Autoroatation and revolution combined blender

A self-revolution, combined technology, applied in mixers, mixers, dissolving and other directions with rotary stirring devices, can solve problems such as inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

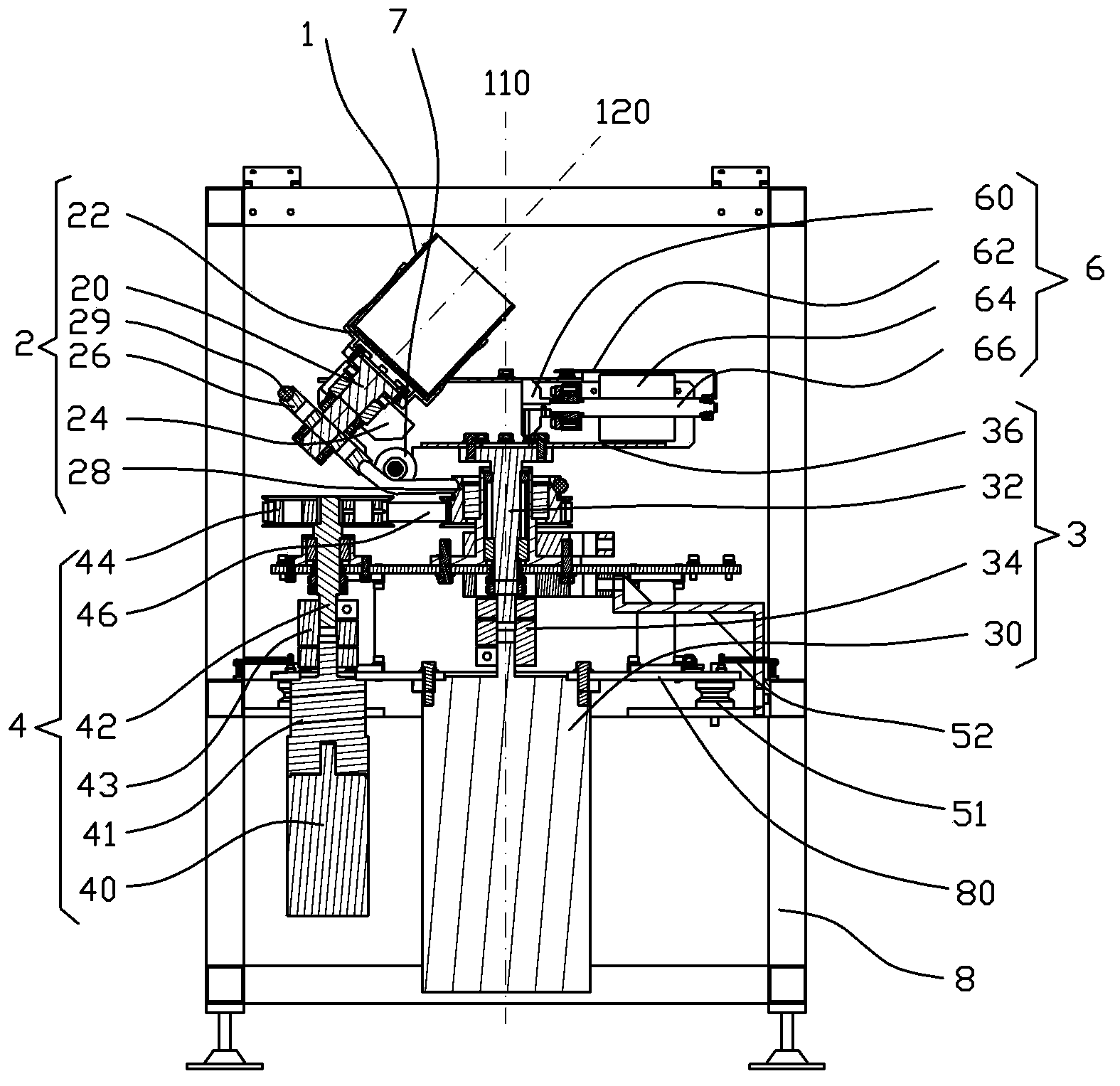

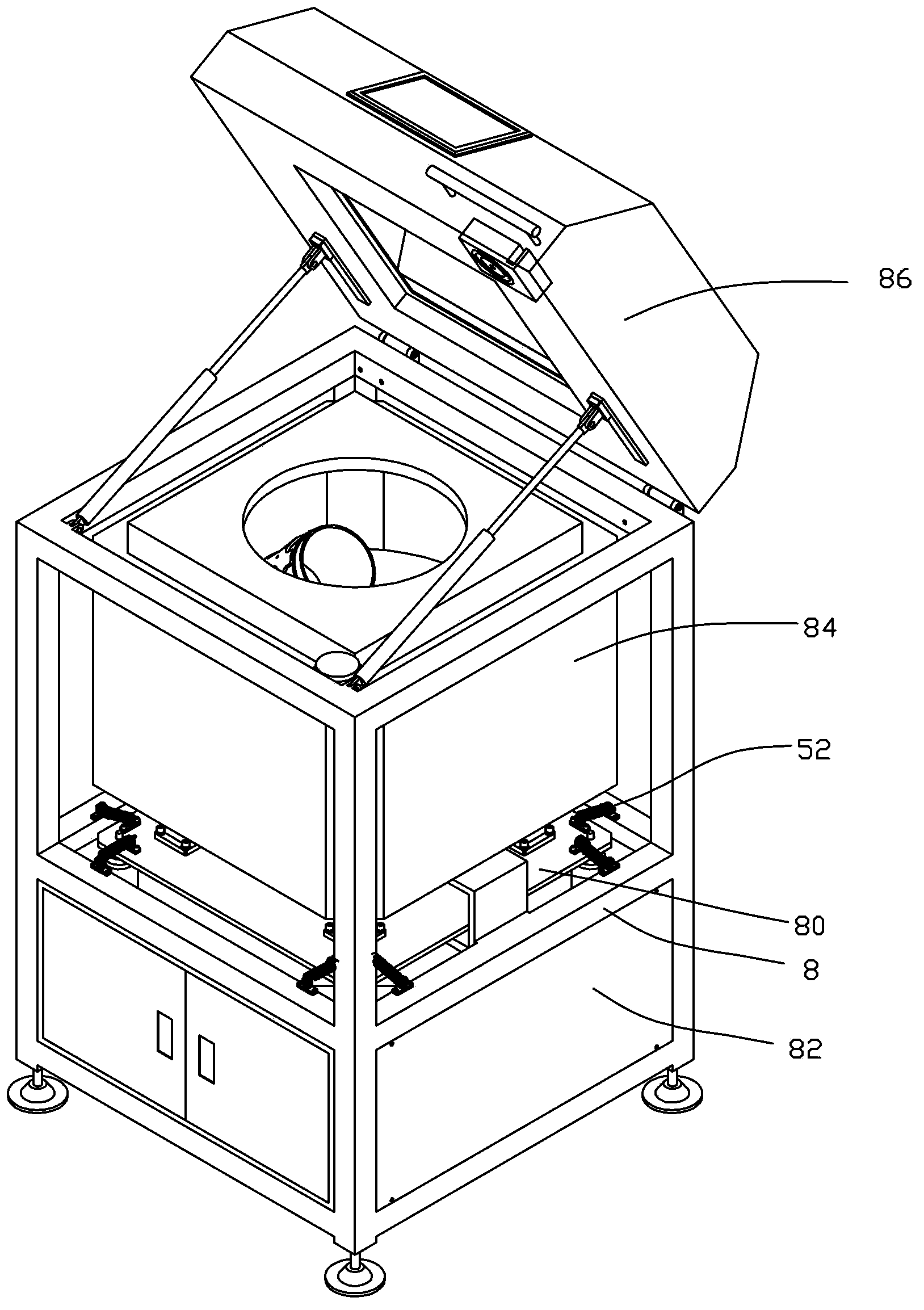

[0024] refer to figure 1 As shown, this embodiment provides a combined rotation and revolution mixer, including:

[0025] The revolution system 3 includes a first motor 30 , a revolution shaft 32 driven to rotate by the first motor 30 , and a rotating bottom plate 36 fixed on the top of the revolution shaft 32 . During specific implementation, the first motor 30 can be connected with the revolving shaft 32 through a first coupling 34 . When the first motor 30 is started, the revolution shaft 32 can drive the rotating bottom plate 36 to realize revolution around the axis 110 of the revolution shaft 32 .

[0026] The autorotation system 2 includes the autorotation shaft fixing seat 24 arranged at the side edge of the rotating bottom plate 36, the autorotation shaft 20 fixed on the autorotation shaft fixing seat 24 by means of bearings, the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com