Patents

Literature

43results about How to "No need to disassemble and clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

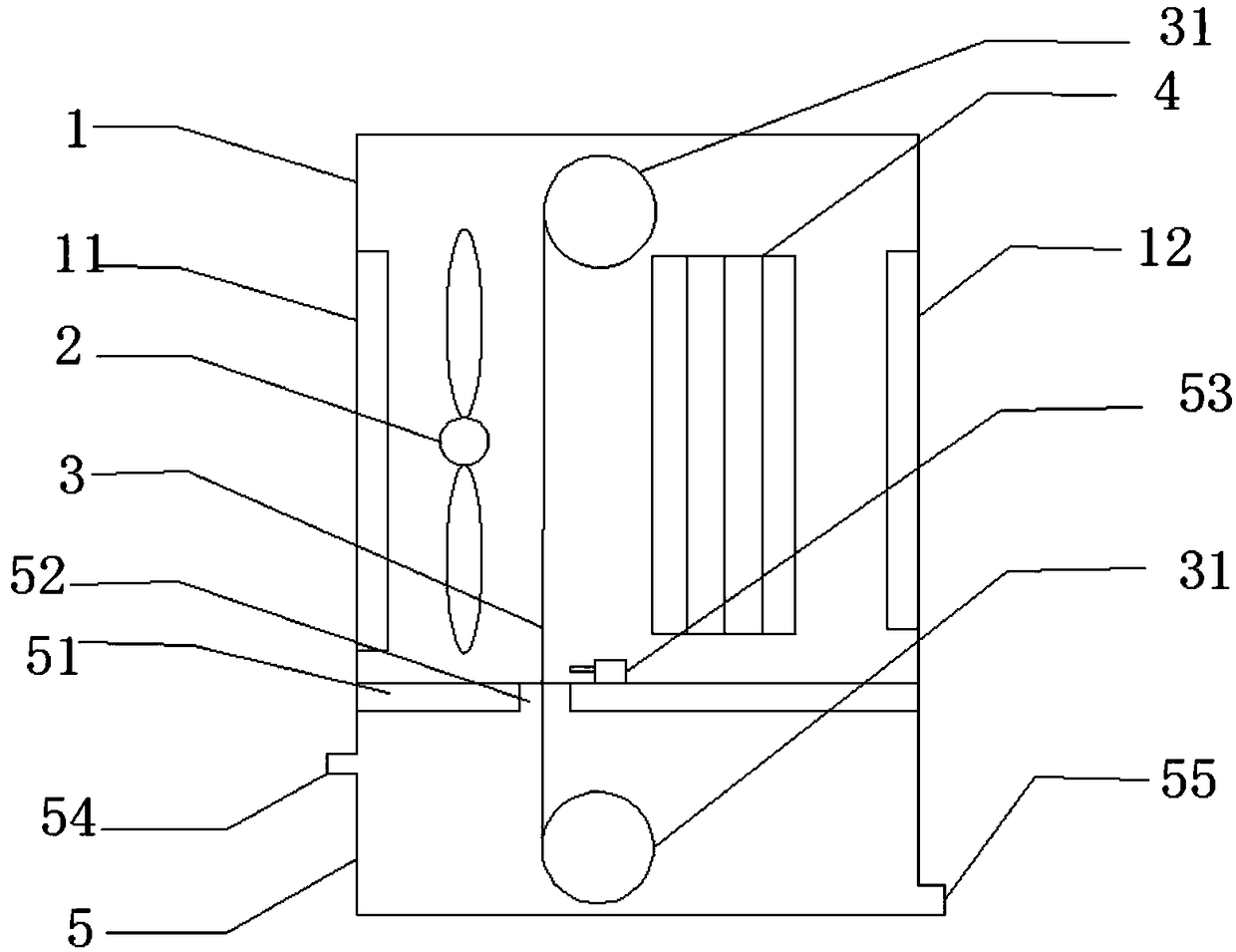

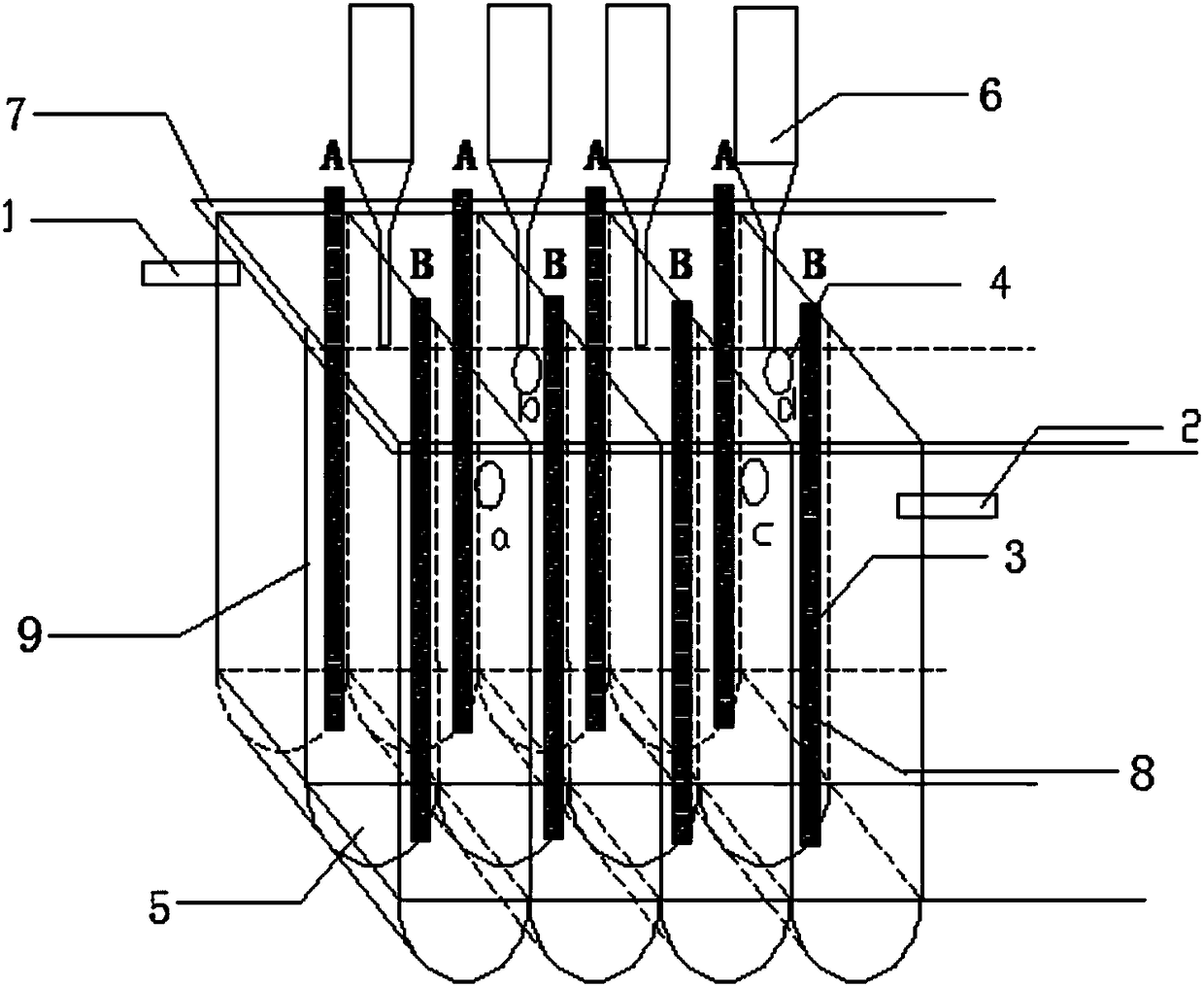

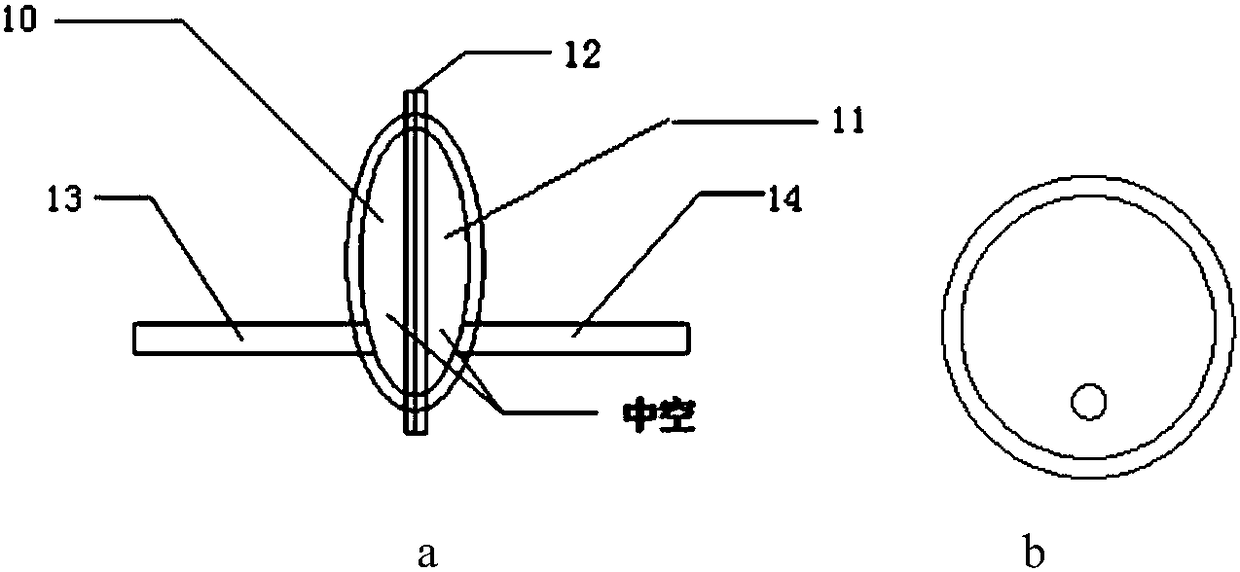

Electrostatic lampblack purifier

ActiveCN111111927AImprove purification efficiencyReduce maintenance costsExternal electric electrostatic seperatorElectrodes cleaningEnvironmental engineeringParticle adsorption

