Patents

Literature

48results about How to "Meet Filtration Needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

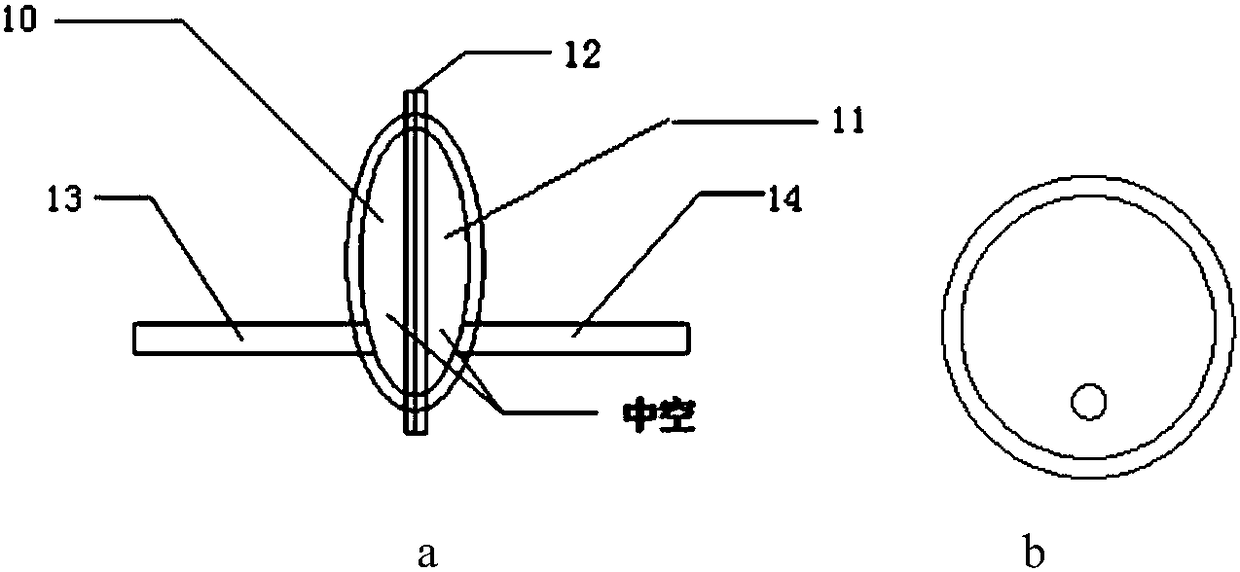

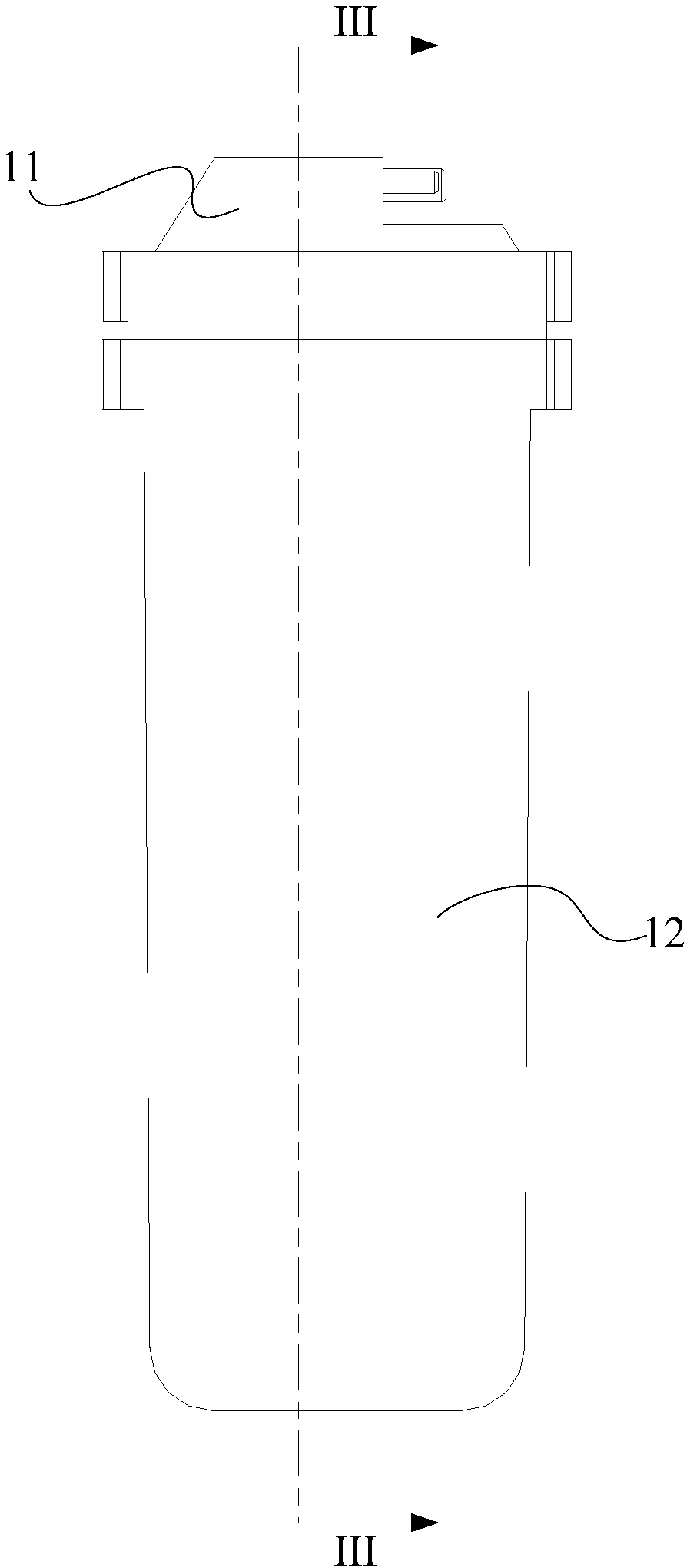

Composite filtration core and water purification equipment

ActiveCN107899281AReduce usageImplement filteringGeneral water supply conservationStationary filtering element filtersFiltrationWater quality

