Ore supply system used for preparation of phosphoric acid from fine ores

A phosphoric acid and ore supply technology, applied in phosphoric acid, phosphorus oxyacid and other directions, can solve the problems of inconvenient management and operation, complicated procedures, power consumption and steel ball, steel forging consumption, etc. The working environment, the effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

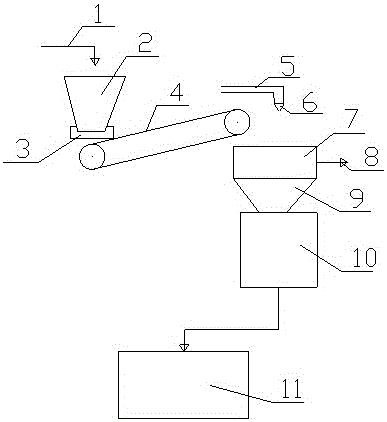

[0018] Below the embodiment of the present invention is combined figure 1 In detail, an ore supply system for producing phosphoric acid from powdered ore, including powdered phosphate rock pipeline 1, hopper 2, disc feeder 3, conveyor 4, sewage pipe 5, washing screen 6, trommel screen 7. Tailings outlet 8, chute 9, slurry mixing tank 10, and slurry storage tank 11, characterized in that: a hopper 2 is provided below the powdered phosphate rock pipeline 1, and there is a circle below the hopper 2 Pan feeder 3, the bottom of the disc feeder 3 is connected to the feed inlet at the lower end of the tail of the conveyor 4, and the outlet at the upper end of the head of the conveyor 4 is connected to the entrance of the trommel 7, so The upper end of the trommel 7 is also provided with a flushing screen 6, the flushing screen 6 is equipped with a sewage pipe 5, the lower end of the trommel 7 is provided with a chute 9, and the right end of the trommel 7 is provided with a tail The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com