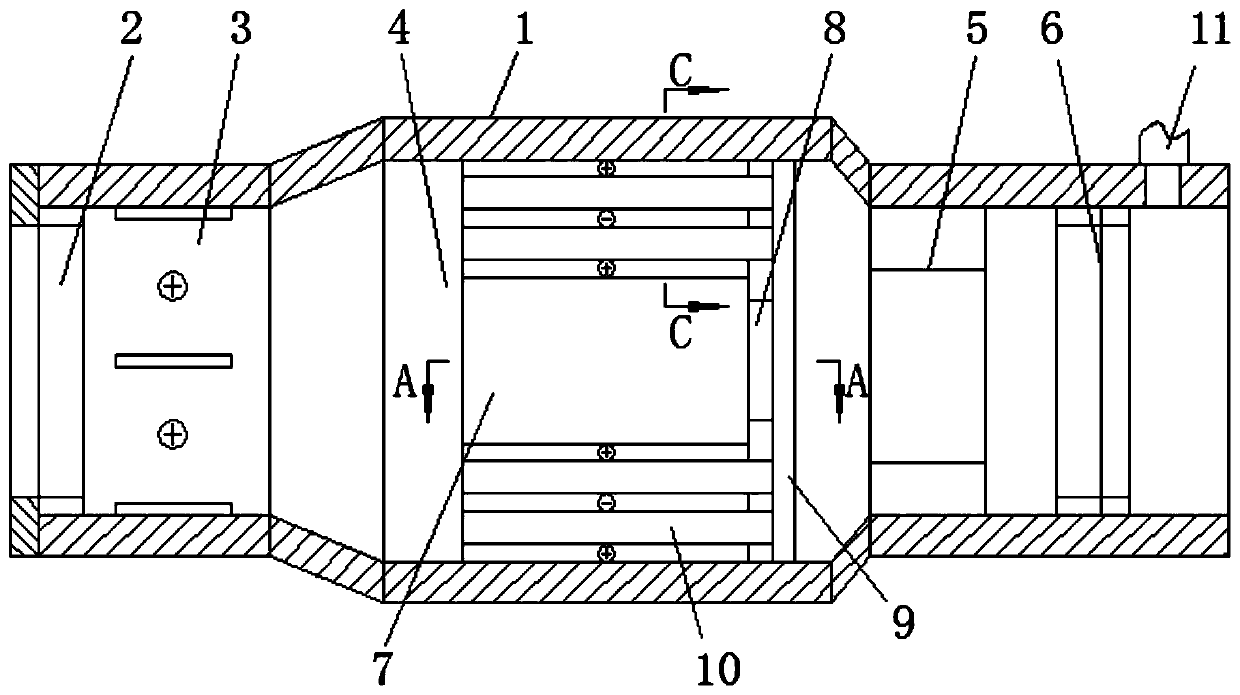

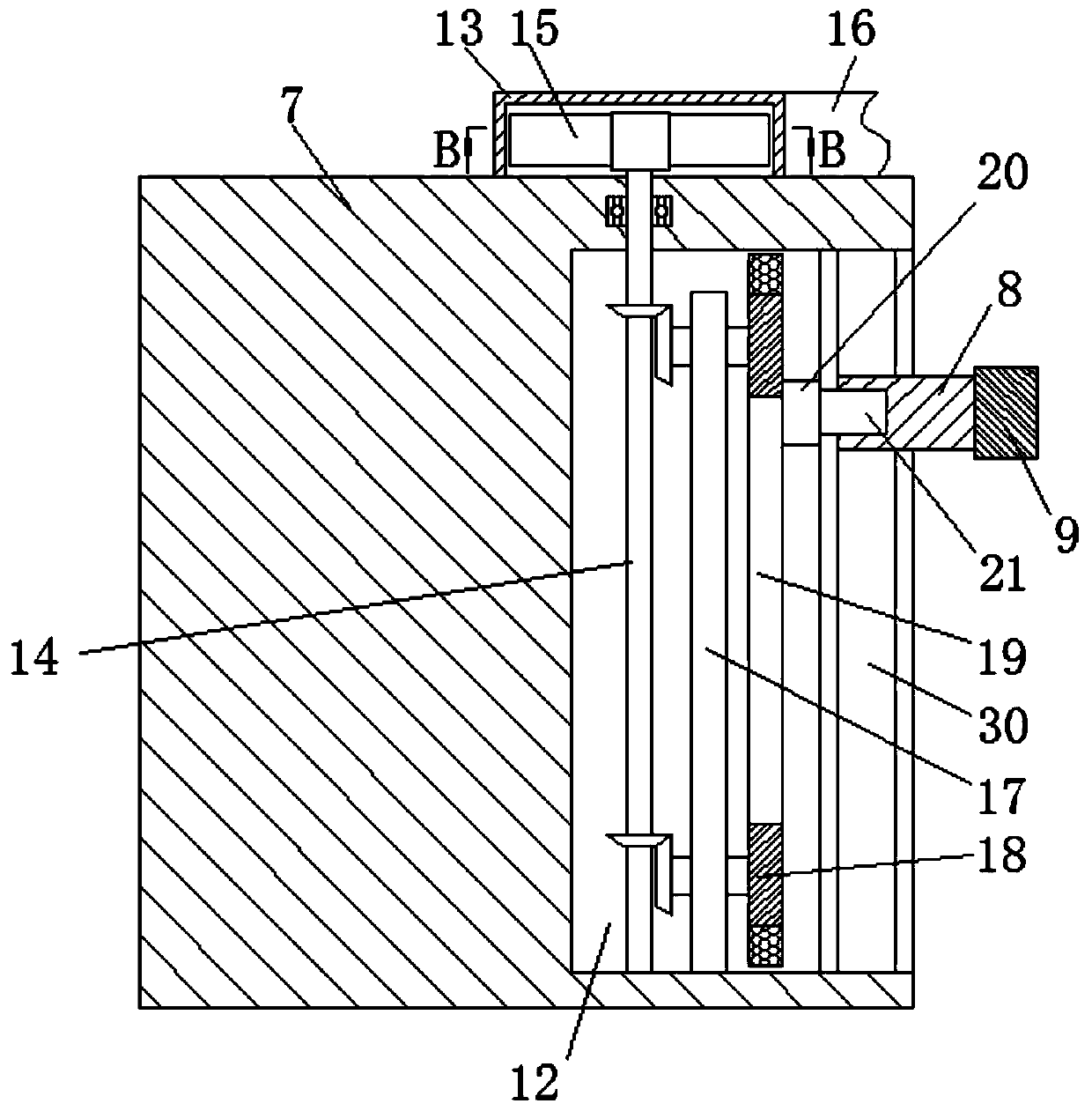

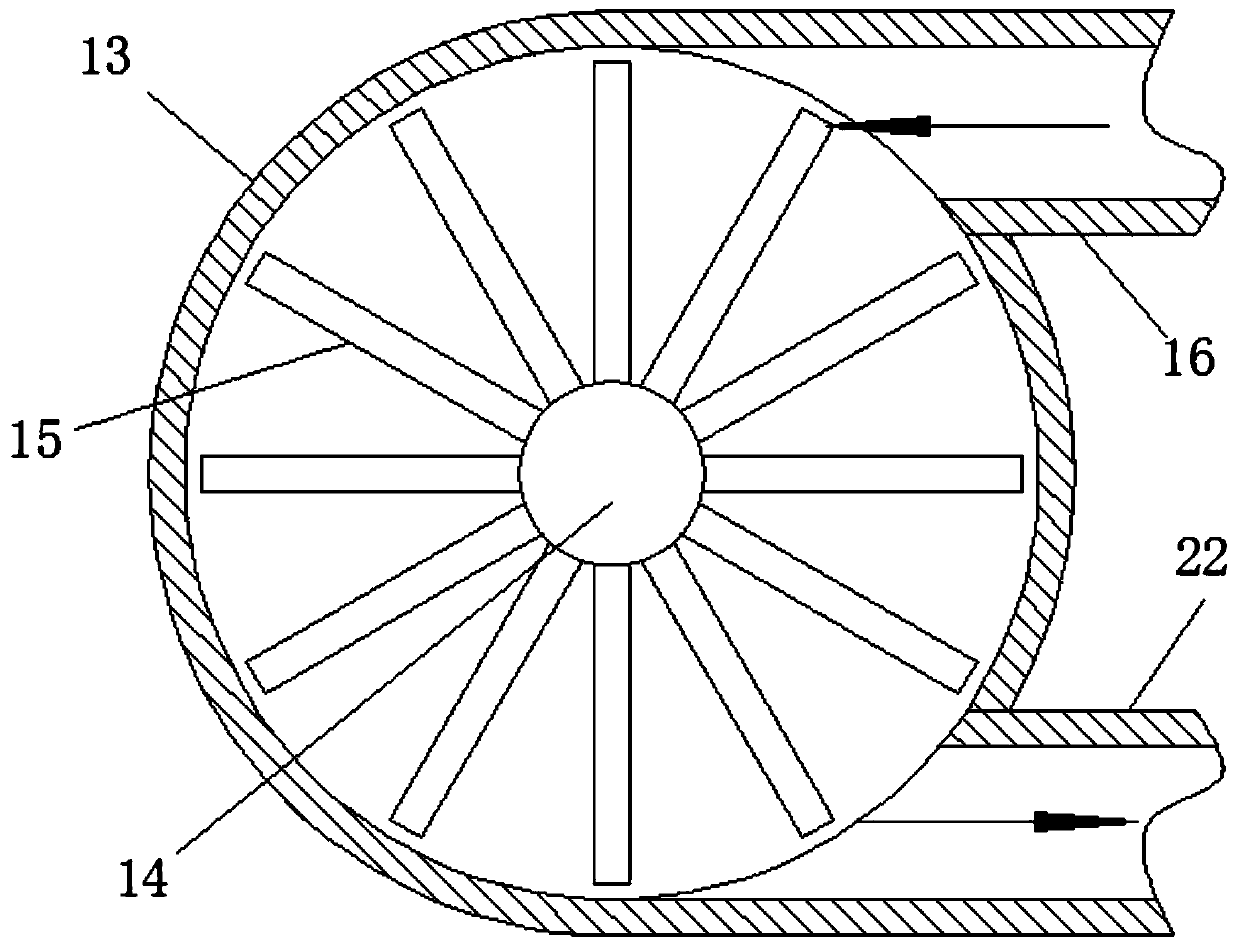

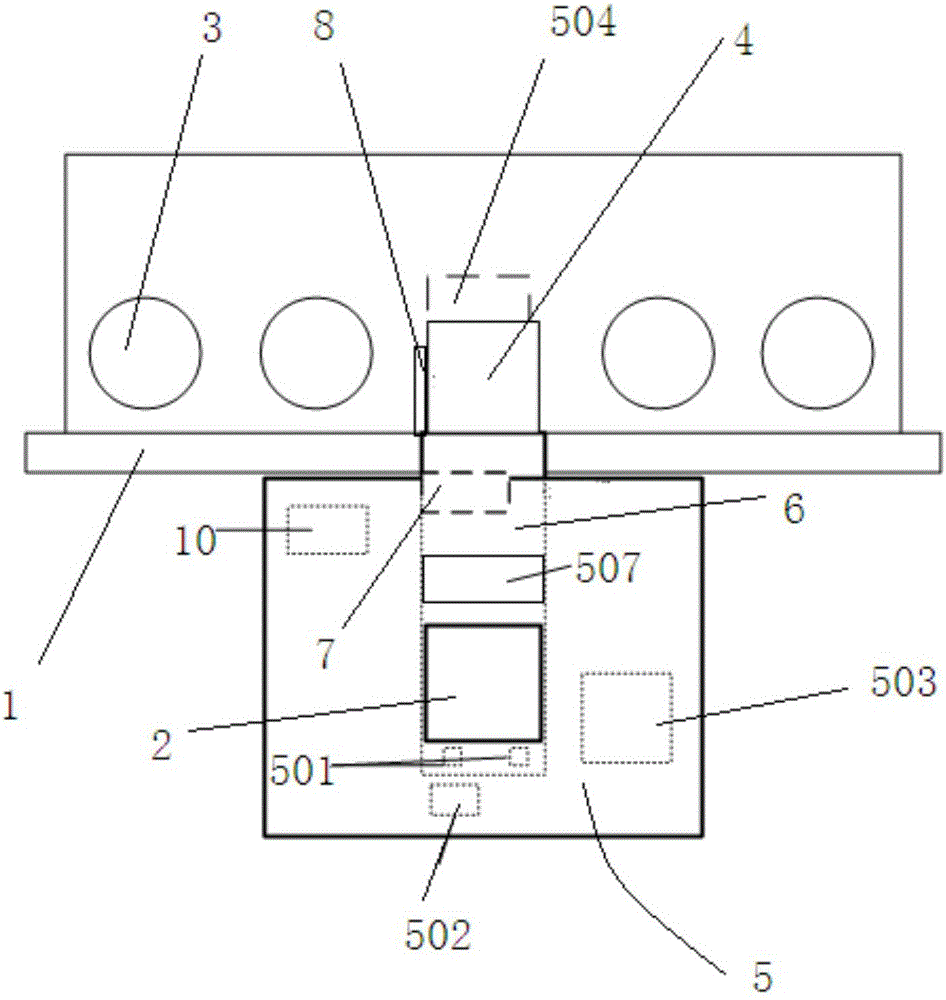

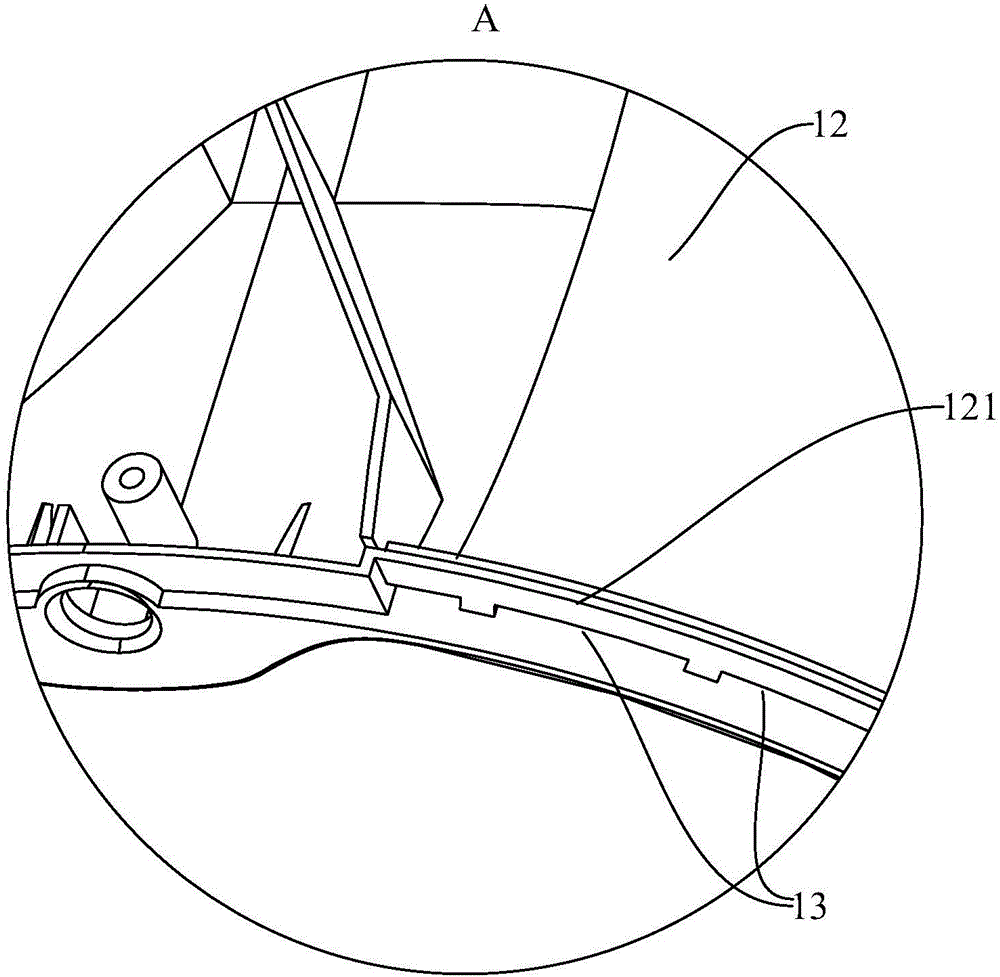

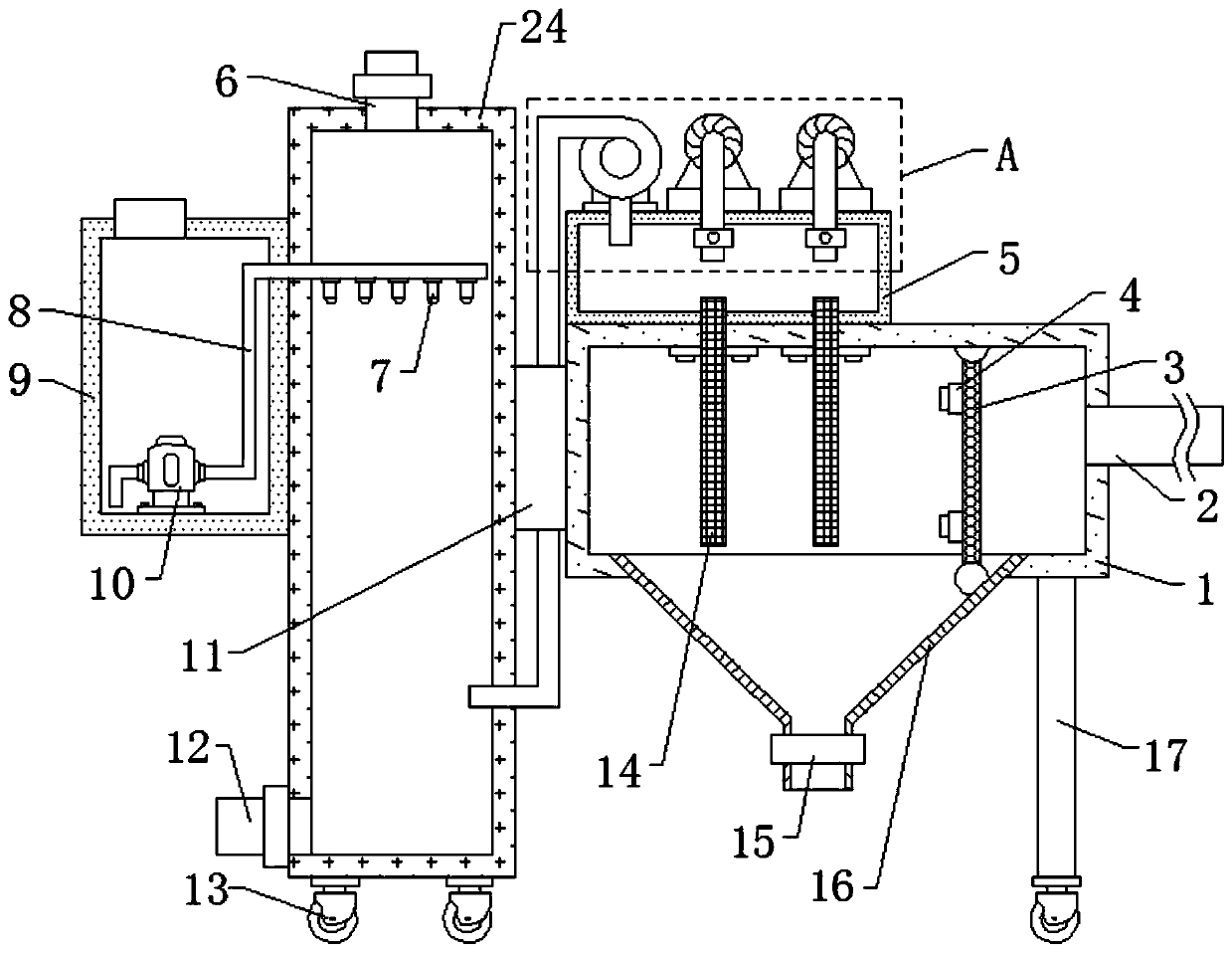

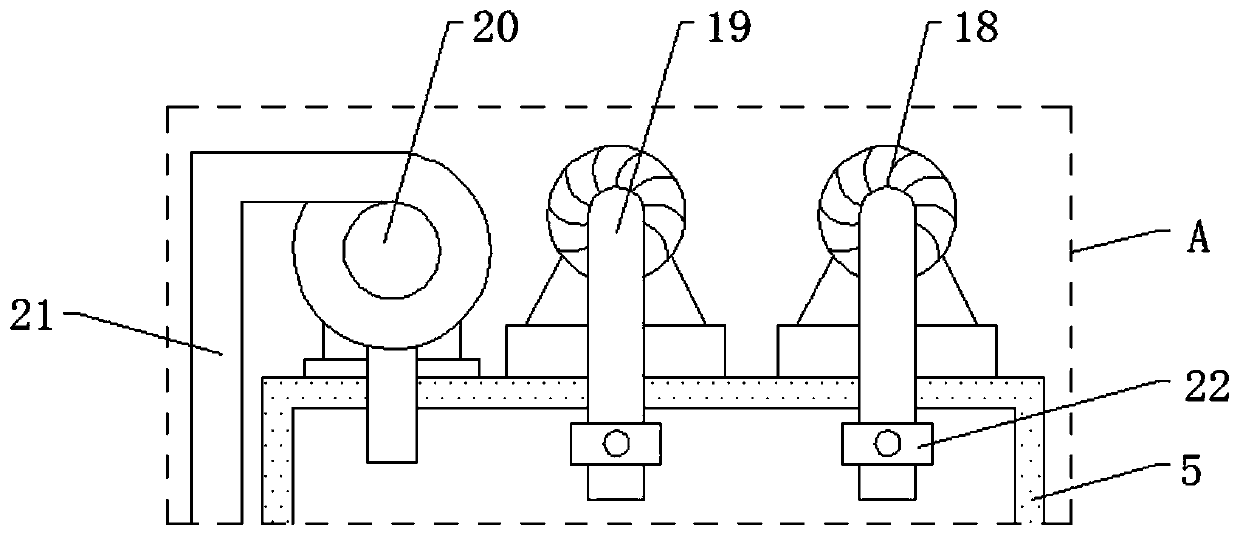

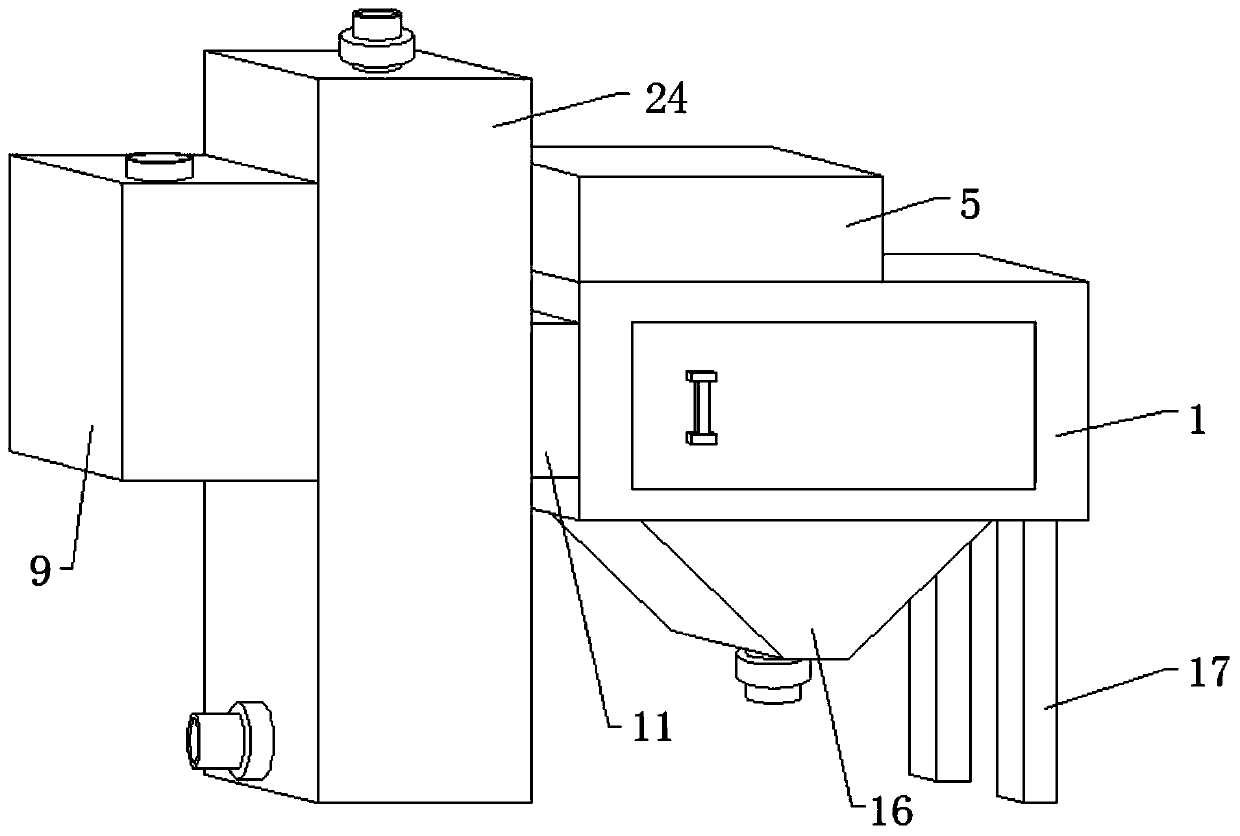

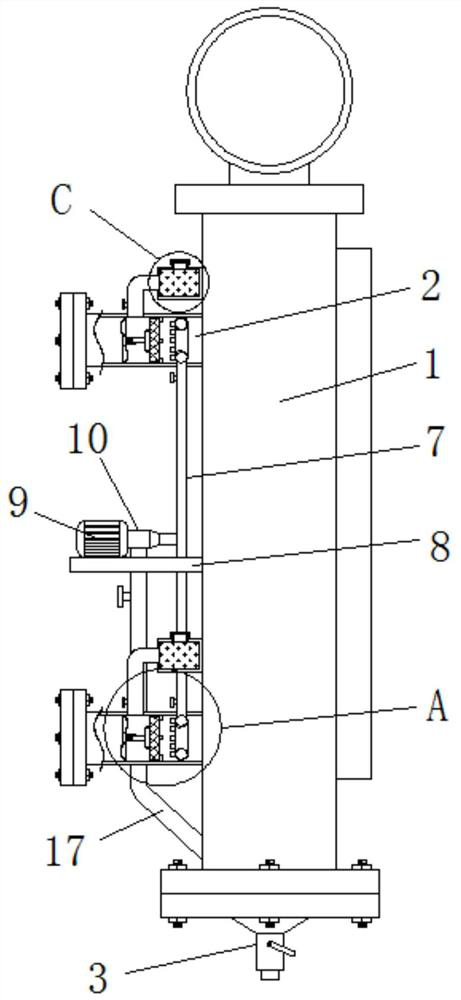

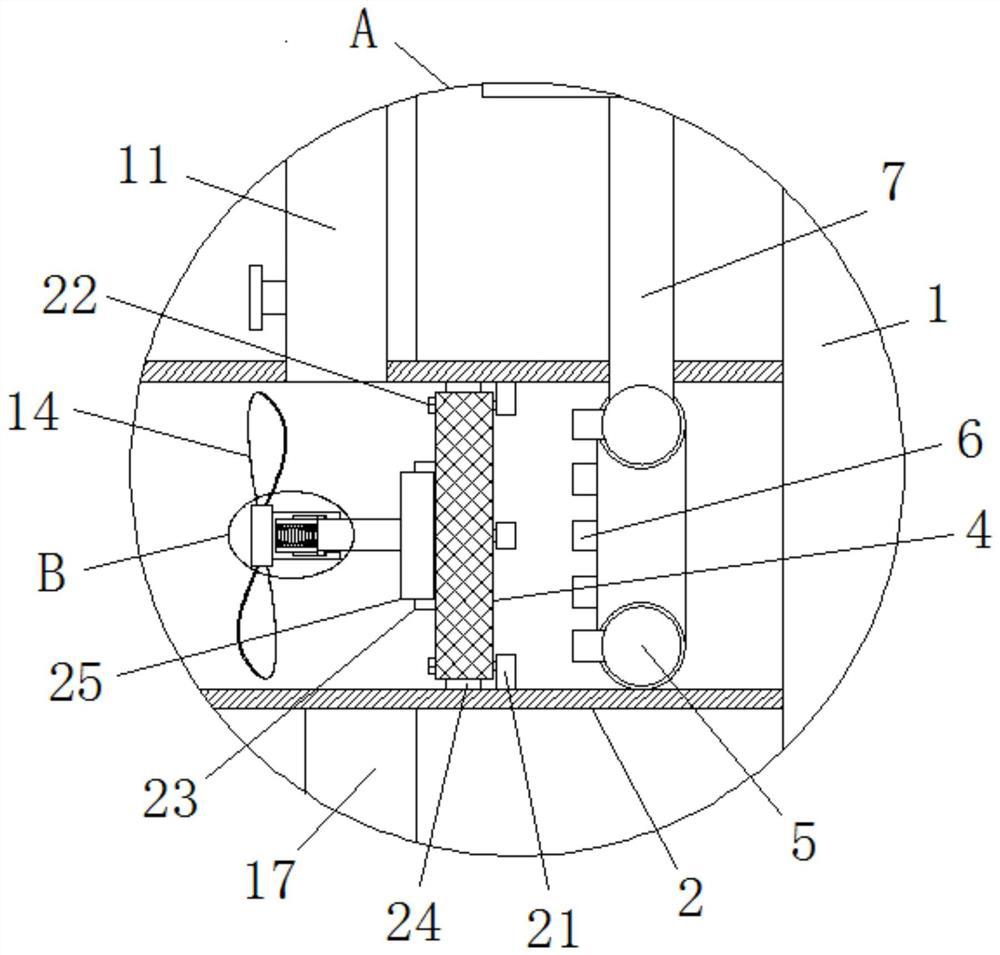

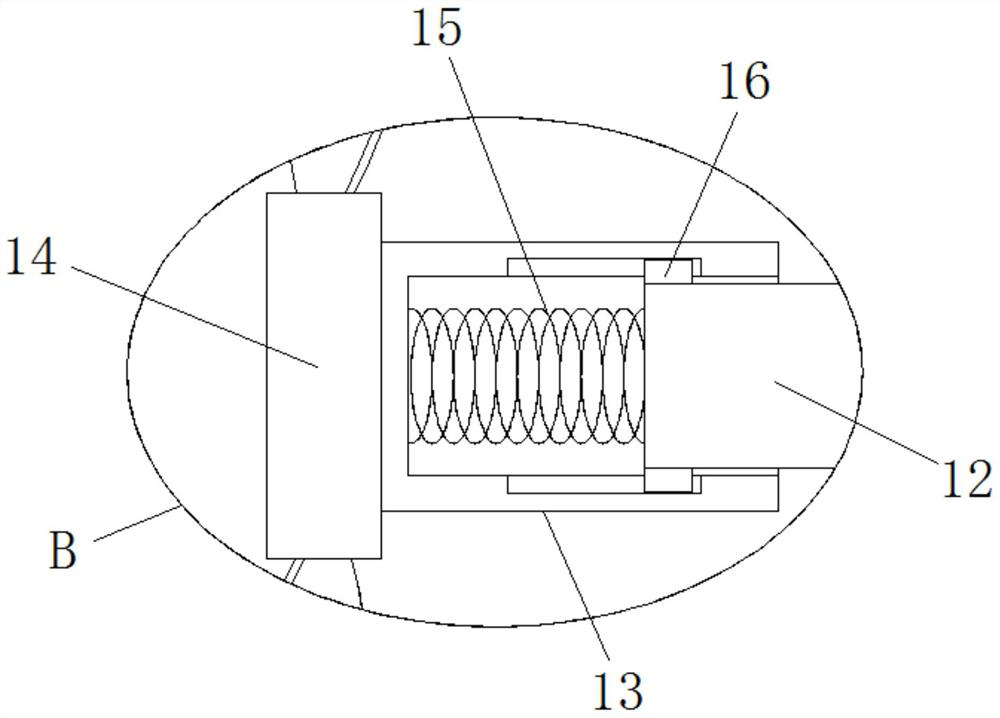

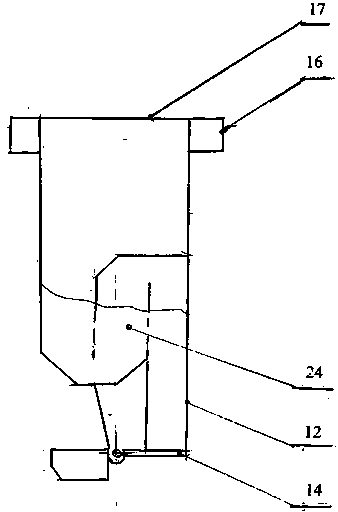

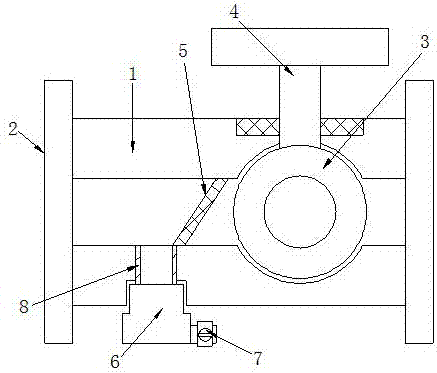

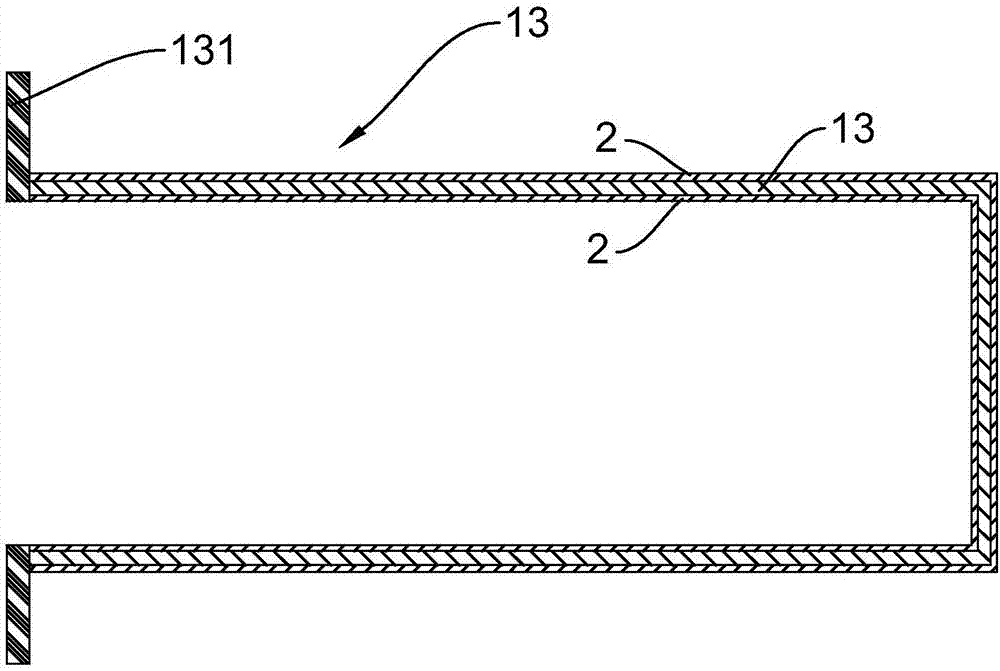

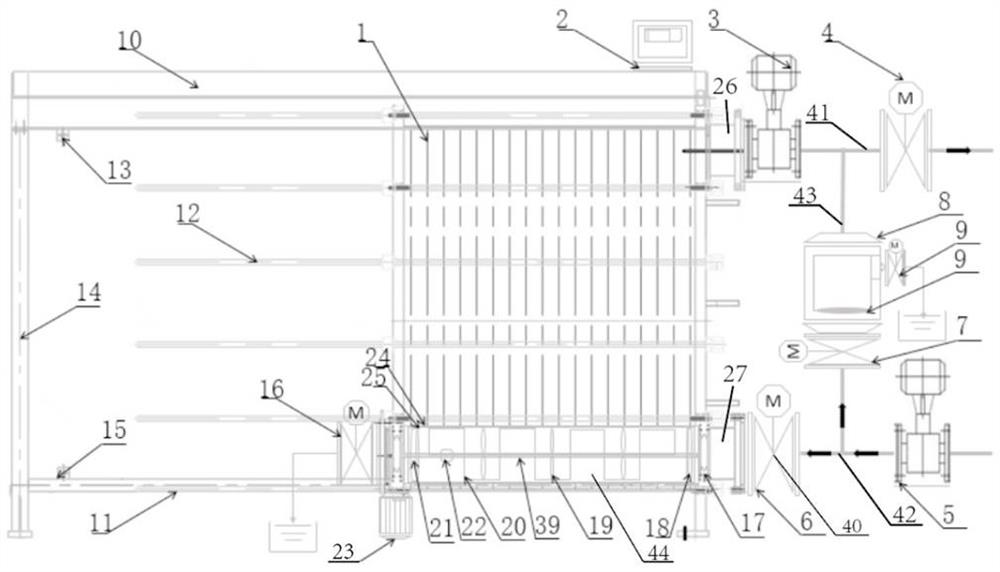

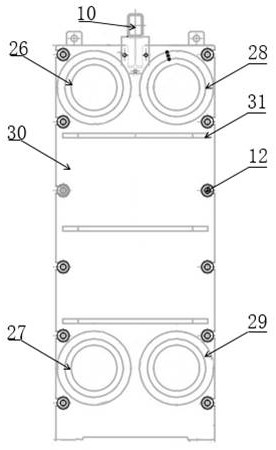

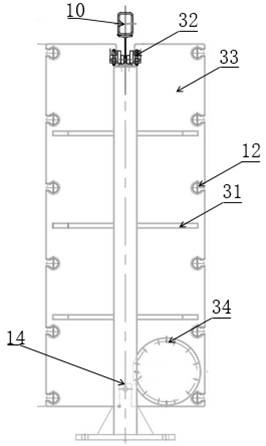

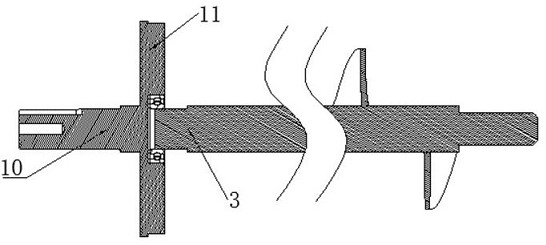

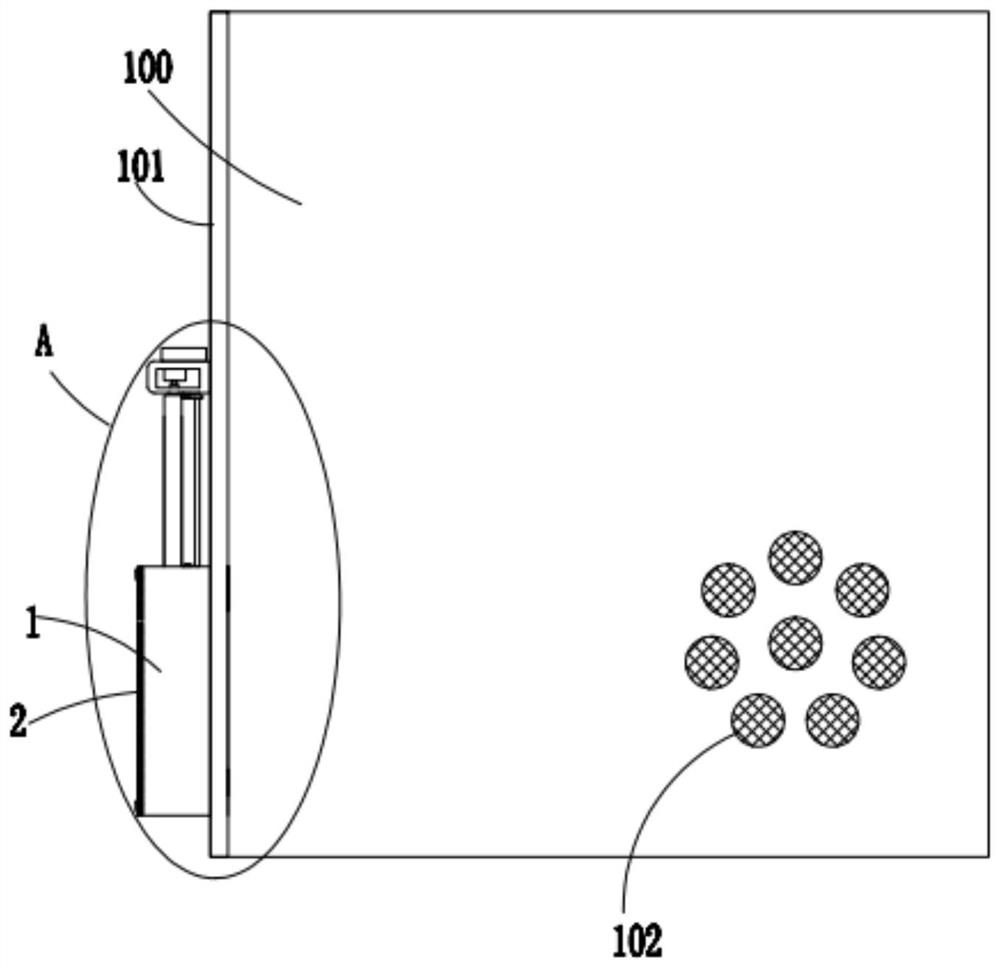

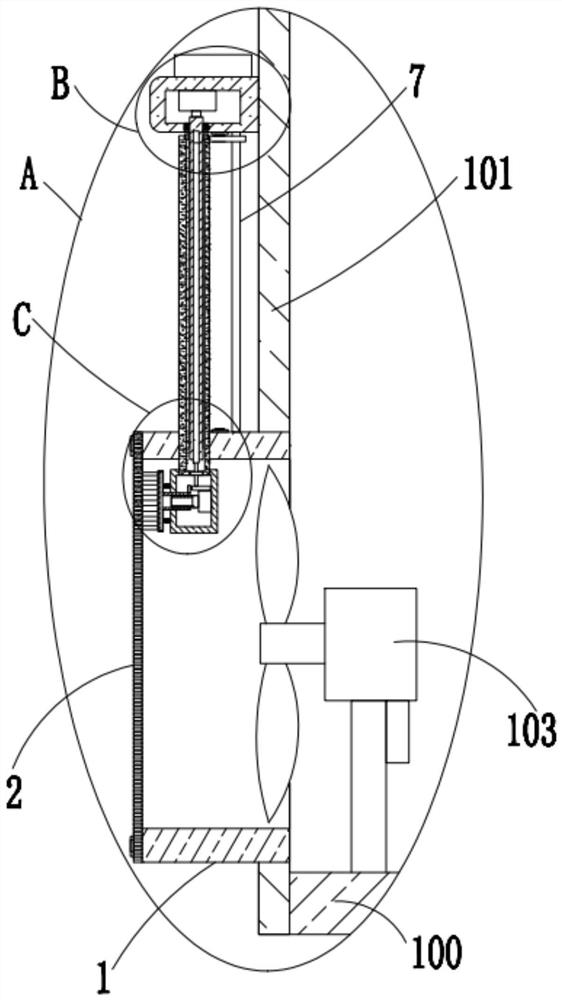

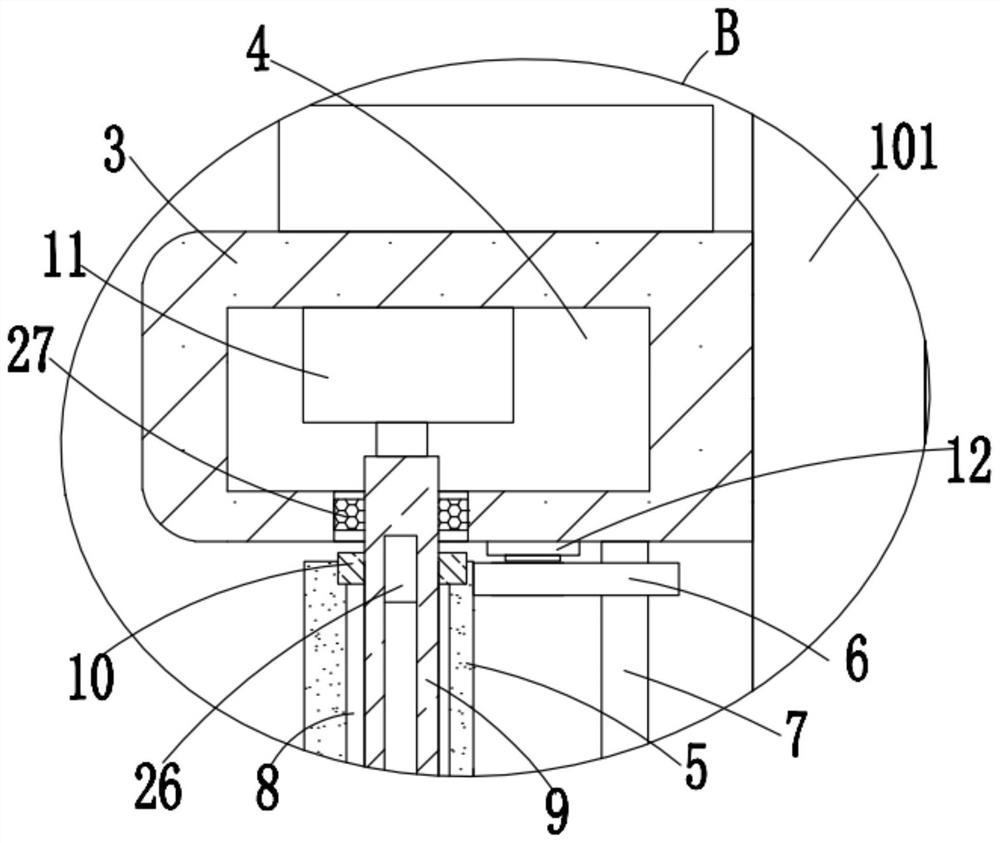

