Magnetic ferrite core forming equipment feeding device

A technology of magnetic ferrite and molding equipment, applied in mixers with rotating stirring devices, packaging, transportation and packaging, etc., can solve the problems of low efficiency and manpower consumption, and achieve the guarantee of preparation quality, good cutting effect, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

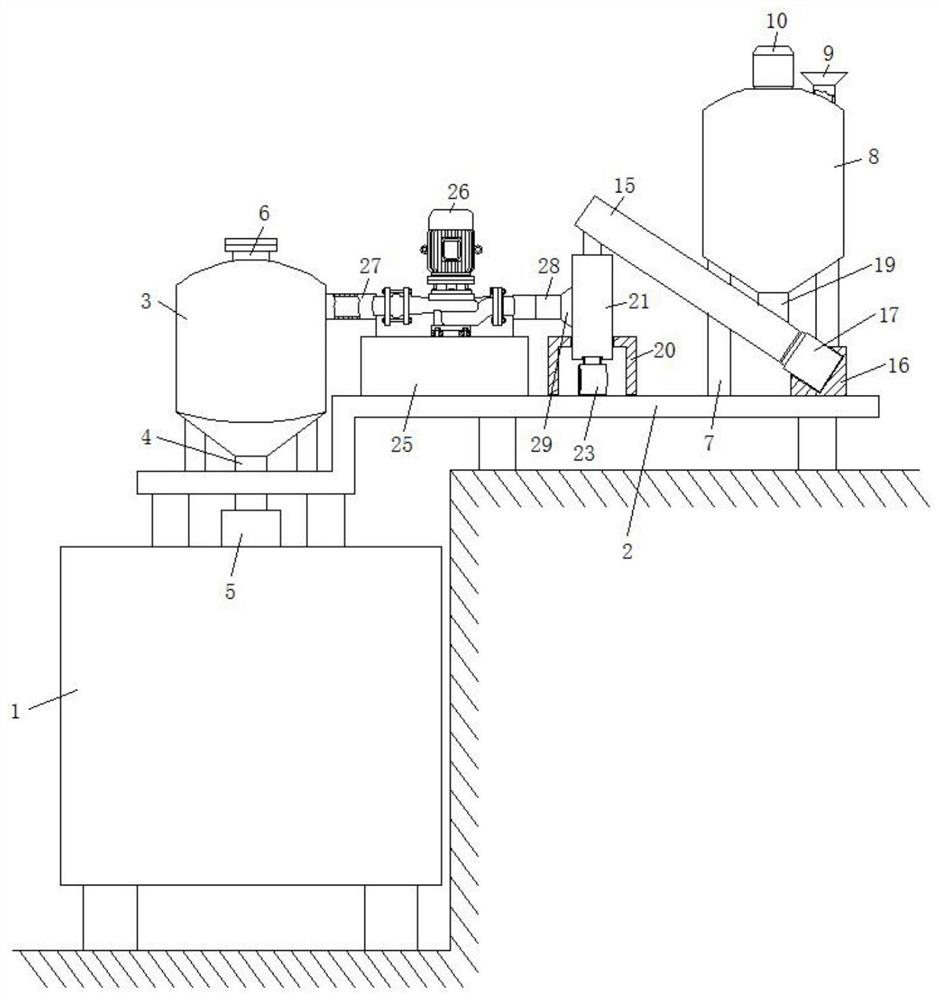

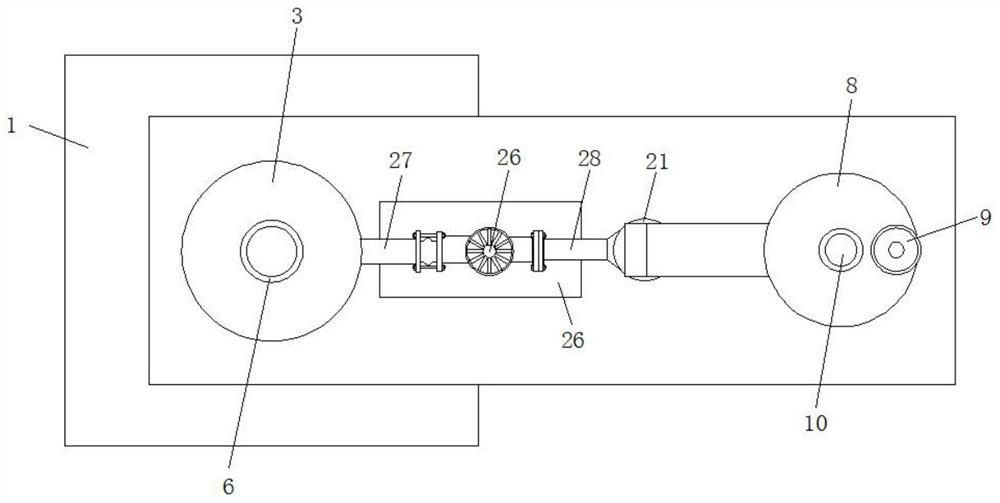

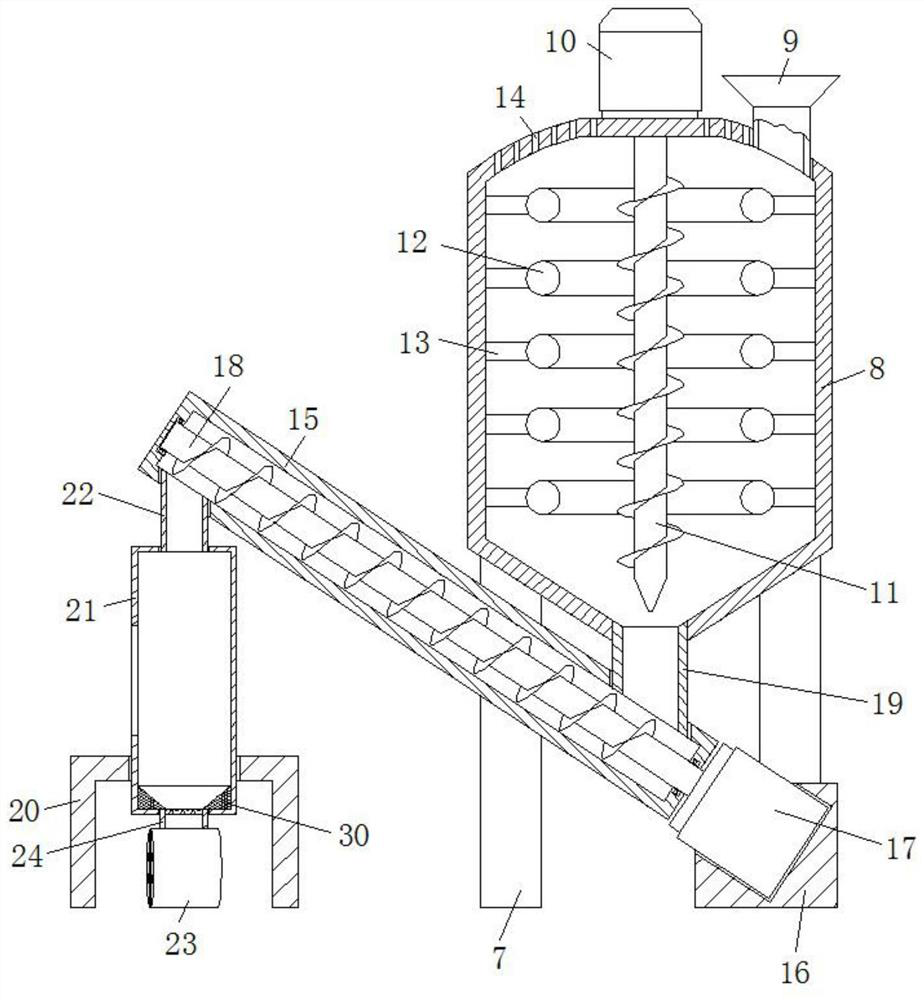

[0027] refer to Figure 1-4 , a magnetic ferrite core molding equipment feeding device, comprising a molding equipment body 1, the feeding end of the molding equipment body 1 is fixed with a feeding pipe 5, the upper end of the molding equipment body 1 is provided with a mounting frame 2, and the mounting frame 2 One side of the top surface is fixed with a cyclone collector 3, the output end of the cyclone collector 3 is fixed with a feeding pipe 4, the lower end of the feeding pipe 4 is placed in the feeding pipe 5, and the top of the cyclone collector 3 is also fixed with an exhaust pipe 6, The other side of the top surface of the mounting frame 2 is also fixed with a support seat 7, the top of the support seat 7 is fixed with a storage barrel 8 by screws, and the upper end of the storage barrel 8 is connected with a feed funnel 9 through one side, and the center of the top surface of the storage barrel 8 The position is also fixed with a servo motor-10 by screws, the output...

Embodiment 2

[0030] Such as image 3 with 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inner bottom surface of the lower material barrel 21 is also fixedly connected with a retaining column 30, and the top surface of the retaining column 30 is provided with a conical hole, and the upper end of the air inlet pipe 24 is fixedly connected to On the lower inner wall of the tapered hole.

[0031] In this embodiment, the retaining column 30 is fixedly connected to the inner bottom surface of the lower material barrel 21, so as to prevent the powder from accumulating on both sides of the bottom surface of the lower material barrel 21, and ensure that the blower 23 can realize the blowing of all the key powder materials, so that the powder material The cutting effect is better.

Embodiment 3

[0033] Such as figure 1As shown, this embodiment is basically the same as Embodiment 1. Preferably, the molding equipment body 1 is fixed on the working surface, and the two sides of the mounting frame 2 are respectively fixed on the top surface of the molding equipment body 1 and the working surface by screws.

[0034] In this embodiment, by fixing the installation frame 2 on the top surface and the working surface of the molding equipment body 1, the operation of the device is made more stable, and the service life of the device is well extended.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com