System for greatly increasing low-load feed water temperature of power station boiler

A technology of feed water temperature and power station boiler, applied in the system field, can solve the problems of limited layout space, complex system and high investment, and achieve the effect of simple technology and rich technical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

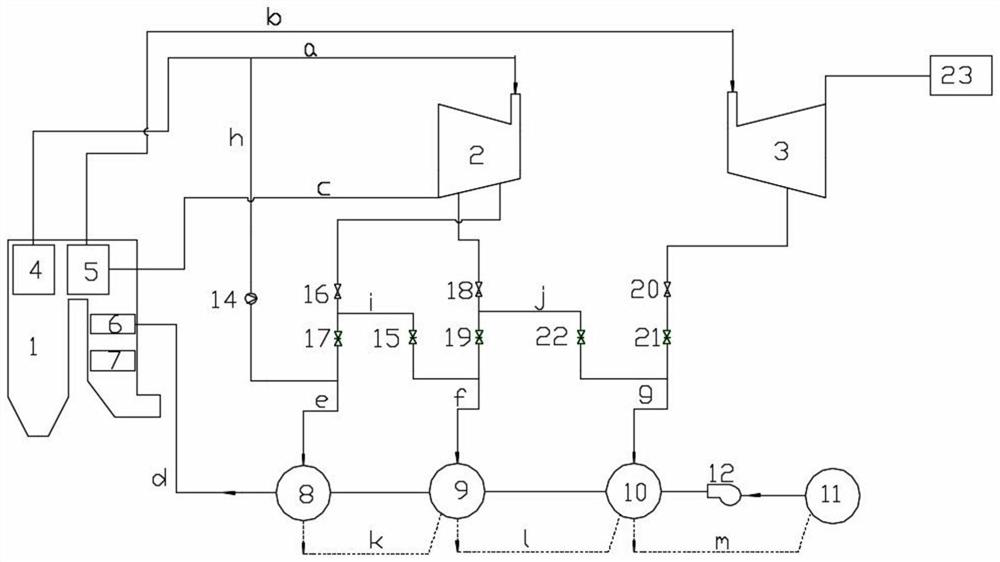

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

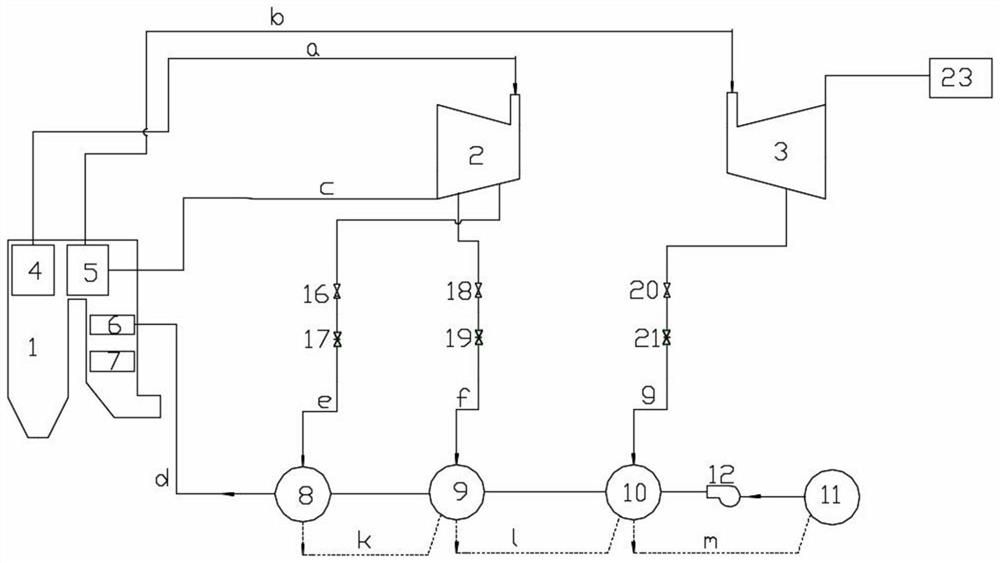

[0015] First, if figure 1 As shown, it is a conventional thermal flow chart, and the specific thermal process of the unit is as follows:

[0016] S1. The condensed water at the outlet of the deaerator 11 is pressurized by the feedwater pump 12 and then enters the No. 3 high-pressure heater 10 of the unit's recovery system for heating. The extraction steam of the No. 3 high-pressure heater 10 is supplied to The input comes from the medium pressure cylinder 3 of the steam turbine; a three-stage steam extraction check valve 20 and a three-stage steam extraction shut-off valve 21 are installed on the three-stage steam extraction pipeline g, which play the roles of preventing backflow and controlling the pipeline path respectively;

[0017] S2. The feed water from the outlet of the No. 3 high-pressure heater 10 of the unit recovery system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com