The invention relates to the field of lampblack purification equipment, in particular to an electrostatic lampblack purifier. The purifier comprises a housing, and a front filtering and purifying device, a high-voltage ionization field, a low-voltage electrostatic adsorption field, an axial flow fan and a rear filtering and purifying device are sequentially arranged in the shell from left to right. The low-voltage electrostatic adsorption field comprises an electrode plate group and a driving box, a driving mechanism and a lifting mechanism are arranged on the driving box, an oil scraping mechanism used for scraping oil stains on the electrode plate group is arranged on electrostatic lampblack purifier utilizes an air flow as driving force to allow the lifting mechanism to drive the oil scraping mechanism to perform oil scraping operation on the electrode plate, so that real-time cleaning of the electrode plate is achieved, the service life of the electrode plate is prolonged, the electrode plate is kept in a stable and efficient oil mist particle adsorption effect all the time, the lampblack purification efficiency is improved, the electrode plate does not need to be disassembledand cleaned, time and labor are saved, and the maintenance cost of the lampblack purifier is greatly reduced.

Owner:北京鑫皓超燃厨具设备有限公司

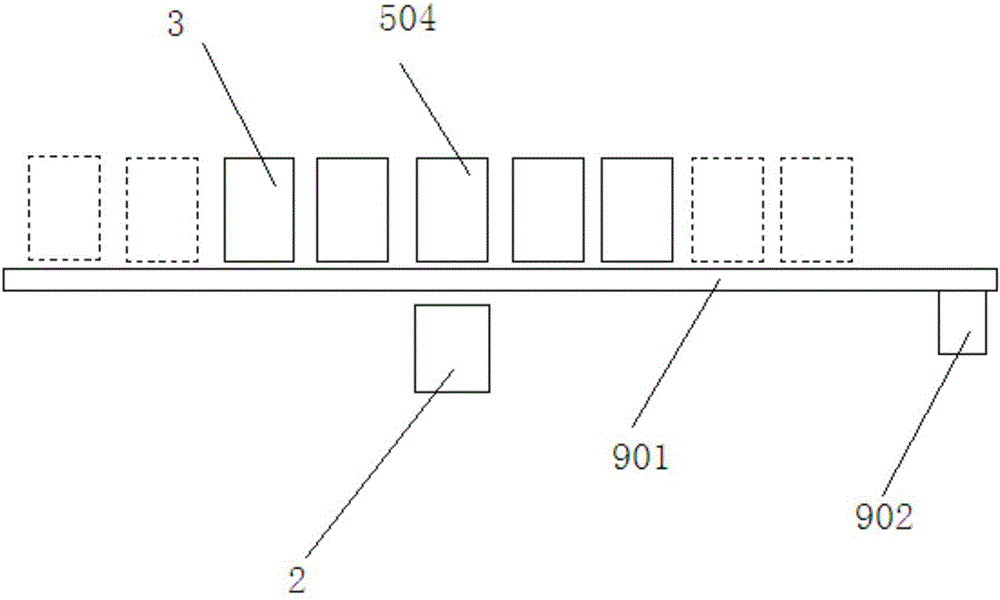

Medical waste classification system provided with cleaning device

InactiveCN106185103ANo need to disassemble and cleanEasy follow-up maintenanceCleaningHollow article cleaningSprayerMedical waste

The invention discloses a medical waste classification system provided with a cleaning device. The medical waste classification system comprises a wall body, a casting opening, a plurality of garbage cans and a sprinkling system, wherein the sprinkling system comprises a plurality of sprayers and a water pump; one end of the water pump is connected to a disinfectant device through a pipeline; the other end of the water pump is connected to a sewage pipe; the sewage pipe is connected to a sewage barrel; the sprayers are arrange on the upper part of a conveyer belt; the sewage barrel is arranged in the middle of the garbage cans; and the sewage barrel and the garbage cans are on the same straight line. According to the medical waste classification system provided with the cleaning device, the conveyer belt and a casting basket can be automatically cleaned on line by the system; detaching is not needed for cleaning; subsequent maintenance is facilitated; and a good effect is exerted on the infection prevention function of the whole machine.