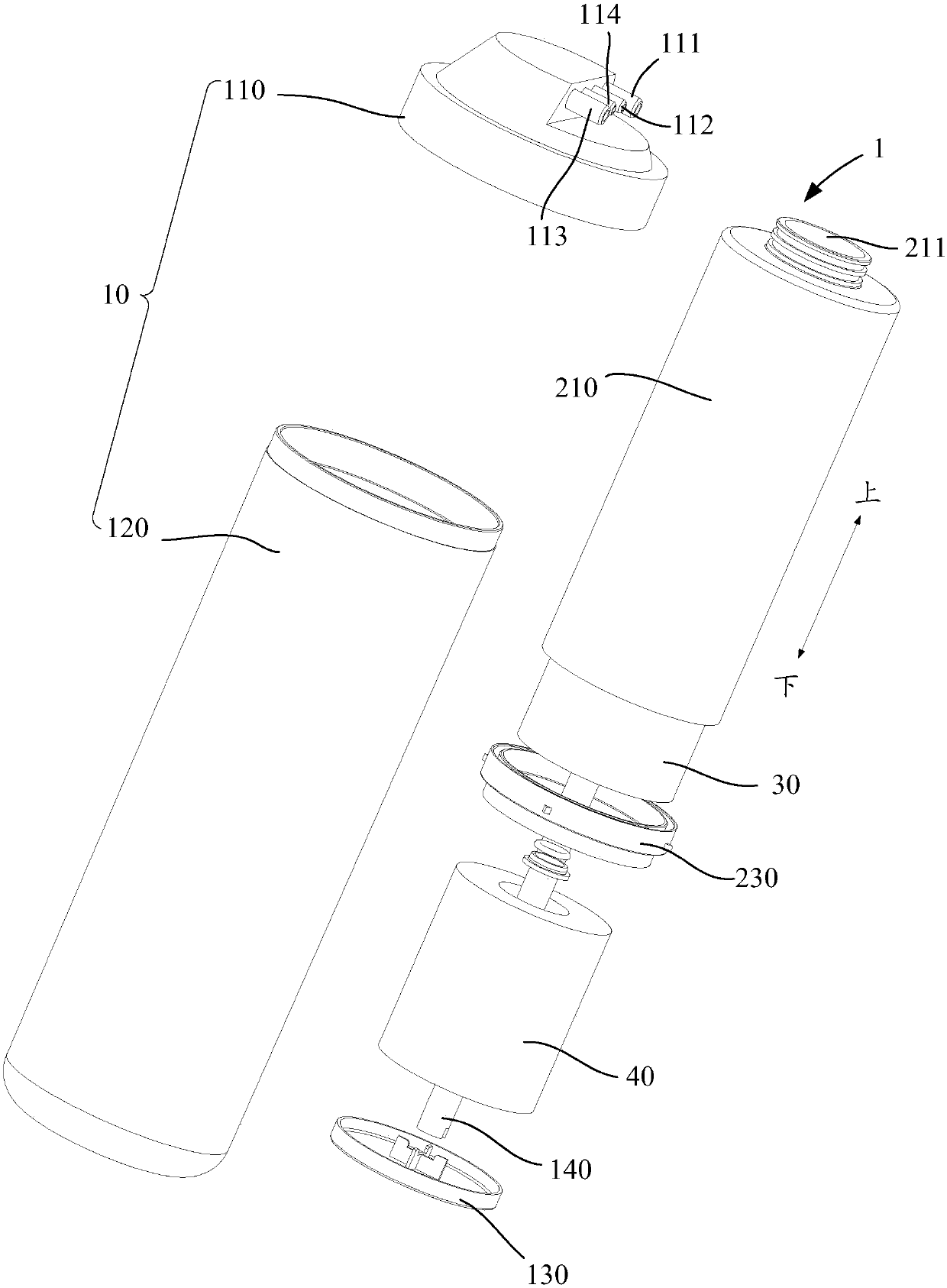

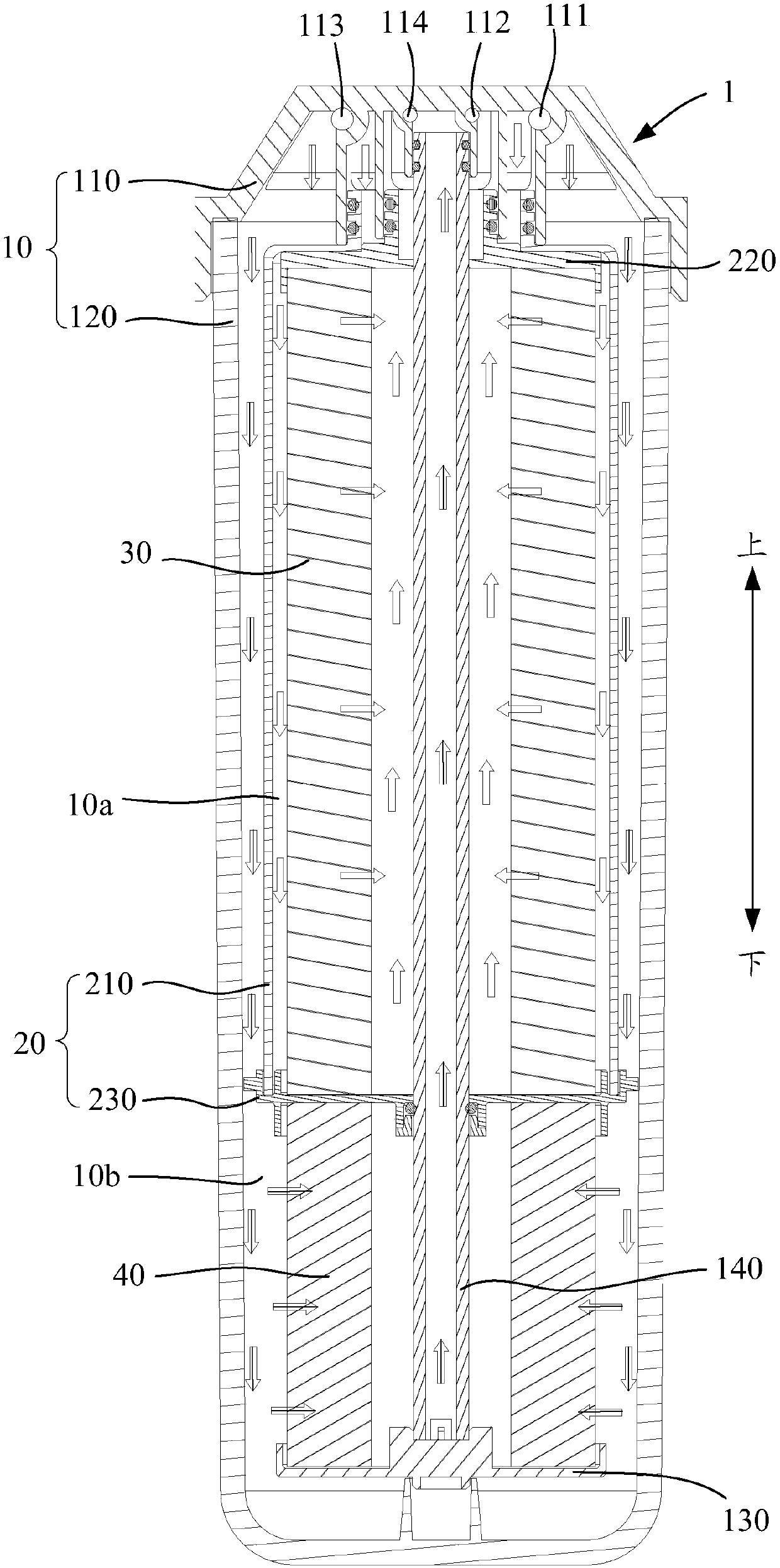

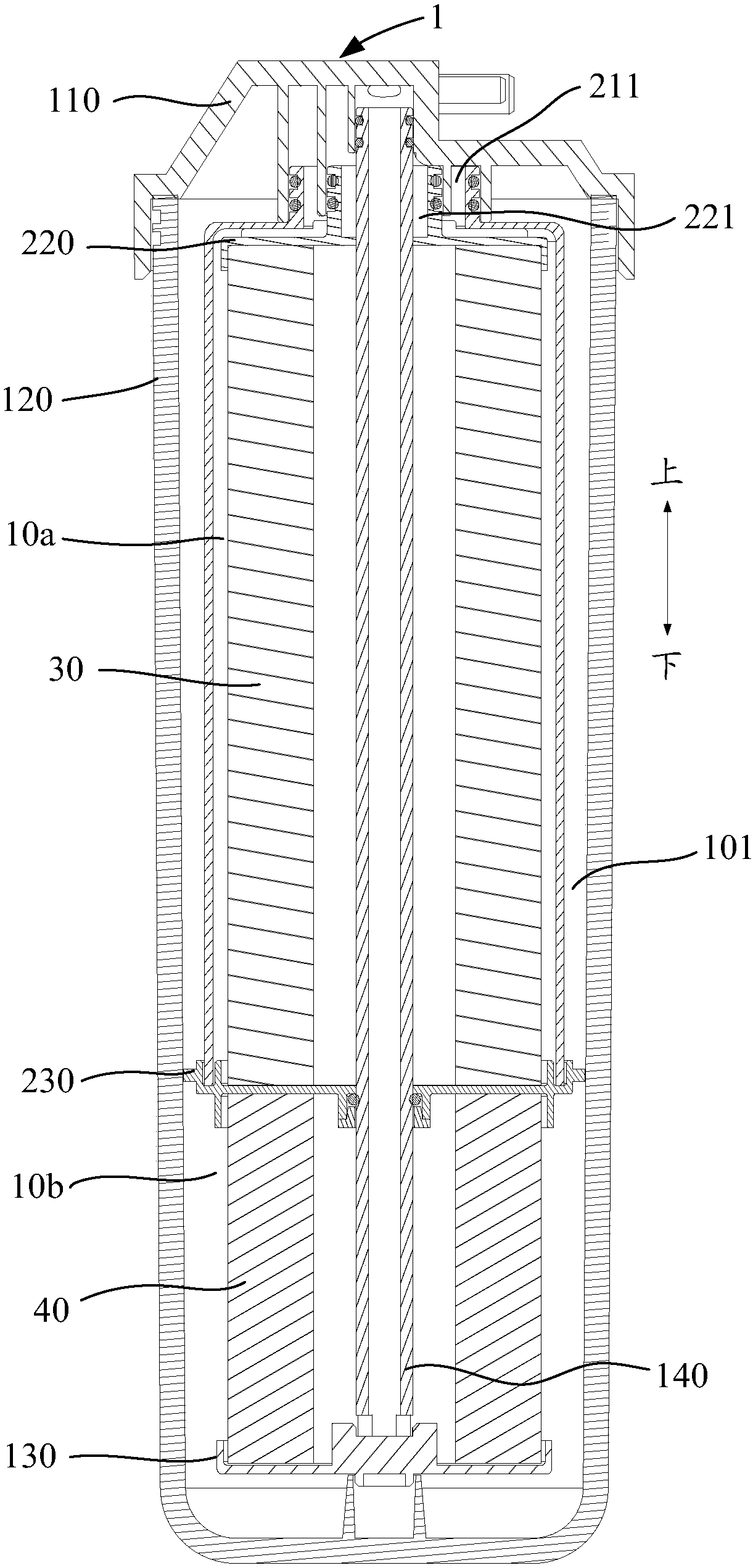

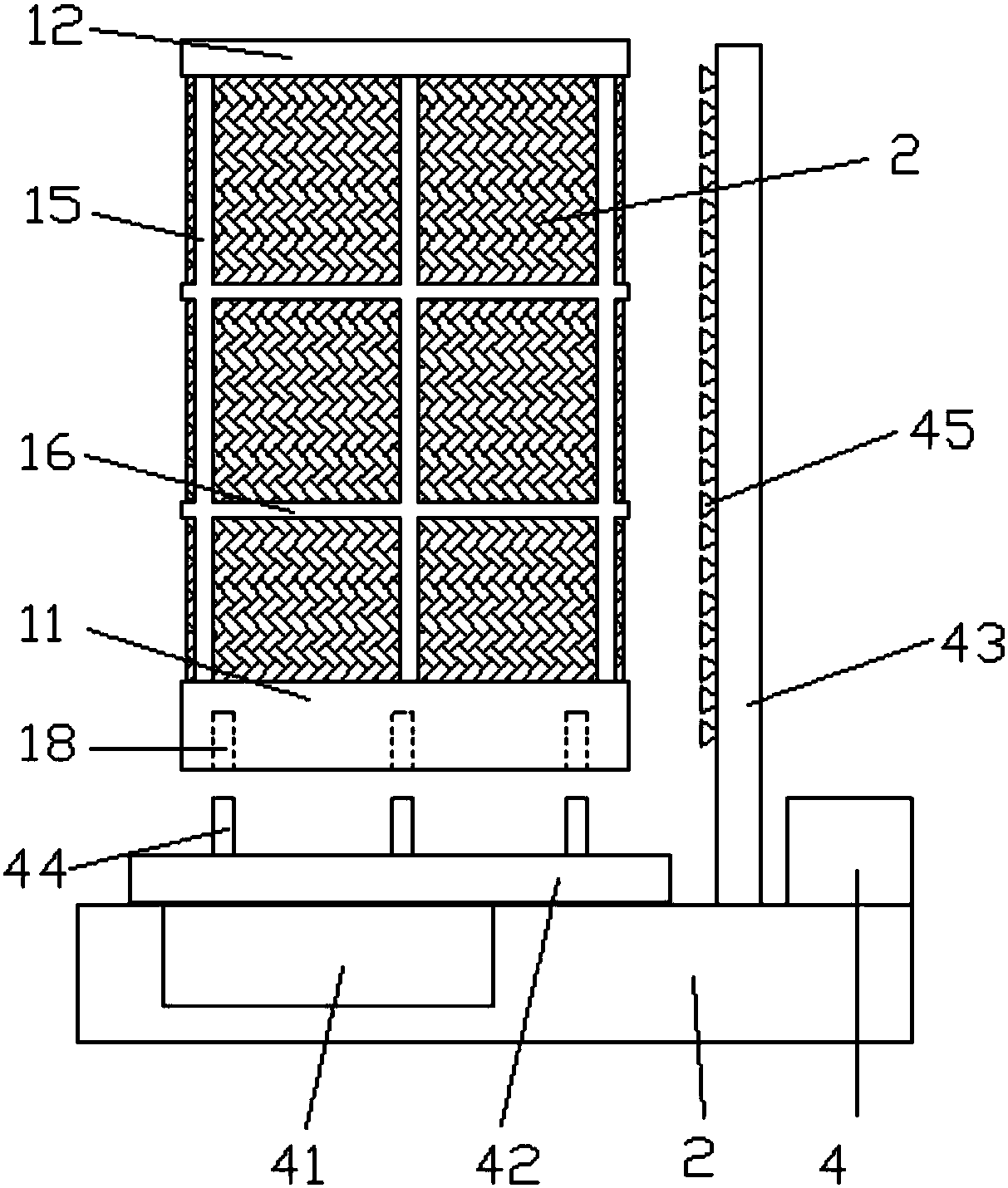

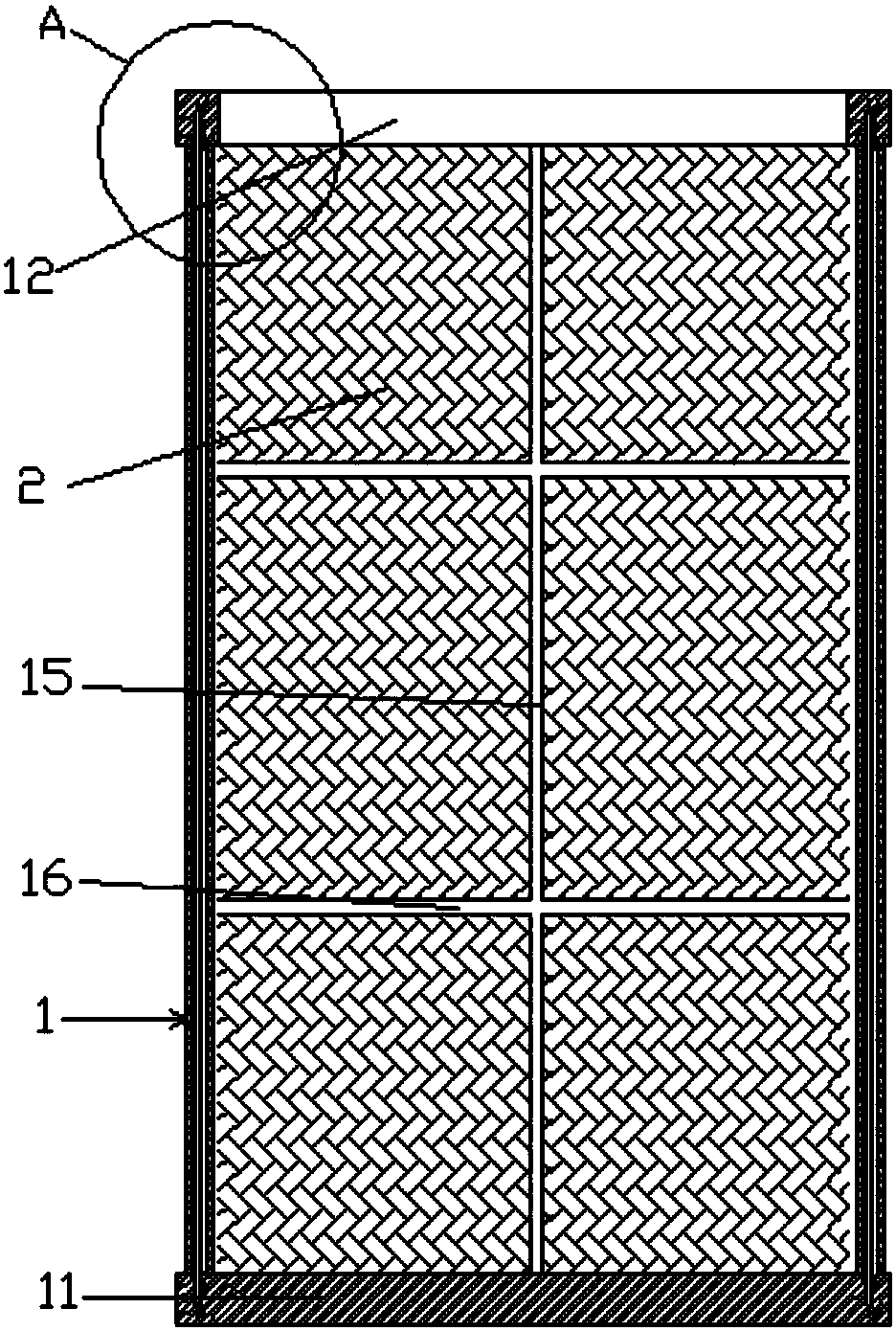

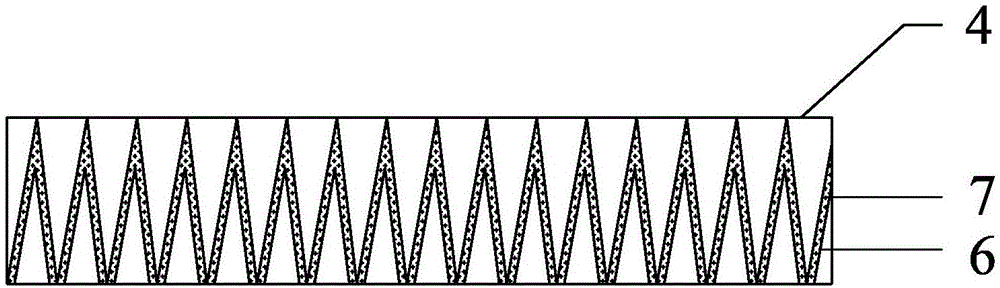

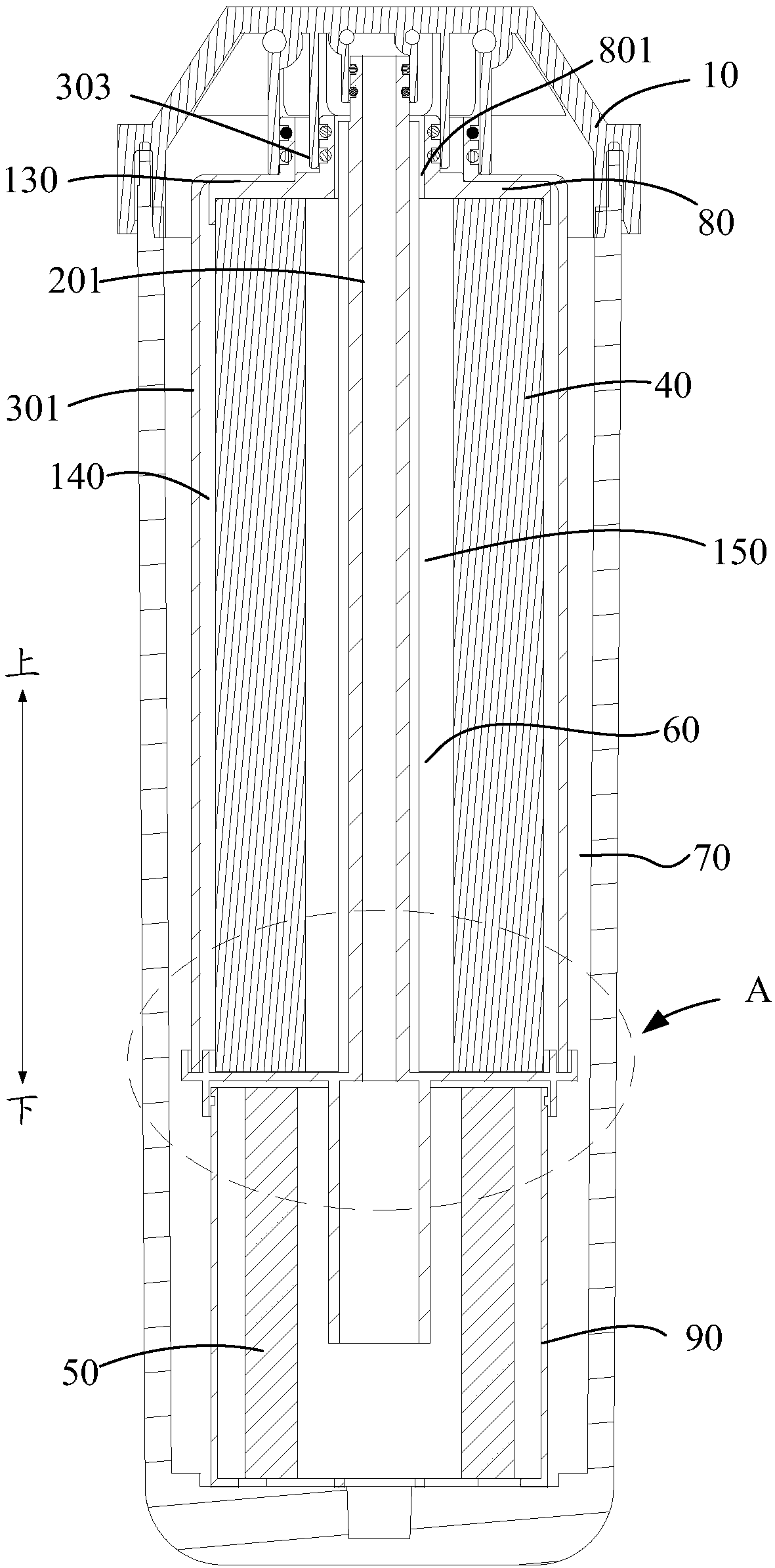

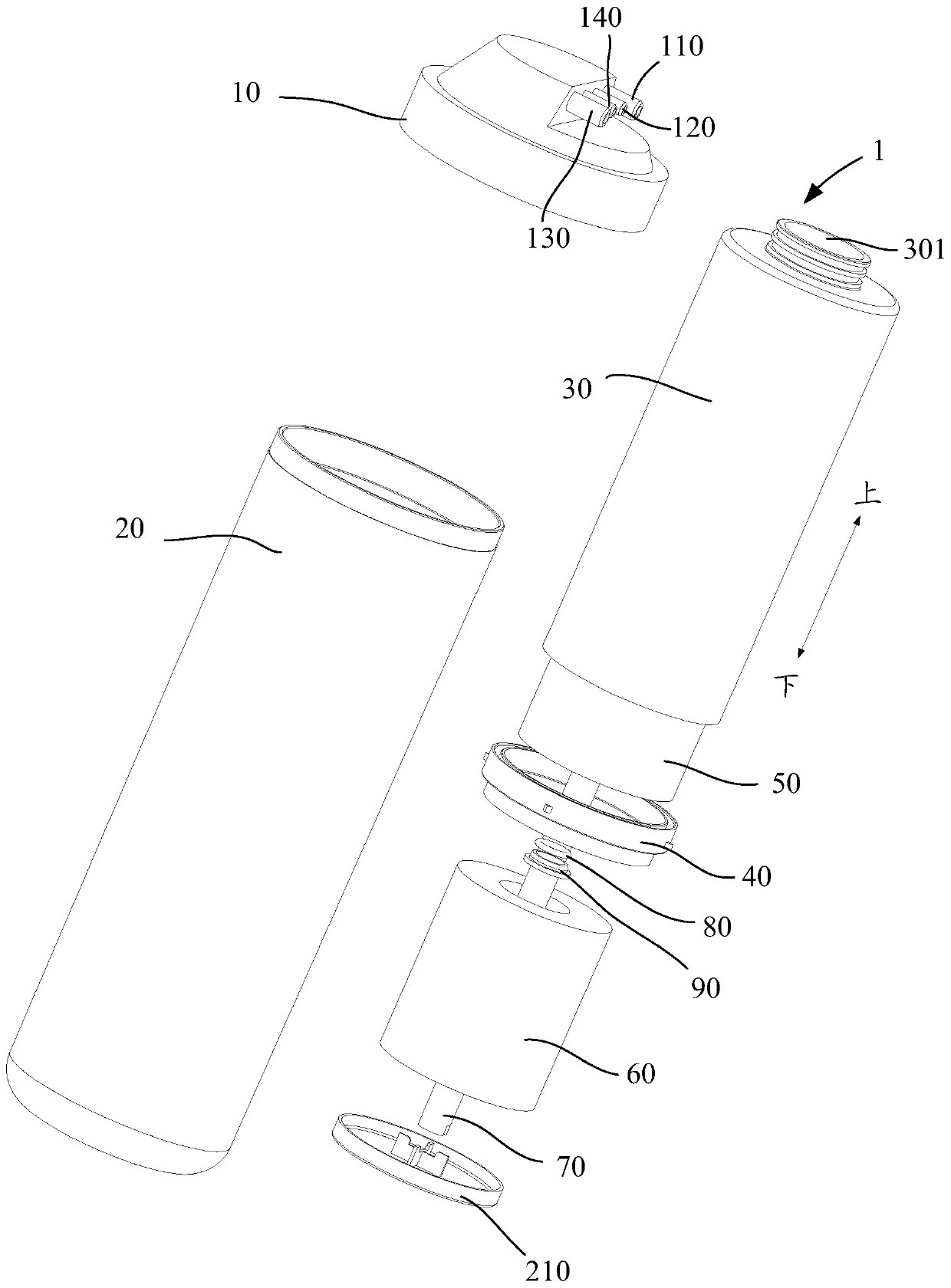

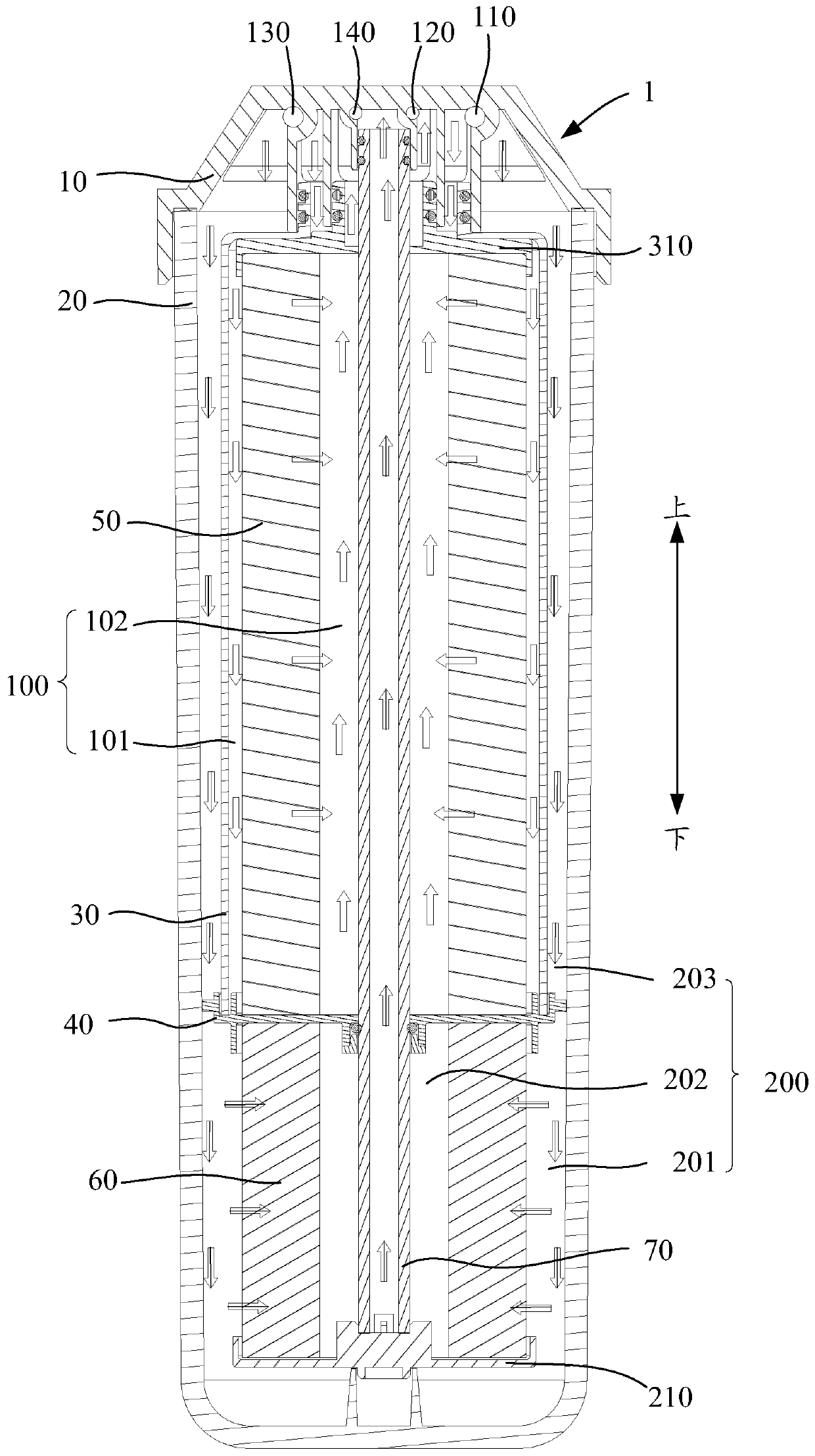

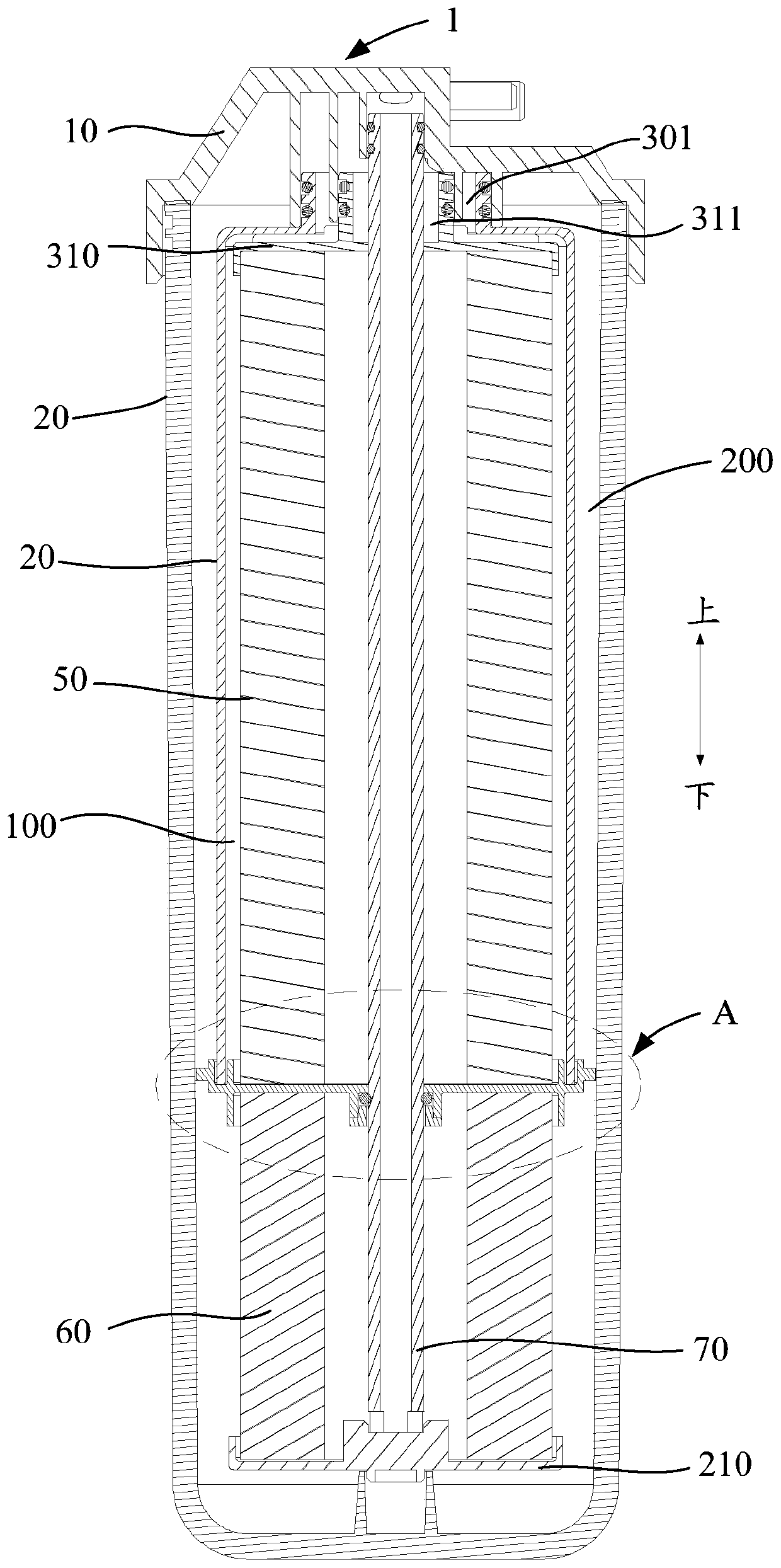

The invention discloses a composite filtration core and water purification equipment. The composite filtration core comprises: a housing with a filtration cavity inside; a separation assembly arrangedin the filtration cavity, wherein the filtration cavity is divided into mutually independent parts such as a first filtration cavity and a second filtration cavity, and the housing is provided with afirst water inlet communicated to the first filtration cavity, a first water outlet communicated to the first filtration cavity, a second water inlet communicated to the second filtration cavity anda second water outlet communicated to the second filtration cavity; a first filtration core arranged in the first filtration cavity and positioned between the first water inlet and the first water outlet; and a second filtration core arranged in the second filtration cavity and positioned between the second water inlet and the second water outlet. With the technical scheme of the present invention, the composite filtration core has the two independent filtration channels, such that the two kinds of water can be respectively filtered, and the filtration requirements on a variety of water qualities by the user can be met.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

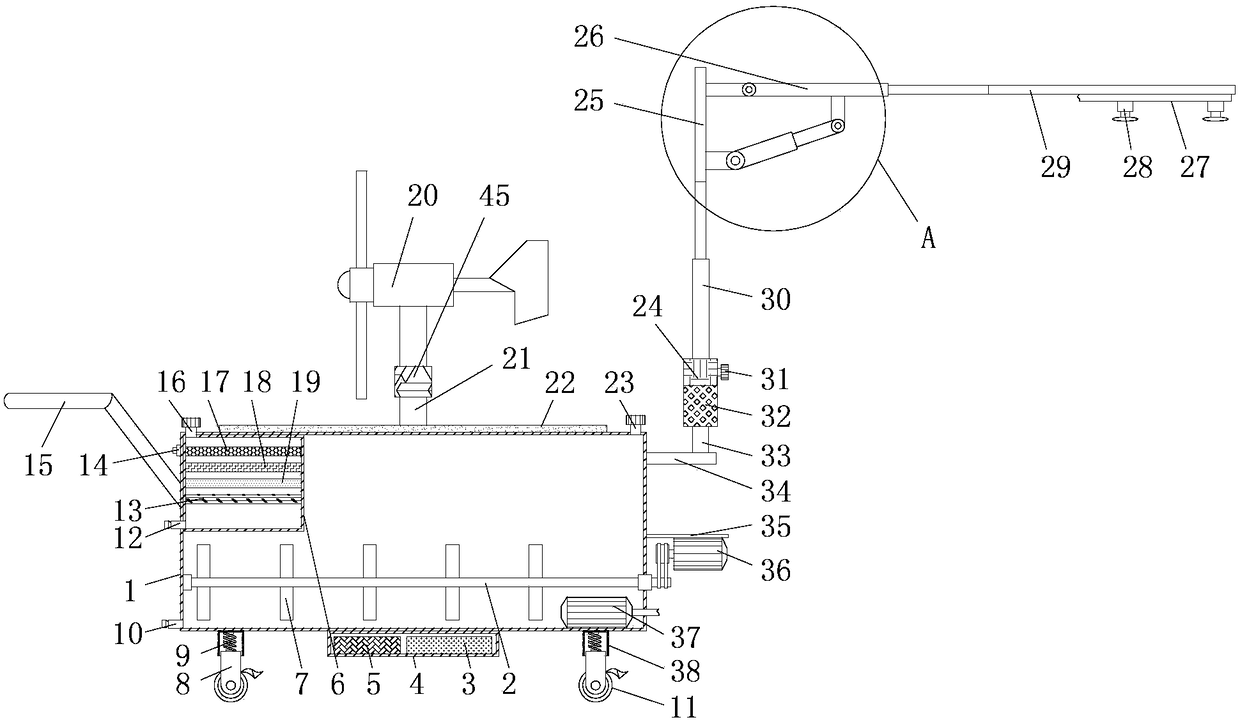

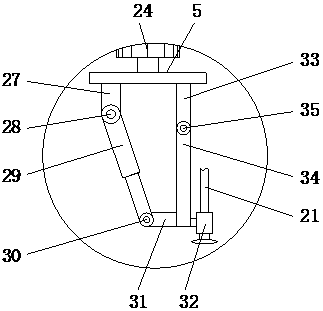

Garden watering and irrigating device

InactiveCN108308152AImprove drug spraying effectMeet Filtration NeedsRotary stirring mixersPV power plantsEngineeringSprayer

The invention discloses a garden watering and irrigating device which comprises a shell. A pump machine is fixedly mounted at the right end of an inner cavity of the shell, a rotating shaft is movablymounted at the lower end of the inner cavity of the shell, stirring blades are fixedly connected on the outer surface of the rotating shaft, and a clear water tank is fixedly connected at the left end of the top of the inner cavity of the shell. According to the device, a second supporting rod is fixedly connected at the right end of the top of a third supporting rod, sixth supporting rods and fourth supporting rods are sequentially and fixedly connected on the right side of an eighth supporting rod from top to bottom, adjusting requirements of people for horizontal positions, vertical positions, inclined angles and telescopic lengths of a steering sprayer are met through actions of a second bearing block, a sleeve, a screw hole, a fastening screw, a first electric telescopic rod, a thirdmovable joint, a second electric telescopic rod, a first movable joint, a third electric telescopic rod, a second movable joint and a fifth supporting rod, and great convenience is provided for watering and irrigating operation of people.

Owner:李元珍

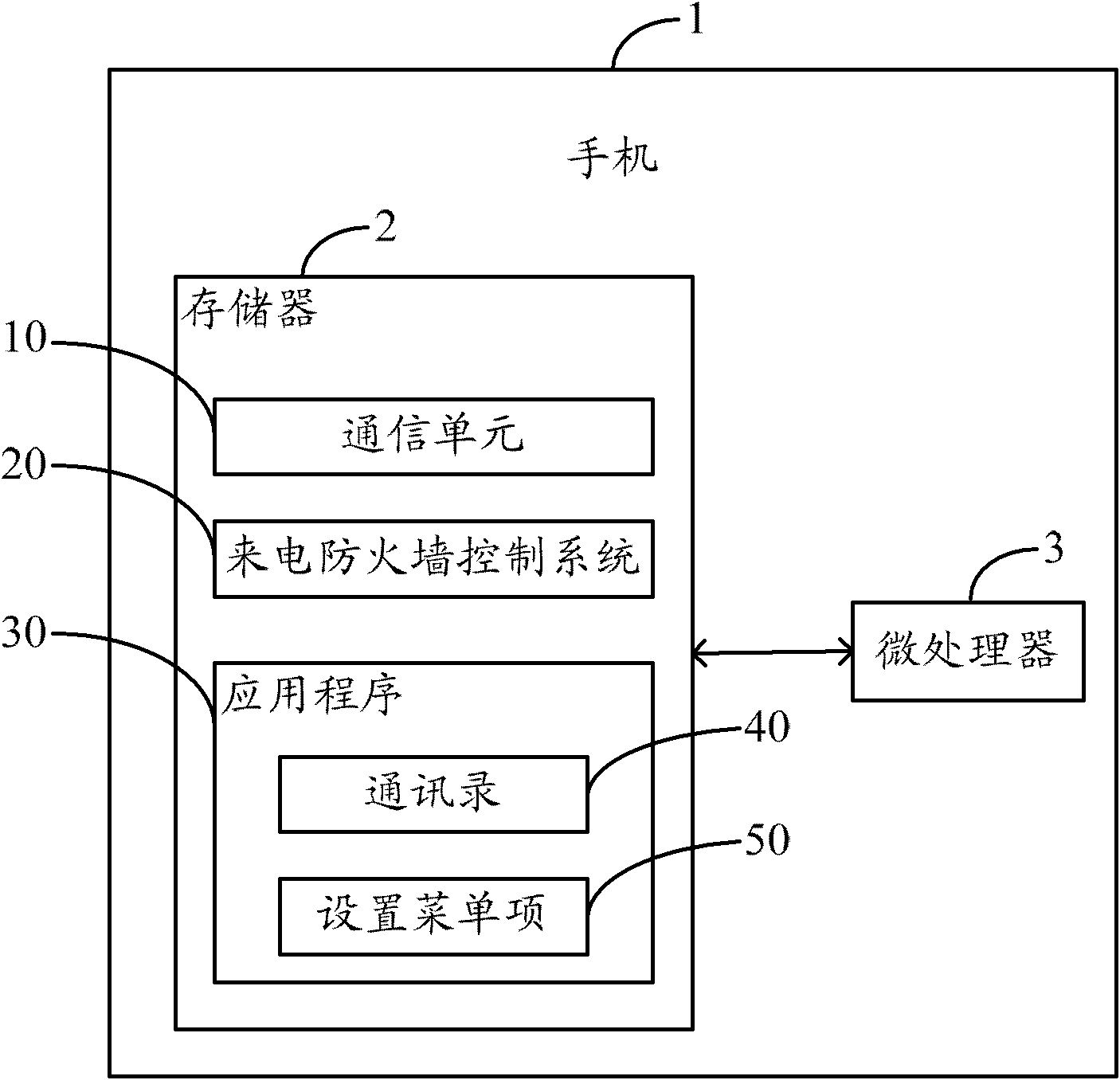

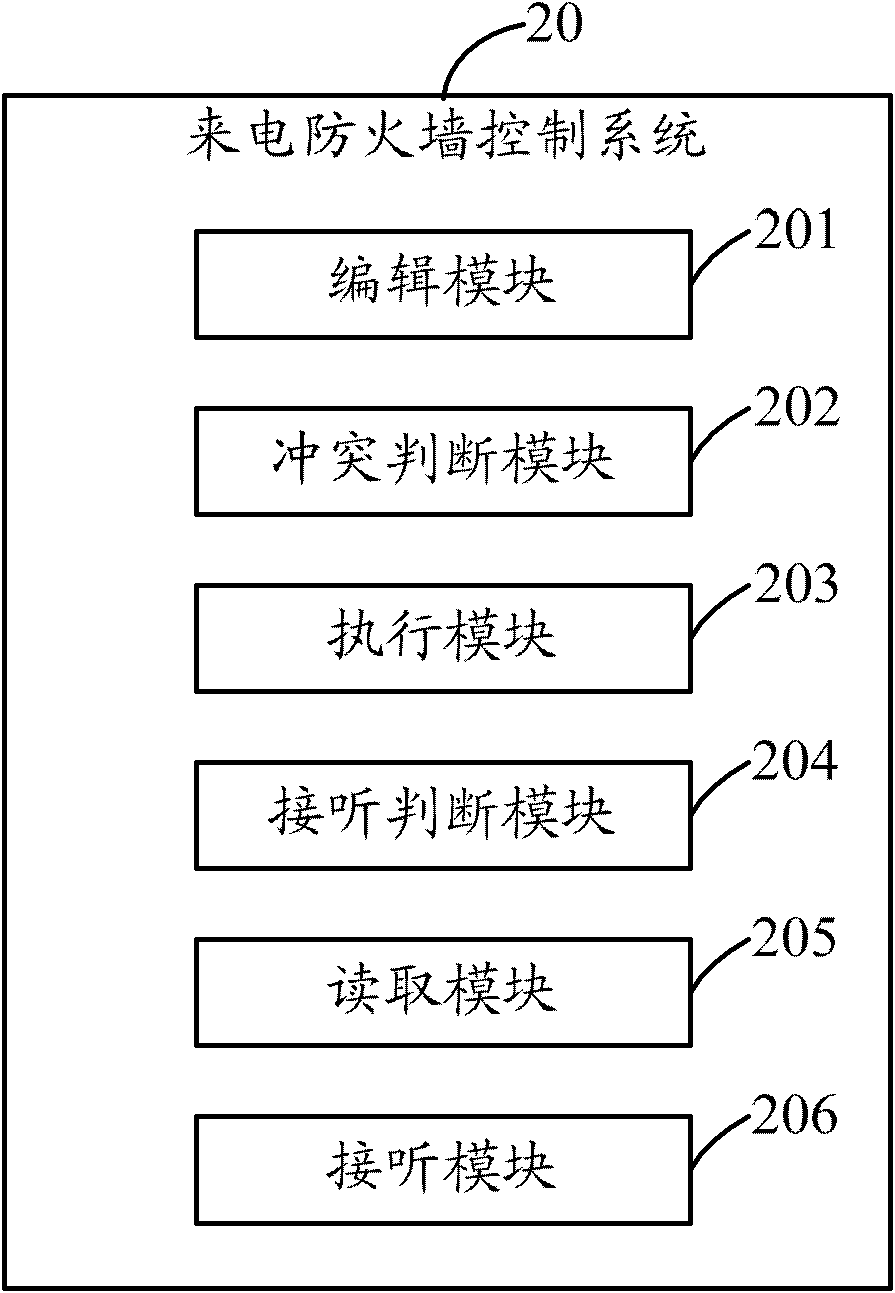

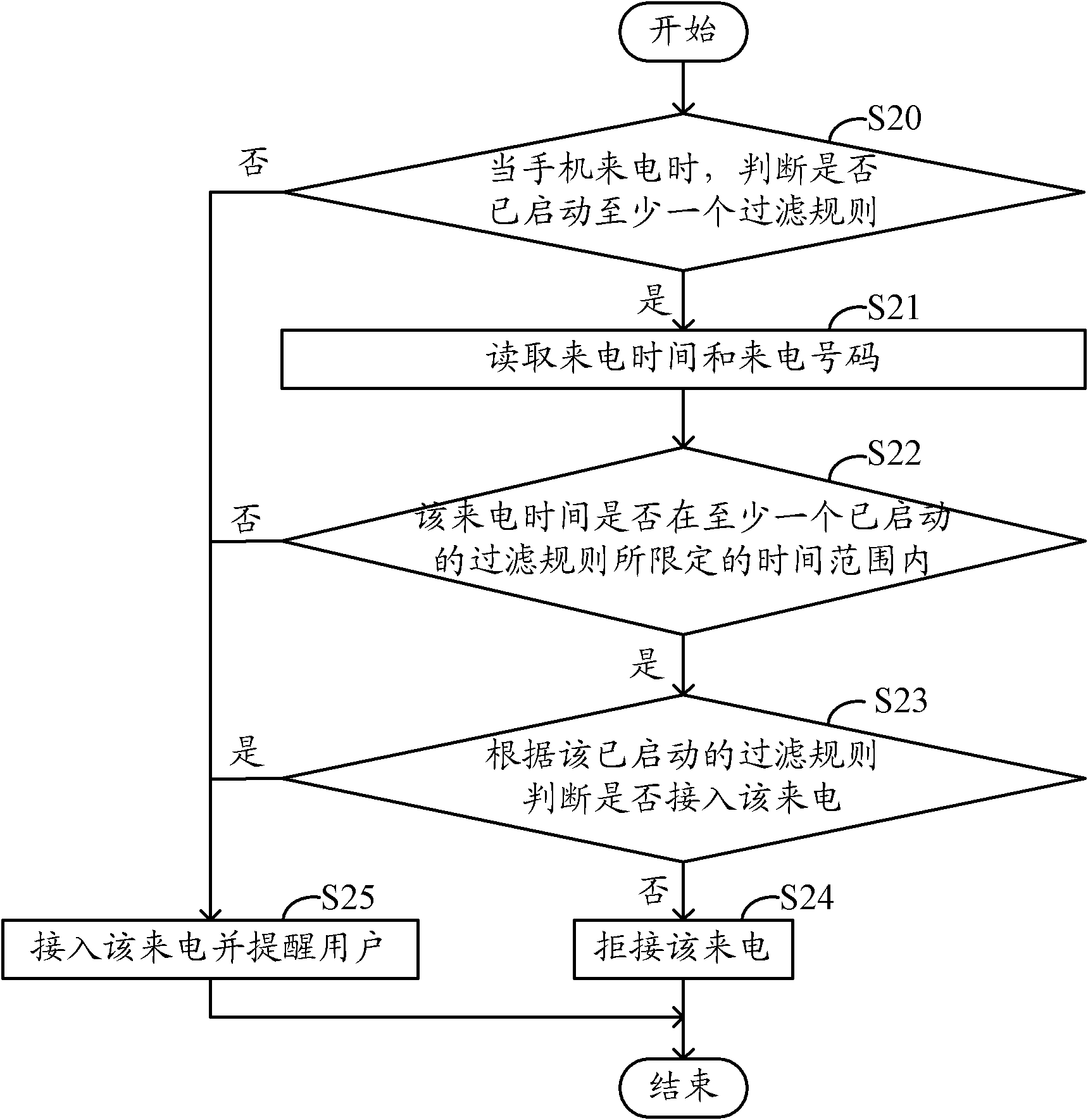

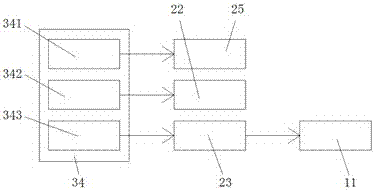

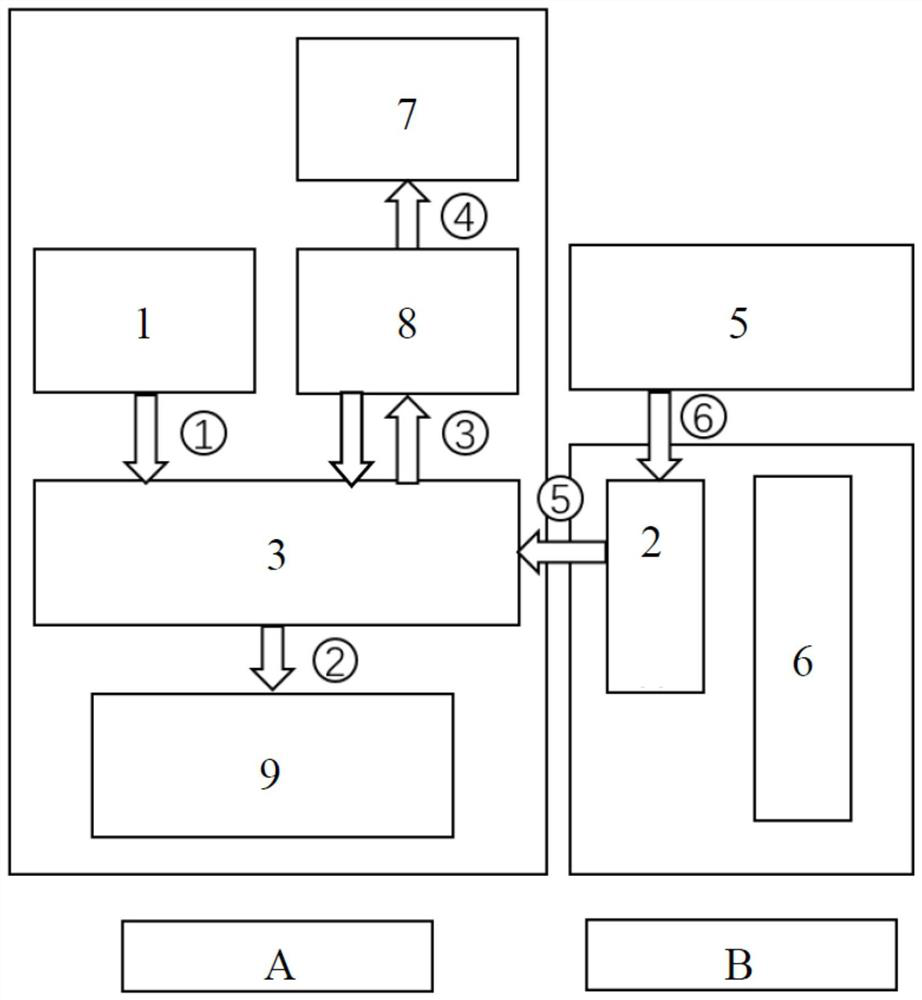

Mobile phone call firewall control system and method

InactiveCN102487412AFlexible filteringMeet Filtration NeedsSubstation equipmentTime rangeControl system

