Linear temperature-equalizing flow-guide shell-and-tube heat exchanger

A shell-and-tube heat exchanger, heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., to meet the needs of mixing, avoid uneven mixing, and reduce size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

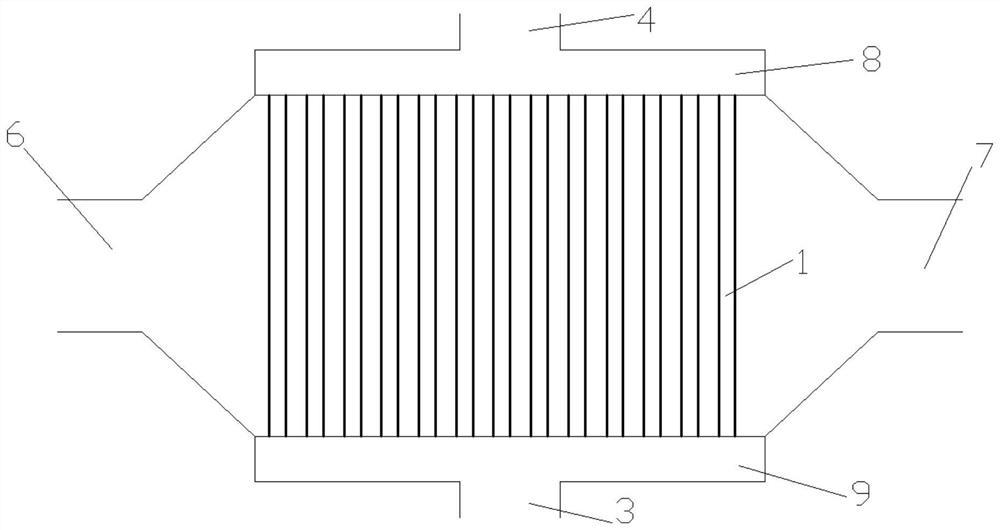

[0035] figure 1 A shell-and-tube heat exchanger for uniform outlet gas temperature is disclosed. like figure 1 As shown, the heat exchanger includes an upper header 8, a lower header 9, and a heat exchange tube 1 arranged between the upper and lower headers; the heat exchanger includes a gas inlet 6 and a gas outlet 7, and the gas flows from the gas inlet 6 flows in, exchanges heat with the fluid in the heat exchange tube 1 in the heat exchanger, and then flows out from the gas outlet 7.

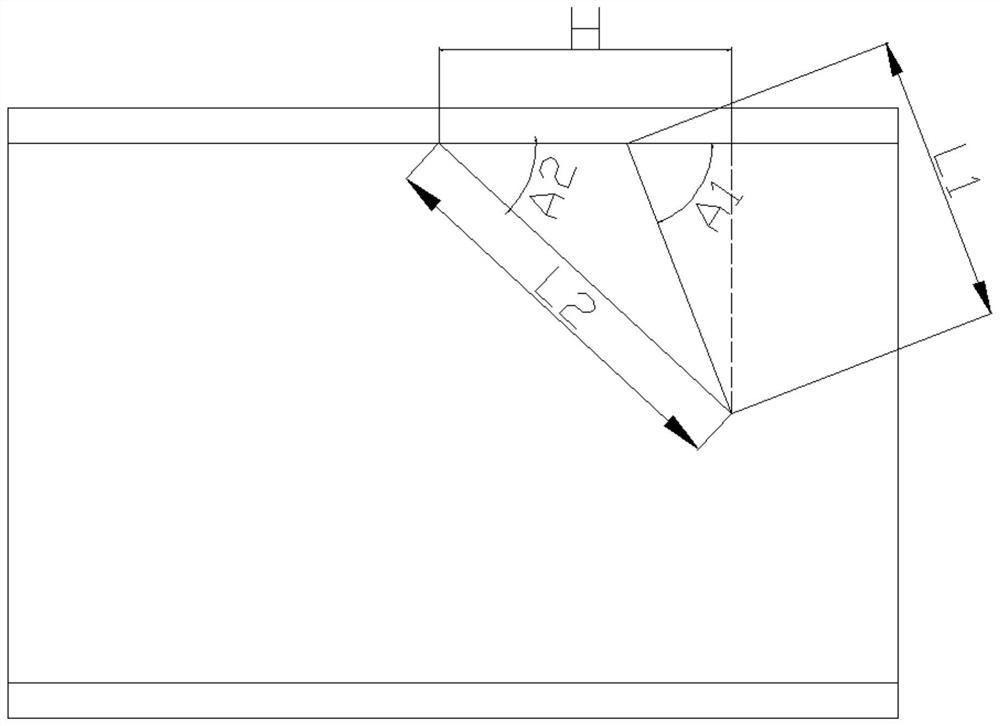

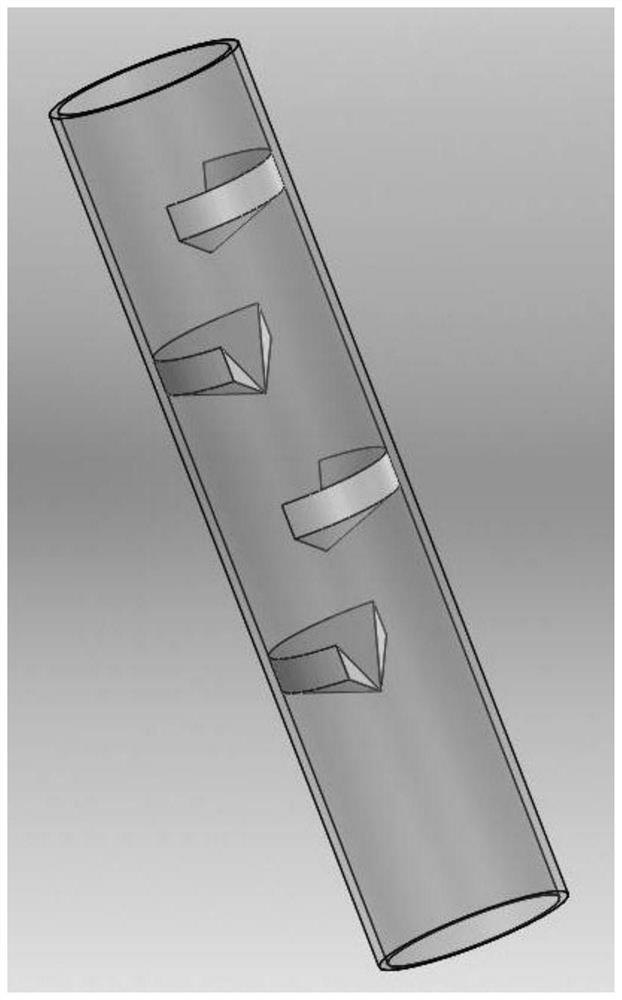

[0036] As an improvement, the gas outlet 7 is connected to the outlet pipe 5, such as figure 2 As shown, the outlet pipe 5 is provided with a baffle 2 extending from the inner wall 51 of the outlet pipe to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com