Owner:SUZHOU DERPIN MEDICAL SCI & TECH CO LTD

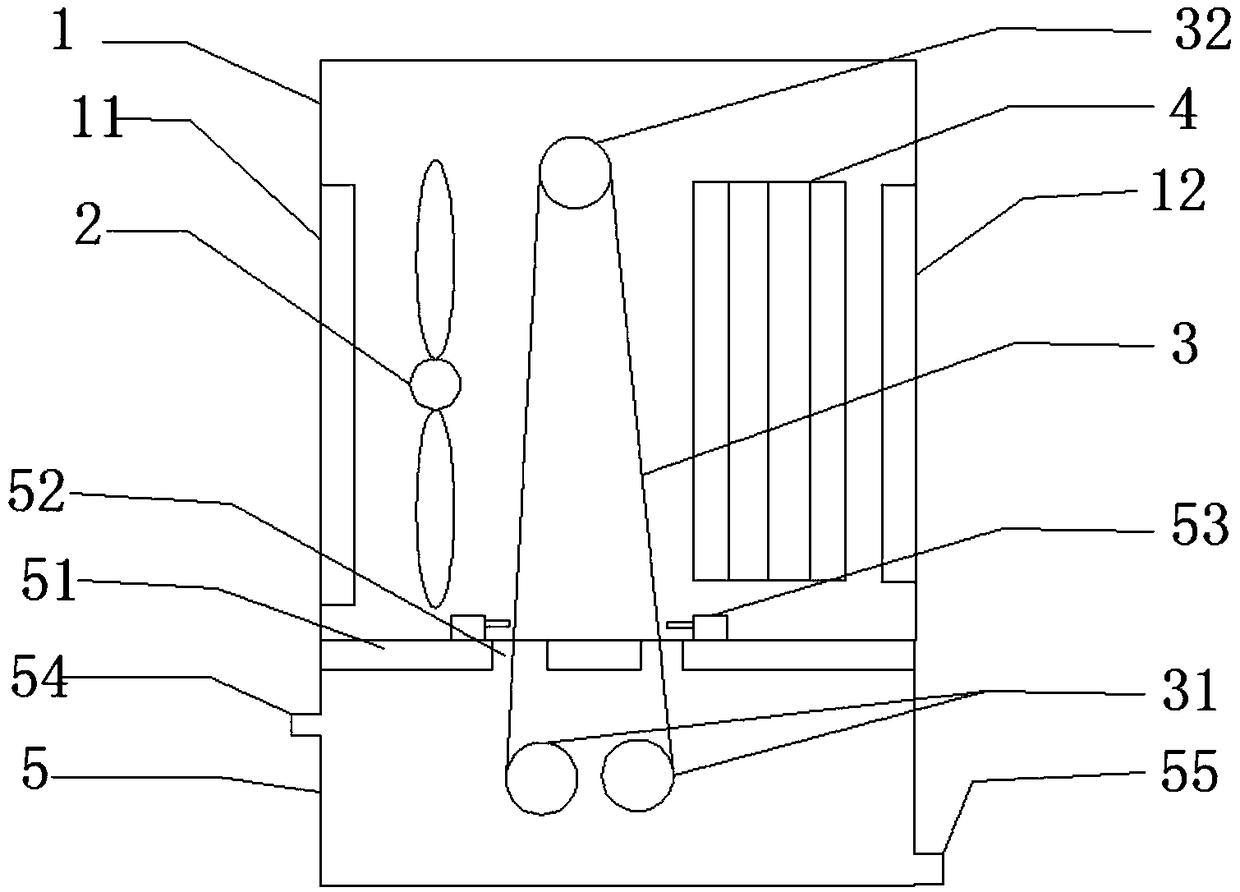

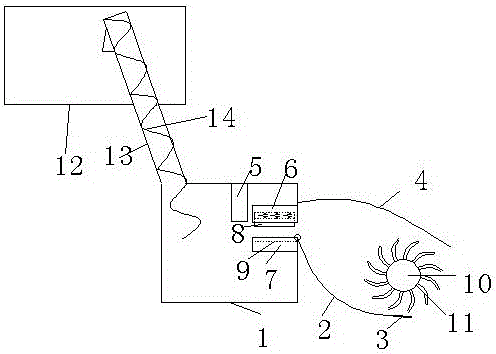

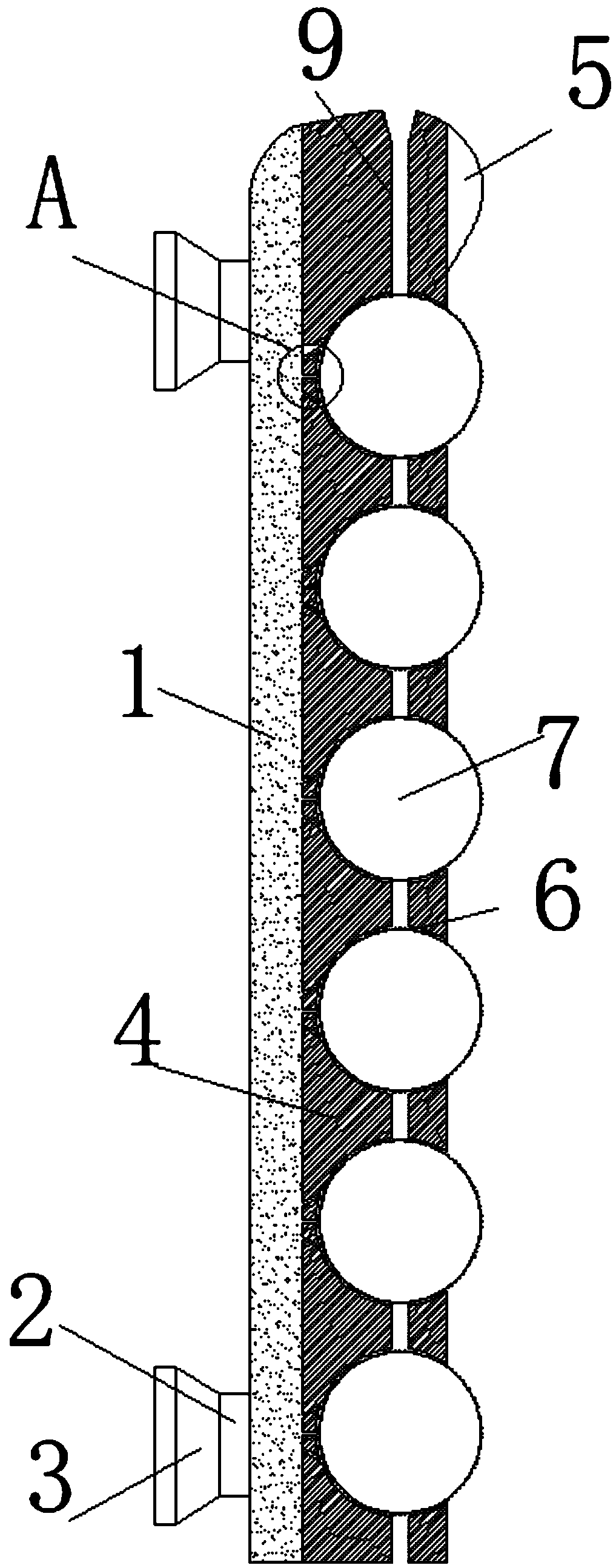

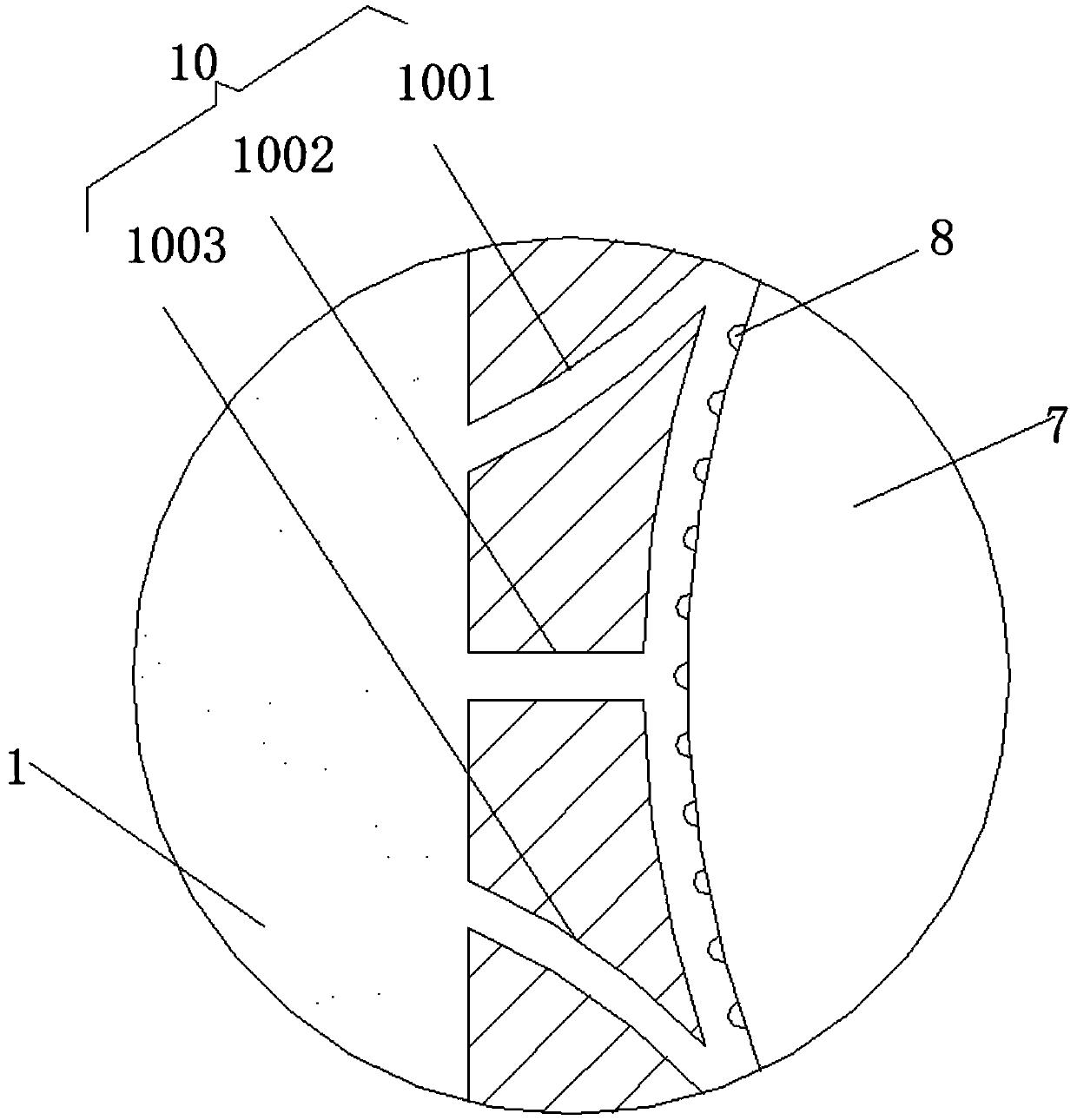

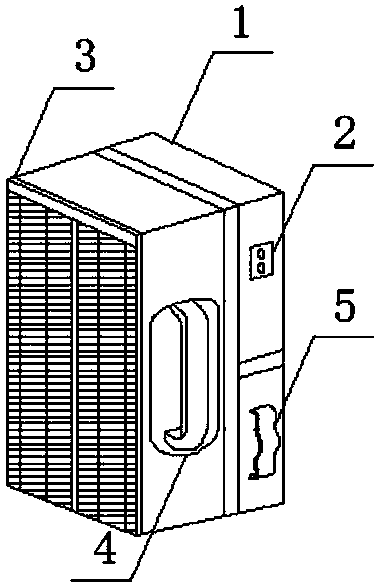

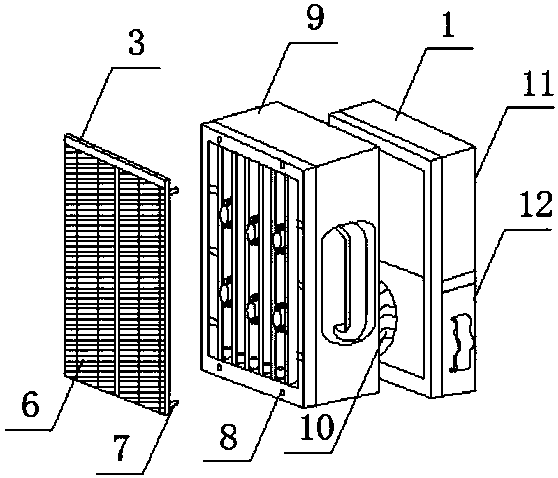

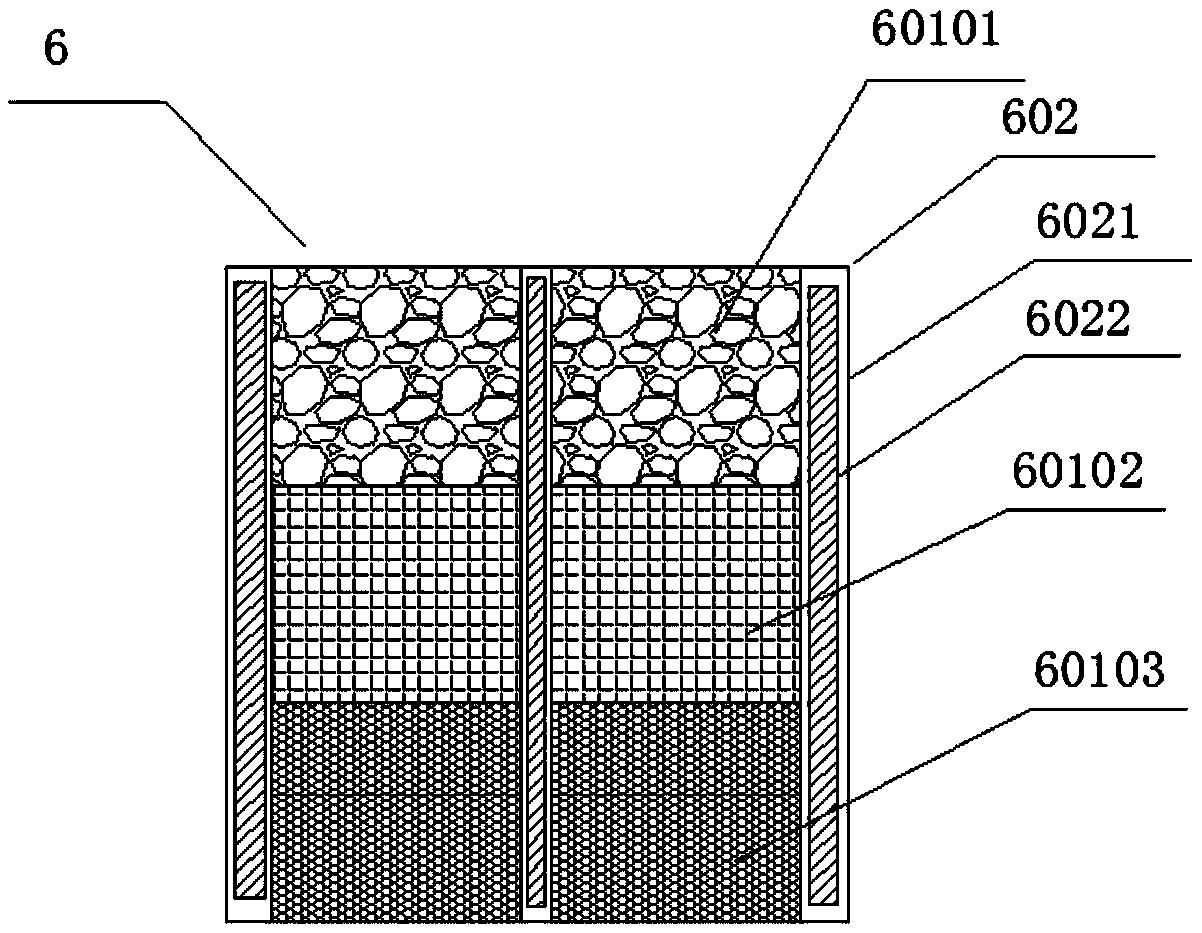

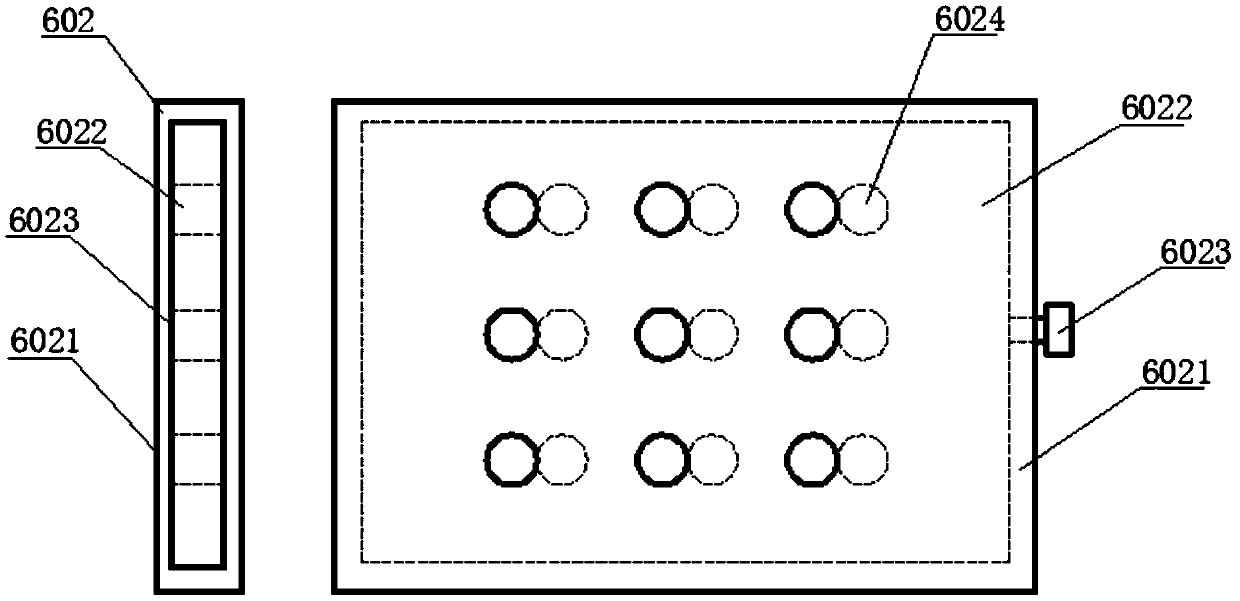

Air purifier capable of automatically cleaning filter screen

InactiveCN109126306AAvoid cloggingImprove purification efficiencyDispersed particle filtrationTransportation and packagingHEPAMotor drive

The invention discloses an air purifier capable of automatically cleaning a filter screen. The air purifier comprises a casing and a purifying unit disposed in the casing, wherein the purifying unit comprises an initial effect filter screen and a high efficiency filter screen group disposed in sequence in a gas flow direction; two ends of the initial effect filter screen are respectively wound ontwo reels disposed in parallel; the reels are