The invention discloses a mobile phone call firewall control system. The system comprises an answering judging module, a reading module and an answering module, wherein the answering judging module is used for judging whether at least one filtering rule is started or not when a mobile phone is called and is also used for judging whether the call is connected or not when the call time is within the time range limited by at least one started filtering rule; the reading module is used for reading calling time and a calling number when the at least one filtering rule is started; and the answering module is used for connecting the call when the filtering rule is not started, or the calling time is not within the time range limited by at least one started filtering rule, or the call is judged to be connected, and is also used for refusing the call when the call is judged to be refused. The invention also provides a mobile phone call firewall control method. By the method, mobile phone calls in different times can be flexibly filtered.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

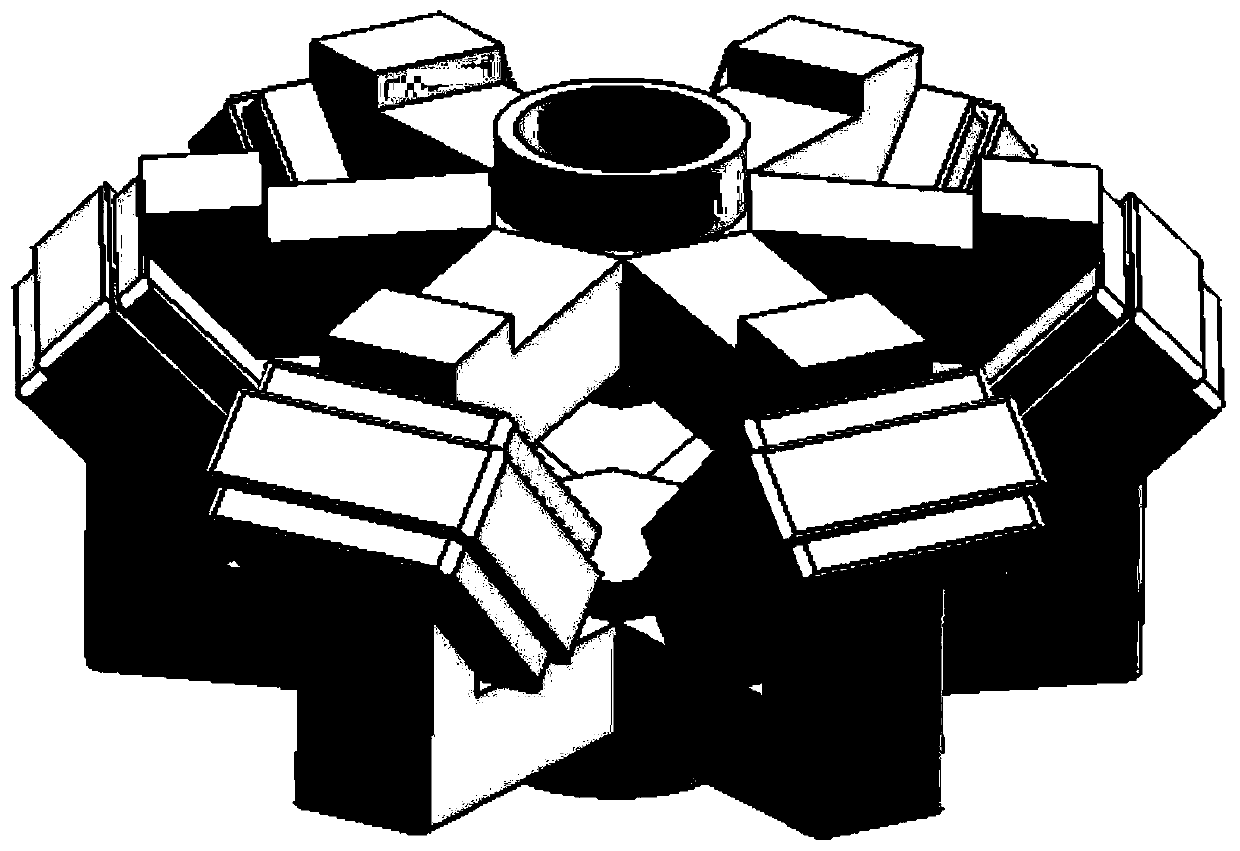

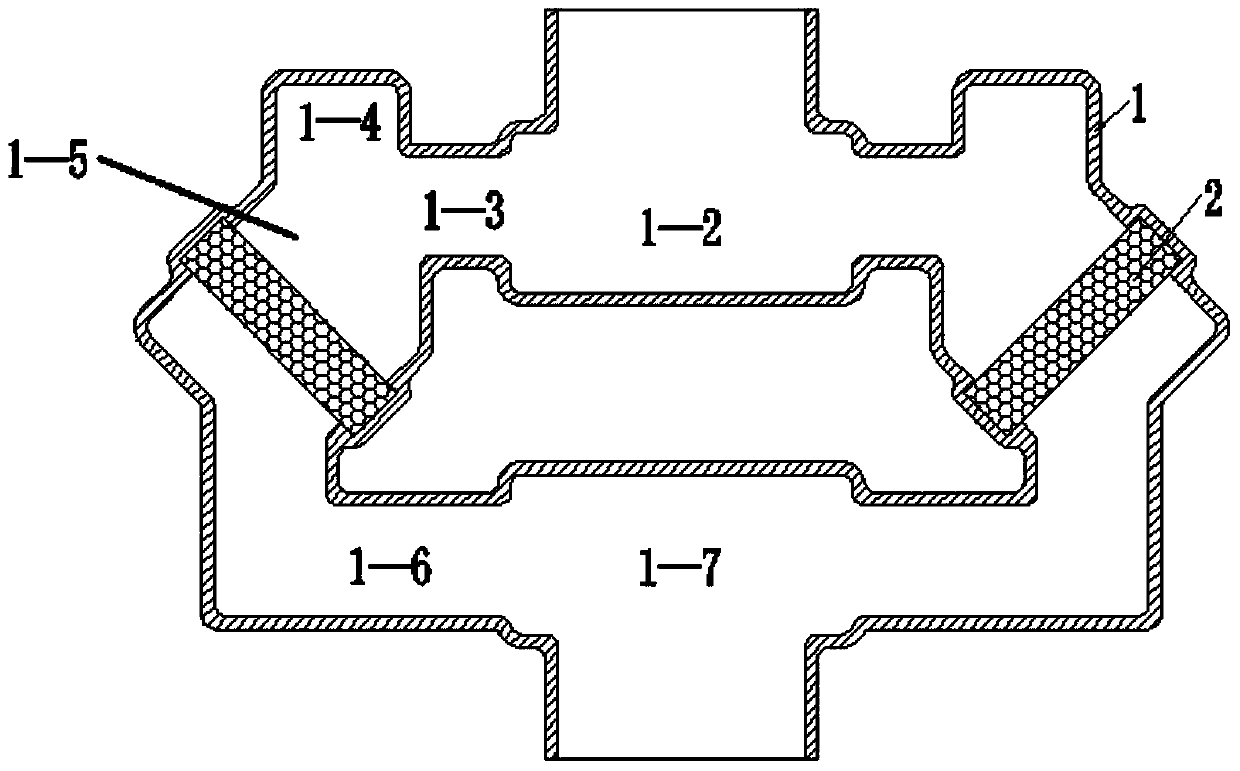

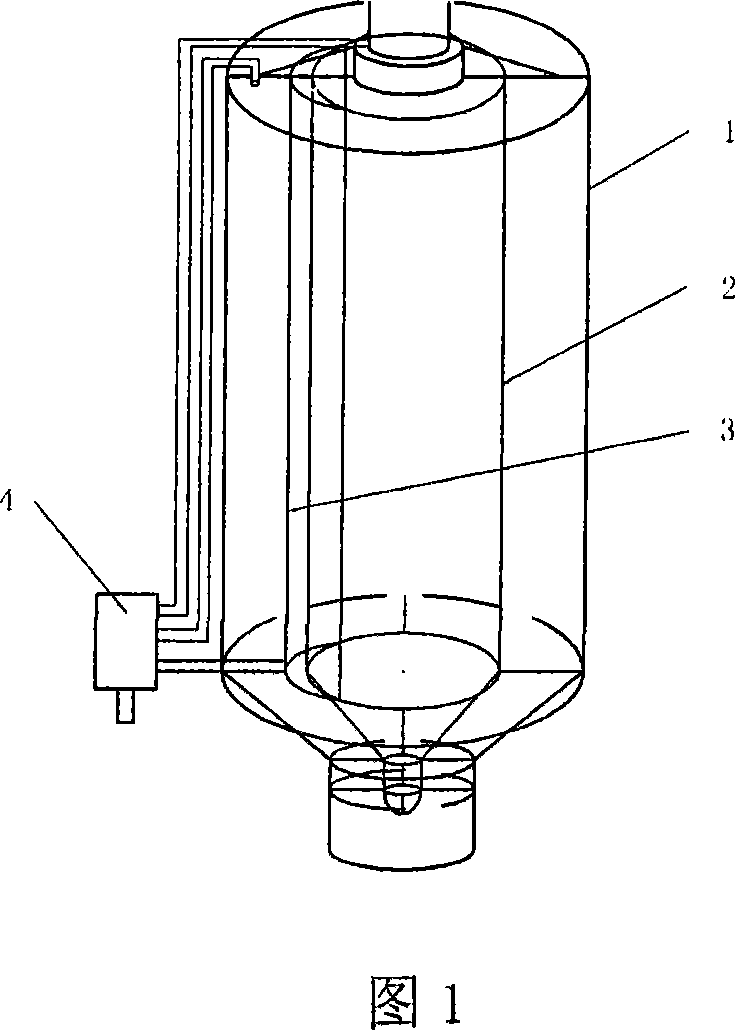

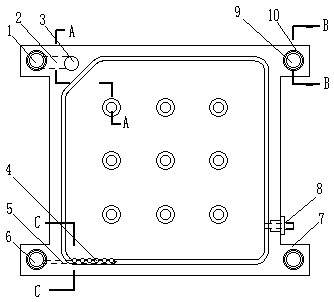

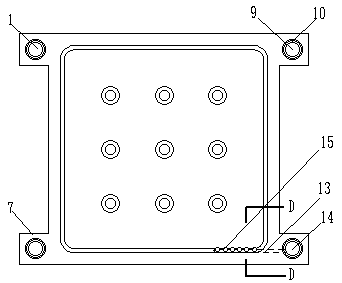

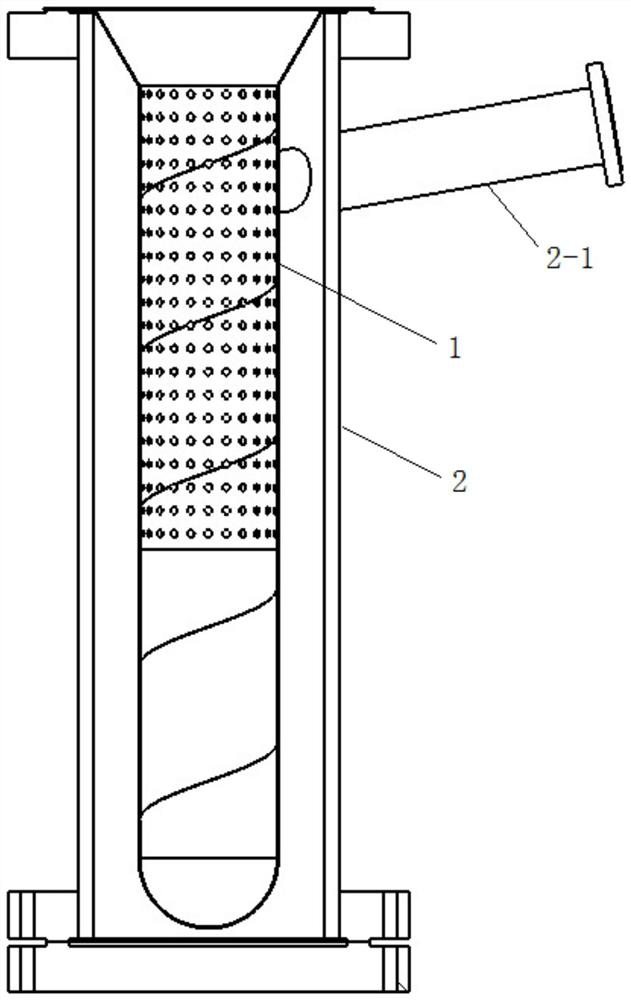

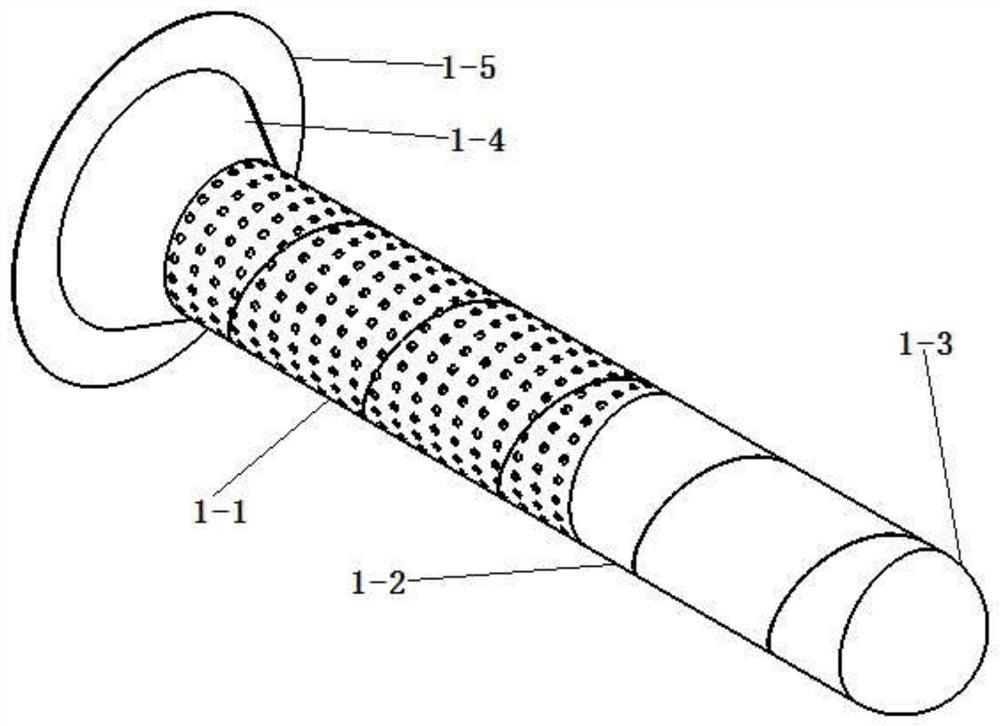

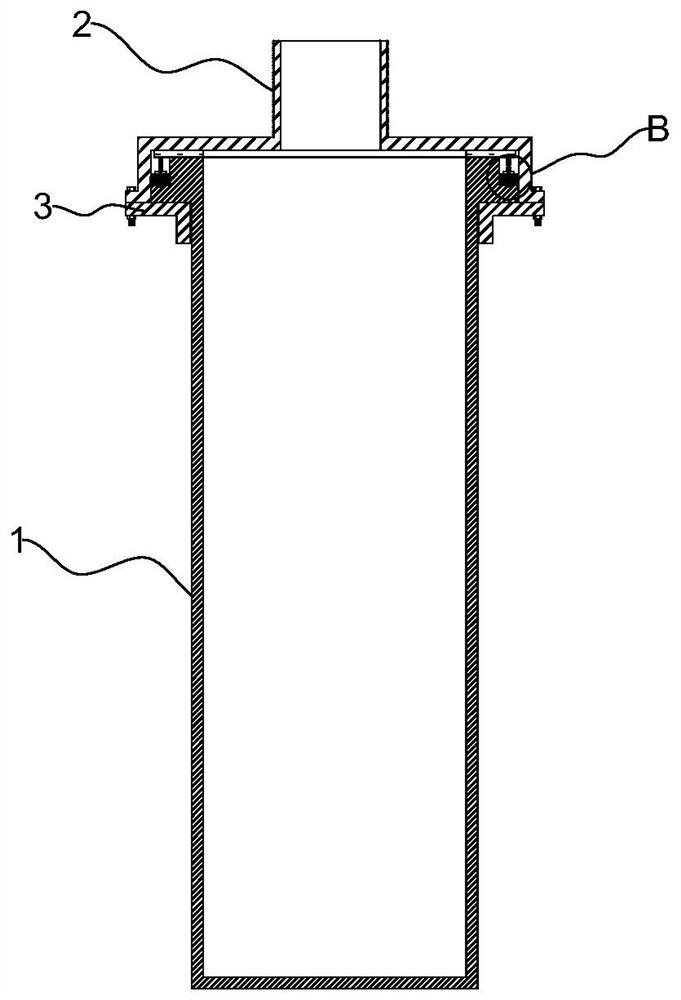

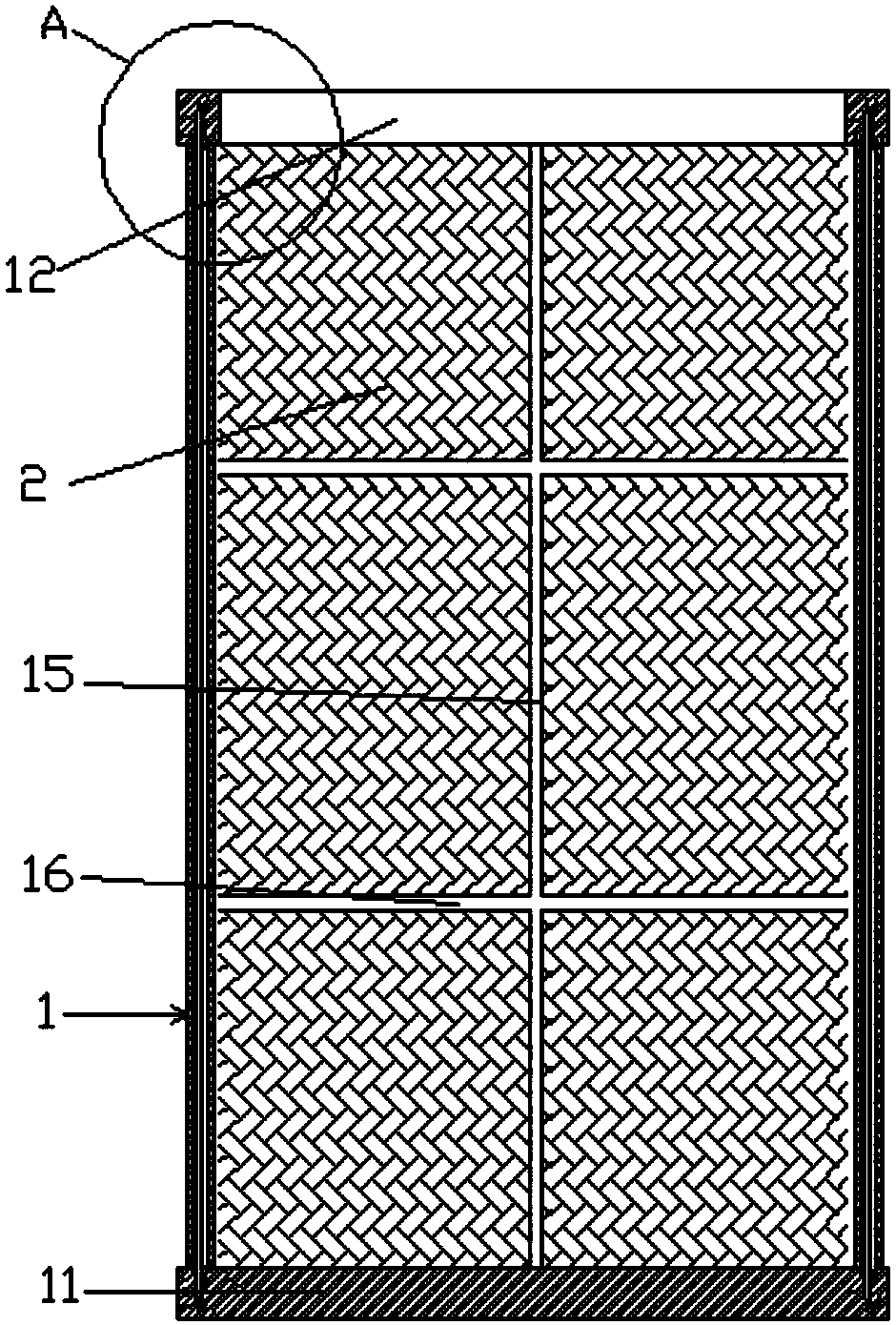

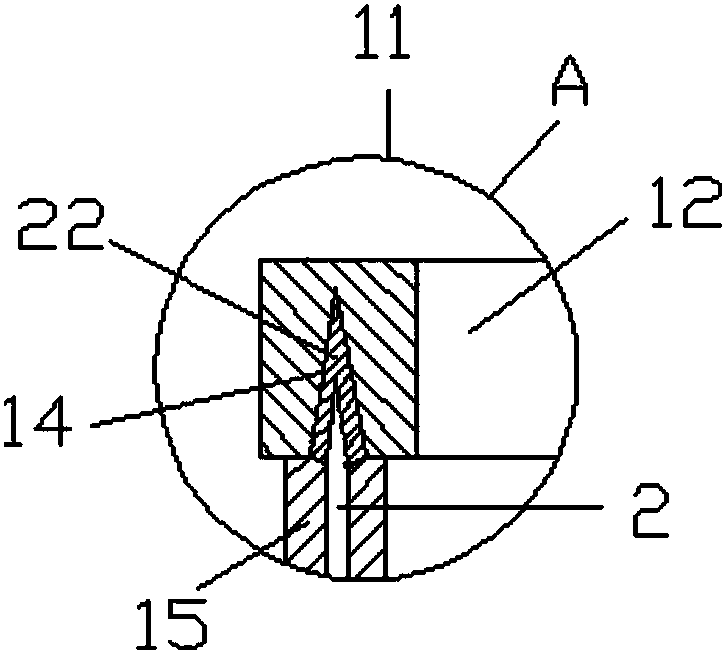

Ceramic shell filtering device integrated with filters

ActiveCN104028698AEasy to installNo need to increase thicknessFoundry mouldsFoundry coresFiltrationCasting mold

