Lubricating oil circulating type coupled disperser

A lubricating oil, circulating technology, applied in mixers, mixers with rotary stirring devices, fluid mixers, etc., can solve problems such as low mixing efficiency, achieve low cost, easy popularization and use, and occupy space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

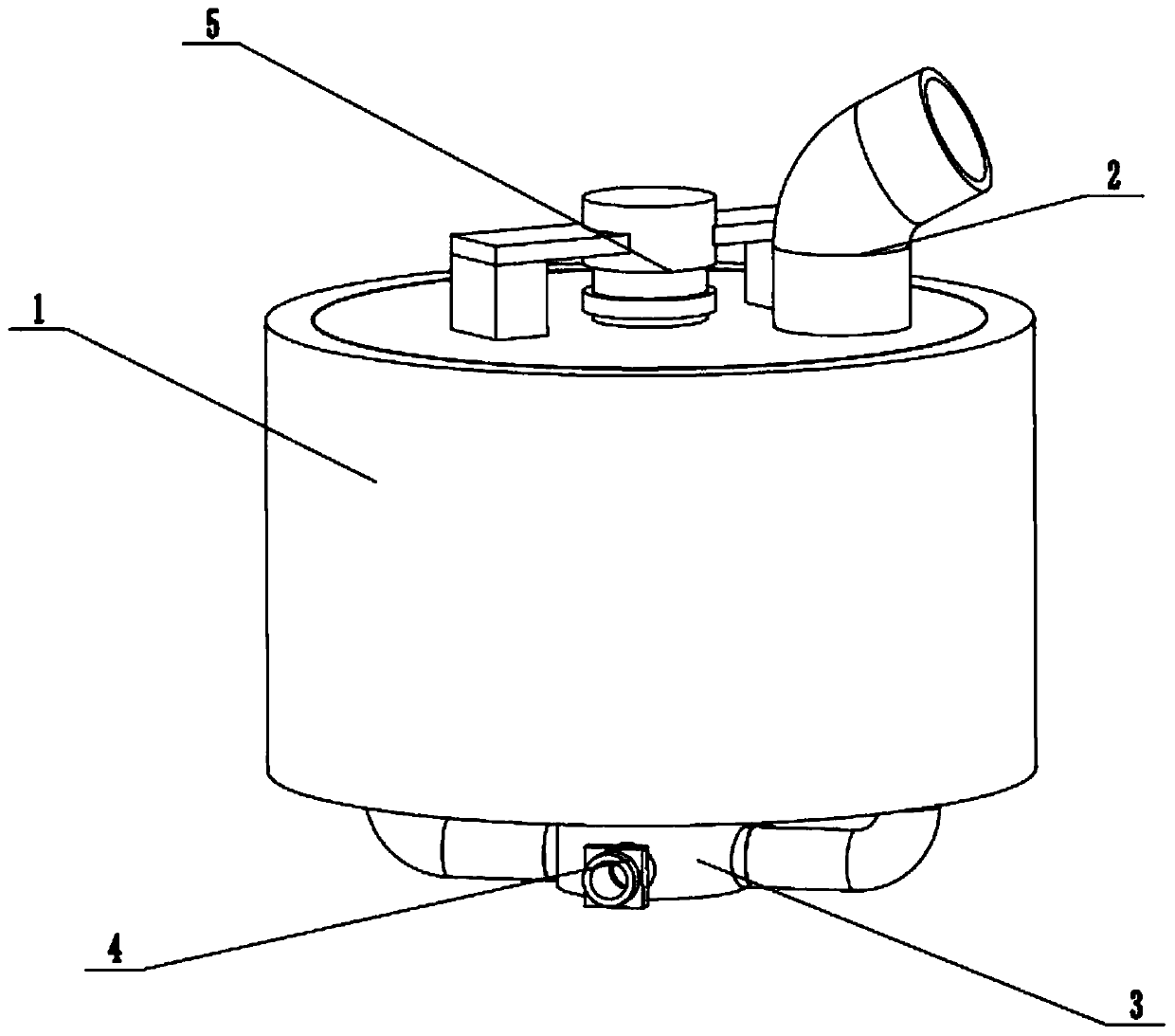

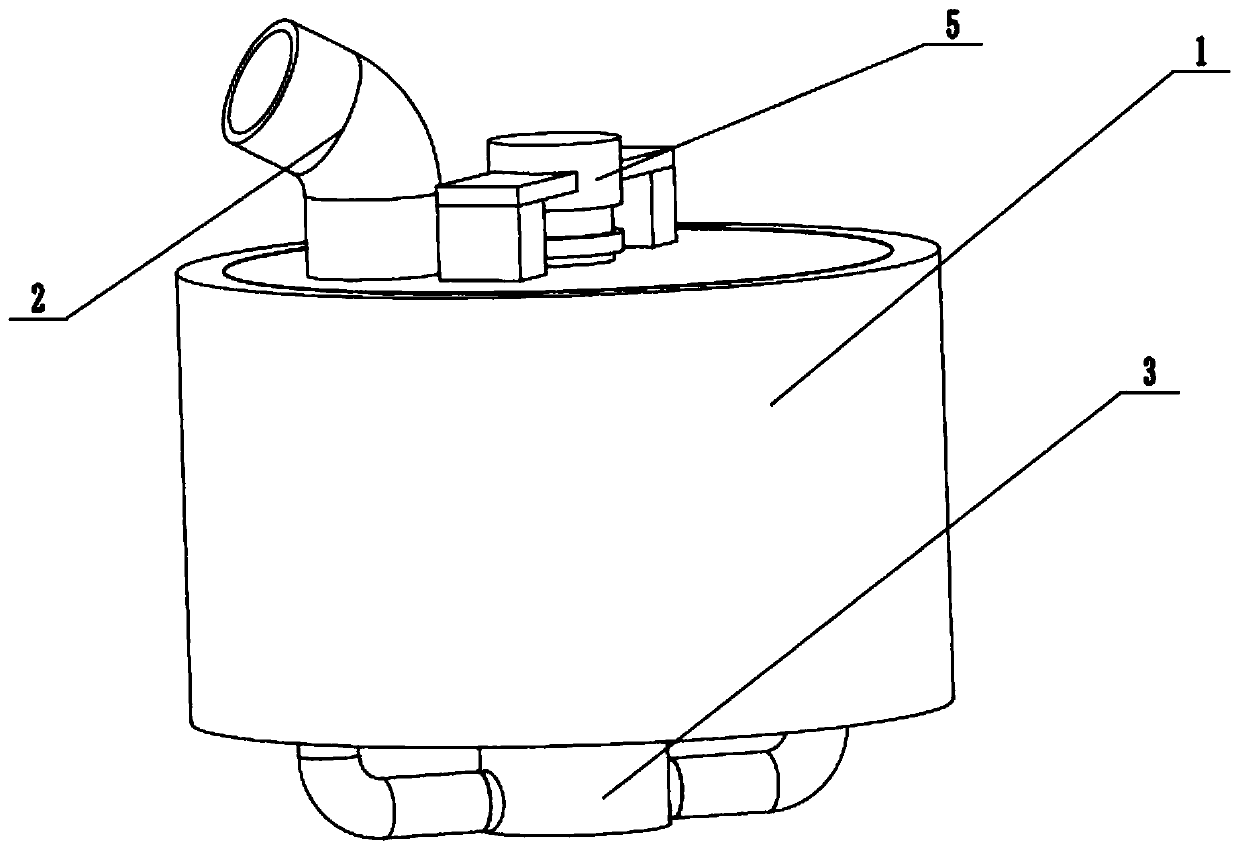

[0030] Such as Figure 1 to Figure 9 As shown, a lubricating oil circulating coupling disperser includes a lubricating oil dispersion box 1, an oil inlet pipe 2, a circulation box 3, a recovery pipe 4 with a valve, a dispersion driver 5 and a circulation driver 6, and the oil inlet pipe 2 is fixedly connected and connected to the eccentric position of the upper end of the lubricating oil dispersion box 1, the middle end of the circulation box 3 is fixedly connected to the center of the lower end of the lubricating oil dispersion box 1, and the circulation box 3 is connected to the lubricating oil dispersion box 1, with The recovery pipe 4 of the valve is fixedly connected and connected to the lower side of the rear end of the circulation box 3, the upper end of the dispersing driver 5 is fixedly connected to the upper end of the lubricating oil dispersing box 1, and the dispersing driver 5 is rotatably connected in the lubricating oil dispersing box 1, The circulation driver 6...

