardous chemical substance supervision method and system

A technology of dynamic configuration and hazardous chemicals, applied in the direction of collaborative devices, instruments, data processing applications, etc., can solve problems such as difficult traceability, lack of information system, and no monitoring means, and achieve easy traceability and perfect technical means Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

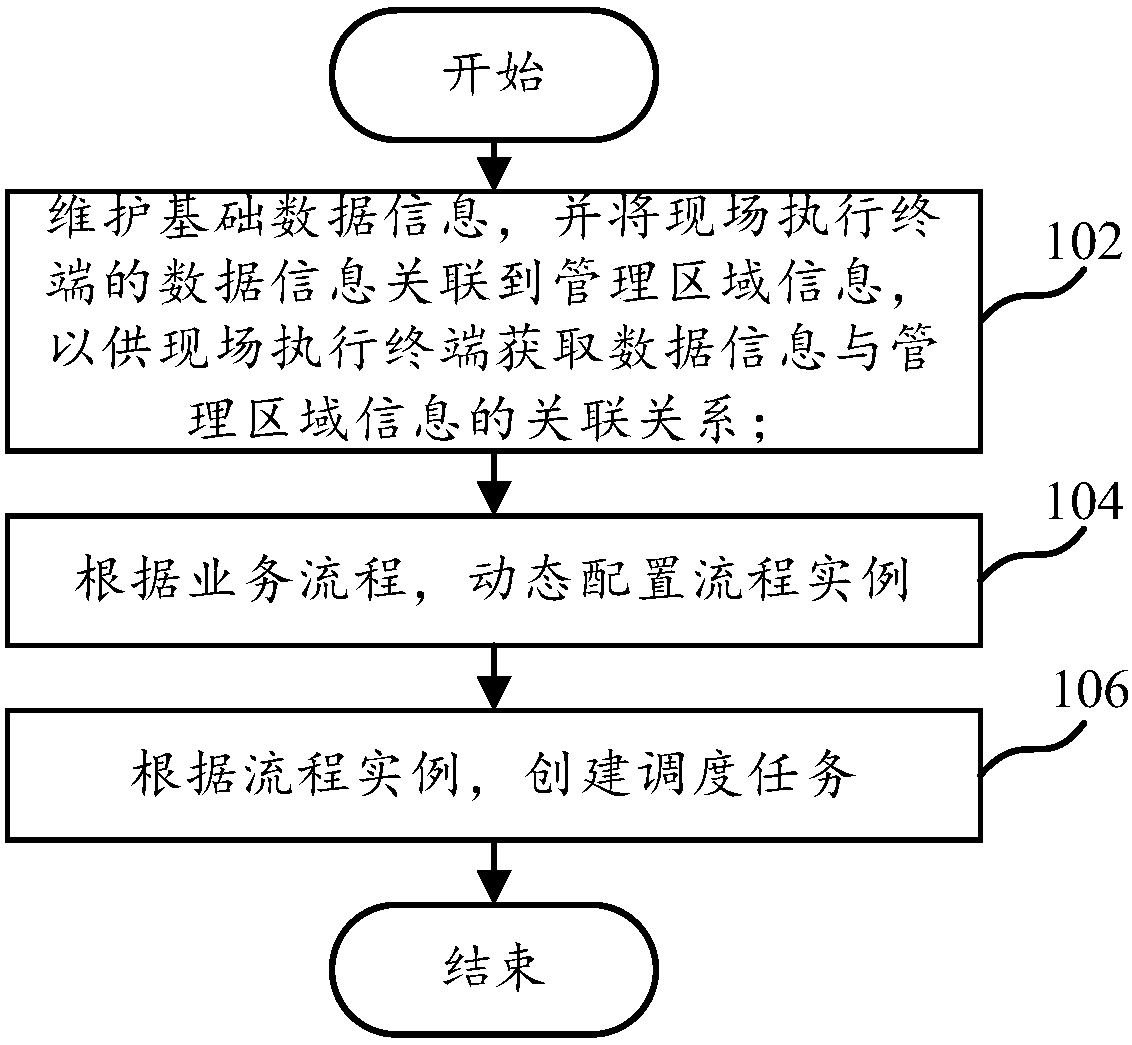

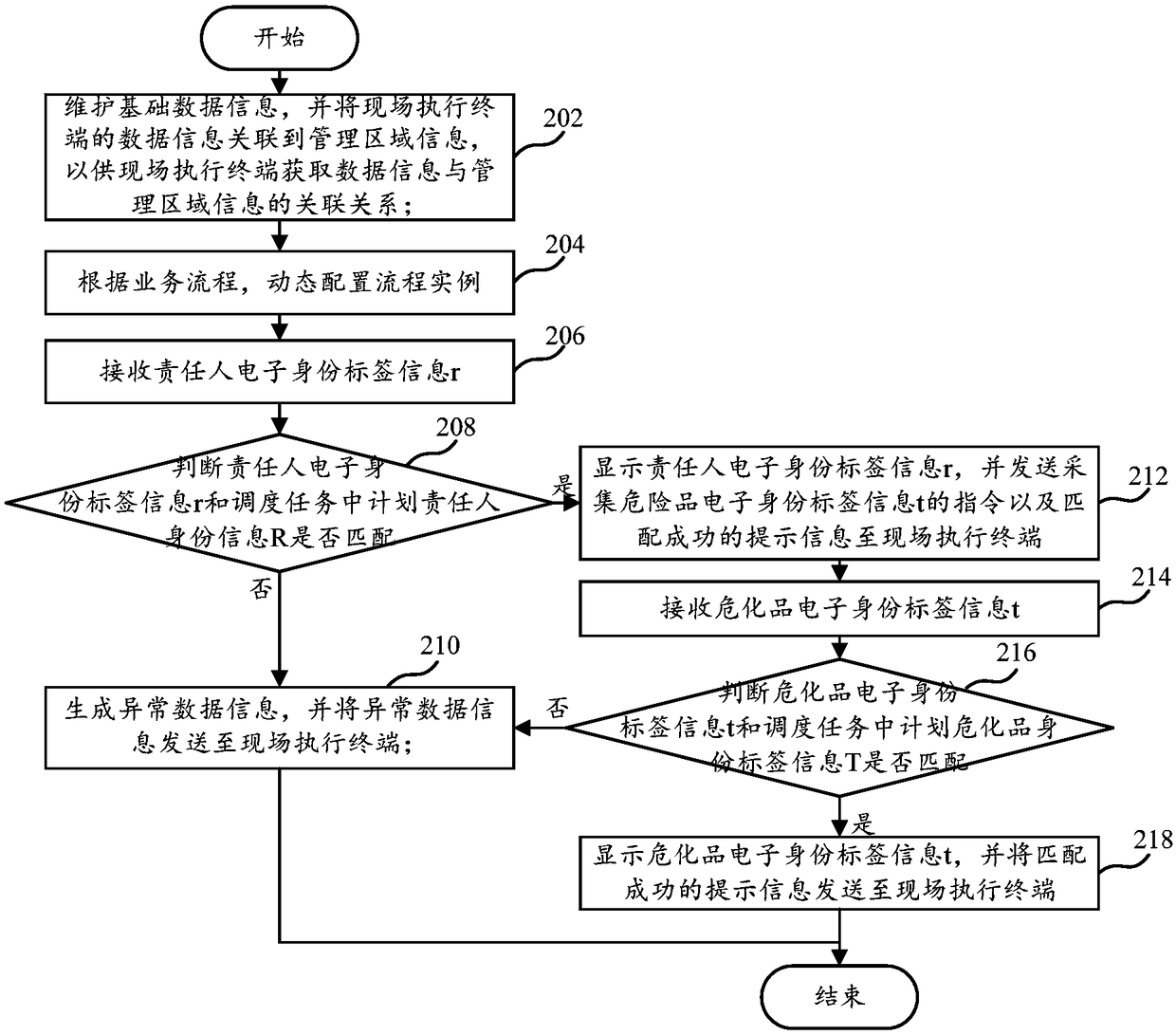

[0243] Specific embodiment one, such as Figure 10 As shown in FIG. 1 , a schematic flow chart of a method for realizing supervision of hazardous chemicals based on process dynamic configuration of a terminal for on-site execution according to the present invention. Among them, the method includes:

[0244] Step 1001, execute scheduling tasks;

[0245] Step 1002, judging whether the set node has reached the thread execution time; when the set node has not reached the thread execution time, proceed to step 1003; when the set node has reached the thread execution time, proceed to step 1006;

[0246] Step 1003, collecting electronic tag information;

[0247] Step 1004, verify the identity conditions of the executor, and judge whether the identity information of the executor is compliant; when the identity information of the executor is compliant, proceed to step 1005; when the identity information of the executor is not compliant, return to step 1002 ;

[0248] Step 1005, ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com