Marking device for road construction

A scribing device and road construction technology, applied in roads, roads, road repairs, etc., can solve the problems of inconvenient adjustment of scribing width, uneven paint mixing, etc., to solve the problem of uneven paint mixing, uniform paint mixing, and prevent precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

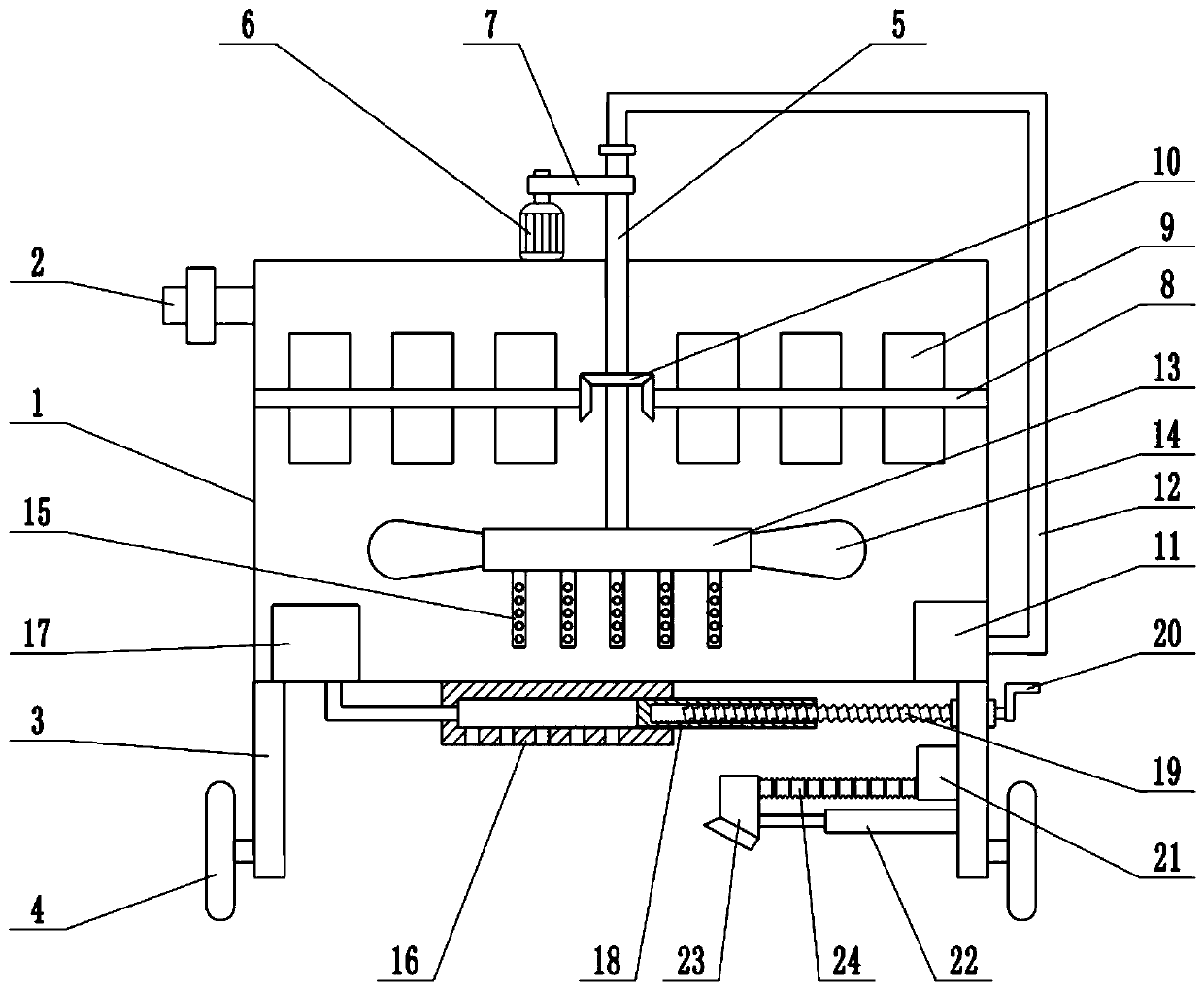

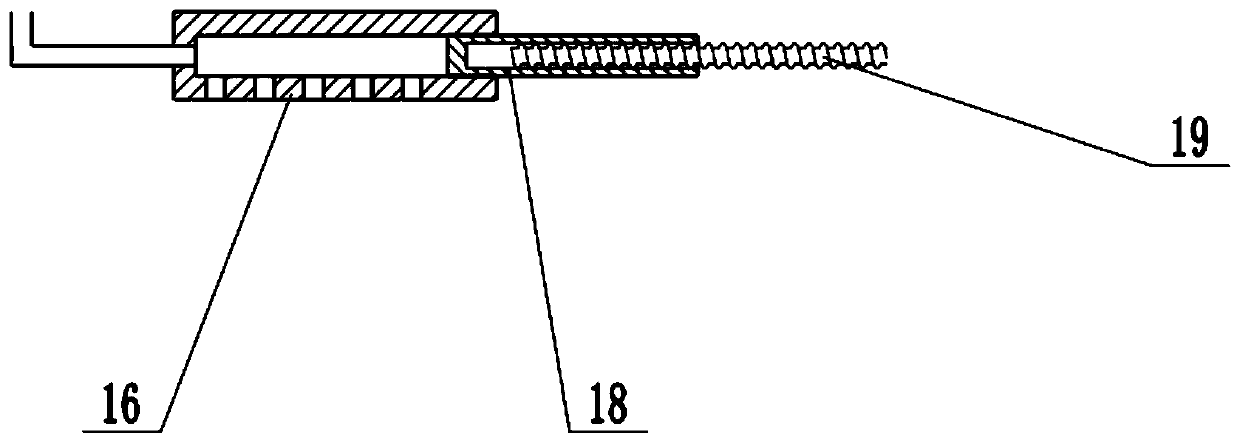

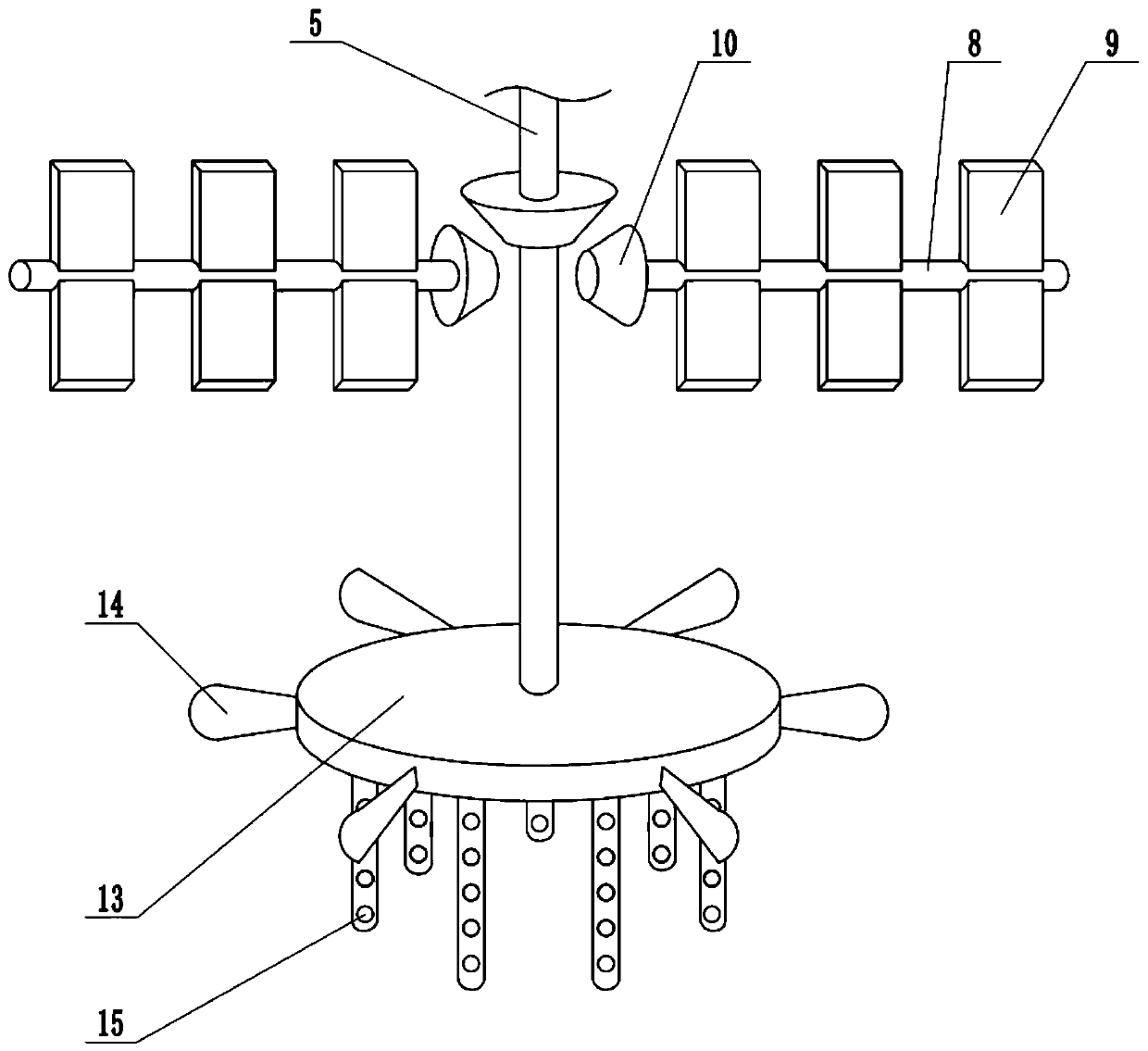

[0024] see Figure 1-3 , in an embodiment of the present invention, a marking device for road construction, including a box body 1, a support plate 3, a roller 4, a spray plate 16 and a booster pump 17, and a feed pipe is installed on the side wall of the box body 1 2. The paint used for scribing is injected into the box body 1 through the feed pipe 2. The