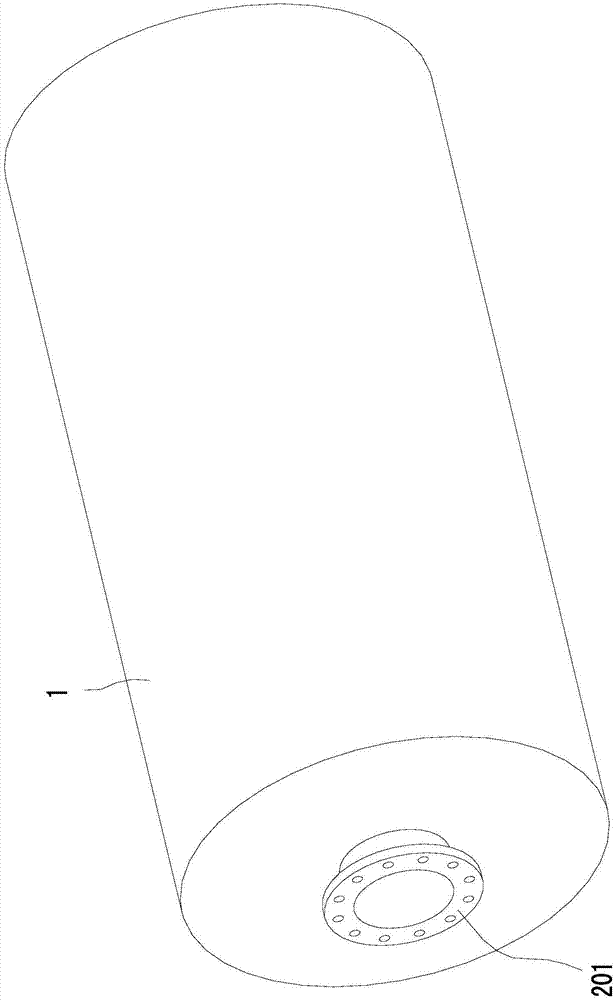

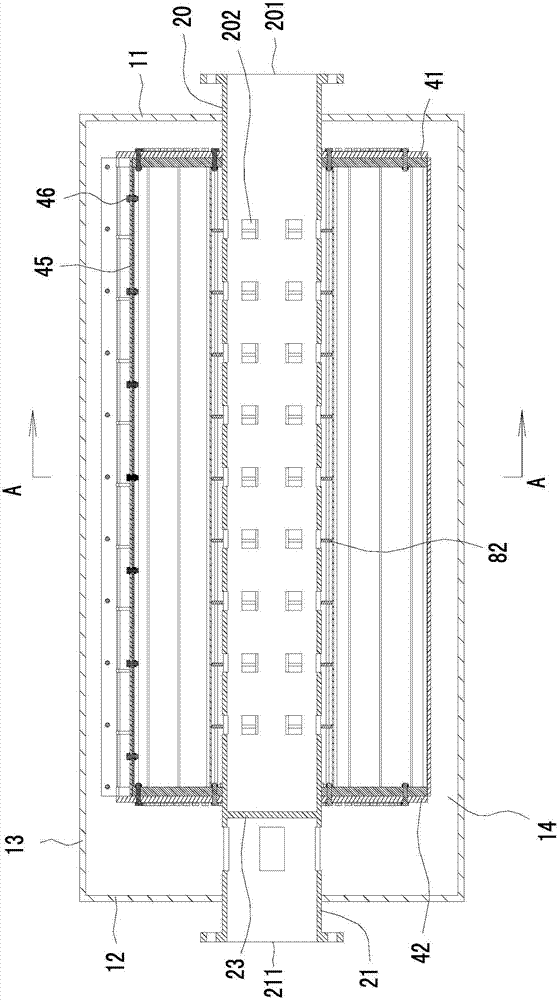

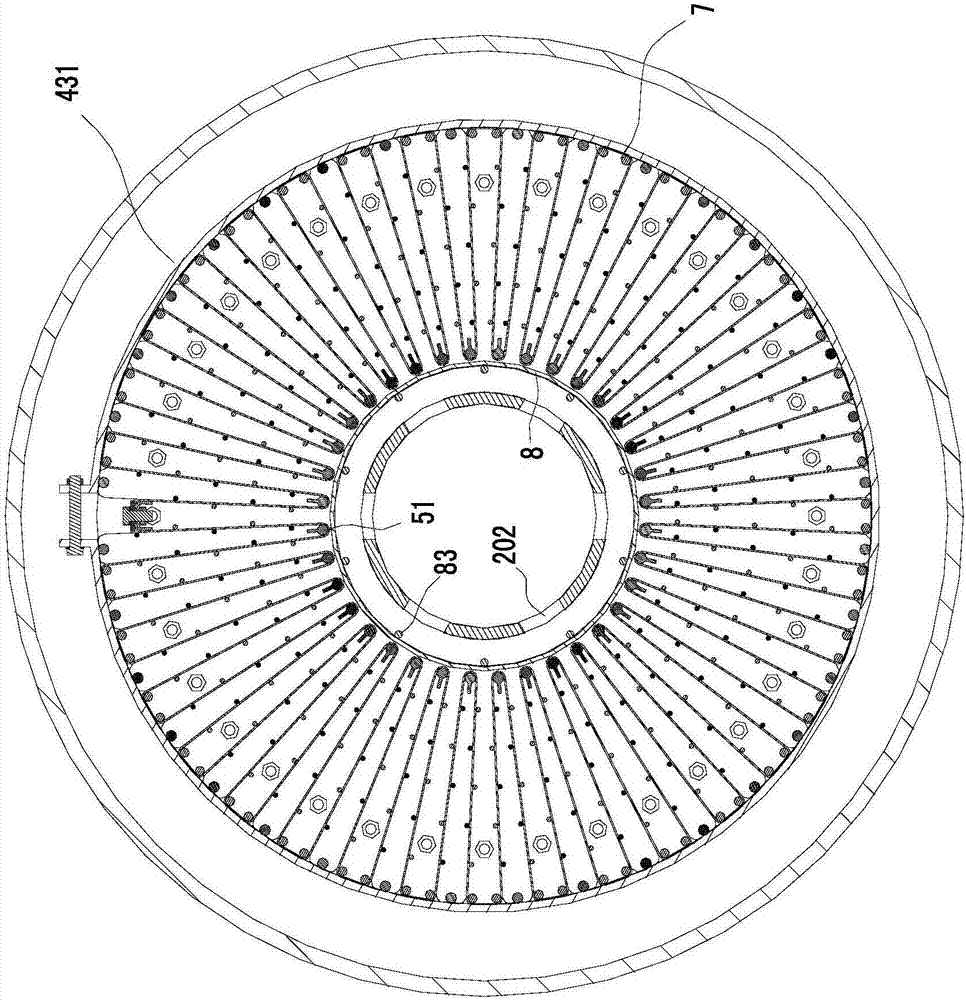

The invention relates to a ceramic shell filtering device. A ceramic shell (1) forms a cavity; the cavity comprises a shunt part (1-2) positioned at the upper part of the shell, a converging part (1-7) positioned at the lower part of the shell, and C-shaped pouring gates in the middle, wherein the upper end of the shunt part (1-2) is an inlet of the filtering device; the lower end of the converging part (1-7) is an outlet of the filtering device; the C-shaped pouring gates are connected in parallel, and are respectively communicated between the shunt part and the converging part; and each of the C-shaped pouring gates is provided with a filter (2). The ceramic shell filtering device realizes the overall filtration of high-flow molten metal outside a casting mold through the design of shunting, filtering and converging, and satisfies the overall filtering requirements of molten metal of a large cast steel piece and an ultra-large cast iron piece outside the casting mold.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

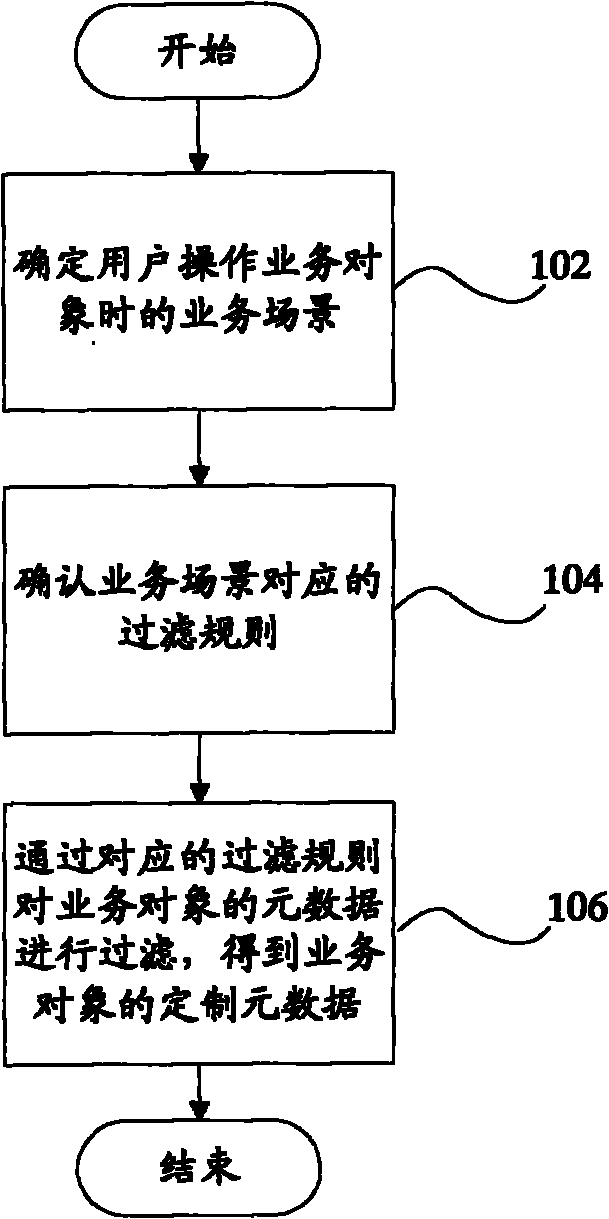

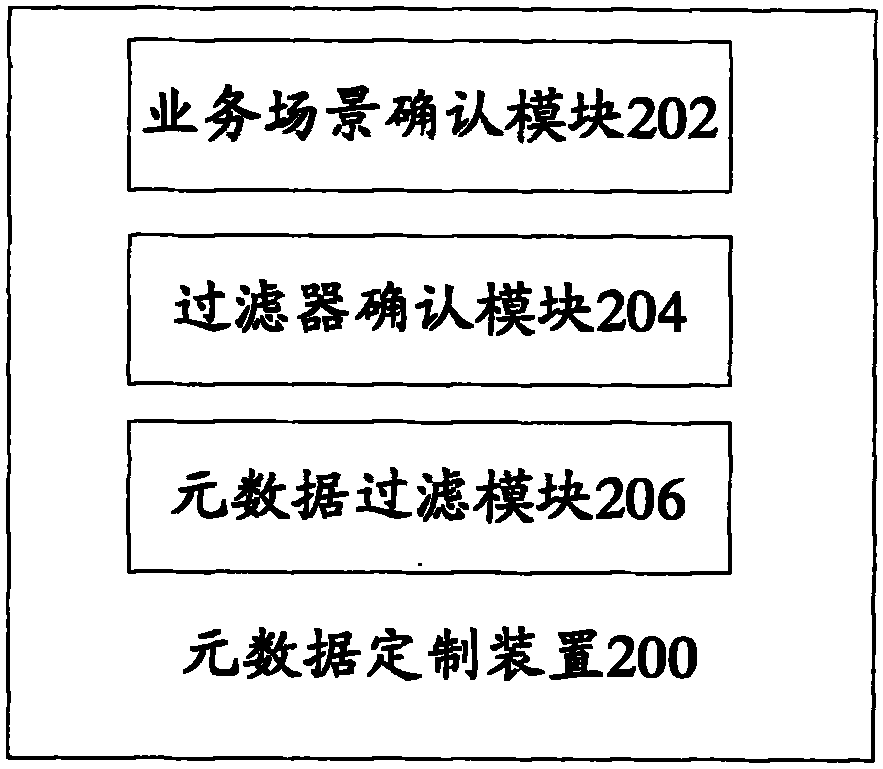

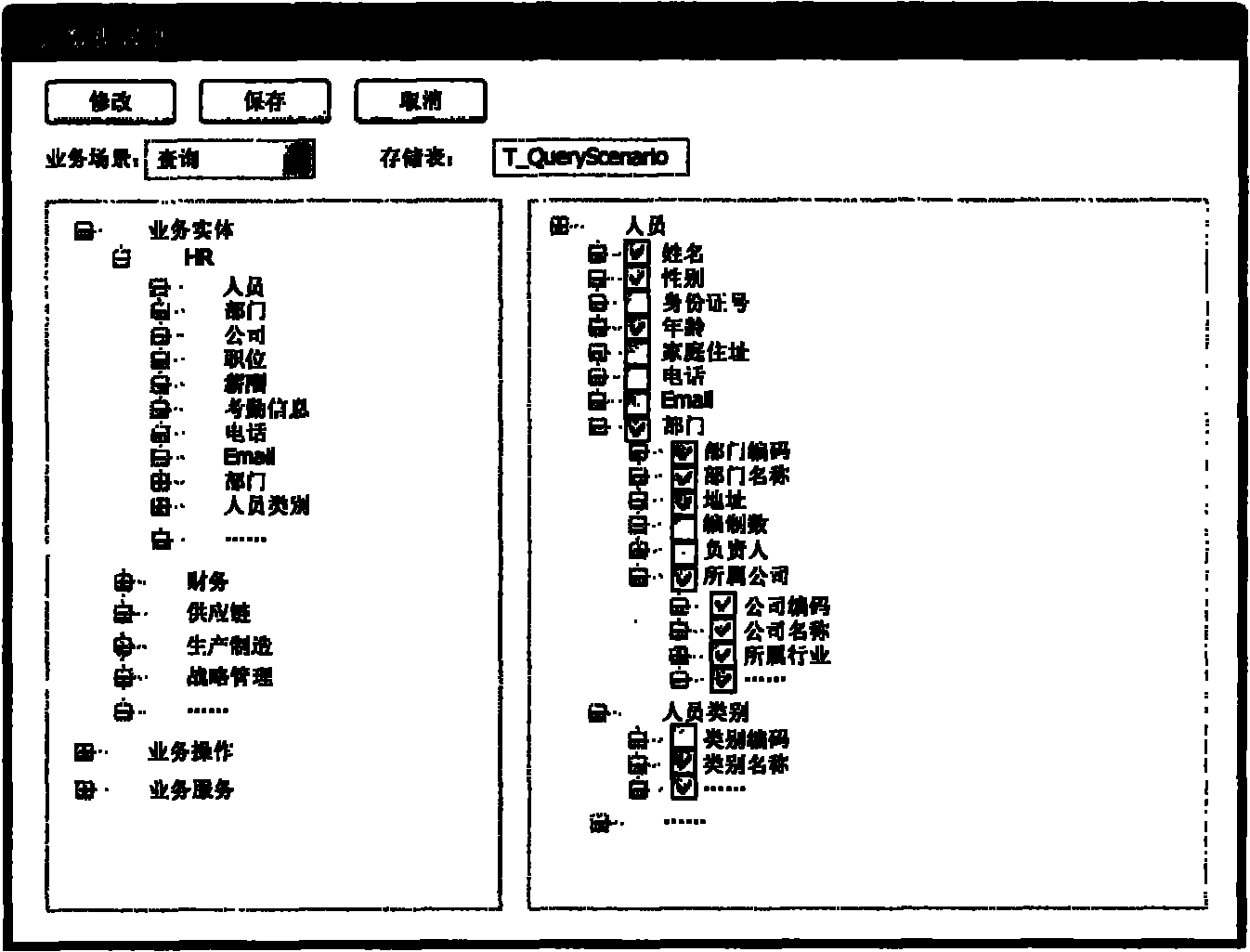

Method and device for customizing metadata

InactiveCN101944209AMeet Filtration NeedsImprove development efficiencySpecial data processing applicationsFiltering rulesUsability

The invention provides a method for customizing metadata. The method comprises the following steps of: (102) determining a service scene when a user operates a service object; (104) determining a filtering rule corresponding to the service scene; and (106) filtering the metadata of the service object through the corresponding filtering rule so as to obtain customized metadata of the service object. The invention further provides a device for customizing the metadata. The device is characterized by comprising a service scene confirmation module, a filter confirmation module and a metadata filtering module, wherein the service scene confirmation module is used for determining the service scene when the user operates the service object; the filter confirmation module confirms a filter corresponding to the service scene; and the metadata filtering module filters the metadata of the service object through the corresponding filter so as to obtain the customized metadata of the service object. According to the technical scheme of the invention, metadata filtering needed by different service scenes can be realized, the customization of the metadata by different users can be supported and the usability and flexibility of a software product developed based on the metadata are improved greatly.

Owner:YONYOU NETWORK TECH CO LTD

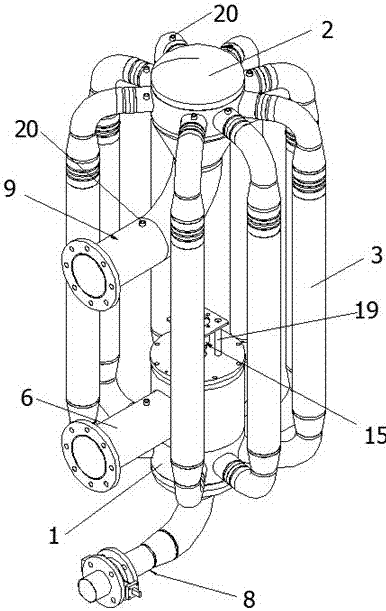

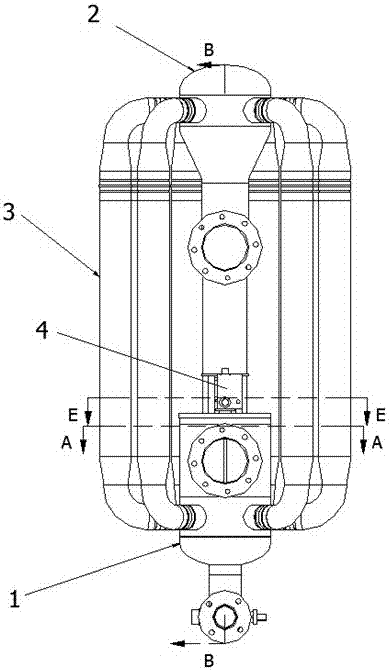

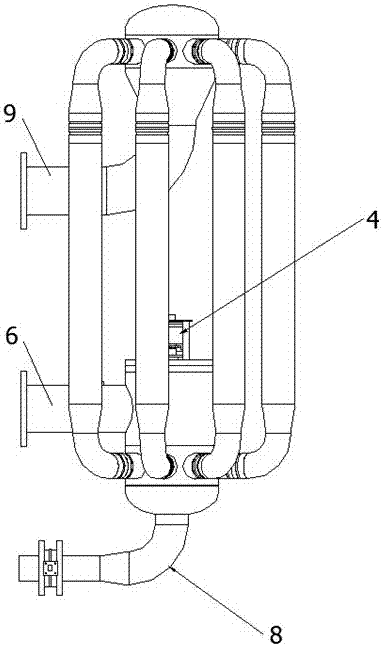

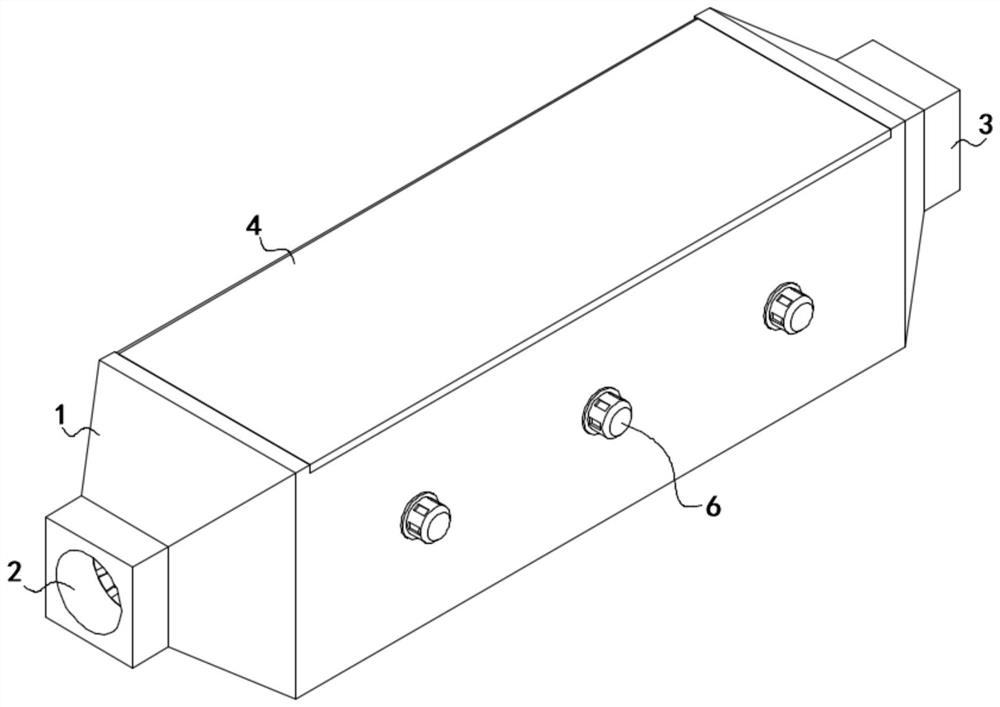

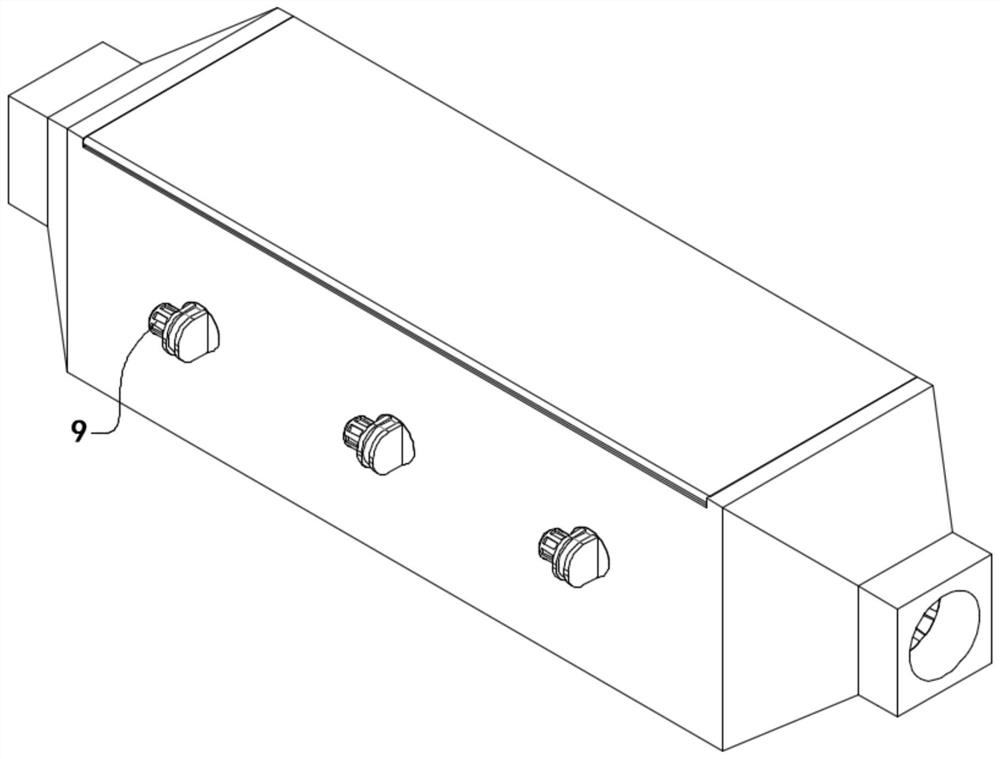

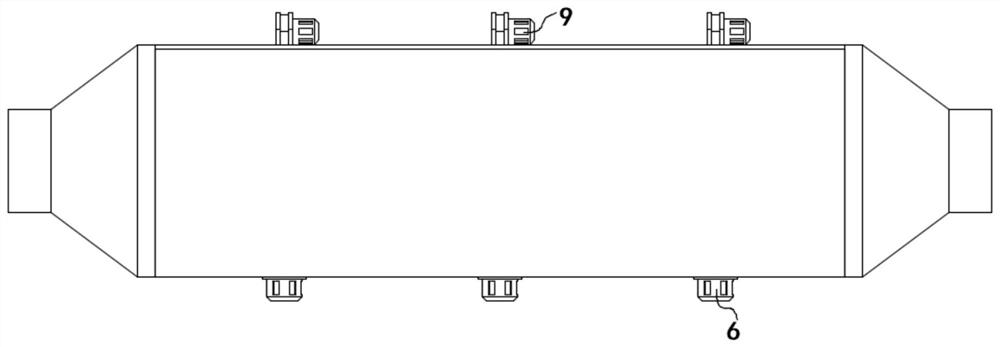

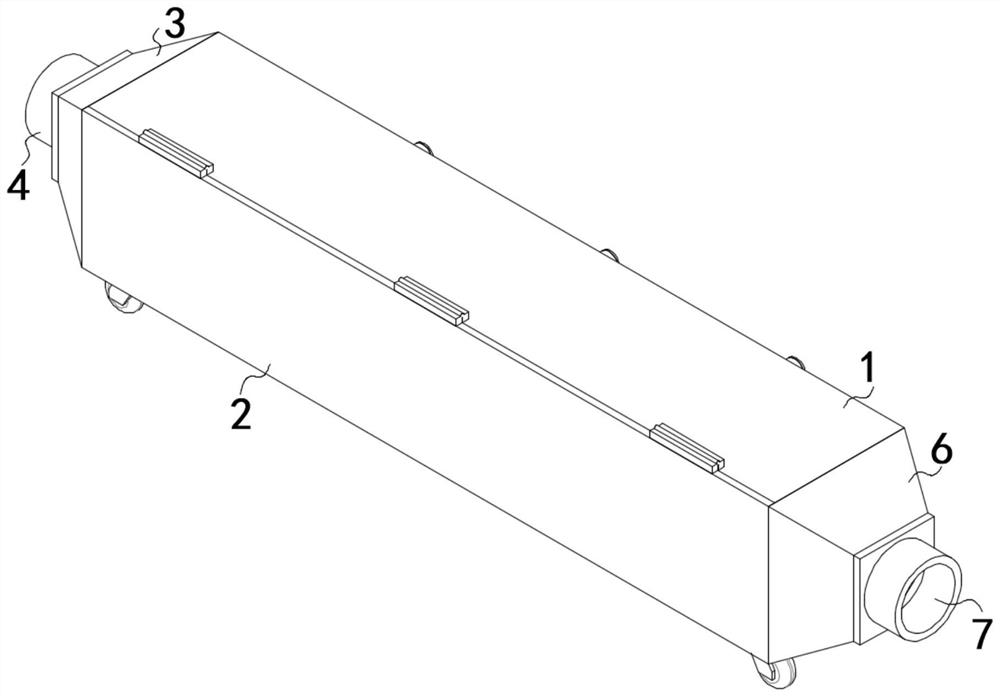

Fully-automatic shell-and-tube type reverse-washing filter and filtering method thereof

InactiveCN107096272AFiltration flow is largeSmall footprintUltrafiltrationStationary filtering element filtersWater dischargeTubes types

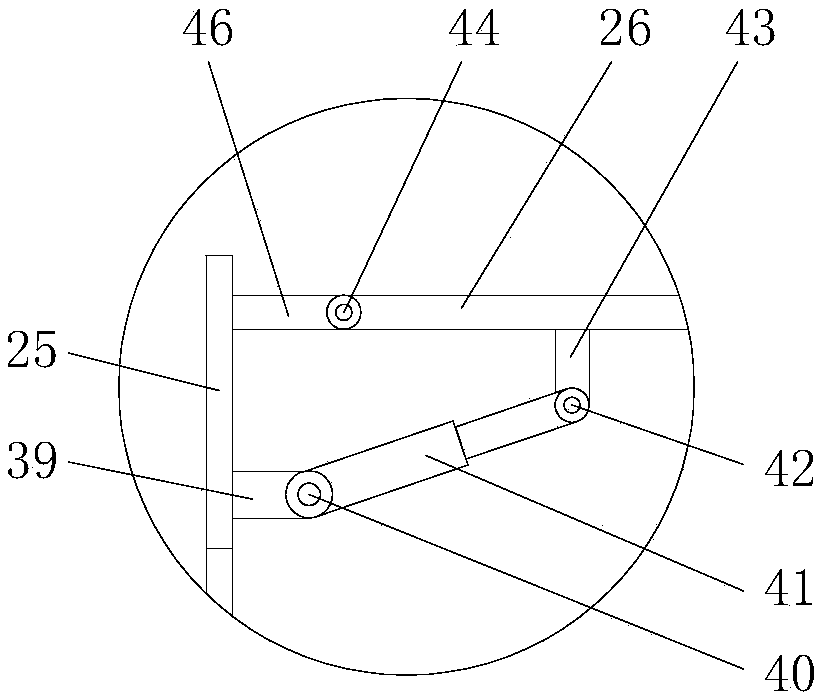

The invention discloses a fully-automatic shell-and-tube type reverse-washing filter and a filtering method thereof. The fully-automatic shell-and-tube type reverse-washing filter comprises an inlet branched seal head, an outlet branched seal head, a plurality of filtering tube, a steering mechanism and a controller; a water inlet pipeline is arranged at the upper part of the inlet branched seal head; a plurality of water inlet holes are formed in the seal head wall of the lower part of the inlet branched seal head in the circumferential direction uniformly; a dirt discharge pipeline is arranged at the bottom of the inlet branched seal head; a water discharge pipeline is arranged at the lower part of the outlet branched seal head; a plurality of water outlet holes are formed in the seal heal wall of the upper part of the outlet branched seal head in the circumferential direction; a pressure sensor is arranged on each of the water inlet pipeline, the water discharge pipeline and each filtering tube; all the pressure sensors are electrically connected with the controller. The fully-automatic shell-and-tube type reverse-washing filter has large filtering flow, can meet the filtering requirement with filtering precision being 1 to 610 microns and is widely applied; in the process of reversely washing the blocked filtering tube, other filtering tube still can perform filtering operation, so the working efficiency of the filter is improved.

