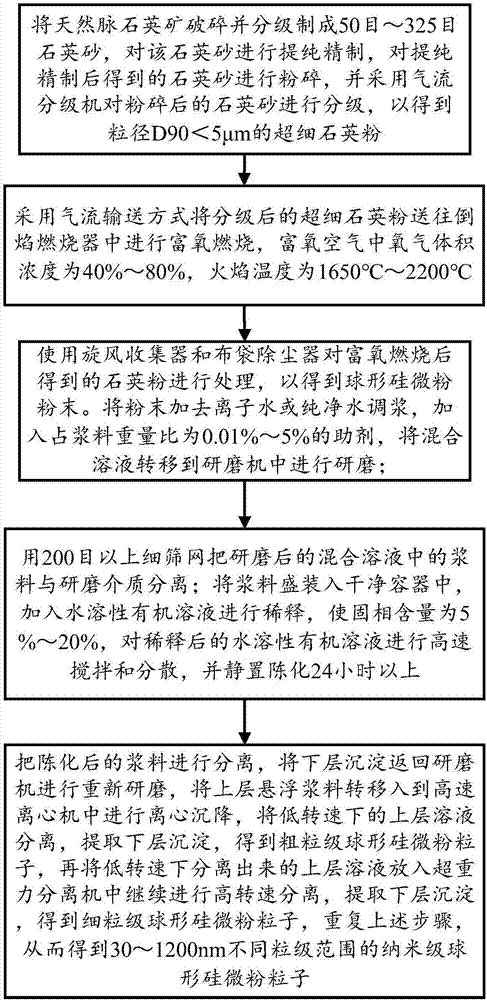

Method for preparing nano-sized spherical silicon micropowder by flame method

A spherical silicon micropowder, flame method, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of low powder particle packing density, great difficulty in industrialization, and high surface activity. High bulk density, not easy to agglomerate and agglomerate, and low surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

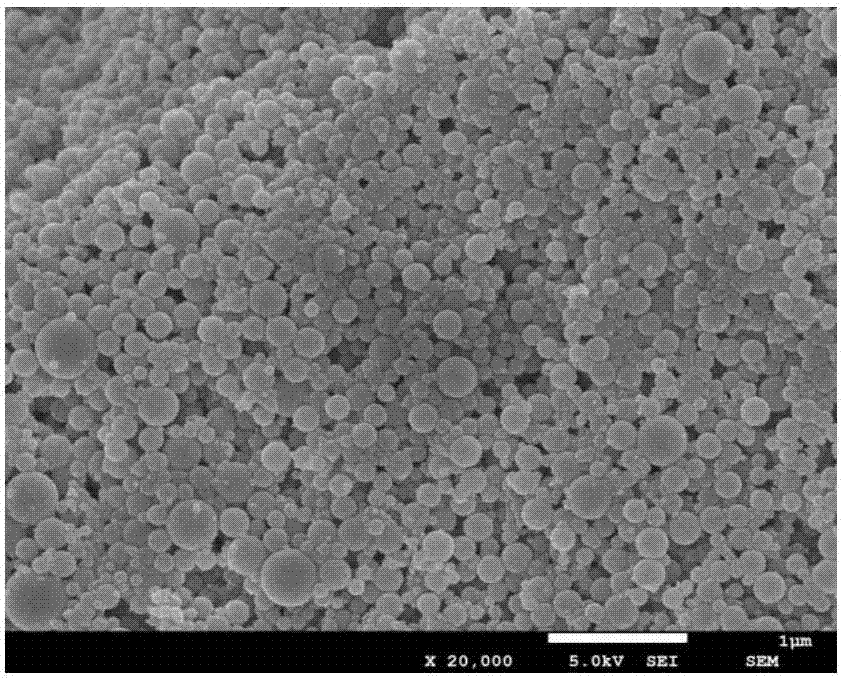

[0048] Using vein quartz as raw material, D 90 =4.33μm; use acetylene as the fuel gas and oxygen-enriched air as the combustion-supporting gas, control the temperature of the burner at 1900°C, and spheroidize; mix the collected powder with pure water according to the solid-liquid weight ratio of 1:5, and add 0.05 % silicone oil, stir evenly and transfer to the omni-directional planetary mill, then add zirconia grinding medium according to the volume ratio of 2:1 medium and slurry, set the speed at 400r / min, and run for 60 minutes; separate the medium balls, and put the slurry Mix with absolute ethanol according to the volume ratio of slurry and ethanol at 1:1, stir at high speed to disperse evenly, and age for 48 hours. Suck out all the suspended slurry, disperse at a high speed, and then transfer it to a supergravity separator, set the rotation speed at 3500r / min for 20 minutes. The precipitate was extracted and analyzed by a scanning electron microscope (SEM for short), to ...

