Miniature energy-saving consumption-reducing vertical bearing boiler

A vertical boiler technology, applied in the field of vertical pressure boilers, can solve the problems of high manufacturing cost and application cost of small vertical pressure boilers, and no improvement in the basic structure of small vertical boilers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

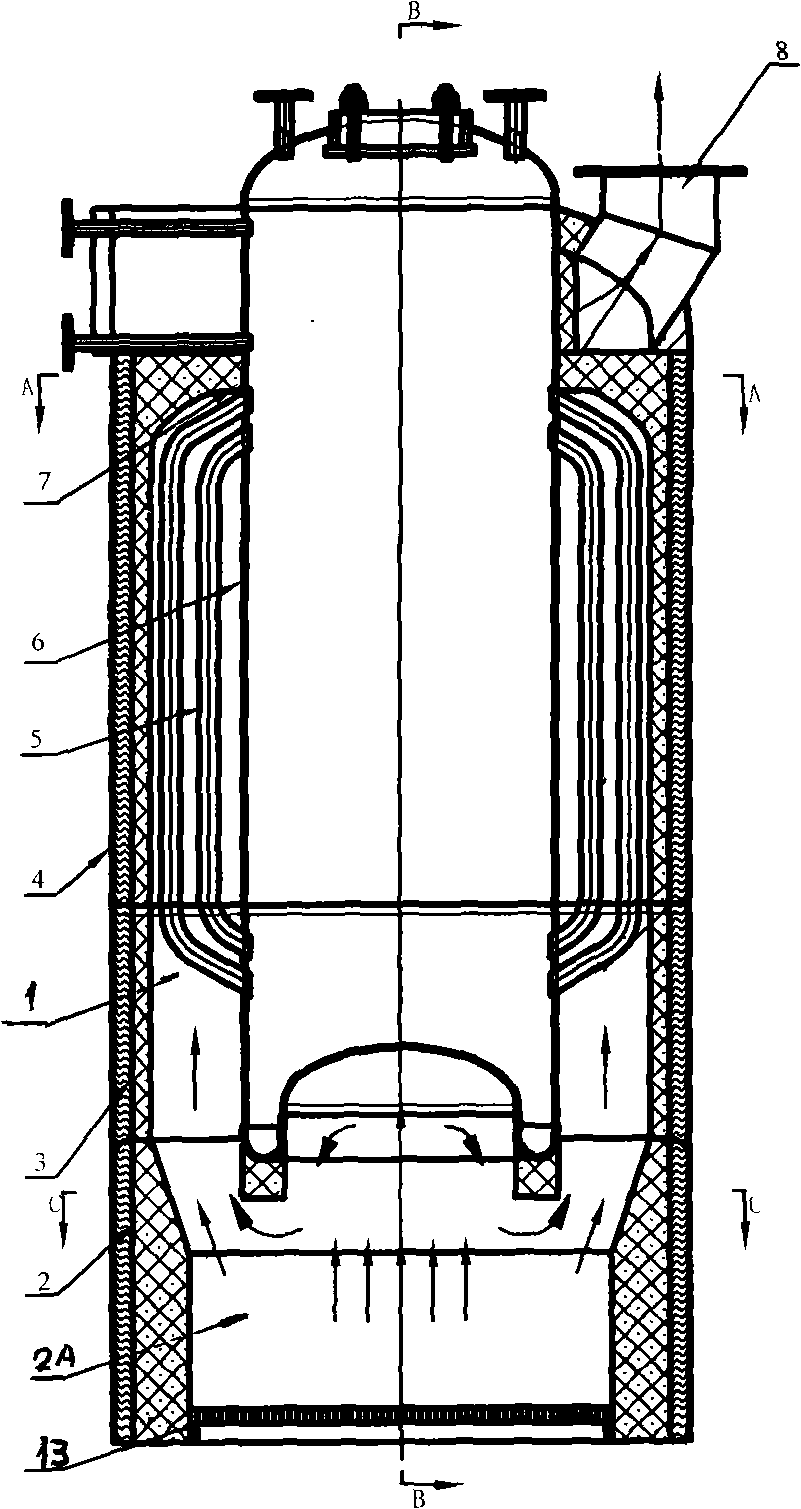

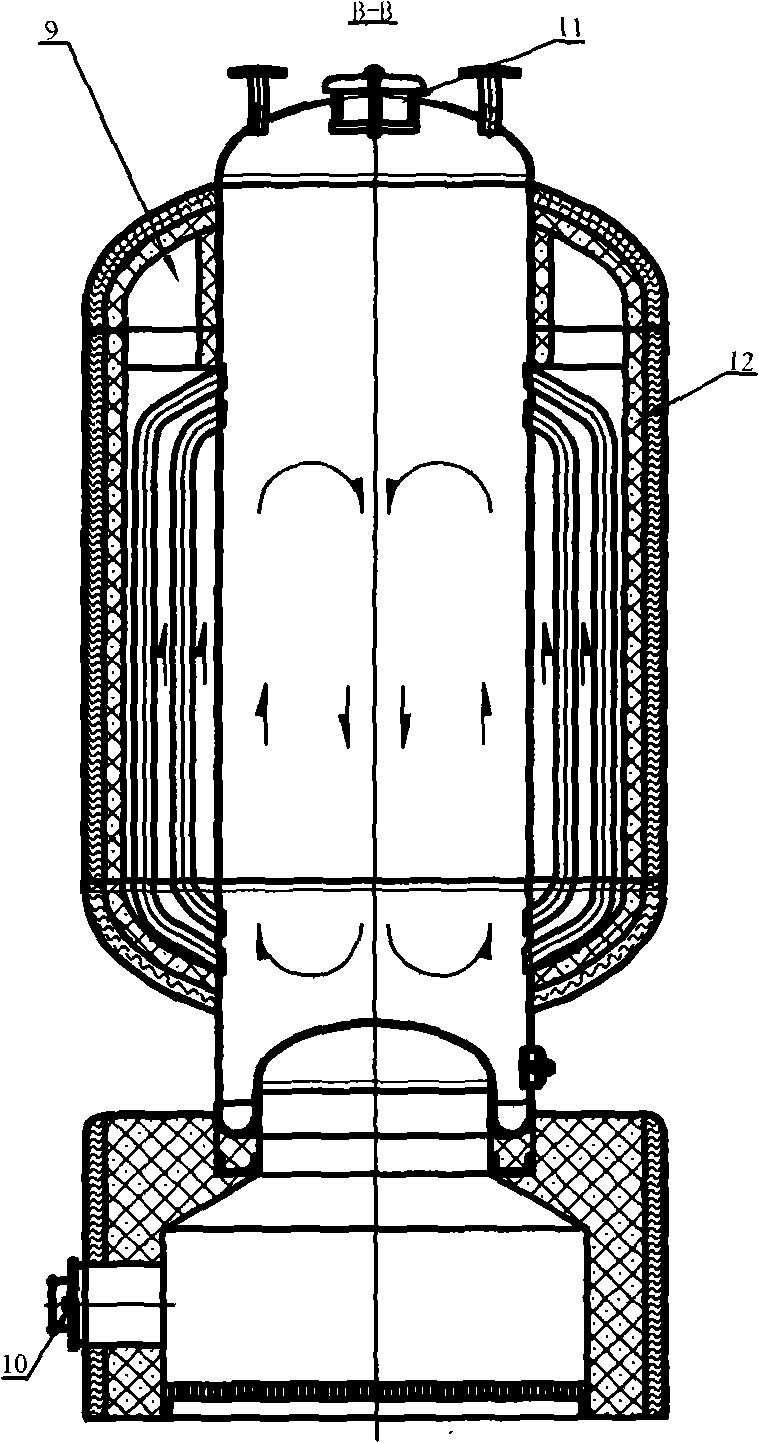

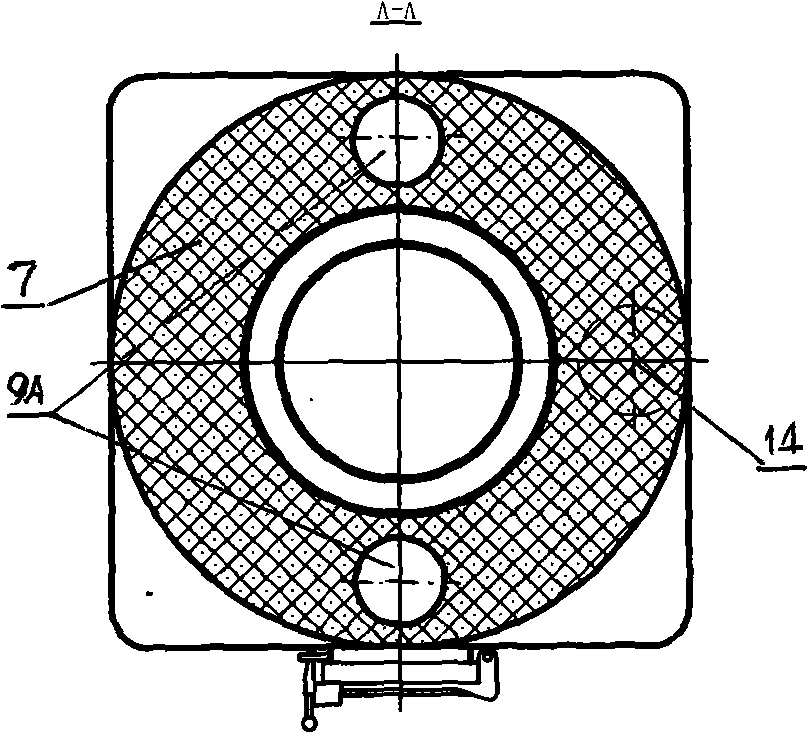

[0016] It can be clearly seen from the accompanying drawings that the technical solution of the present invention is an improved design for the existing small vertical boiler. The improved structure includes the water tank of the boiler, the combustion chamber below the water tank, and the flue connecting the combustion chamber and the chimney mouth. The key technical measures are:

[0017] ① The interlayer water storage tank is transformed into a vertical pressure vessel 6 matching the tonnage and pressure of the boiler,

[0018] ② The vertical pressure vessel 6 is positioned above the combustion chamber 2 composed of outer skin and composite refractory material, and a composite thermal insulation shell is arranged around the vertical pressure vessel 6, and a flue gas channel is formed between the thermal insulation shell and the pressure vessel 1. Set the chimney interface 8 on the upper side of the heat preservation shell.

[0019] ③ Rib-shaped water pipes 5 are evenly dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com