Owner:上海伶尔亿环境工程有限公司 +1

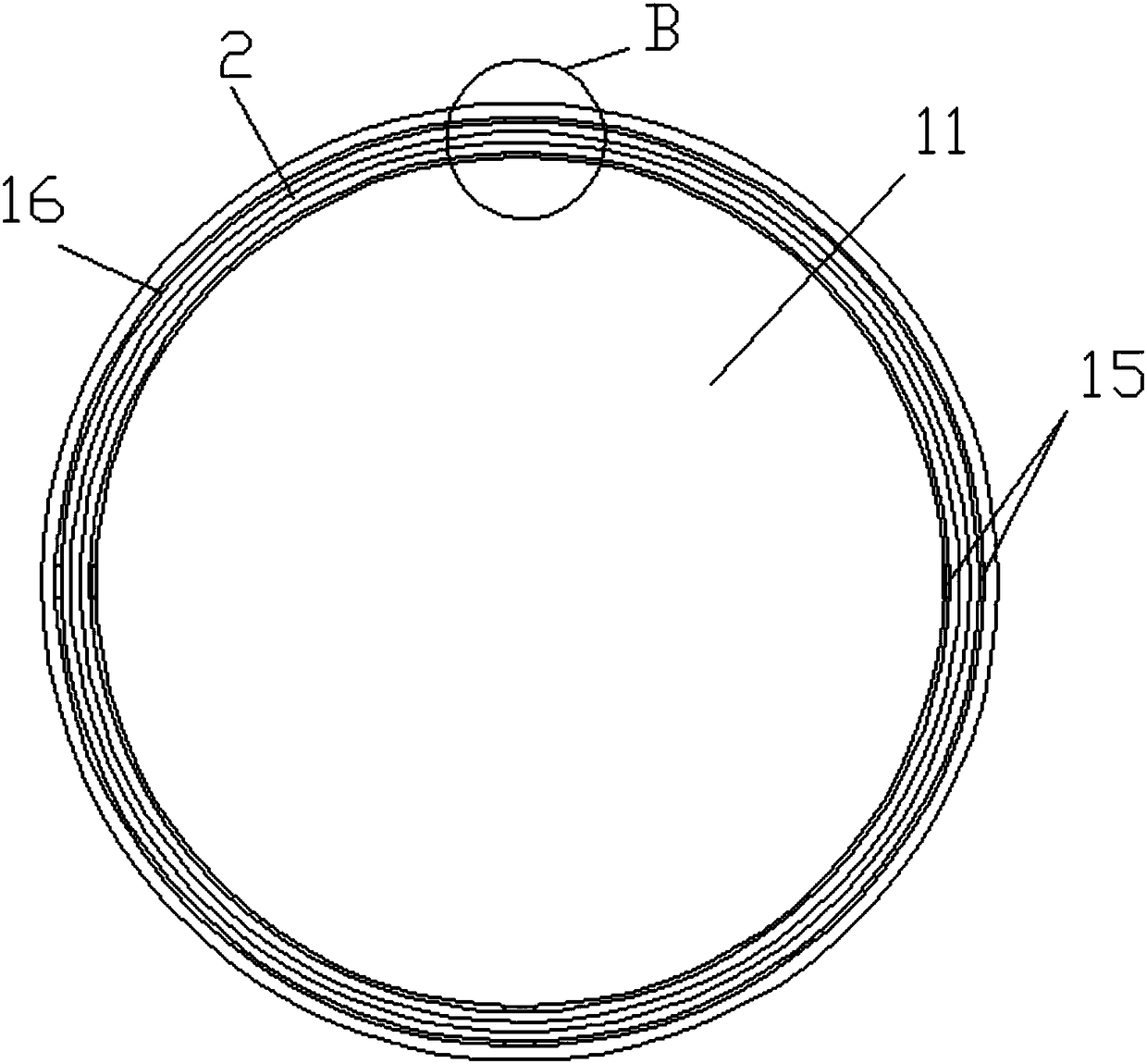

Self-flushing intermittent filter

InactiveCN101073728ASolve the automatic flushing problemMeet Filtration NeedsMoving filtering element filtersImpellerFiltration

The invention is concerned with a batch self-flush filter, relating to filter shell, revolving filter core body, self flush implement and batch control valve. The filter shell is made up of cylinder type of crust, upper cover, down cover and bolt of splint, and the filter core body is a cylinder made of core bracket connecting with upper and down covers through bolts. The filer net is on outside of the bracket, and the filter core body connects with filter shell in type of bearing. The down cover of filter core body is made up with impeller as a whole and crescent type of self-flush implement insert on the upper cover of filter shell and the groove of splint. The different pressure control valve connects with upper cover, main press and assistant press shell, dirt excluding shell and bolt of down cover. The press film connects with bolt, sleeve and control head through screw thread. The assistant press pipe and main press pipe connect with inner and outside press pipe of shell respectively. It completes filtration and self- flush of filter core by the energy of liquid owning press without additional power in simple installation and convenient use.

Owner:HOHAI UNIV

Micro-pore filtering membrane producing technology

InactiveCN105126651AMeet Filtration NeedsWide variety of sourcesSemi-permeable membranesDispersed particle separationThermal compressionPore diameter

The invention provides a micro-pore filtering membrane producing technology including the steps of: with polyurethane sponge being uniform in pore size in the prior art, performing thermal-compression to the polyurethane sponge with a high-temperature-resistant board at 150-220 DEG C to form the filtering membrane being 0.5-10 mm in thickness and less than 10 [mu]m in pore size. The producing technology is easy to control, is low in cost, is smoothly breathable and can be cleaned for being recycled. The filtering membrane can be used in an air purifier and such filtering products.

Owner:胡志刚

Filter bag device and dust remover

ActiveCN111389118AImprove versatilityMeet particle size requirementsDispersed particle filtrationElectrostatic separationProcess engineeringMechanical engineering

The invention discloses a filter bag device and a dust remover. The filter bag device comprises an elastic filter bag and a bag cage arranged in the elastic filter bag, wherein the bag cage can adjustthe size of filter holes of the elastic filter bag. According to the filter bag device, by adopting the elastic filter bag, the elastic filter bag can deform, and the bag cage capable of adjusting the size of the filter holes of the elastic filter bag is adopted, when the size of dust needing to be filtered is changed, the size of the filter holes of the elastic filter bag can be adjusted throughthe bag cage to meet the filtering requirement, the universality of the elastic filter bag is effectively improved, the requirements of different dust particle sizes can be met, namely the requirements of different smoke and different coal types are met, and the dust removing effect of the dust remover is improved; meanwhile, when the elastic filter bag is deformed, a dust layer on the elastic filter bag can fall off, and the service life of the elastic filter bag is prolonged; by adjusting the pore size of the filter holes of the elastic filter bag, the filtering resistance of the elastic filter bag is reduced, the energy consumption of a fan is reduced, and the service life of the elastic filter bag is prolonged.

Owner:FUJIAN LONGKING

Textile humidifying device

InactiveCN107254748AMeet scraping needsGuaranteed humidityTextile treatment machine arrangementsTextile treatment by spraying/projectingArchitectural engineeringProduction quality

The invention discloses a textile humidifying device, which comprises a casing, the middle end on the left side of the inner cavity of the casing is fixedly connected with a first spray seat through a first hollow tube, and the upper left end of the inner cavity of the casing is fixedly installed with a first spray seat. Mounting seat, the right side of the first mounting seat is fixedly connected with the first sleeve, the inner cavity of the first sleeve is movably connected with the first connecting rod through the first spring, and the upper end of the inner cavity of the housing is movably installed There is a second transmission roller, the upper right end of the inner cavity of the housing is fixedly installed with a second mount, and the left side of the second mount is fixedly connected with a second sleeve. In the present invention, the scraper is fixedly connected to the ends of the second connecting rod and the first connecting rod, and through the second spring, the second sleeve and the second mounting seat and the first spring, the first sleeve and the first mounting seat It can meet the needs of people to scrape off the moisture on the surface of the fabric, ensure the normal humidity of the fabric, and improve its production quality.

Owner:湖州南浔贵丰纺织有限公司

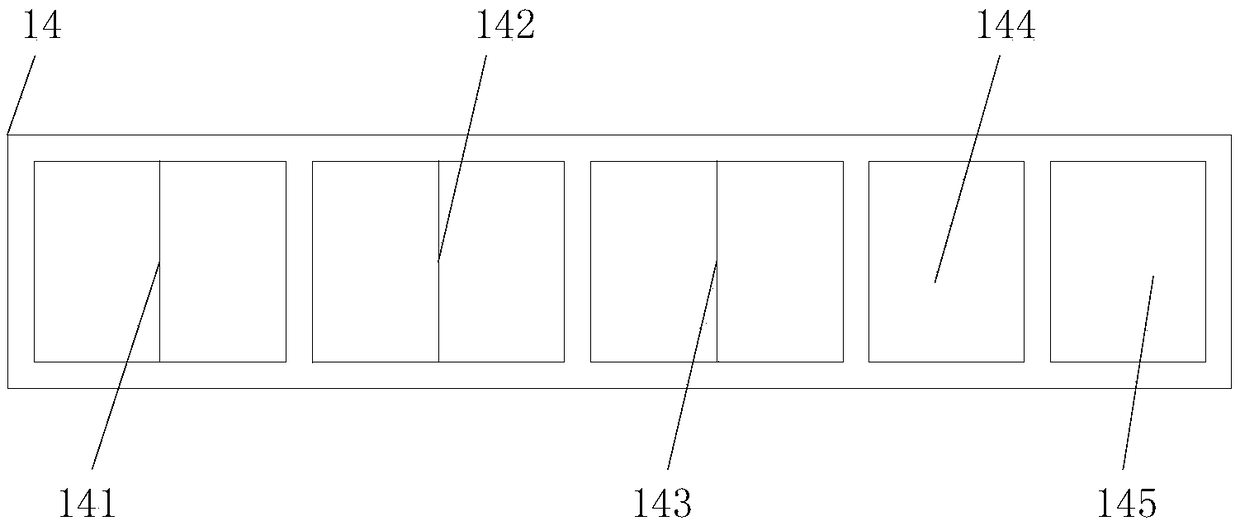

Method for material feeding and liquid discharging of combined diaphragm filter plate

InactiveCN109550288AReduce moisture contentImprove sealingFiltration separationEngineeringSingle chamber

The invention relates to a method for material feeding and liquid discharging of a combined diaphragm filter plate. According to the invention, a core plate is formed at the middle of a main board, diaphragms are formed at both sides of the main board, and the diaphragms and the core plate are integrally joined by heat fusion to form the integral diaphragm filter plate; and a lateral side of the main board is provided with a press hole, a material feeding passage is arranged at an outer ear part of the left upper corner of the main board, a single-chamber material feeding hole is connected with the material feeding passage, a flow-splitting hole is connected with the single-chamber feeding hole, the flow-splitting hole is connected to filter chambers on both sides of the main board, the main board and a matching board are combined to form a set of filtering unit, and the structure of the matching board is a box type filter plate. When filtering, a material enters the single-chamber feeding hole through a left-corner feeding channel of the main board, and enters a filtering chamber through the flow-splitting hole, a filtrate enters a left liquid outlet hole from a left lower cornerof one main board filter chamber, the left liquid outlet hole is connected to a left dark flow hole for discharging of the filtrate, and the filtrate in the filter cake is further reduced by pressingof a main board diaphragm, so that energy is saved, production cost is reduced, market filtration demands are met, and economy benefit is improved.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

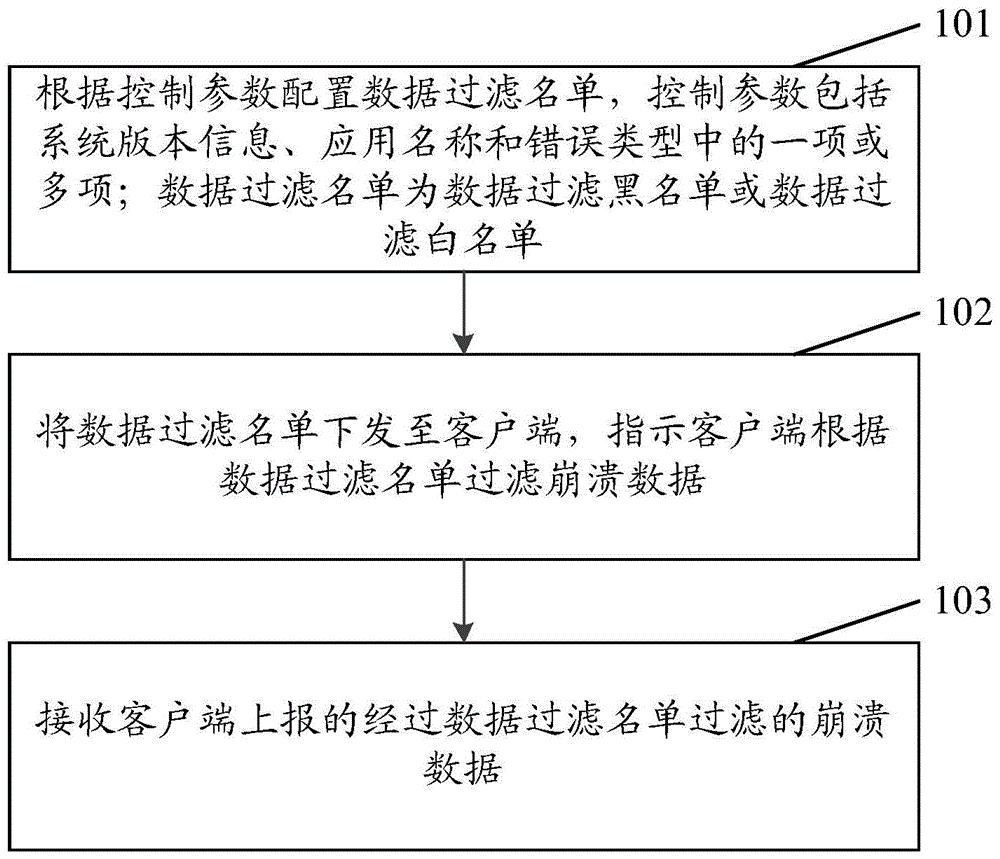

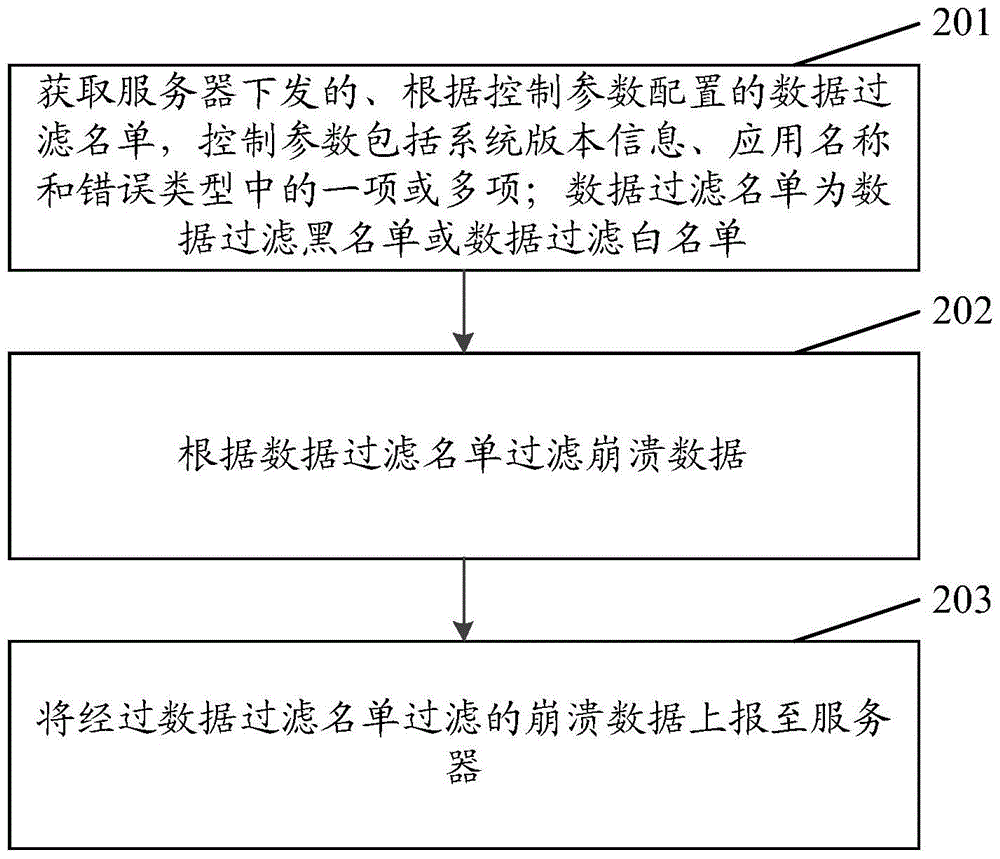

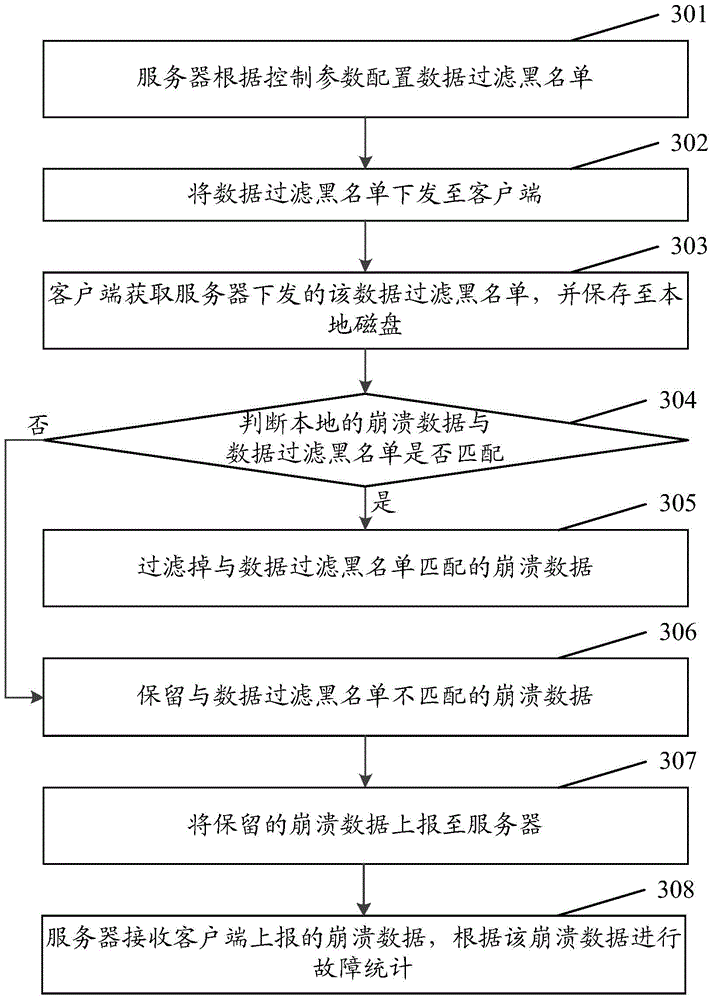

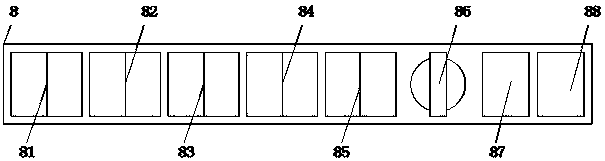

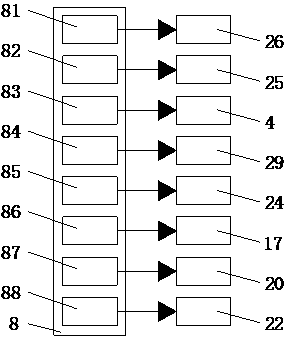

Method, server and client for controlling reporting of crash data

InactiveCN105915365AMeets requirementsMeet Filtration NeedsData switching networksClient-sideBlack list

The invention discloses a method, server and client for controlling reporting of crash data. The method comprises the following steps: according to control parameters, configuring a data filtering list, wherein the control parameters comprise one item or more items from system version information, application names and error types, and the data filtering list is a data filtering black list or a data filtering white list; issuing the data filtering list to the client, and indicating the client to filtering the crash data according to the data filtering list; and receiving the crash data filtered by the data filtering list, reported by the client. According to the method, the server configures the data filtering list, the client can determine a current requirement for reporting the crash data according to the data filtering list, accordingly, the reporting better accords with the crash data demanded by the server, and the method can be applied to a condition of system version change.

Owner:LE SHI ZHI ZIN ELECTRONIC TECHNOLOGY (TIANJIN) LTD

Chemical spraying device

InactiveCN108380412AReduce pollutionMeet mixing needsLiquid spraying apparatusPolypropyleneCompound (substance)

The invention discloses a chemical spraying device which comprises a support seat. A filter tank is fixedly connected to the left end of the bottom part of the support seat; a polypropylene filter screen layer, a particle filter screen layer and a sponge filter layer are sequentially and fixedly connected into an inner cavity of the filter tank from top to bottom; and a reflowing hole is formed between the left end of the top part of the filter tank and the left end of the bottom part of a reflowing tank. According to the chemical spraying device provided by the invention, a first slider is slidably connected to the outer surface of a first sliding seat, a second slider is slidably connected to the outer surface of a second sliding seat, a first electric telescopic rod is fixedly connectedto the bottom part of the second slider, a second support rod and a fifth support rod are sequentially and fixedly connected to the bottom part of a first support rod from left to right, and throughthe action of a first movable joint, a second electric telescopic rod, a second movable joint, a third support rod, a third movable joint, a fourth support rod and a steering motor, the demand on all-dimensionally spraying a chemical product without a dead corner can be met, and great convenience is brought for the use by people.

Owner:李丽倩

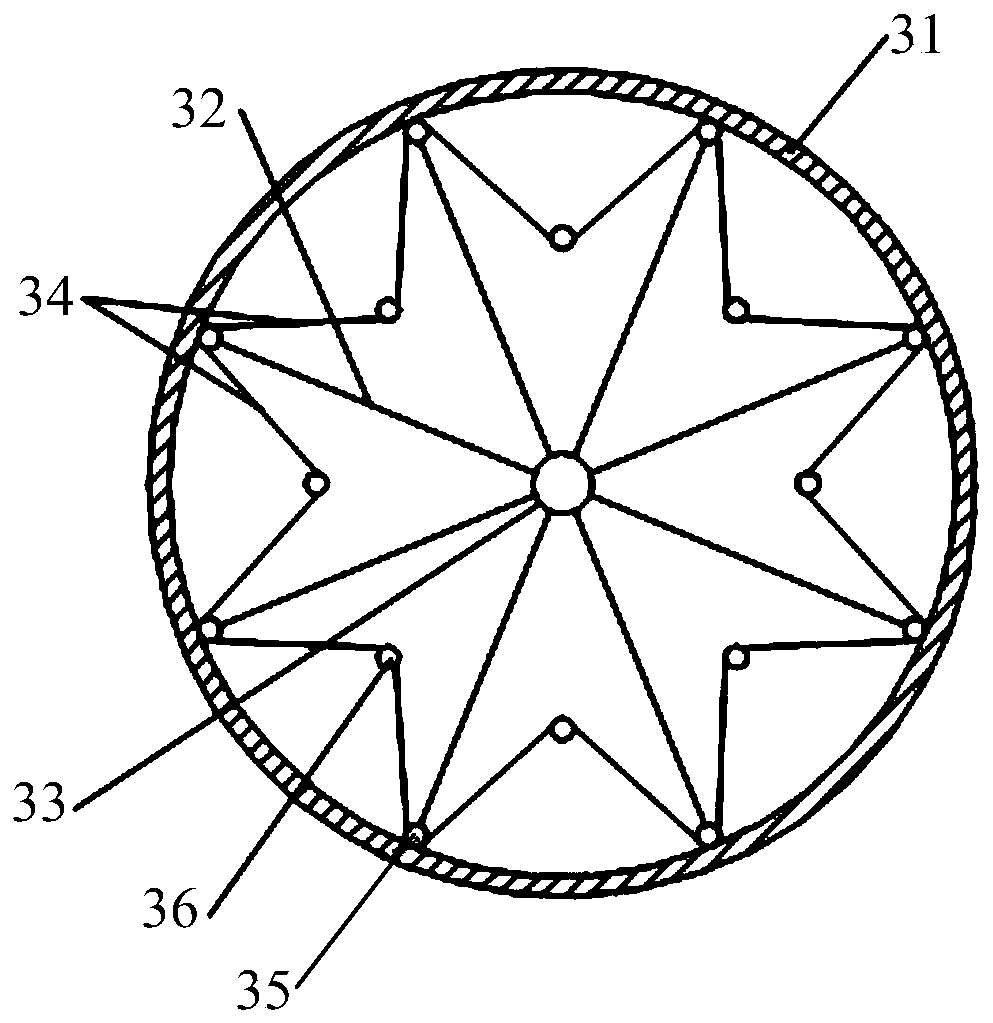

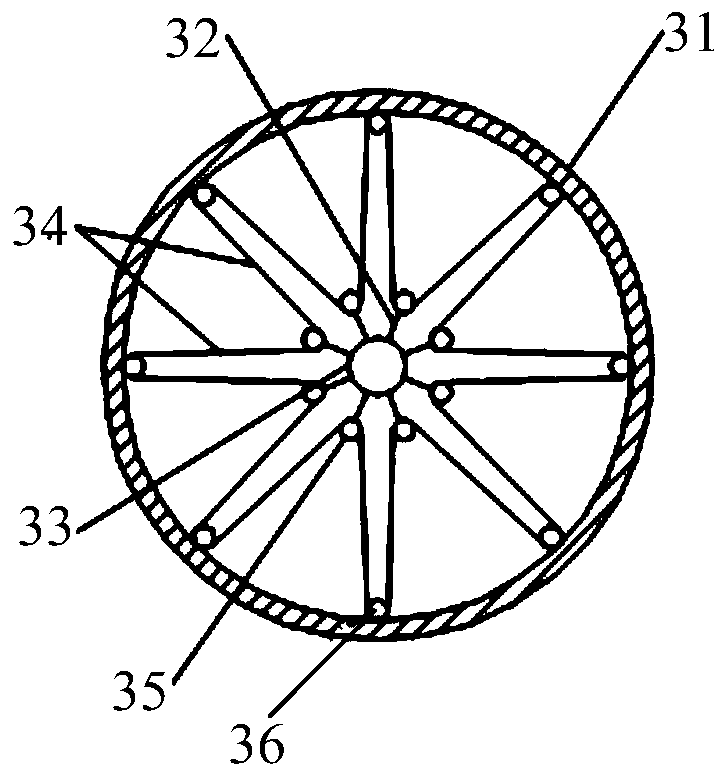

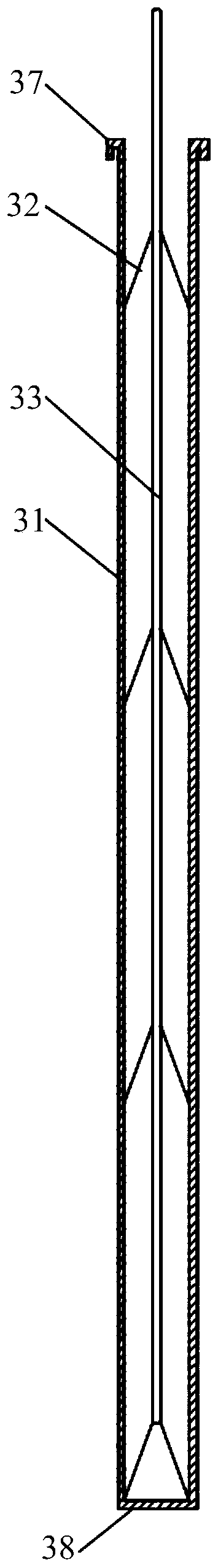

Filter

ActiveCN106975261AMeet Filtration NeedsIncrease water flow areaStationary filtering element filtersEngineeringMechanical engineering

The invention relates to a filter with a high flow and a good effect. The filter comprises an outer cylinder, a central pipe and a filter net, wherein the outer cylinder comprises a first end plate, a second end plate and a circumferential wall, the central pipe penetrates through the first end plate and enters a filter cavity of the outer cylinder, a first port is formed in the outer end of the central pipe, the inner end of the central pipe is closed, a second port is formed in the second end plate, the central pipe is communicated with the filter cavity through a first circumferential wall hole formed in the circumferential wall, and therefore, a filter channel is formed between the first port and the second port.

