Stirring device of organic garbage microbial treater

A technology of organic waste and stirring device, applied in mixers with rotary stirring devices, chemical/physical processes, mixers, etc., can solve the problems of low efficiency, unsatisfactory particle size, poor stirring effect, etc., and reduce blade load. , Improve the stirring efficiency, the effect of fast stirring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

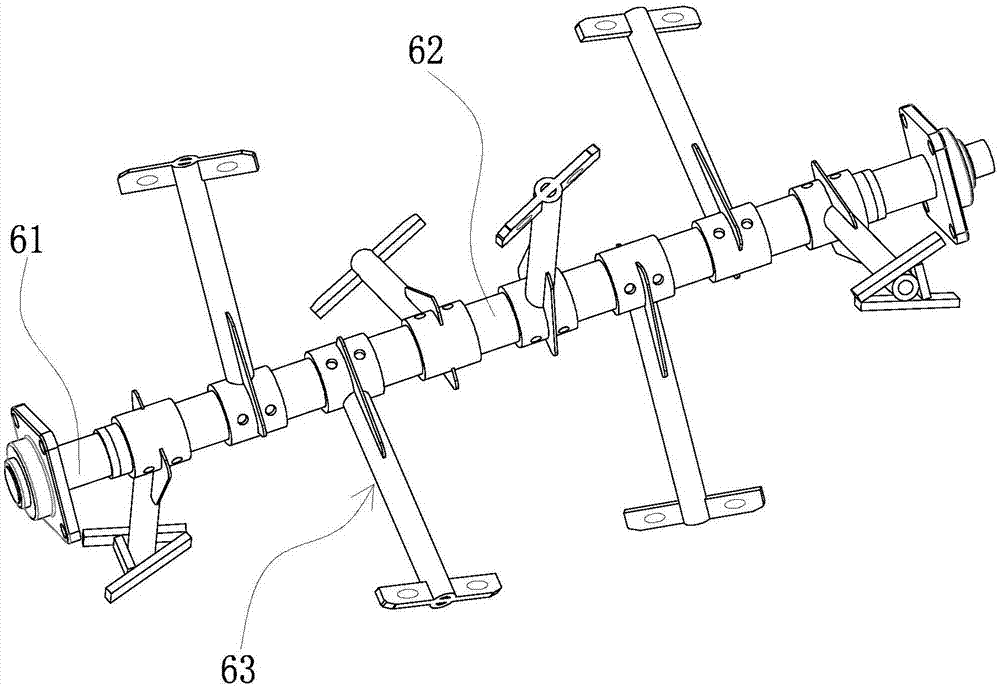

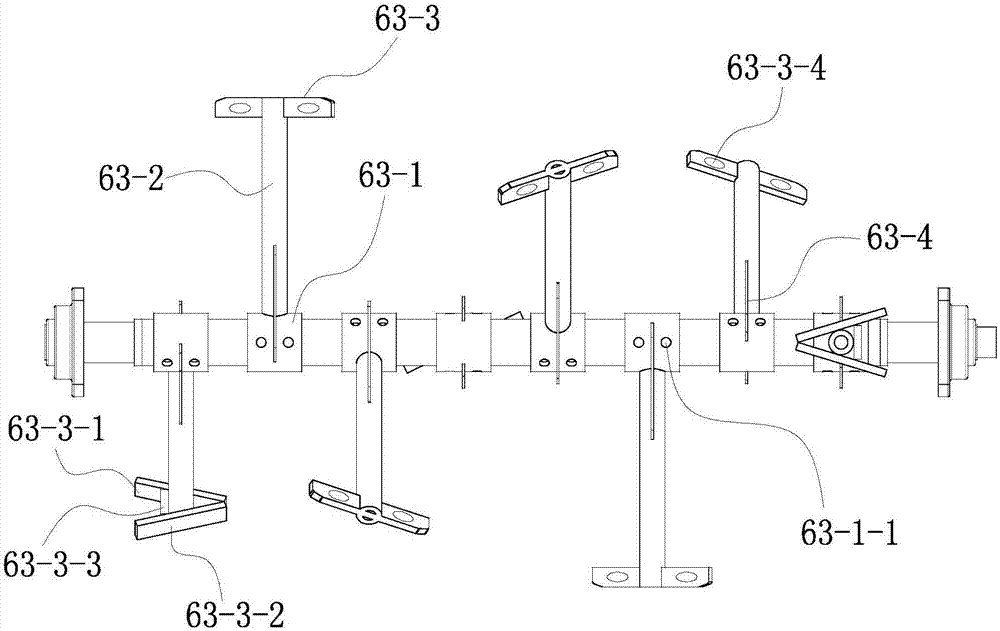

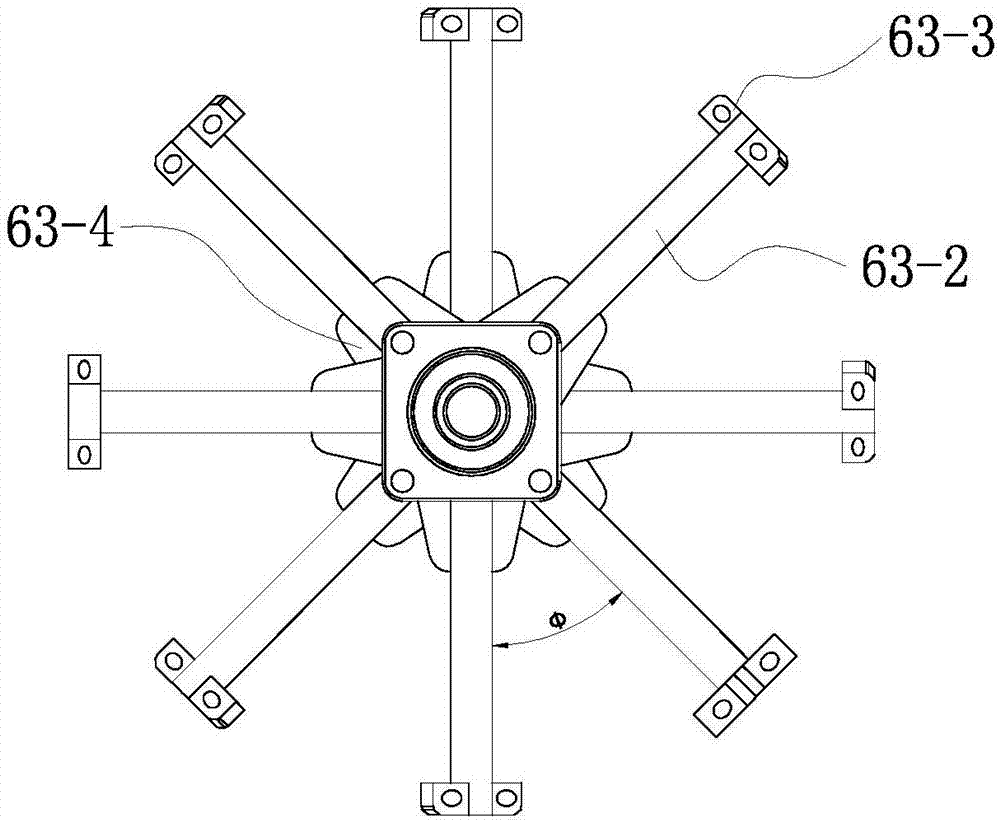

[0027] Example: such as Figure 1-3 As shown, the stirring device of the organic waste microbial processor includes a main shaft 61, a stirring shaft 62 and several stirring blade mechanisms 63 sleeved on the stirring shaft 62; Then drive the main shaft 61 and the stirring shaft 62 to rotate, the stirring shaft 62 is sleeved on the main shaft 61, and the stirring blade mechanism 63 includes a connecting pipe 63-1, a blade fixing rod 63-2 and a blade 63-3; the blade fixing rod One end of 63-2 is fixedly connected with the connecting pipe 63-1, and the other end of the blade fixing rod 63-2 is used to fix the blade 63-3; several connecting pipes 63-1 are equidistantly socketed on the stirring shaft 62, and the adjacent blades The fixed rod 63-2 has the same inclination angle along the circumferential direction of the stirring shaft 62; along with the rotation of the stirring shaft 62, the blade 63-3 is driven to decompose the organic waste in the decomposition chamber, stir even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com