connected with a motor with a controller; the motor drives the reels to rotate so as to drive the initial effect filter screen to move on the two reels ina reciprocating manner; the reels are disposed in a cleaning tank equipped with cleaning liquid; and the cleaning tank is disposed below the purifying unit. The air purifier provided by the inventionis capable of continuously replacing the initial effect filter screen on the outside while purifying air, and preventing the problem of the degradation of purification efficiency caused by the blockage of the initial effect filter screen, and can realize timely cleaning of the replaced initial effect filter screen.

Owner:亚都科技集团有限公司

Tree leaf collecting device for sweeping vehicle

Owner:NANTONG MINGNUO ELECTRIC TECH CO LTD

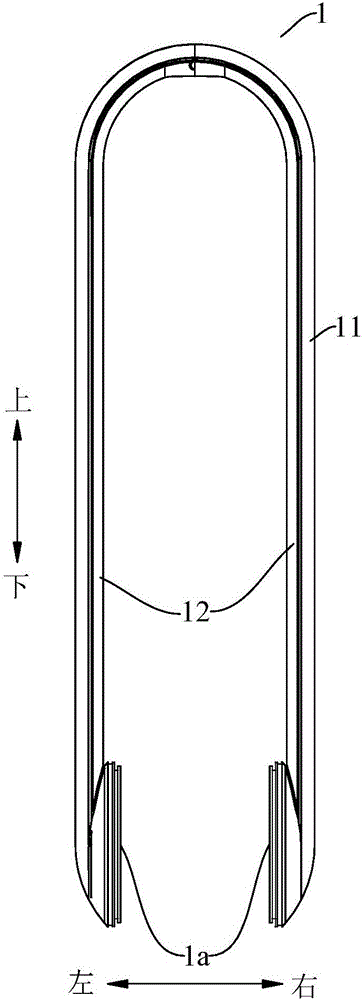

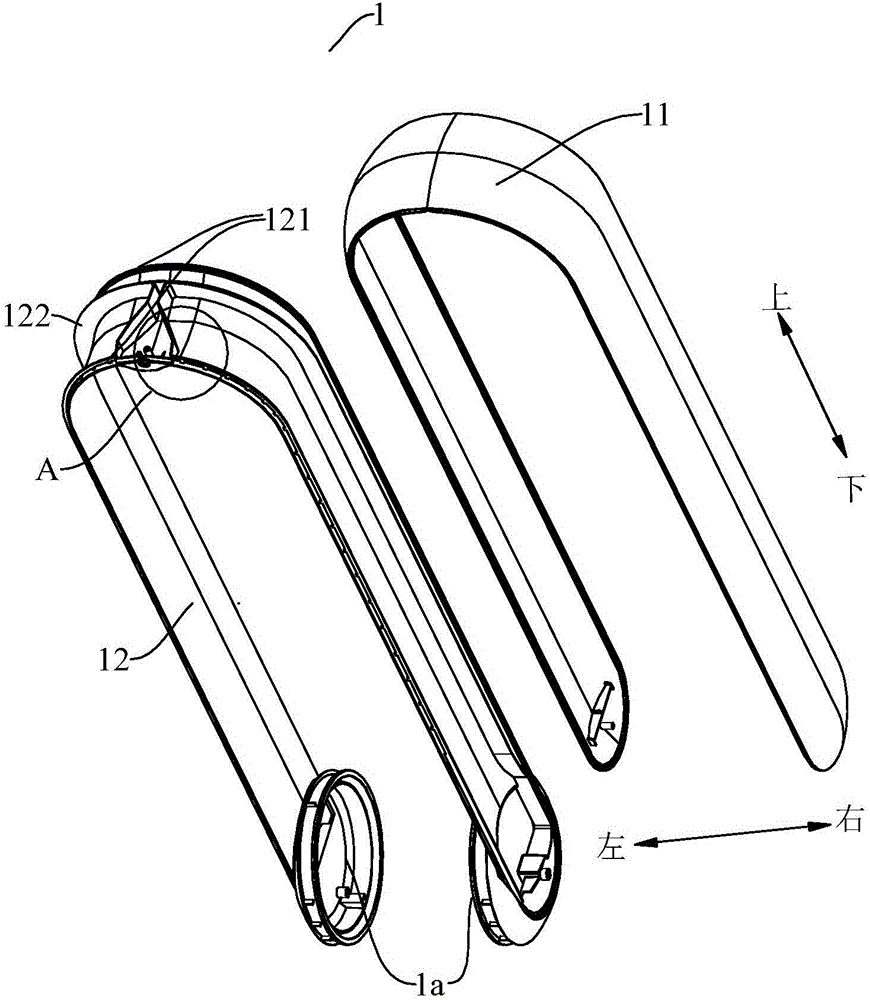

Bladeless fan machine head and bladeless fan provided with same

ActiveCN106194856ADoes not affect appearanceSimple structureJet pumpsPump installationsEngineeringAirflow