Owner:中山市欣意诚科技有限公司

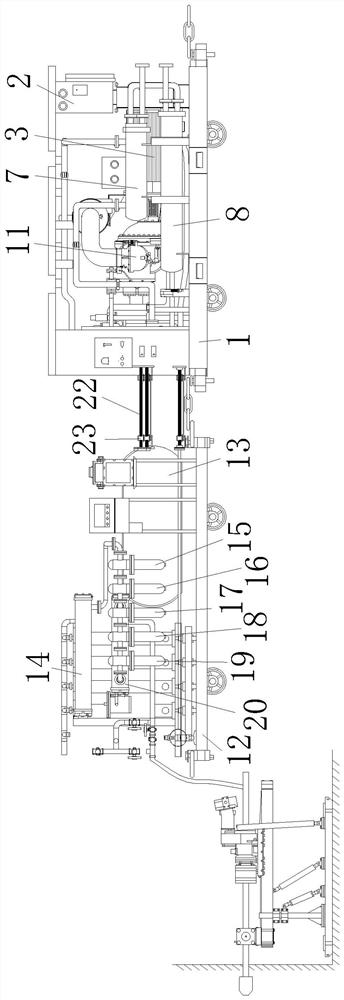

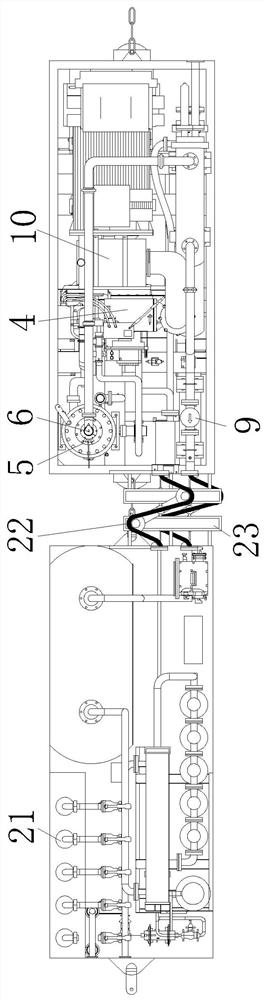

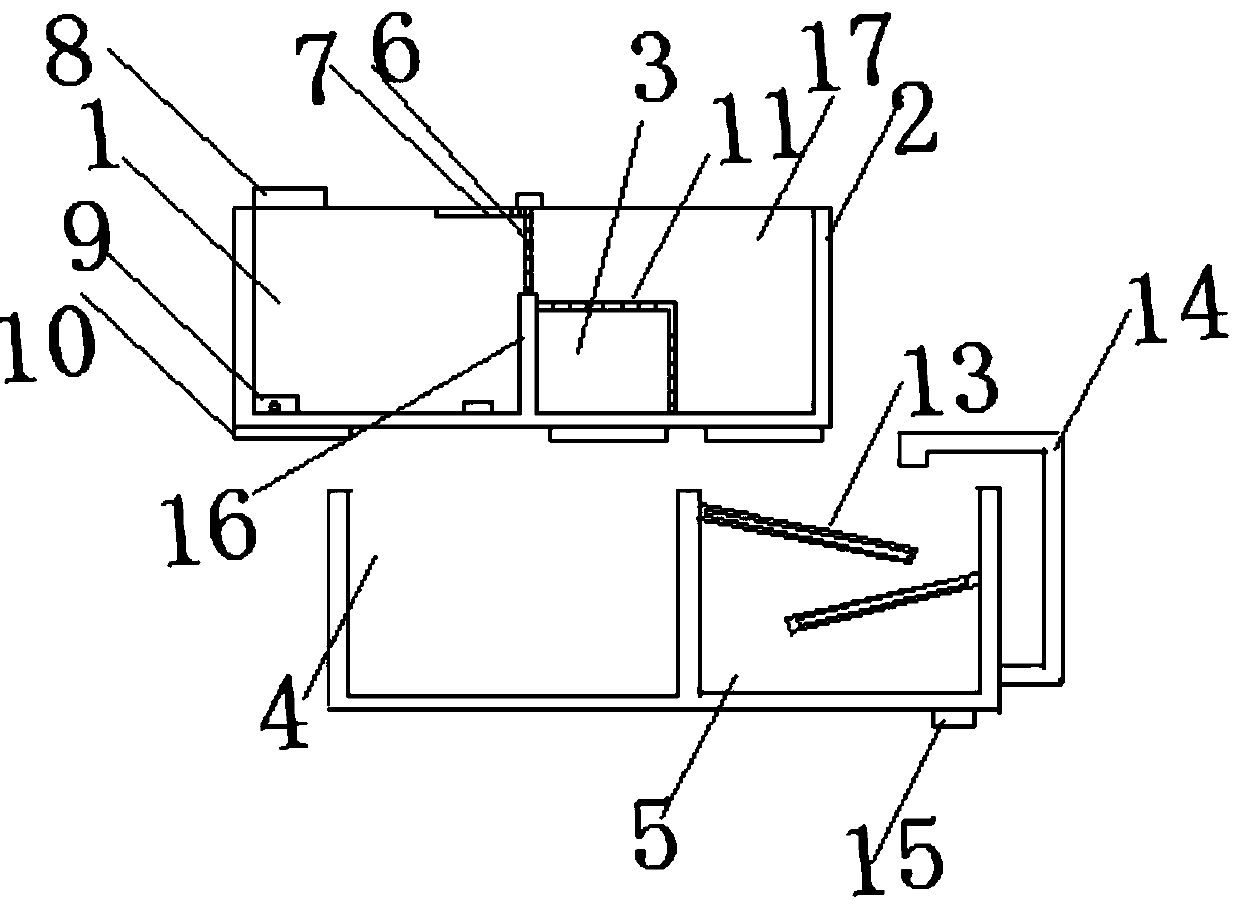

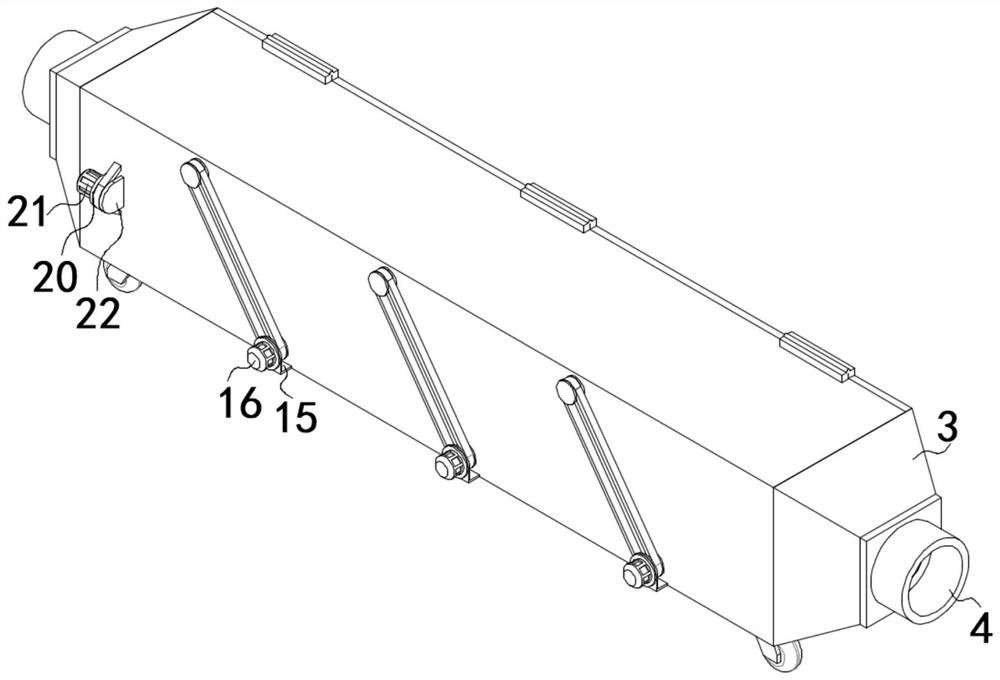

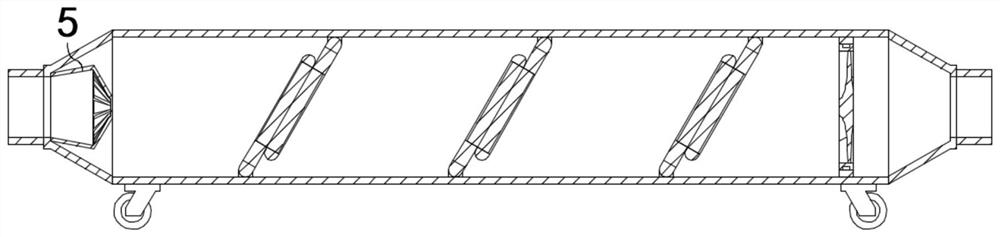

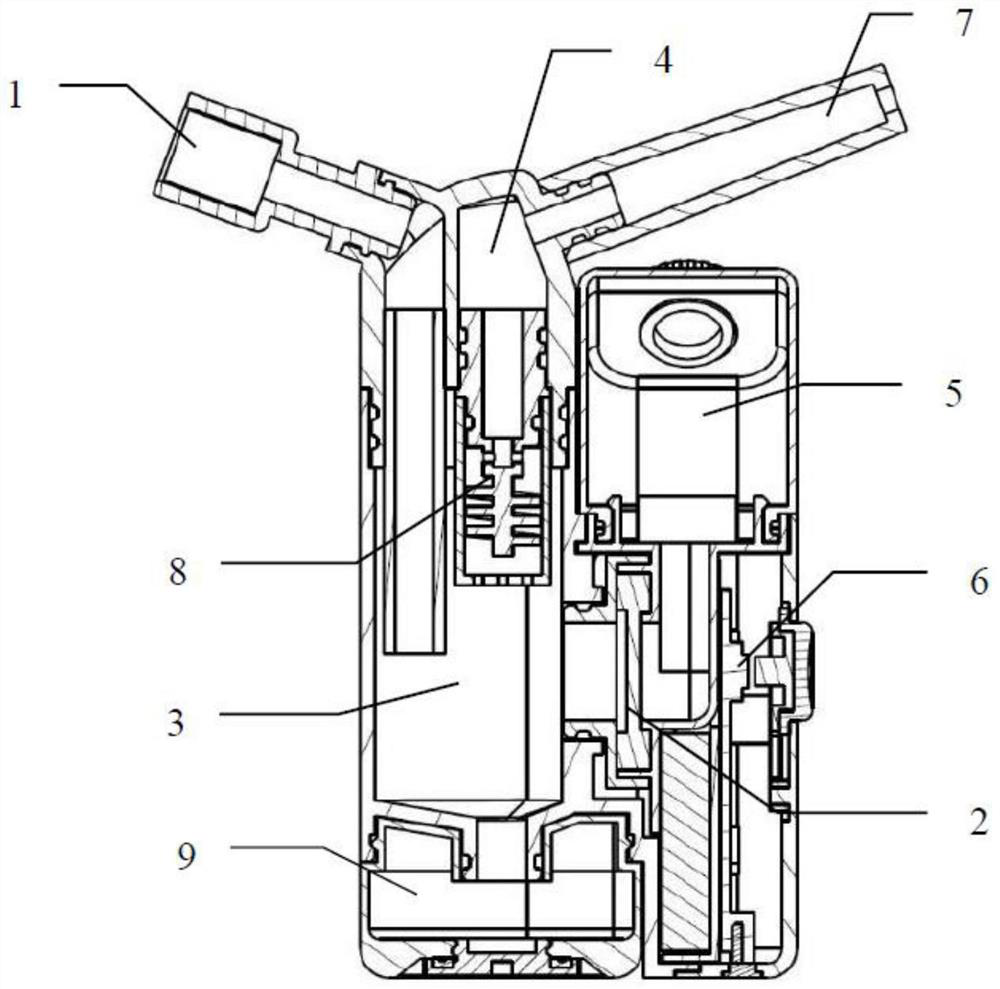

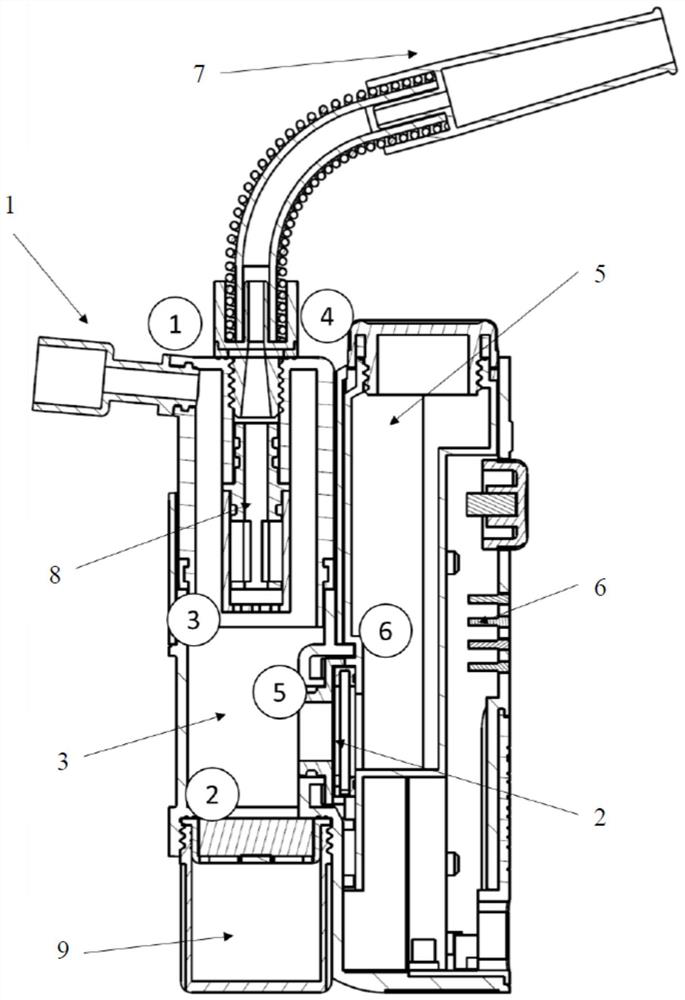

Coal mine underground movable nitrogen making device and process thereof

ActiveCN113521971AImprove slagging abilityMeet the needs of long drillingRotary/oscillating piston combinations for elastic fluidsNitrogen purification/separationAir filtrationNitrogen generator

The invention provides a coal mine underground movable nitrogen making device and a process thereof, and belongs to the technical field of underground nitrogen making. The coal mine underground movable nitrogen making device comprises an air compression mechanism, a membrane separation nitrogen making mechanism and a scaling constraint assembly. According to the coal mine underground movable nitrogen-making device and the process thereof, air is filtered and compressed through the air compression mechanism to obtain high-pressure gas, then high-pressure nitrogen is prepared through the membrane separation nitrogen-making mechanism, the requirement of medium and long drill holes in the coal mine underground can be fully met, meanwhile, pressure loss in the nitrogen conveying process can be made up, the nitrogen deslagging effect in the drilling process is improved, the filter plate can be replaced under the non-stop state, the requirements for the air filtering quality and the air inlet amount in the nitrogen making process can be fully met in time, meanwhile, the problem that unfiltered air directly enters a nitrogen making device to affect the nitrogen purity and flow can be effectively solved, and the stability of the pressure value of the generated nitrogen and the purity and flow of the nitrogen are improved.

Owner:沈阳煤炭科学研究所有限公司

Electrochemical preparation method of chloroiridic acid

InactiveCN108977837ANo need to disassemble and cleanMeet Filtration NeedsElectrolysis componentsIridiumPhysical chemistry

The invention relates to an electrochemical preparation method of chloroiridic acid. The electrochemical preparation method comprises: 1, arranging an electrolytic cell, wherein the electrolytic cellis separated into at least two tanks by a first separation plate arranged in the electrolytic cell, the first separation plate is provided with an overflow hole, the tank is divided into two electrodechambers by a second separation plate arranged in the tank, the two electrode chambers are communicated to each other, and electrodes are respectively arranged in the electrode chambers; 2, adding iridium powder into the tank, making a hydrochloric acid solution sequentially pass through the tanks, and carrying out a continuous electrolysis reaction on the iridium powder and the hydrochloric acidsolution by applying voltage on the electrodes; 3, when the iridium in the hydrochloric acid solution in the electrolytic cell reaches a certain concentration, supplementing the tank with a hydrochloric acid solution and the iridium powder to continuously form a product stream containing stable iridium concentration; and 4, filtering the product stream, concentrating, and drying to obtain a chloroiridic acid solid. According to the present invention, the method has advantages of simple preparation process, high automation degree, environmental protection, no by-products and high product purity.

Owner:CHINA PETROLEUM & CHEM CORP +1

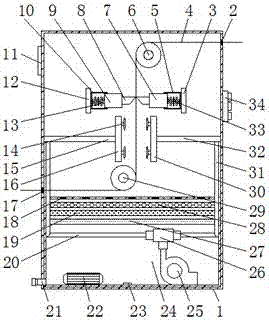

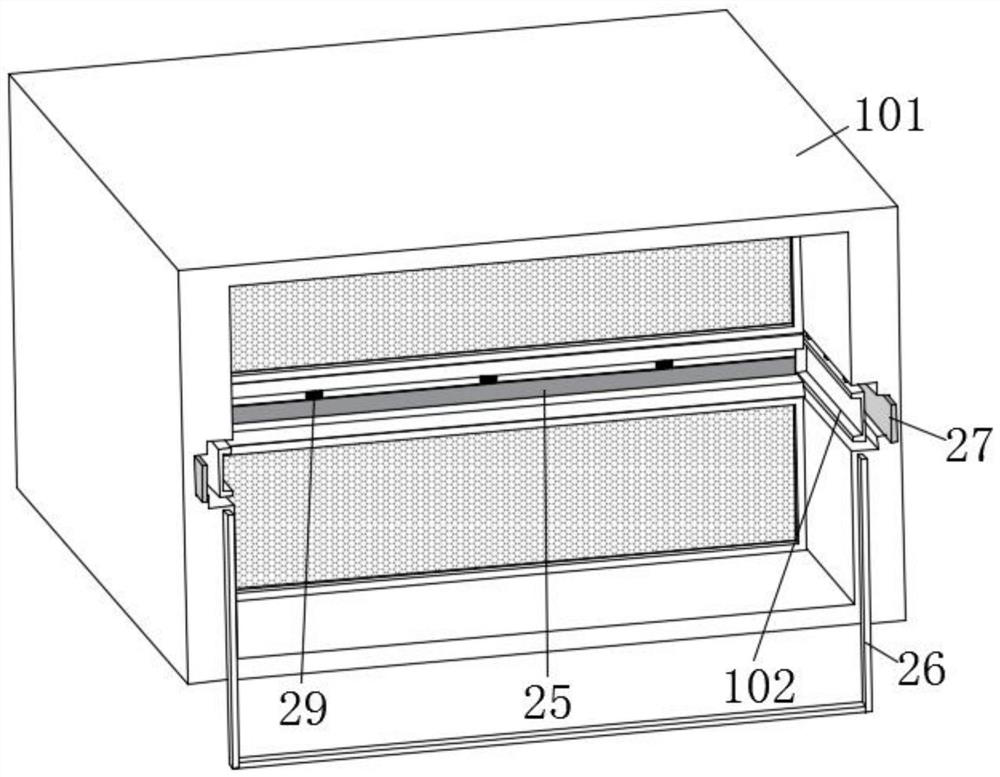

Convenient-to-maintain waste gas particulate matter purifying and filtering device

InactiveCN111991947AEasy maintenanceImprove maintenance convenienceDispersed particle filtrationTransportation and packagingParticulatesElectric machine

The invention discloses a convenient-to-maintain waste gas particulate matter purifying and filtering device, and relates to the technical field of waste gas treatment. The device comprises an outer shell, and an air inlet is fixedly formed in one surface of the outer shell; an air outlet is formed in the surface, away from the air inlet, of the outer shell; a box door is hinged to one surface ofthe outer shell; an air diffusion seat is fixedly connected to one surface of the outer shell and is positioned at the air inlet; one surface of the outer shell is fixedly connected with a group of driving motors; one end of an output shaft of each driving motor is fixedly connected with a filtering assembly; the surfaces of the group of filtering assemblies are rotationally connected with the outer shell; each filtering assembly comprises a support; and the surface of each support is rotationally connected with the outer shell. Through the design of the outer shell, the box door, the supportand a rotating seat, the problem that the service life of an existing convenient-to-maintain waste gas particulate matter purifying and filtering device is short, the filtering effect is poor and thefiltering efficiency is low due to the fact that internal parts of the device are difficult to maintain and replace are solved.

Owner:杨立新

Industrial screen net with long life

PendingCN108211462AHigh mechanical strengthEasy to fixDispersed particle filtrationFilter regenerationCircular discClamp connection

The invention discloses an industrial screen net with long life. The industrial screen net with long life comprises a net frame, net cloth, a bottom plate and a cleaning device; a lower clamping ringis arranged on the lower edge of the net cloth; an upper clamping ring is arranged on the upper edge of the net cloth; the net frame comprises a fixed disk, a covering ring and a supporting structure;a lower clamping groove is formed above the fixed disk; an upper clamping groove is formed below the covering ring; the supporting structure comprises a longitudinal supporting strip and a circumferential supporting strip; the cleaning device comprises an air compressor, a rotating motor, a rotating platform and a vertical pipe; at least three clamping connection projections for mounting the fixed disk are arranged above the rotating platform; clamping connection grooves matched with the clamping connection projections are formed at the bottom of the fixed disk; and a plurality of nozzles arearranged on one side, facing towards the net cloth, of the vertical pipe uniformly. The screen net is simple in structure, reasonable in design, convenient to clean and long in service life.

Owner:四会市华通金属筛网制品有限公司

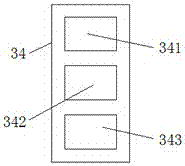

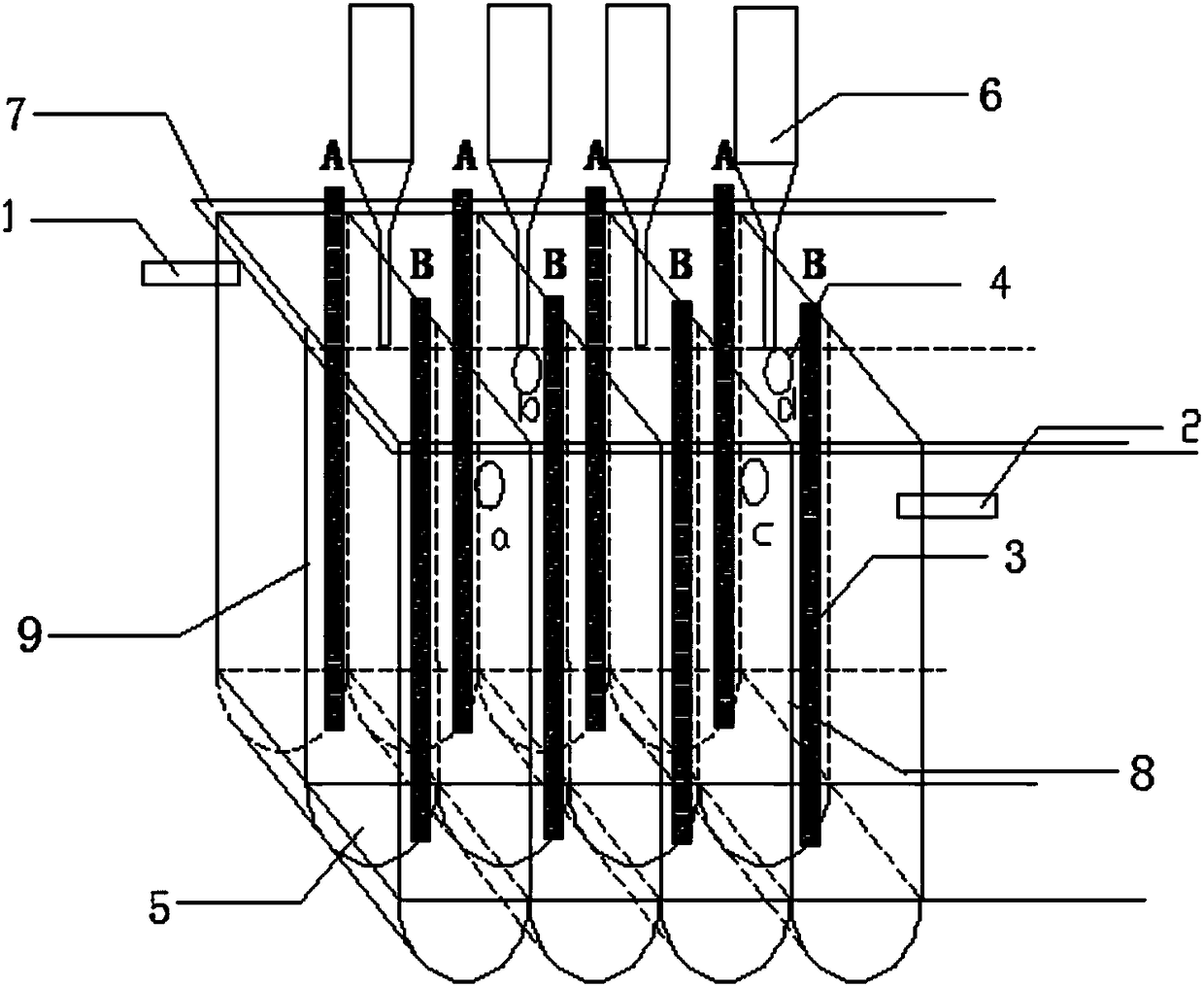

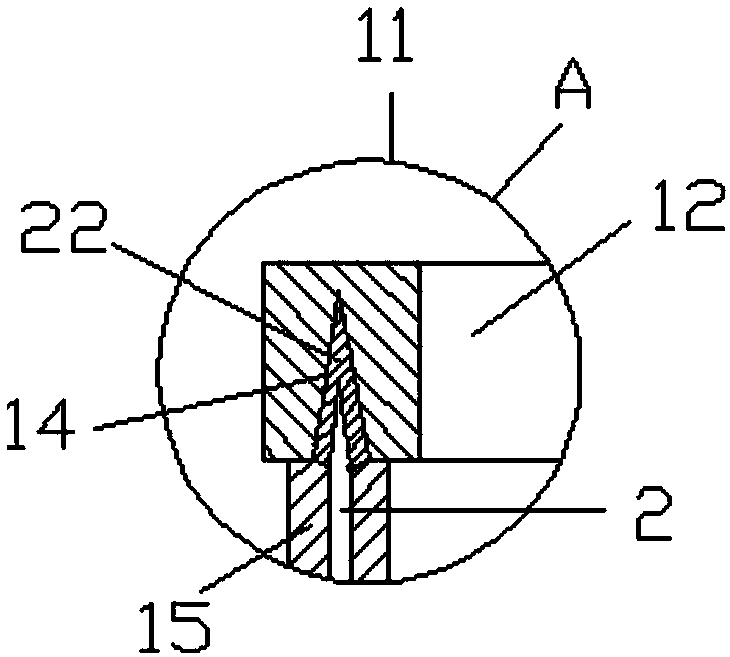

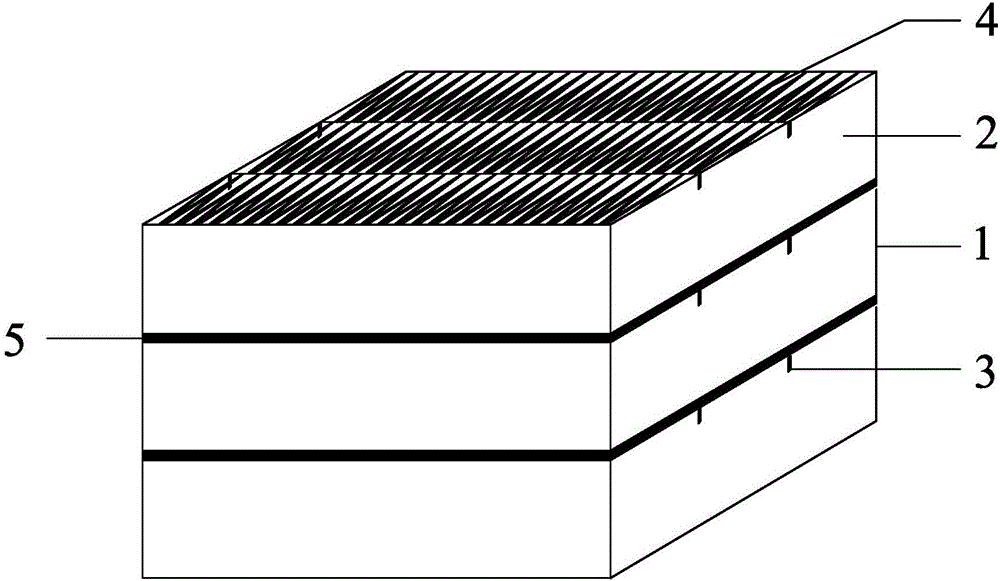

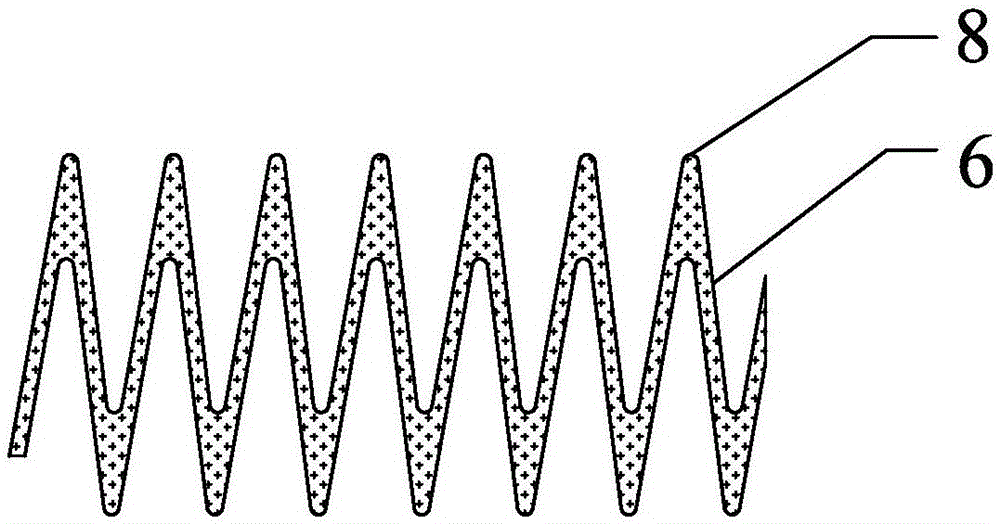

Regeneration filter device for fine particles

InactiveCN106481392AHigh temperature resistantAntioxidantSilencing apparatusMachines/enginesHeat conductingComputer module

The invention provides a regeneration filter device for fine particles. The device is characterized in that a filter device body includes at least two layers of filter boxes; multiple clamping ports with the same gaps are formed in the upper ends of two opposite side walls of the filter boxes; filter modules are matched with holding spaces divided in the filter boxes, and are fixedly clamped in the filter boxes through the clamping ports; metal fiber felts for filtering are arranged in the filter modules in a triangular array form; absorption heat conducting layers are arranged between every two layers of filter boxes, and are carbon fiber felts; and the absorption heat conducting layers are connected with external heating equipment. The filter device has multiple layers of filter boxes; the layer number can be set according to actual demands to satisfy the filter demands under various conditions; in addition, large particles in tail gas can be effectively absorbed according to an arranging form of the metal fiber felts; one part of gasifiable impurities are decomposed through a heating mode to prevent blockage of filter holes; and the filter device has such advantages as simple structure and high practicability.

