Preparation method of crystal L-arginine alpha-ketoglutarate

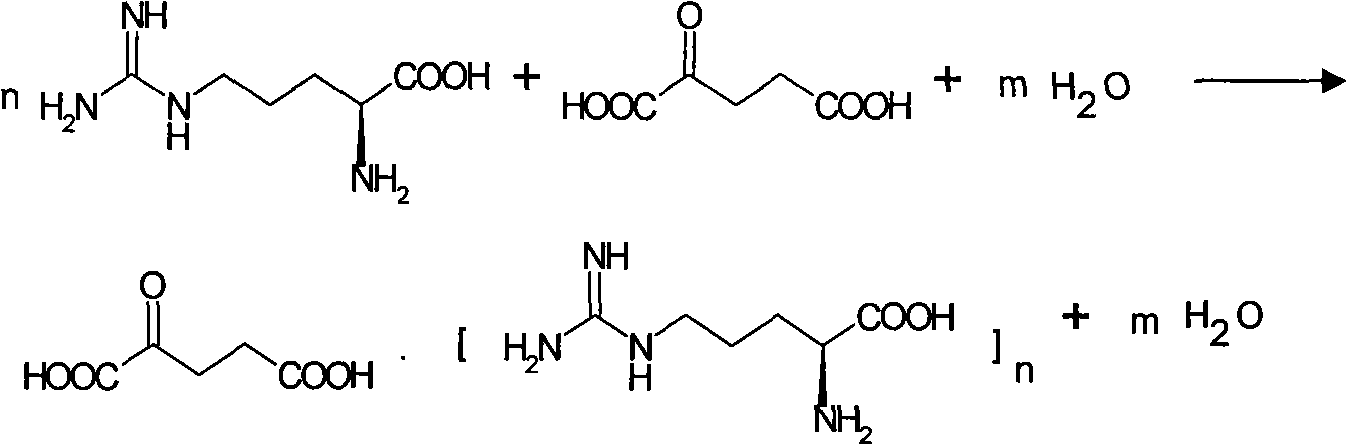

A technology of ketoglutarate and ketoglutarate, applied in the field of amino acid salts, can solve the problems of complex L-arginine α-ketoglutarate, unsuitable for industrial production, poor crystal form, etc. Not easy to agglomerate, easy to transport and use, simple step effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of crystalline L-arginine α-ketoglutarate: in a 500ml reaction bottle, add 70ml (69.6g) of 25% (weight) L-arginine solution (equivalent to 0.1molL - arginine), stirring, slowly add 14.6g (0.1mol) α-ketoglutaric acid, react at room temperature for 10mins, dissolve completely, then concentrate under reduced pressure, water bath temperature 55°C, concentrate the total volume of the reaction solution to about 56ml, cool to 23°C, slowly add 95% ethanol dropwise while stirring until a small amount of crystals are precipitated, stir for 10mins, then continue to add 95% ethanol dropwise, the total amount of ethanol is 42ml, and the dropping time is 2hr, then reduce the temperature of the crystallization solution to 5~10 ℃, stand for 30mins, make the crystal crystallize completely, filter, crystal wash with 95% ethanol, and vacuum-dry at 60 ℃, obtain white flaky crystal form L-arginine α-ketoglutarate (1: 1) 26.0g, the yield is 81.4%, the purity is 99.8%, [α...

Embodiment 2

[0027] A preparation method of crystalline L-arginine α-ketoglutarate: in a 500ml reaction bottle, add 70ml (69.6g) of 20% (weight) L-arginine solution (equivalent to 0.08molL - arginine), stir, slowly add 5.84g (0.04mol) α-ketoglutaric acid, react at room temperature for 10mins, dissolve completely, then concentrate under reduced pressure, water bath temperature 50°C, concentrate the total volume of the reaction solution to about 28ml, cool to 20°C, slowly add anhydrous methanol dropwise while stirring until a small amount of crystals are precipitated, stir for 10mins, then continue to add anhydrous methanol dropwise, the total amount of methanol is 168ml, and the dropping time is 2.5hr, then lower the temperature of the crystallization solution to 5-10°C, stand for 30mins, crystallize completely, filter, wash the crystals with anhydrous methanol, and vacuum-dry at 50°C to obtain white flaky crystals of L-arginine α-ketoglutarate (2 : 1) 15.89g, the yield is 80.4%, and the pu...

Embodiment 3

[0029] A preparation method of crystalline L-arginine α-ketoglutarate: in a 500ml reaction bottle, add 70ml (69.6g) of 30% (weight) L-arginine solution (equivalent to 0.12molL - arginine), stirring, slowly add 17.52g (0.12mol) α-ketoglutaric acid, react at room temperature for 10mins, completely dissolve, then concentrate under reduced pressure, water bath temperature 80°C, concentrate the total volume of the reaction solution to about 49ml, cool to 22°C, slowly add isobutanol dropwise while stirring until a small amount of crystals precipitate, stir for 10mins, and then continue to add isobutanol dropwise, the total amount of isobutanol is 63ml, and the dropping time is 2hr, and then the crystallization solution temperature Decrease to 5~10 ℃, stand 30mins, make crystal crystallize completely, filter, crystal wash with isobutanol, and vacuum-dry at 70 ℃, obtain white flaky crystalline L-arginine α-ketoglutarate ( 1:1) 26.5g, yield 82.8%, purity 98.6%, [α] D +16.0° (c=4, 6N H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com