Color master batch processing stirring device and stirring method

A technology of mixing device and color masterbatch, which is applied in the field of color masterbatch processing and mixing device, can solve the problems of large load of mixing equipment, affecting the efficiency of mixing, and long mixing time, so as to achieve short time consumption, improved efficiency and small load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

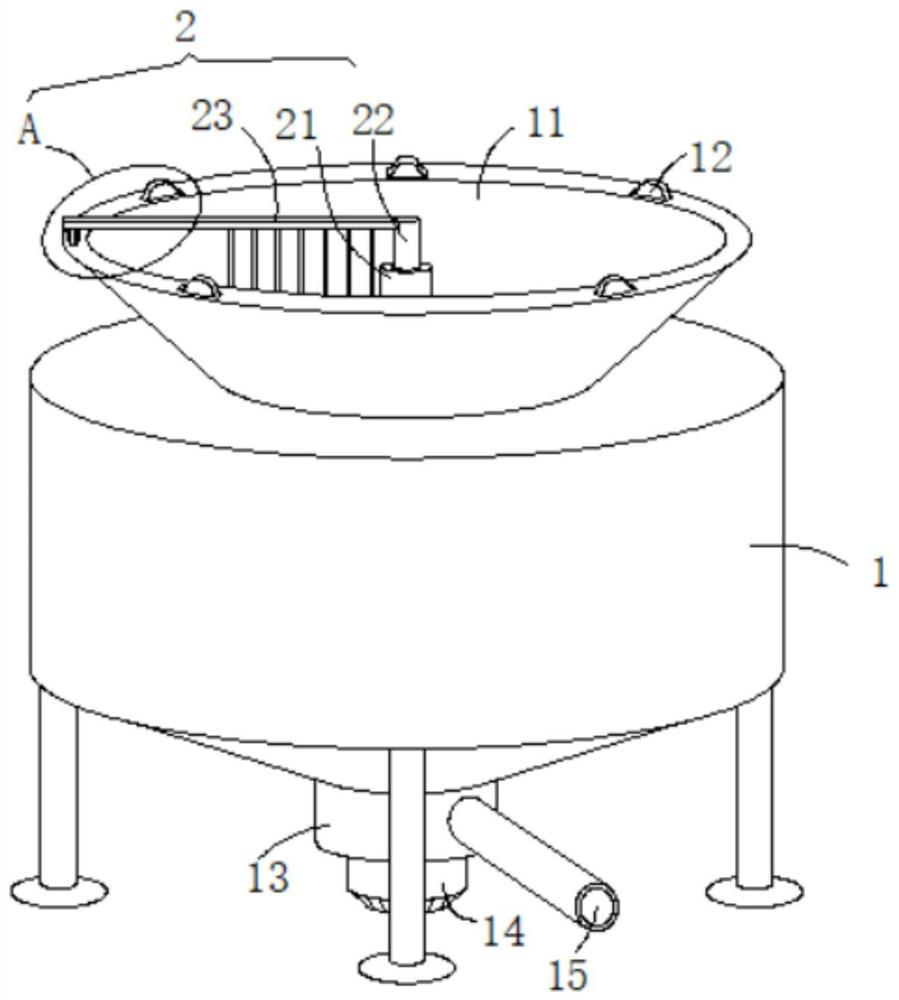

[0029] see Figure 1-4 , this embodiment provides a color masterbatch processing mixing device and mixing method, including a mixing drum 1 and a stirring mechanism 3, the top of the mixing drum 1 is provided with a feeding port, and the opening of the feeding port is provided with a feeding hopper 11 , feed the color masterbatch to be stirred into the mixing drum 1 through the feeding hopper 11, and wait for the stirring operation.

[0030] The stirring mechanism 3 is set inside the mixing drum 1, and the stirring mechanism 3 is located directly below the feeding hopper 11, and the stirring mechanism 3 accepts the color masterbatch thrown in from the feeding hopper 11, so that the color masterbatch can be stirred , to meet the mixing needs.