Owner:DALIAN KAIHONG SCI & TECH

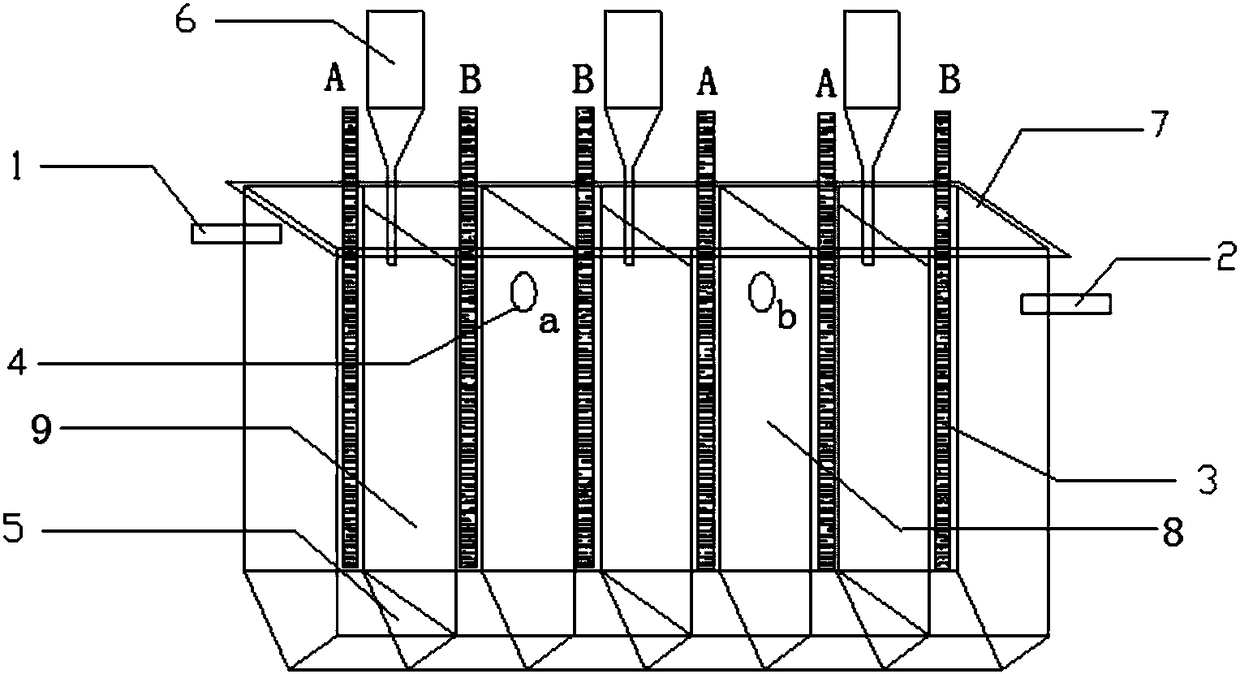

Rainwater-collecting hierarchic purification treatment system and method

The invention provides a rainwater-collecting hierarchic purification treatment method and a rainwater-collecting hierarchic purification treatment system. Through the rainwater-collecting hierarchicpurification treatment method and the rainwater-collecting hierarchic purification treatment system, control can be performed according to different conditions at different times of water accumulationduring raining, so that excessive impurities in the early stage are avoided from entering primary and secondary filtering devices to increase the burden of subsequent purification; the situation of rainwater is monitored according to increase of the rainwater per unit time, so that the inflow situation is monitored more scientifically and quantitatively. A right-angled filtering device in a primary filtering chamber can secondarily filter water entering the primary filtering chamber to enhance the filtering effect, and then the water flows out from a right water outlet to enter a secondary filtering chamber, so that the filtering need of cleaner water is met.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Multi-layer treatment type anti-explosion air pollution treatment device with adjustable filtering strength

InactiveCN112023554AChange filter strengthMeet Filtration NeedsDispersed particle filtrationTransportation and packagingAir treatmentElectric machinery

The invention discloses a multi-layer treatment type anti-explosion air pollution treatment device with adjustable filtering strength, and relates to the technical field of air treatment. The device comprises an outer frame body, and a box door is hinged to the surface of the outer frame body; one surface of the outer frame body is fixedly connected with an air inlet hopper; one surface of the airinlet hopper is fixedly connected with an air inlet pipe; one surface of the air inlet hopper is fixedly connected with an air dispersing seat; one surface of the outer frame body is fixedly connected with an air outlet hopper; one surface of the air outlet hopper is fixedly connected with an air outlet pipe; the inner wall of the outer frame body is fixedly connected with a group of upper hingedsupports; an upper filtering seat is hinged between the opposite surfaces of every two upper hinged supports; the inner wall of the outer frame body is fixedly connected with a group of lower hingedsupports; a lower filtering seat is hinged between the opposite surfaces of every two lower hinged supports; filter plates are fixedly connected to the inner walls of the upper filtering seats and thelower filtering seats. Through the design of the upper filtering seats, the lower filtering seats, a driving roller, a driven roller and a driving motor, the problems of poor applicability and practicability of an existing atmospheric pollution treatment device are solved.

Owner:李玉苓

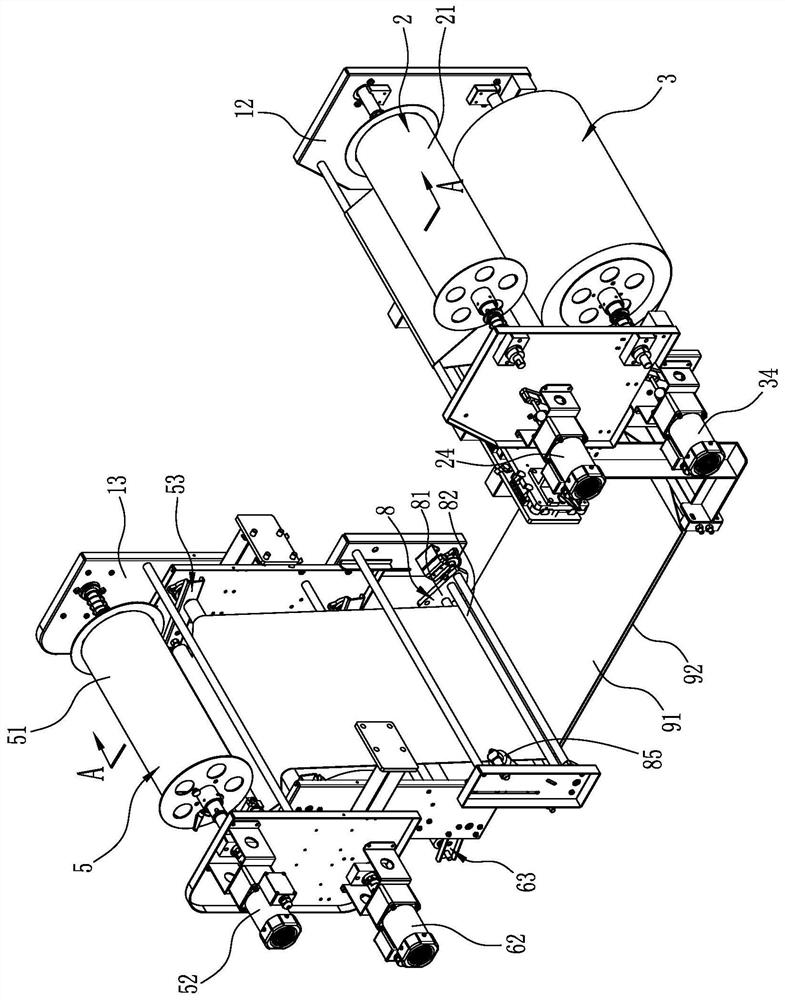

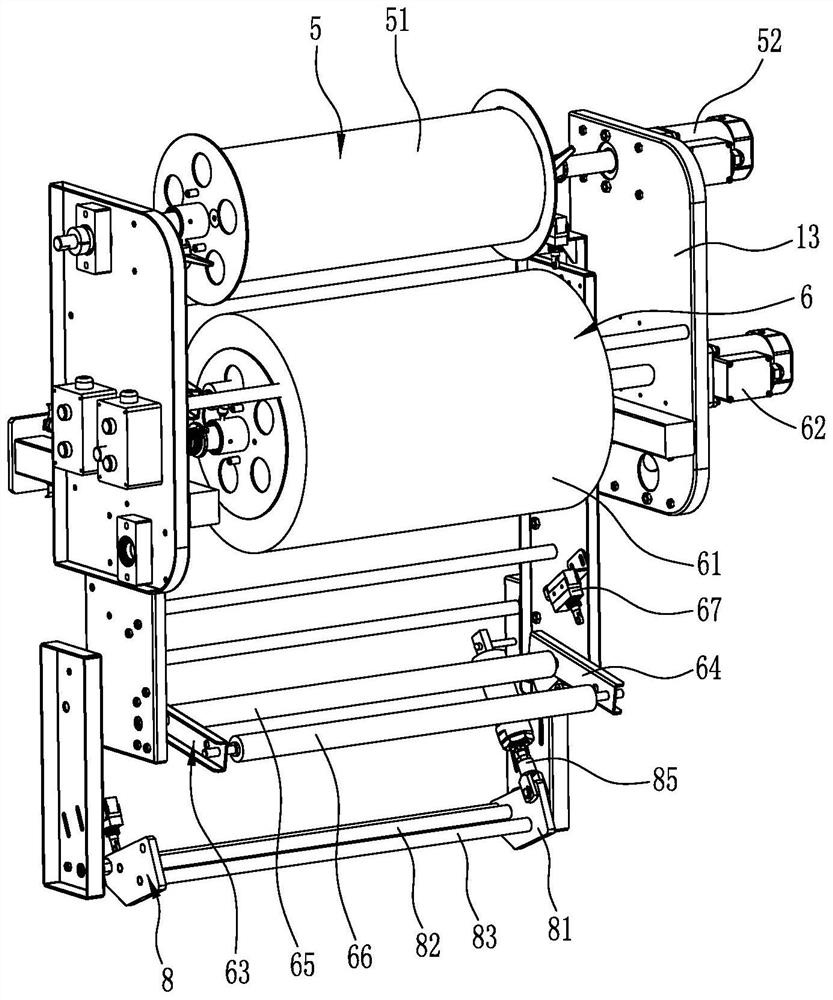

Efficient suction filtration device of press

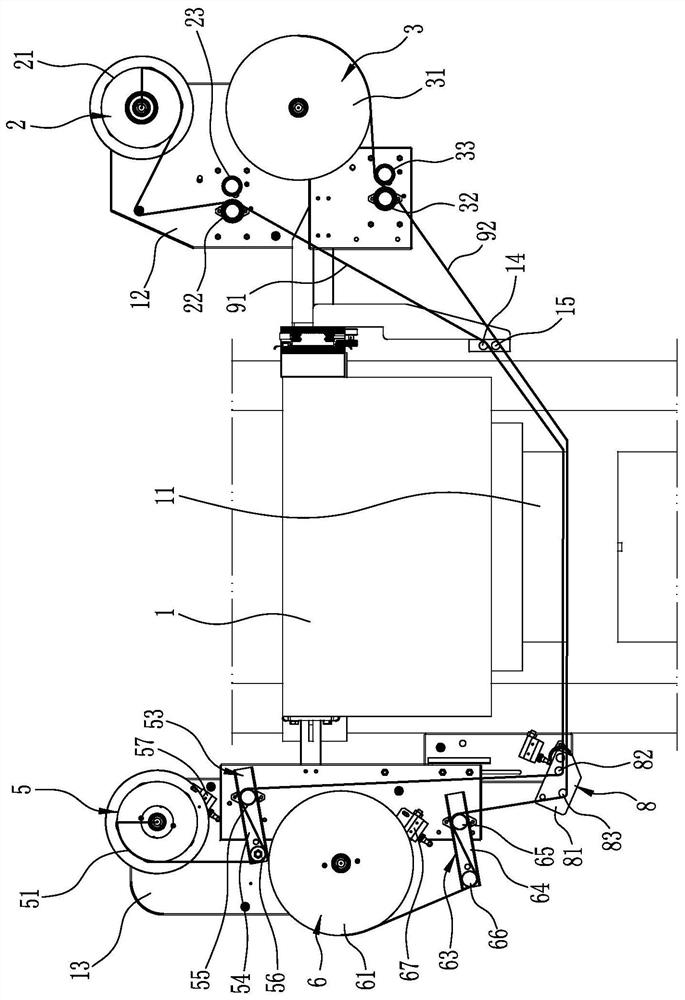

PendingCN111957098AImprove replacement efficiencyAchieve tensionSludge treatmentFiltration circuitsProcess engineeringFilter paper

The invention discloses an efficient suction filtration device of a press. The efficient suction filtration device comprises a cloth unwinding bracket and a cloth winding bracket; a cloth unwinding device and a paper unwinding device are arranged on the cloth unwinding bracket; a cloth winding device and a paper winding device are arranged on the cloth winding bracket; filter cloth passing throughthe lower portion of an upper pressing die is arranged between the cloth unwinding device and the cloth winding device, and filter paper located below the filter cloth is arranged between the paper unwinding device and the paper winding device; the cloth winding bracket or the cloth unwinding bracket is provided with a winding-unwinding pre-supporting device, and the cloth winding bracket is provided with a cloth winding elastic tensioning device and a paper winding elastic tensioning device. Automatic replacement is achieved by winding and unwinding the filter cloth and the filter paper, andthe replacement efficiency is high. Due to the fact that the filter paper, which is low in price, is arranged below the filter cloth, which is high in price, pollution to the filter cloth is smaller,the filter cloth can be replaced from fifty molds to one hundred molds, and consumption of the filter cloth is obviously reduced. Meanwhile, the filter cloth and the filter paper can be seamlessly and continuously used in the length direction, and the utilization rate of the filter cloth is obviously increased.

Owner:上海奇宝智能科技有限公司

Rotational flow high-pressure-difference filter and manufacturing method

PendingCN112915678AOvercoming the problem that it is easy to break and not easy to meet the filtration requirementsSatisfy Strength QuestionsDispersed particle filtrationSmall particleMechanics

The invention discloses a rotational flow high-pressure-difference filter and a manufacturing method. The filter comprises a core body and a shell, and the core body comprises a gasket, a core body transition section, a core body plate sheet, a core body settling section and a core body end which are sequentially connected in a welded mode. The filter is made of a 4-6mm stainless steel plate, the strength problem caused by the front-back pressure difference of the filter screen can be sufficiently solved, a 0.3 mm micro channel is etched in the steel plate by adopting a chemical etching technology, and the filtering requirement can be sufficiently met; meanwhile, an inlet is tangent to a main pipe section of the filter, airflow tangentially enters the filter, air flow rotationally flows in the filter and flows downwards in the axial direction at the same time, impurities diffuse all around under the action of centrifugal force and finally settle downwards, a settling section is designed on the lower portion of the filter, a filter element of the settling section is not provided with a cavity and can be regarded as a dead zone, the flow speed is low, and a space is created for settling of solid impurities, so the filter can bear high pressure difference, fine particles are filtered, and the filtering effect is good.