Embodiment 2

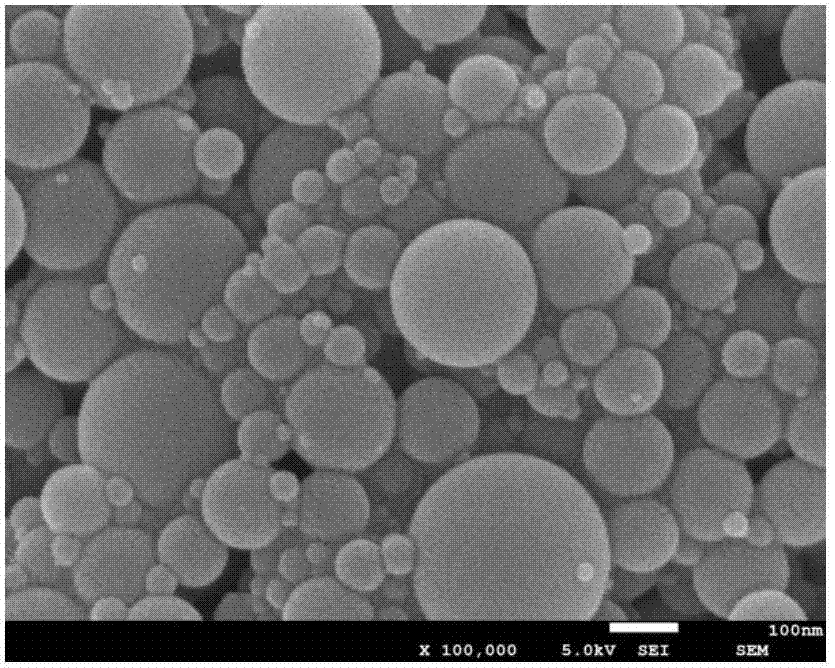

[0050] Using vein quartz as raw material, D 90 =2.84μm; use hydrogen as the fuel gas and oxygen-enriched air as the combustion-supporting gas, control the temperature of the burner at 1850°C, and carry out spheroidization; mix the collected powder with pure water according to the solid-liquid weight ratio of 1.5:10, and add 0.2 % Dispersant LT560, after stirring evenly, transfer it to the stirring mill, then add zirconia grinding media according to the volume ratio of 3:2 media and slurry, set the speed at 380r / min, and run for 45 minutes; separate the media balls, and put the slurry Mix methanol according to the volume ratio of slurry and methanol at 1:1, stir at high speed to disperse evenly, and age for one week. Suck out all the suspended slurry, disperse at a high speed, and transfer it to a supergravity separator, set the rotation speed at 8500r / min for 15 minutes. The precipitate was extracted and analyzed by SEM to obtain spherical silicon micropowder particles with a...

Embodiment 3

[0052] Using vein quartz as raw material, D 90 =2.51μm; use liquefied petroleum gas as fuel gas and oxygen as combustion-supporting gas, control the temperature of the burner at 1800°C, and carry out spheroidization; mix the collected powder with pure water according to the solid-liquid weight ratio of 1:4, and add 1.2 % water glass, stir evenly and transfer to the omnidirectional planetary mill, then add zirconia grinding medium according to the volume ratio of 2:1 medium and slurry, set the speed at 400r / min, and run for 60 minutes; separate the medium balls, and put the slurry The material is mixed with ethanol+methanol (1+1) mixed solvent according to the volume ratio of slurry and mixed solvent at 1:2, stirred at high speed to disperse evenly, and aged for 100h. Suck out all the suspended slurry, disperse at a high speed, and then transfer it to a supergravity separator, set the rotation speed at 10000r / min for 5 minutes. The precipitate was extracted and analyzed by SEM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com