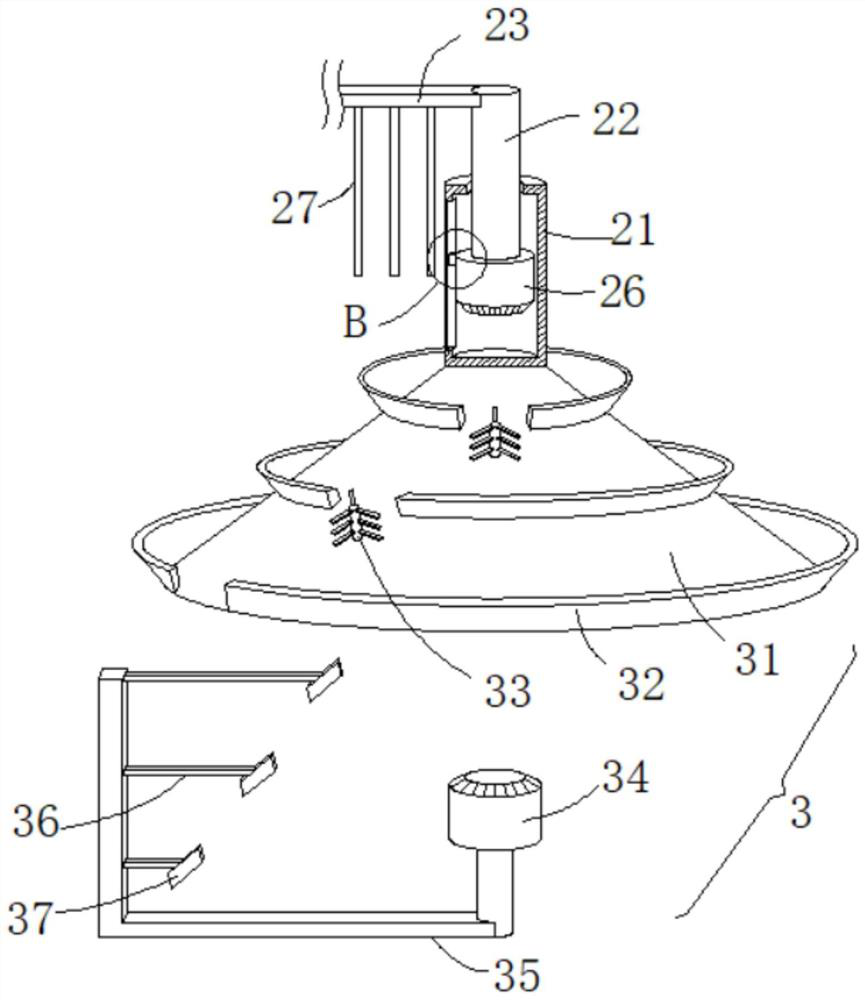

[0031] The stirring mechanism 3 includes a frustum-shaped material guide seat 31, a first drive motor 34 and an L-shaped transmission rod 35. The frustum-shaped material guide seat 31 is fixed inside the mixing drum 1 through a support ...

Embodiment 2

[0035] see Figure 1-4 , made further improvement on the basis of embodiment 1:

[0036] In order to prevent the color masterbatch from agglomerating, several transmission shafts located below each blanking gap are arranged on the side wall of the truncated cone-shaped material guide seat 31, and the radial side walls of the transmission shaft are fixedly provided for breaking up the agglomeration. The dispersing teeth 33 of the color masterbatch, and the third drive motor used to drive the transmission shaft to rotate is fixed inside the cone-shaped material guide seat 31, and the third drive motor provides power to drive the drive shaft to rotate, which can drive the dispersing The tooth 33 rotates at the lower side of the blanking gap of each annular partition 32, so that the color masterbatches derived from the blanking gap can be broken up to avoid agglomeration of the color masterbatches.

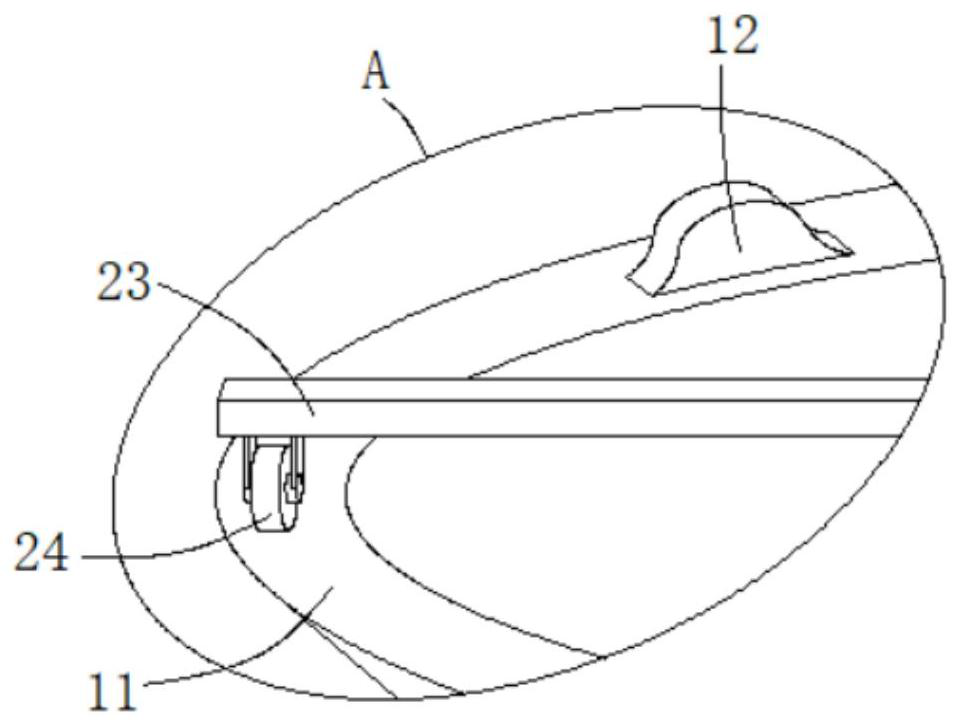

[0037] The inside of the feed hopper 11 is provided with a conduction mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com