Owner:XIAN THERMAL POWER RES INST CO LTD

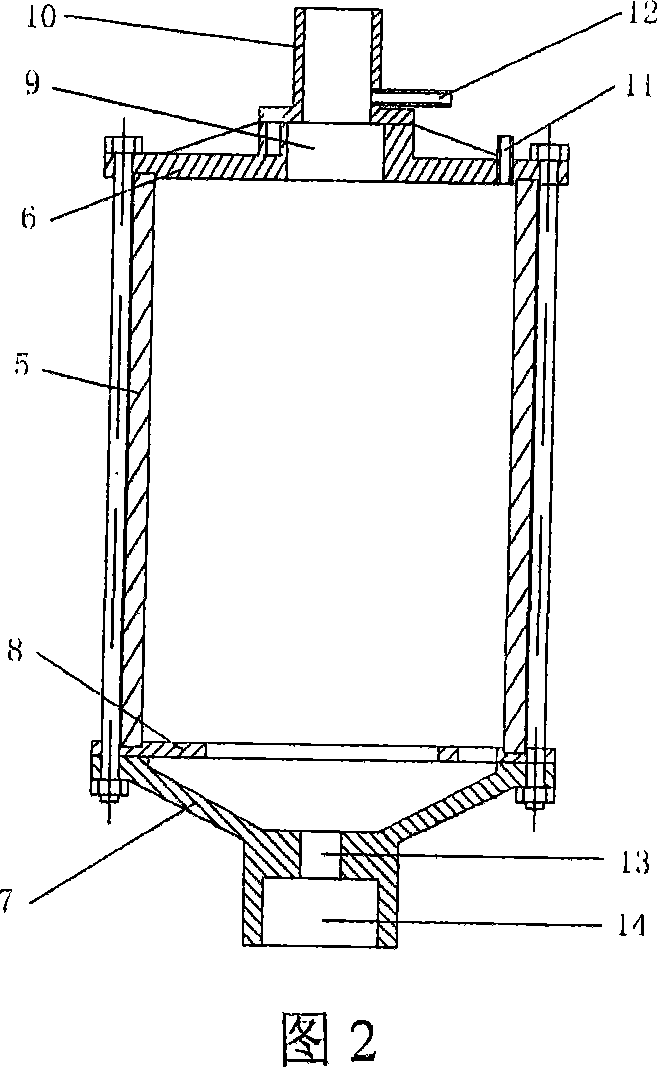

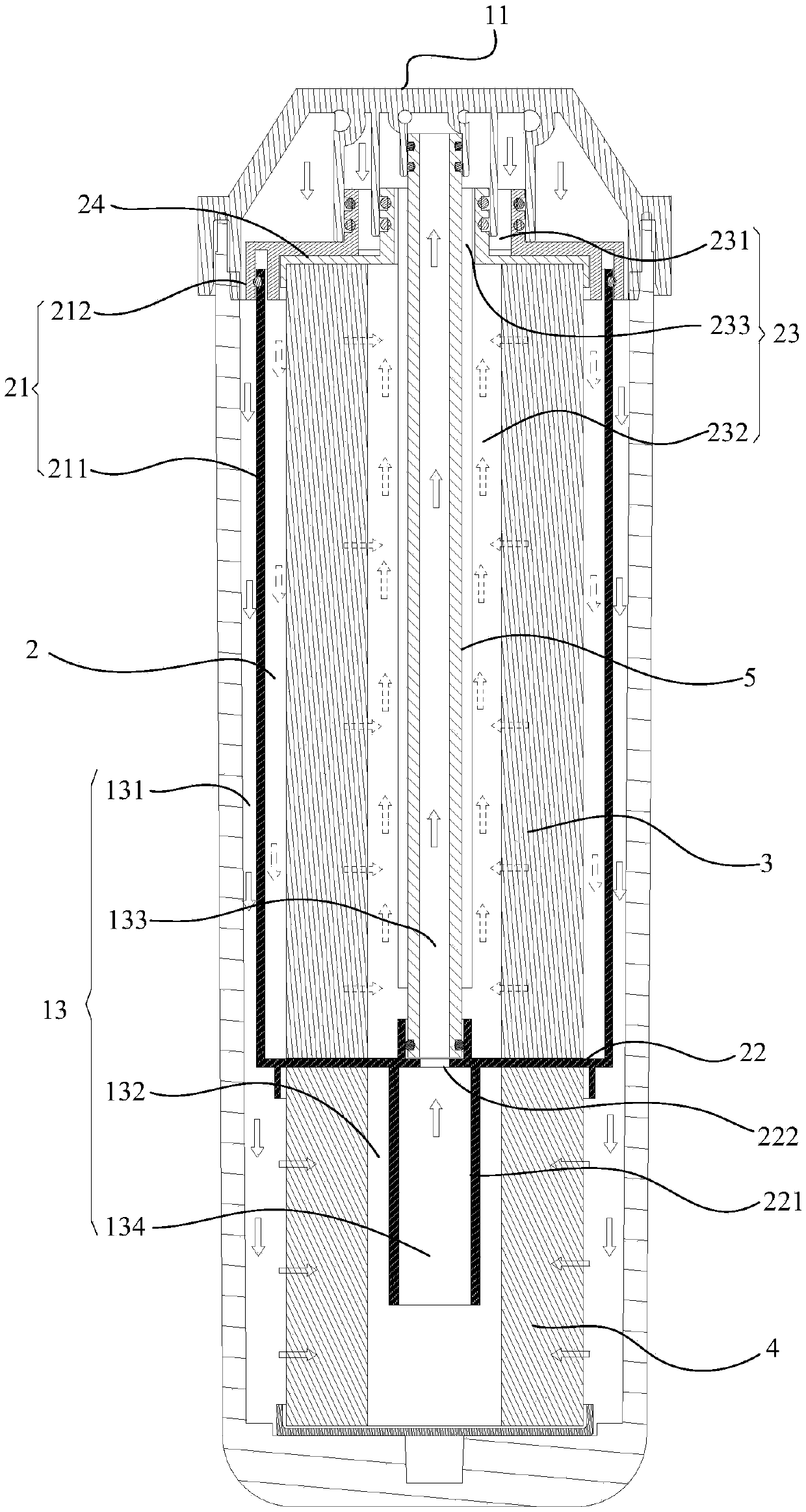

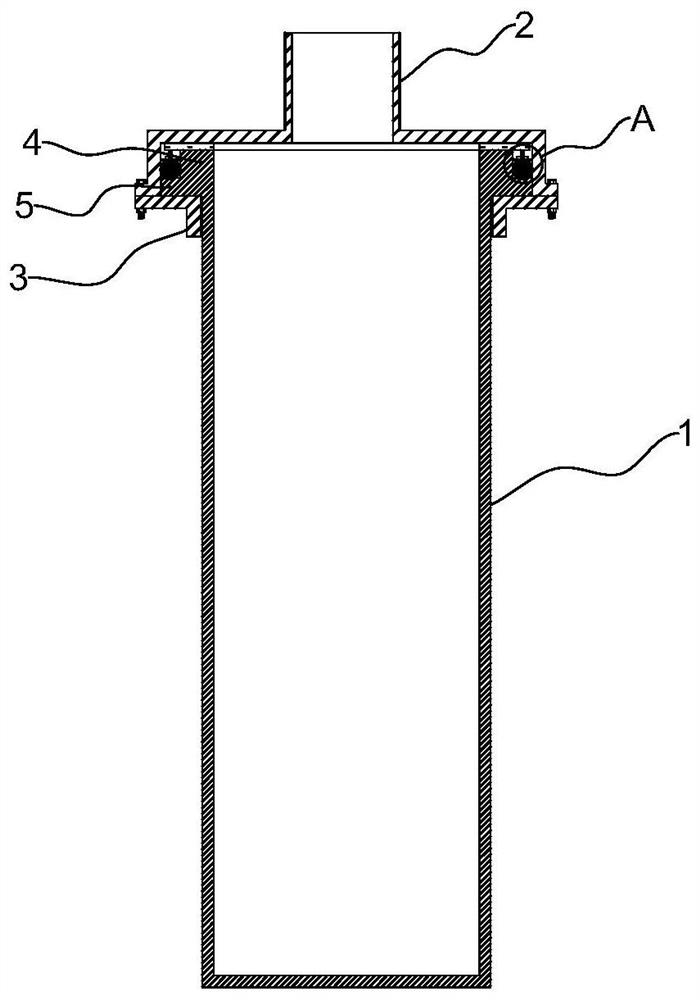

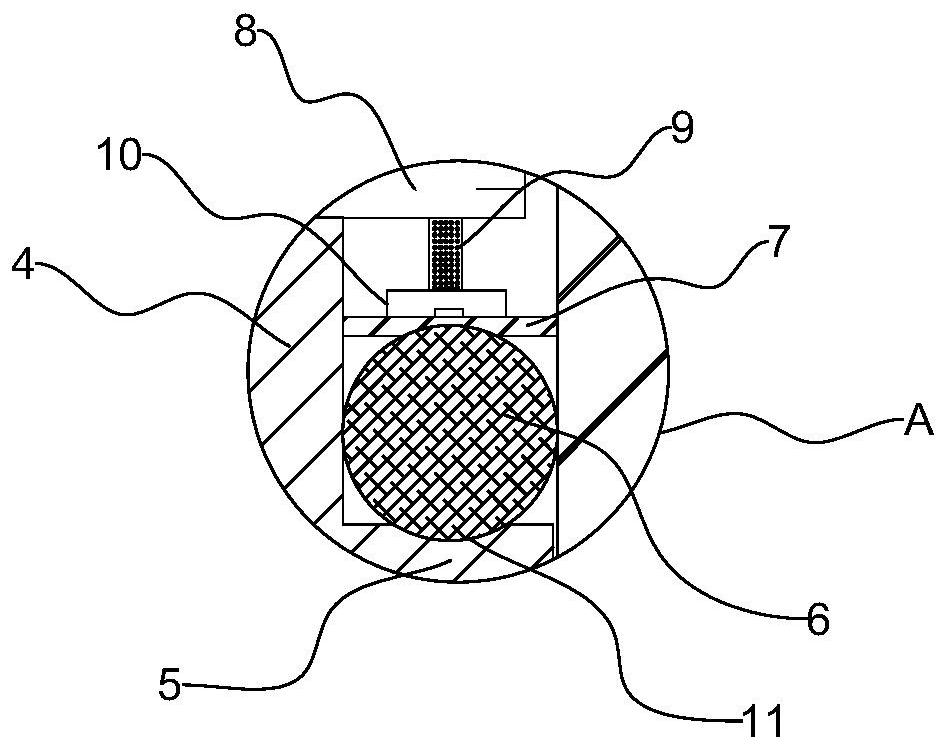

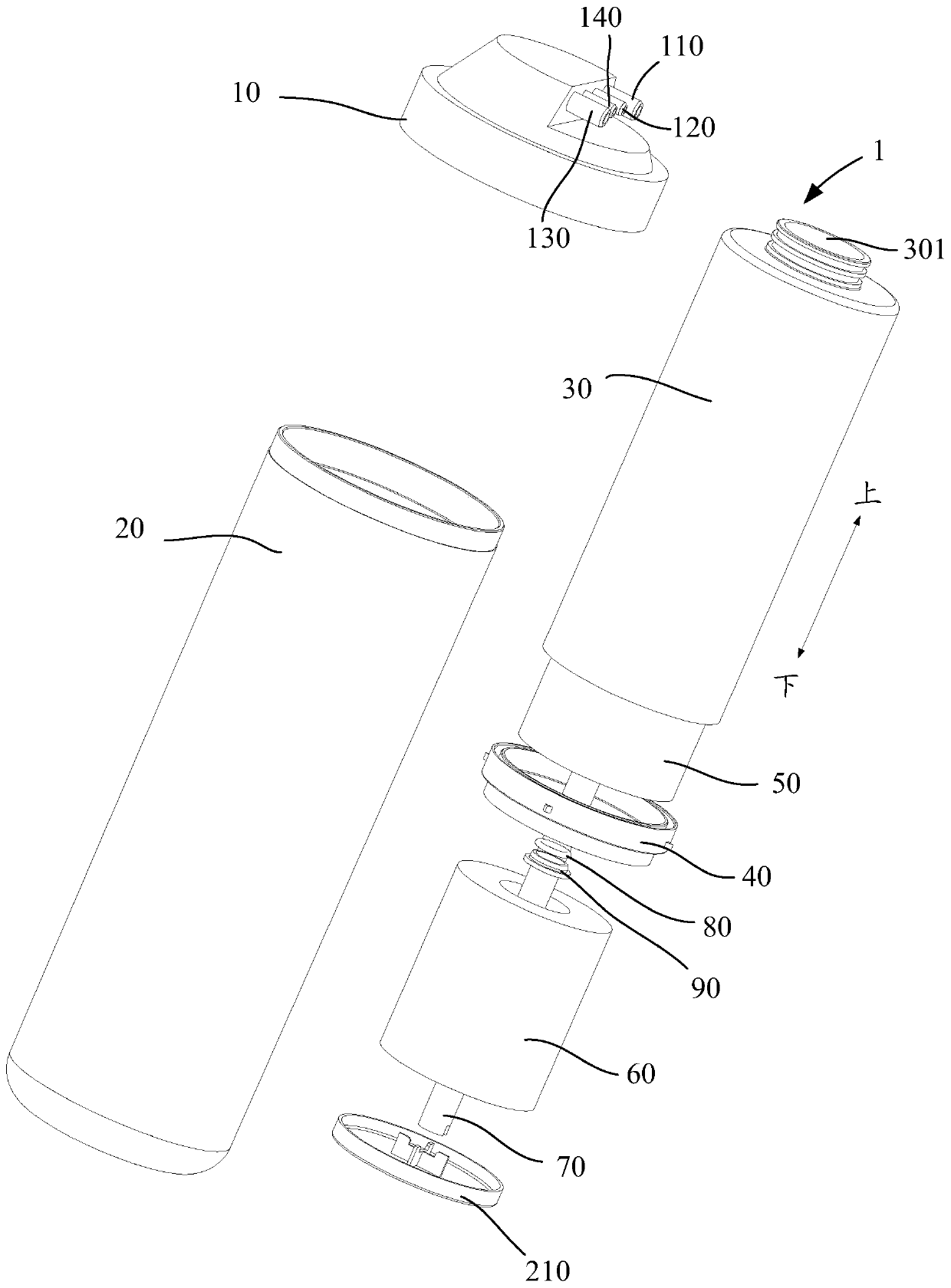

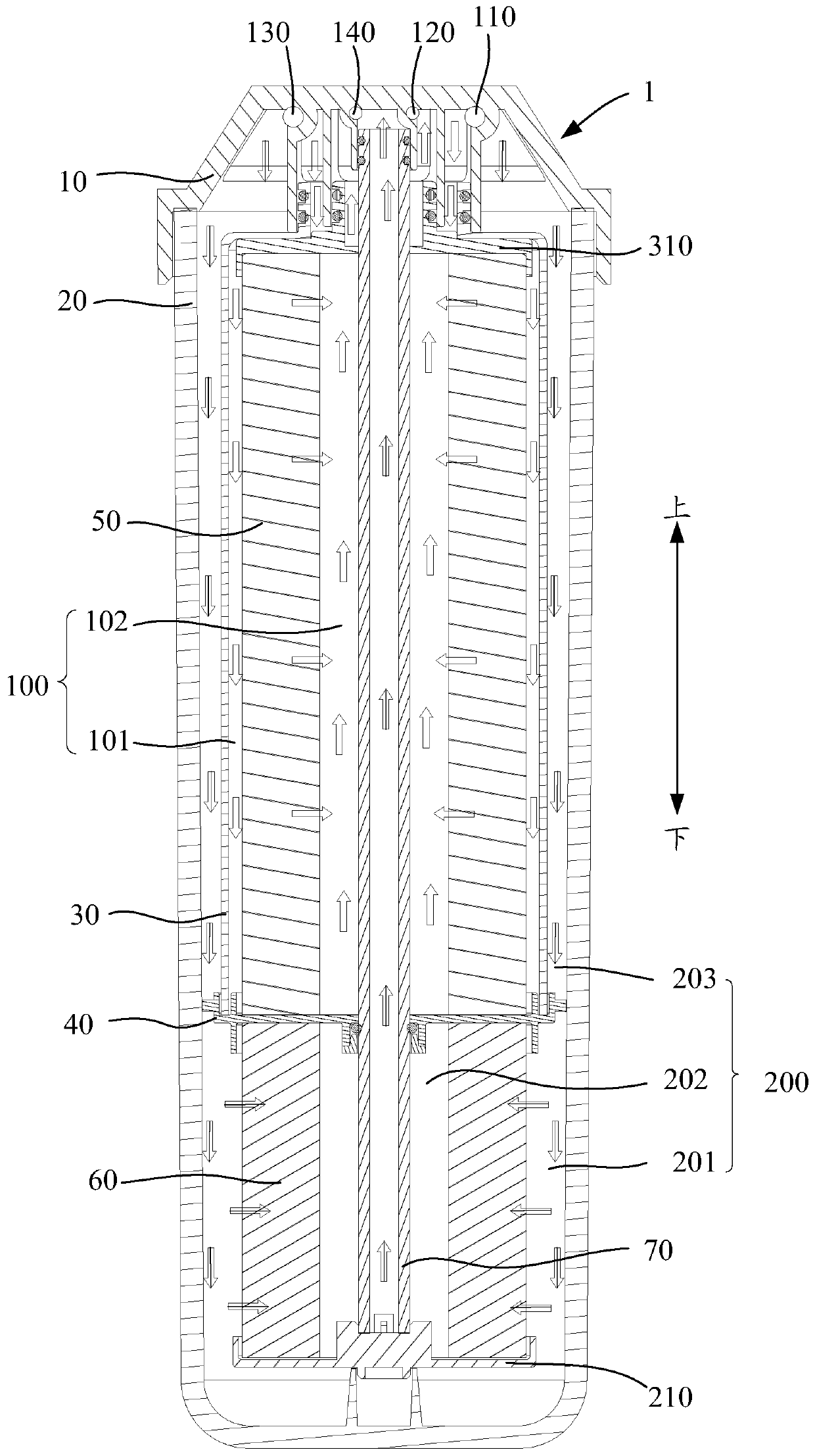

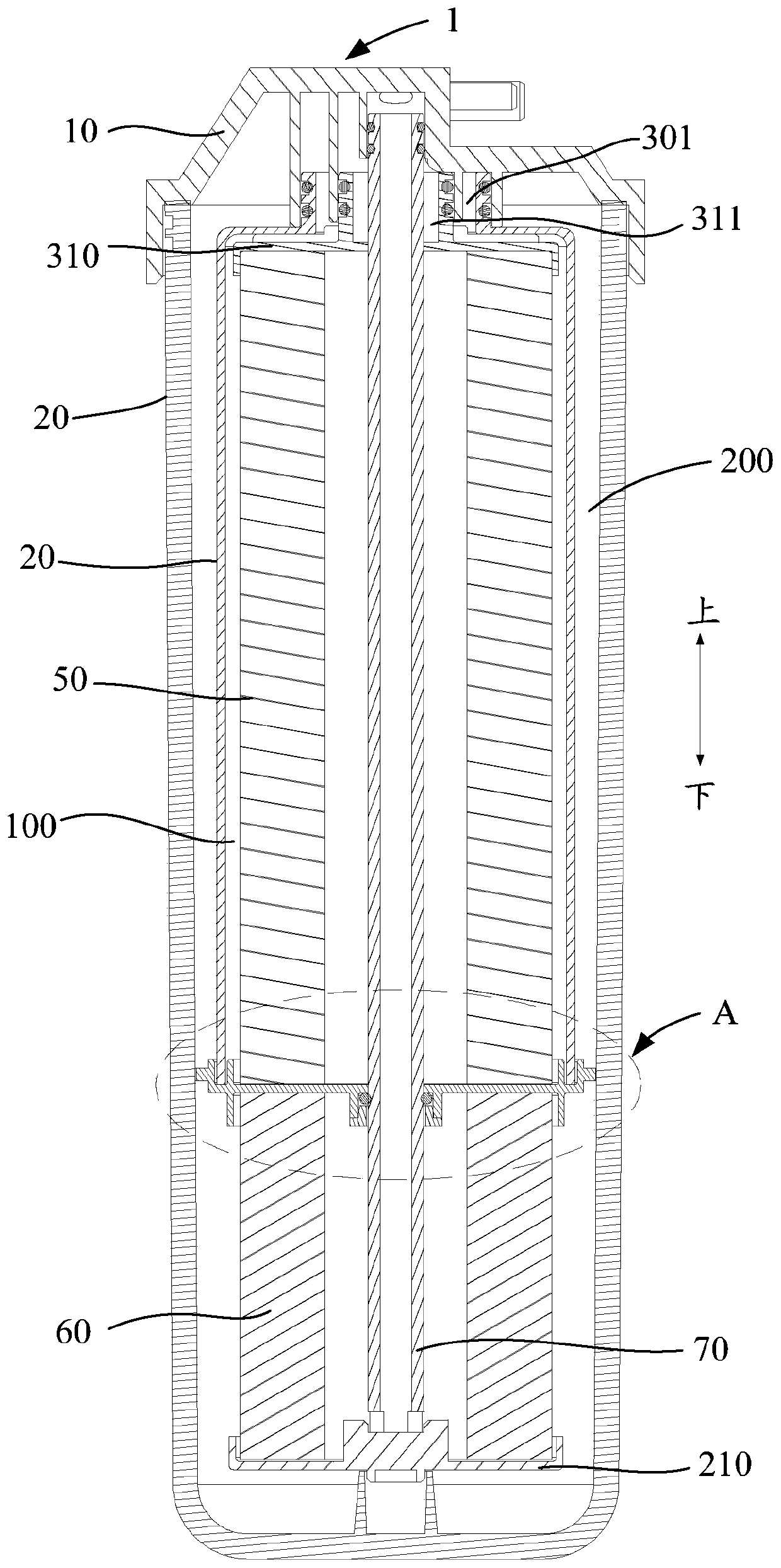

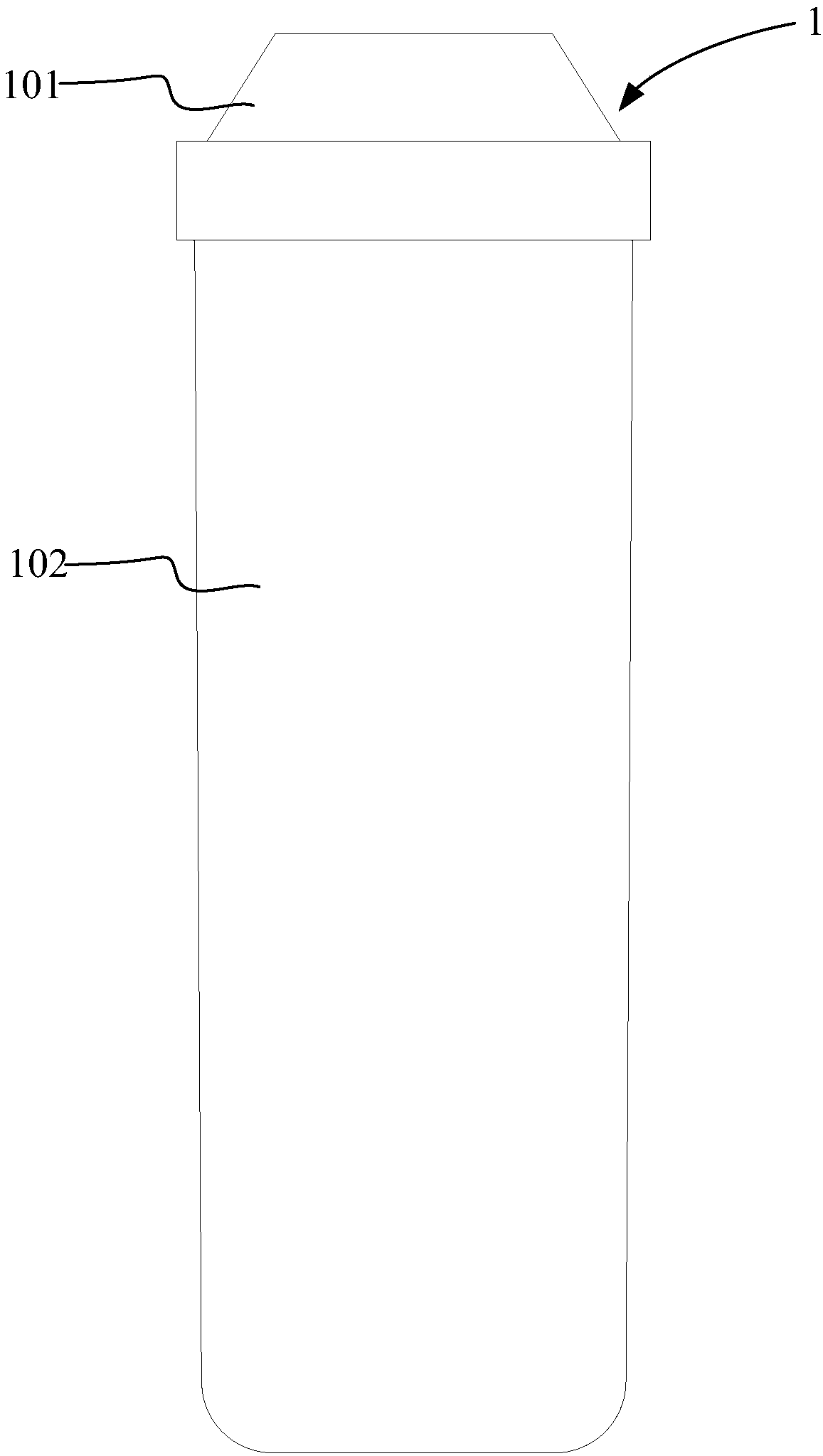

Composite filter element and water purification device

PendingCN110404331AReduce usageMeet Filtration NeedsTreatment involving filtrationFiltration circuitsEngineeringComposite filter

The invention discloses a composite filter element and a water purification device. The composite filter element comprises a shell, an isolation assembly, a first filter element and a second filter element; the isolation assembly is arranged in the shell, a first filter cavity is formed in the isolation assembly, a second filter cavity is formed between the shell and the isolation assembly, and the first filter cavity and the second filter cavity are mutually independent; the first filter element is arranged in the first filter cavity, and the second filter element is arranged in the second filter cavity; the isolation assembly comprises an inner barrel and a separation plate fixed to the lower end of the inner barrel in a sealed mode; a first flow channel is formed between the outer wallsurface of the inner barrel and the inner wall surface of the shell at intervals, and a second flow channel is formed between the lower plate surface of the separation plate and the inner wall surfaceof the shell at intervals. According to the technical scheme, the integration degree of the filter element in the water purification device can be effectively improved, and thus the convenience of disassembly and assembly of the filter element structure of users is improved.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

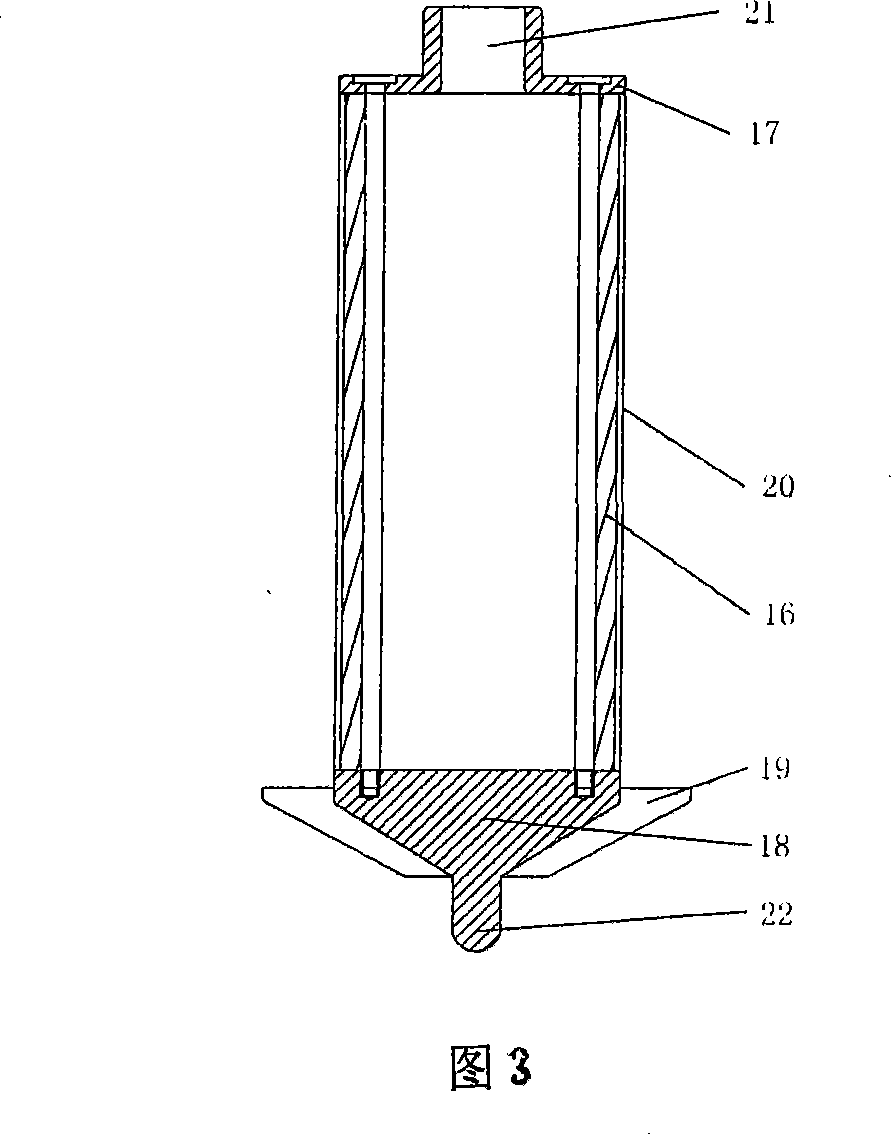

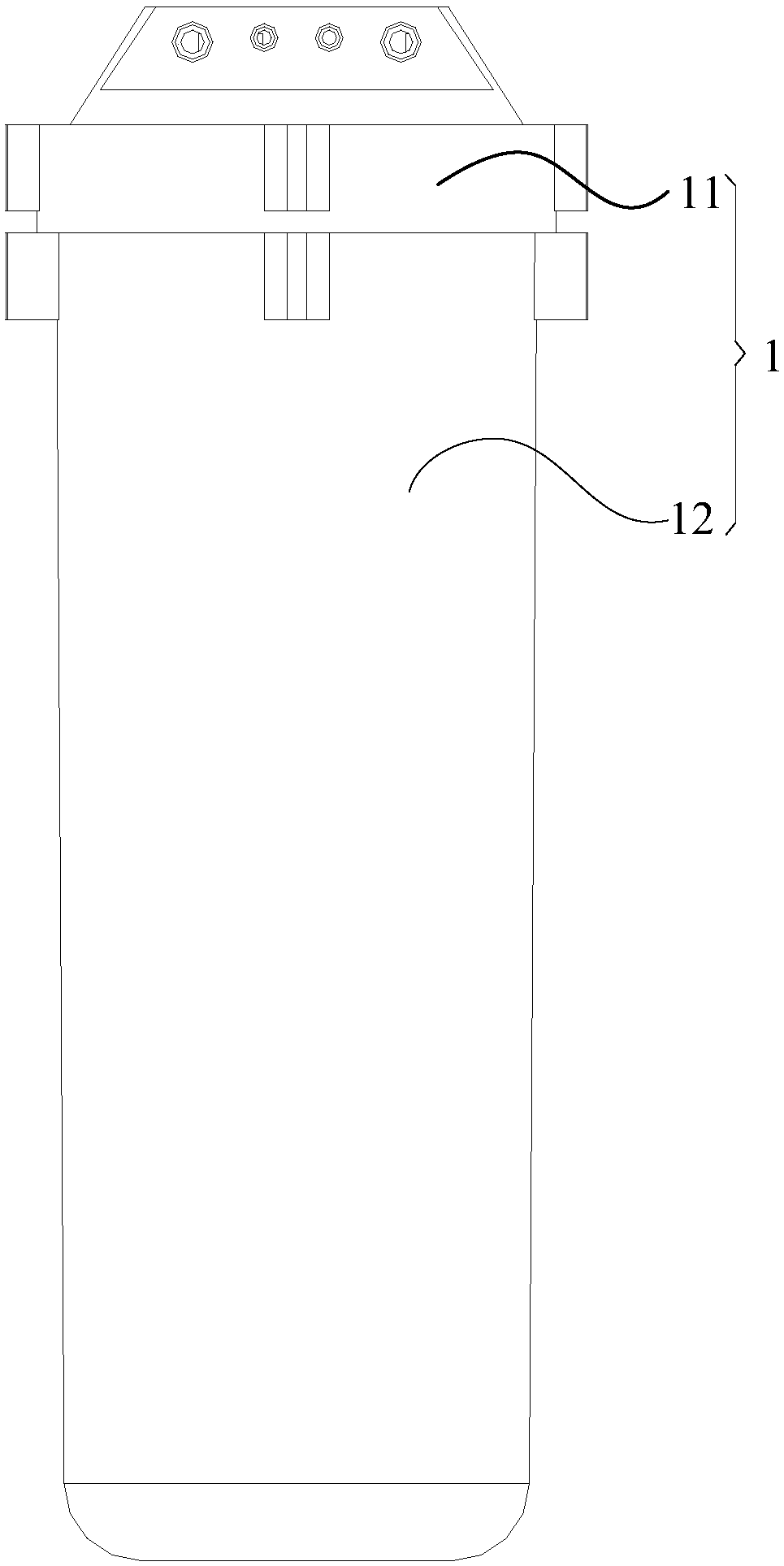

Nano-aperture metal filter element and preparation method thereof

InactiveCN113577908AIncreased stability and longevityEasy assemblyFiltration separationPhysicsEngineering

The invention discloses a nano-aperture metal filter element and a preparation method thereof. The nano-aperture metal filter element comprises a filter material, an end cover located at the opening end of the filter material and a chuck, a convex positioning part is formed at the end of the filter material, the end cover and the chuck are located on the two sides of the positioning part respectively, and the positioning part is fixed between the end cover and the chuck. A sealing component is arranged between the end cover and the positioning part. During preparation, the filter material, the end cover, the chuck, the sealing component and other auxiliary materials can be separately processed without welding, so that a user can select different components for combined use according to use requirements, and can independently replace and use a component after the part of the components are damaged without completely replacing the components, the use cost of the filter element is reduced, and meanwhile, the filter element also has extremely high sealing performance and an extremely good use effect.

Owner:四川好鑫量子科技有限公司

Composite filter element and water purification equipment

ActiveCN107913540BMeet Filtration NeedsReduce usageTreatment involving filtrationWater/sewage treatment apparatusStructural engineeringComposite filter

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

Filter network applied to industry

PendingCN108159780AEasy to install and disassembleHigh mechanical strengthDispersed particle filtrationStationary filtering element filtersEngineeringTextile

Owner:四会市华通金属筛网制品有限公司

Liquid mist filtering smoking set with controllable filtering effect

PendingCN112641131AMeet Filtration NeedsControl Key IndicatorsTobacco pipesMixing chamberMechanical engineering

The invention discloses a liquid mist filtering smoking set with a controllable filtering effect, the liquid mist filtering smoking set comprises a smoke inlet, a liquid mist generating device, a mixing chamber, a smoke outlet and a control system, and is characterized in that the smoke inlet is communicated with the mixing chamber, and smoke enters the mixing chamber from the smoke inlet; the smoke outlet is communicated with the mixing chamber; the liquid mist generating device is communicated with the mixing chamber; after liquid mist generated by the liquid mist generating device and the smoke are mixed in the mixing chamber, the mixed smoke flows out from the smoke outlet; and the control system is arranged to receive a user instruction and control the liquid mist filtering smoking set to operate according to the instruction.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Composite filter element and water purification device

PendingCN110404330AReduce the number of usedSimplify water connectionsTreatment involving filtrationFiltration circuitsComposite filterEngineering

The invention discloses a composite filter element and a water purification device. The composite filter element comprises a shell, a water guiding pipe and an inner barrel; the lower end of the innerbarrel is an open end, the water guiding pipe comprises a cover body and a pipe body disposed on the cover body in a penetrating mode, the lower end of the inner barrel is covered with the cover bodyin a sealing mode, and the pipe body is arranged in the inner barrel in a penetrating mode; the inner barrel is disposed in the shell, a first filter cavity is formed in the inner barrel, a second filter cavity is formed between the lower part of the shell and the cover body, and the first filter cavity and the second filter cavity are independent of each other; a first filter element is disposedin the first filter cavity, and a second filter element is disposed in the second filter cavity; a first flow path is formed between the outer wall surface of the inner barrel and the inner wall surface of the shell at intervals, and a second flow path is formed between the lower side surface of the cover body and the inner wall surface of the shell at intervals, and the first flow path communicates with the second flow path; and a third flow path is disposed in the pipe body, and the third flow path is in communication with the second flow path. The technical scheme of the composite filter element and the water purification device enables the composite filter element to be provided two independent filter channels.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG +1

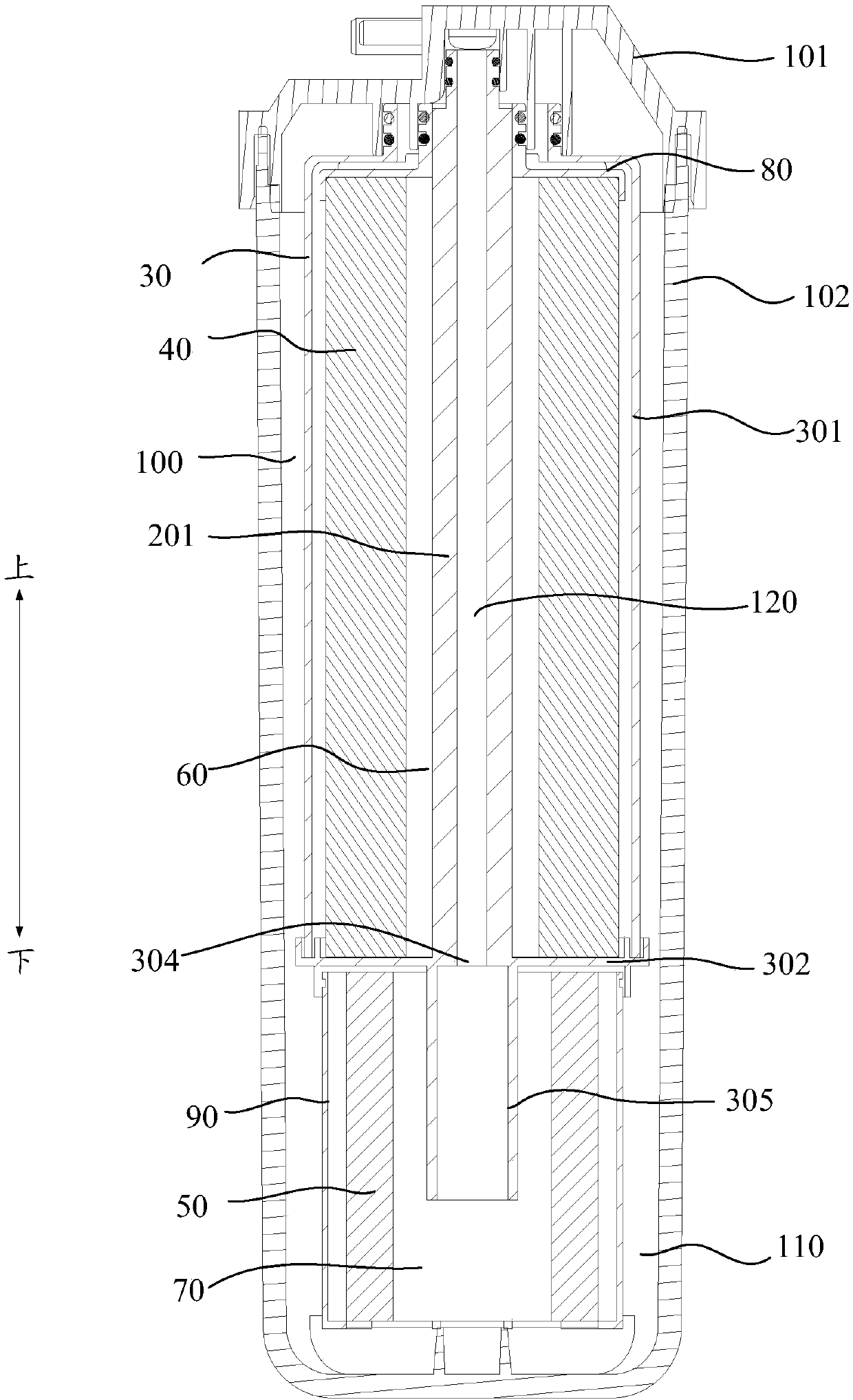

Composite filter element and water purification equipment

ActiveCN111495005AMeet Filtration NeedsReduce usageTreatment involving filtrationWater/sewage treatment apparatusFiltrationComposite filter

The invention discloses a composite filter element and water purification equipment, wherein the composite filter element comprises a filter element joint, an outer barrel, an inner barrel, a separation disc, a first filer core and a second filter core; the upper end of the outer barrel is connected with the filter element joint in a sealing manner; the inner barrel is arranged in the outer barrel, and the upper end of the inner barrel is connected with the filter element connector in a sealed mode; the separation disc seals the lower end of the inner barrel, so that the inner barrel and the outer barrel form a first filter cavity and a second filter cavity which are relatively independent, the interior of the inner barrel is a first filter cavity, the exterior of the inner barrel is a second filter cavity, and a gap is formed between the outer side of the inner barrel and the inner side of the outer barrel to form a water inlet channel of the second filter cavity; the first filter element is arranged in the first filter cavity; and the second filter element is arranged in the second filter cavity and is positioned below the separation disc. According to the invention, independentfiltration of two water qualities is further realized so as to meet the filtration requirements of users on various water qualities.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com