Gas mixing system of heptafluoroisobutyronitrile

A technology of heptafluoroisobutyronitrile and gas mixing, which is applied in the direction of gas and gas/steam mixing, mixers, mixing methods, etc., which can solve the problem of inability to ensure uniform mixing of two gases, inability to determine the end point of gas mixing, and reduce work efficiency, etc. Problems, to achieve the effect of saving pipelines and multiple circulating pumps, easy operation, and rapid gas mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The scheme of the specific embodiments described here does not limit the present invention. Professionals in the field can improve and change it according to the spirit of the present invention. The described These improvements and changes should be considered within the scope of the present invention, and the scope and essence of the present invention are defined by the claims.

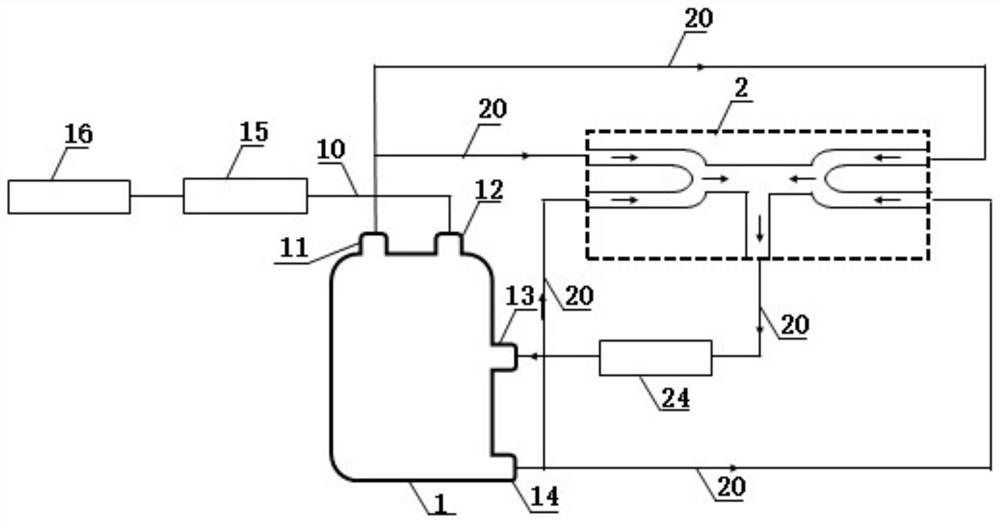

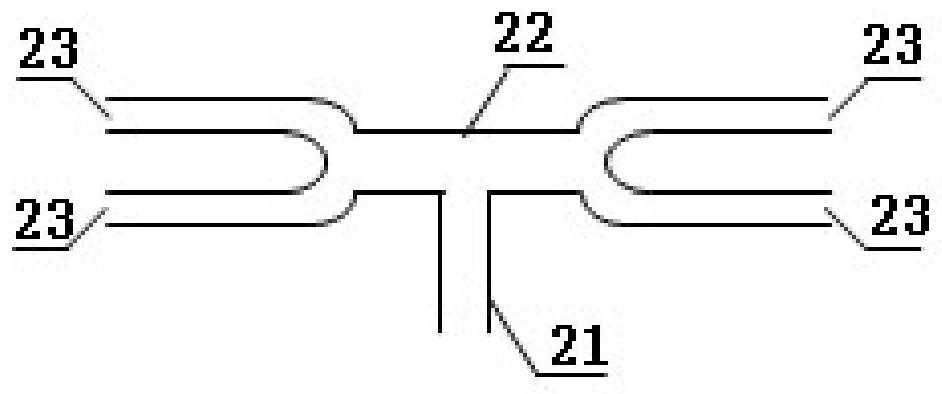

[0022] Such as figure 1 , figure 2 As shown, a gas mixing system for heptafluoroisobutyronitrile includes a gas mixing tank 1 connected to a gas circulation mixing pipeline 20 and a gas detection pipeline 10 .

[0023] The gas detection pipeline 10 is sequentially connected with a sampling unit 15 and an analysis unit 16 , and the gas detection pipeline 10 communicates with the sampling port 12 on the mixing tank 1 . The sampling port is connected with a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com