specific Embodiment approach 2

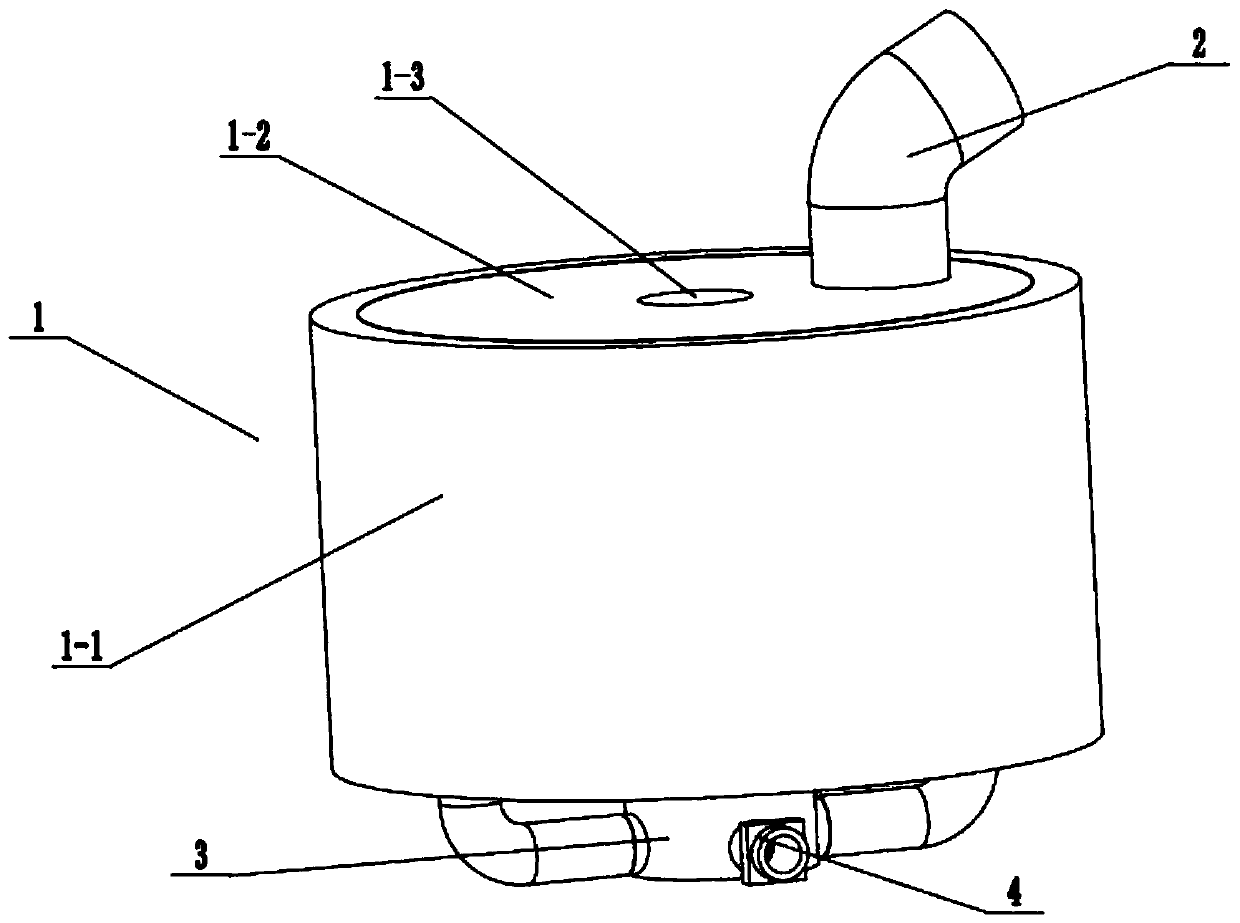

[0032] Such as Figure 1 to Figure 9As shown, this embodiment will further describe Embodiment 1. The lubricating oil distribution box 1 includes a main box 1-1, an upper end cover 1-2, an upper center turning hole 1-3 and a central partition ramp 1- 4. The upper end cover 1-2 is fixedly connected to the upper end of the inner wall of the main box body 1-1, and the eccentric part of the upper end cover 1-2 is provided with an opening, and the upper center turning hole 1-3 is set through the center of the upper end cover 1-2. The central partition ramp 1-4 is fixedly connected to the center of the inner wall of the main box body 1-1;

[0033] Described central separation slope plate 1-4 is provided with two circulating flow holes 1-5, four stirring shaft turning holes 1-6, four falling flowing holes 1-7 and lower center turning holes 1-8, two A circulation flow hole 1-5 is evenly arranged on the eccentric part of the central separation ramp 1-4, and four stirring shaft rotatio...

specific Embodiment approach 3

[0035] Such as Figure 1 to Figure 9 As shown, this embodiment further describes the second embodiment, the oil inlet pipe 2 is fixedly connected to the upper end of the upper end cover 1-2, and the oil inlet pipe 2 communicates with the opening of the upper end cover 1-2. The lubricating oil flows down to the central separation ramp 1-4 through the opening of the oil inlet pipe 2 and the upper end cover 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com