bottom of the box body 1 is equipped with a support plate 3. There are two support plates 3, which are arranged symmetrically on the left and right. A hollow shaft 5 is installed inside the body 1, and the upper end of the hollow shaft 5 extends through the top of the box 1 to the top of the box 1. The hollow shaft 5 is connected to the top of the box 1 in rotation, and the upper surface of the box 1 is fixedly connected. There is a motor 6, and the whole body of the motor 6 is connected with the hollow rotating shaft 5 through the transmission belt 7. When the motor 6 is running, the hollow rotating shaft 5 is driven to rot...

Embodiment 2

[0026] On the basis of Embodiment 1, a dryer 21 is fixedly connected to the side wall of the support plate 3, and a telescopic mechanism 22 is arranged below the dryer 21. The telescopic mechanism 22 is an electro-hydraulic telescopic cylinder. The support plate 3 is fixedly connected, and the extended end of the telescopic mechanism 22 is fixedly connected with an air outlet 23. The air outlet of the dryer 21 communicates with the air outlet 23 through a telescopic hose 24, and the hot air generated by the dryer 21 passes through the telescopic hose. 24 is transported to the air outlet 23, and then sprayed out through the air outlet 23 to dry the paint on the ground and improve the marking efficiency.

[0027] Combined with Embodiment 1 and Embodiment 2, the working principle of the present invention is: inject the paint bucket feed pipe 2 into the box body 1, and when it is necessary to carry out the marking operation, turn the handle 20 to drive the screw rod 19 to rotate, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com