The invention discloses a bladeless fan machine head and a bladeless fan provided with the same. The bladeless fan machine head comprises a machine head inner shell and a machine head outer shell, wherein multiple connection parts extending along the length direction of the machine head inner shell are arranged on the machine head inner shell; the machine head outer shell covers the outer side of the machine head inner shell and is connected with the connection parts through welding; an air flow passage is defined between the machine head outer shell and the machine head inner shell; and inlets and air vents which communicate with the air flow passage are formed in the machine head outer shell and / or the machine head inner shell. According to the bladeless fan machine head disclosed by the embodiment of the invention, the multiple connection parts extending along the length direction are arranged on one side, opposite to the machine head outer shell, of the machine head inner shell, so that welding joints between the machine head outer shell and the machine head inner shell are located on the inner side of the machine head; and fixed connection between the machine head outer shell and the machine head inner shell is ensured, and the appearance attractiveness of the machine head is not affected. Furthermore, the whole component is of a closed structure, and during work of the bladeless fan, a user cannot touch any component in the machine head, so that use safety of the bladeless fan is ensured.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Waste gas filtering factory environment-friendly equipment

InactiveCN110975437AEasy to cleanNo need to disassemble and cleanGas treatmentDispersed particle filtrationFlue gasDust control

The invention discloses waste gas filtering factory environment-friendly equipment. The problem that a filter screen and other dust removal components need to be detached and cleaned is solved. The waste gas filtering factory environment-friendly equipment comprises a dust removal box and a spraying box, a connecting block is fixed on the outer wall of one side of the spraying box through bolts; the dust removal box is fixed to the side, away from the spraying box, of the connecting block through bolts; a dust inlet pipe is inserted into the outer wall of one side of the dust removal box; a mounting opening is formed in the outer wall of the bottom of the dust removal box, an ash bucket is fixed to the outer wall of one side of the mounting opening through bolts, a filter screen is hingedto the position, close to the dust inlet pipe, of the inner wall of the top of the dust removal box, one end of the filter screen is hinged to the inner wall of one side of the ash bucket, and multiple vibrators are fixed to the outer wall of one side of the filter screen through bolts. Flue gas is blocked for the first time through the filter screen, after the flue gas passes through the filter screen, part of dust and other impurities are left on the surface of the filter screen, then the dust and other impurities can fall down through vibration of the vibrator and are intensively dischargedthrough the dust hopper, and cleaning of the filter screen is facilitated.

Owner:夏立中

Anti-blocking mechanism of magnetic turning plate liquid level meter

PendingCN113101716AAvoid being blockedEasy to useLevel indicators by floatsStationary filtering element filtersJet flowEngineering

The invention relates to the technical field of liquid level meters, and discloses an anti-blocking mechanism of a magnetic turning plate liquid level meter. The anti-blocking mechanism comprises a liquid level meter body, which comprises two mounting pipes and a blow-down valve, wherein the right sides of the interiors of the two mounting pipes are connected with mounting mechanisms and are connected with filter screens through the mounting mechanisms, annular pipes are fixedly arranged at the positions, located on the right sides of the filter screens on the same sides, in the two mounting pipes, a plurality of evenly-distributed jet pipes are fixedly connected to the left sides of the pipe walls of the two annular pipes, a T-shaped connecting pipe is jointly and fixedly communicated between the two annular pipes, and a mounting plate is fixedly connected to the left outer side wall of the liquid level meter body. According to the anti-blocking mechanism of the magnetic turning plate liquid level meter, solid particle impurities embedded in the filter screen can be rapidly cleaned so as to prevent the blocking phenomenon, disassembly is not needed so as to facilitate the continuous detection of a detected medium, and the situation that due to the fact that the flow speed of the medium is too high, the magnetic floater excessively floats up and down, and observation of the detection effect is affected can be prevented.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Replaceable permanent combined odor-resistant floor drain core

InactiveCN103790225ANot easy to evaporateNot easy to loseSewerage structuresDomestic plumbingEngineeringWater pipe

The invention discloses a replaceable permanent combined odor-resistant floor drain core which comprises a seal water pipe, a close plate and a mounting support. The seal water pipe and the mounting support are structurally integrated, a seal water chamber is formed inside the seal water pipe, the close plate is hinged to a top inlet and / or a bottom outlet of the seal water chamber and is of a valve type structure, the close plate and the seal water chamber are in closed states when the replaceable permanent combined odor-resistant floor drain core is in a constant non-drain state, the close plate is automatically opened under impulse force of water when the replaceable permanent combined odor-resistant floor drain core is in a drain state, the water can be drained, and the normal closed states of the close plate and the seal water chamber are recovered after the water is completely drained. The seal water pipe is a straight drain seal water pipe or a lateral drain seal water pipe. The seal water chamber with internal S-shaped channels is formed in the seal water pipe. The mounting support is arranged on a mounting base and is sealed. The replaceable permanent combined odor-resistant floor drain core has the advantages that components of the replaceable permanent combined odor-resistant floor drain core can be optionally combined with one another to form a single drain combination or multiple drain combinations; a thorough odor-resistant effect and permanent anti-blocking, odor-resistant, rat-proof, insect-proof, fungus-proof and anti-poison effects can be realized after a drain system with the replaceable permanent combined odor-resistant floor drain core is used, and the replaceable permanent combined odor-resistant floor drain core is convenient to mount, construct, replace and maintain.

Owner:王丹

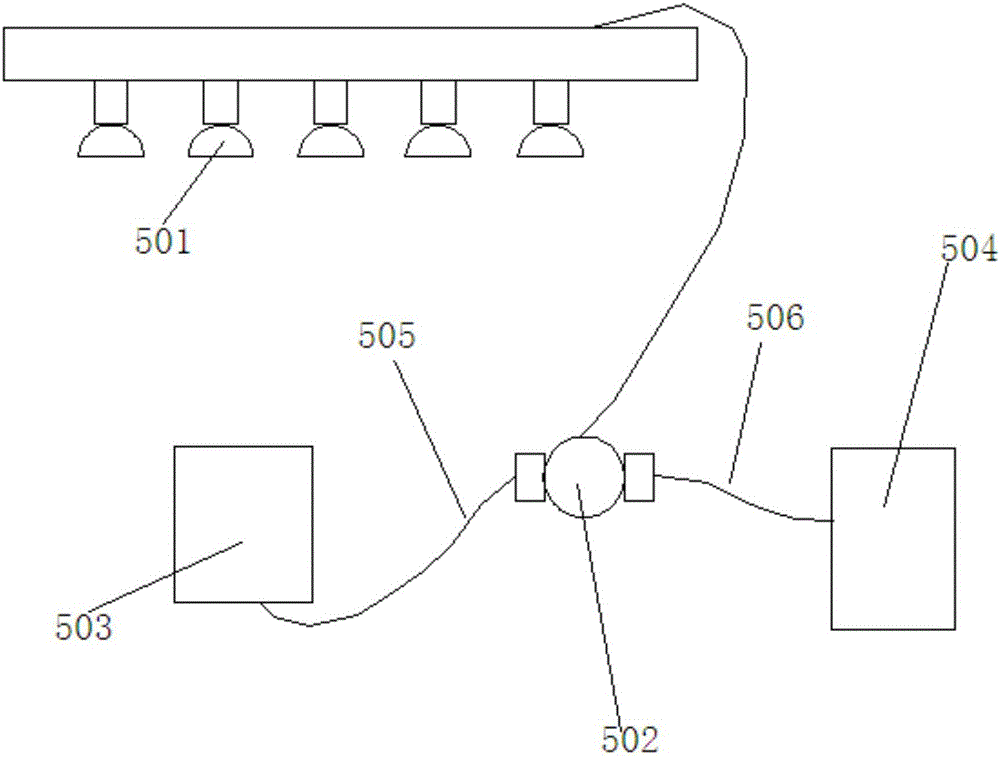

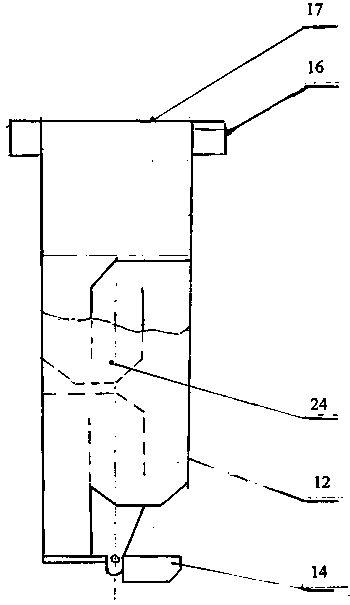

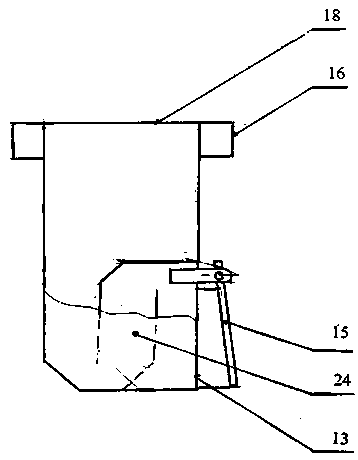

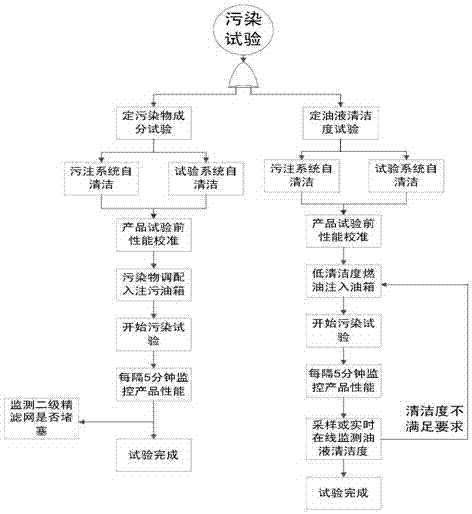

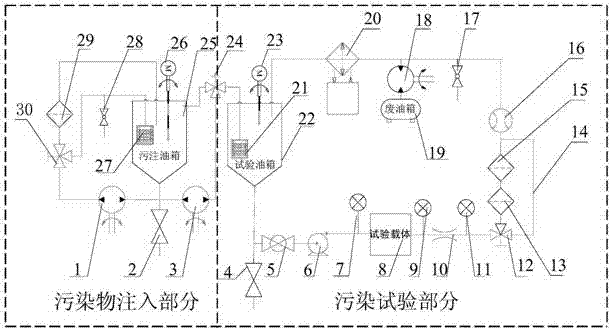

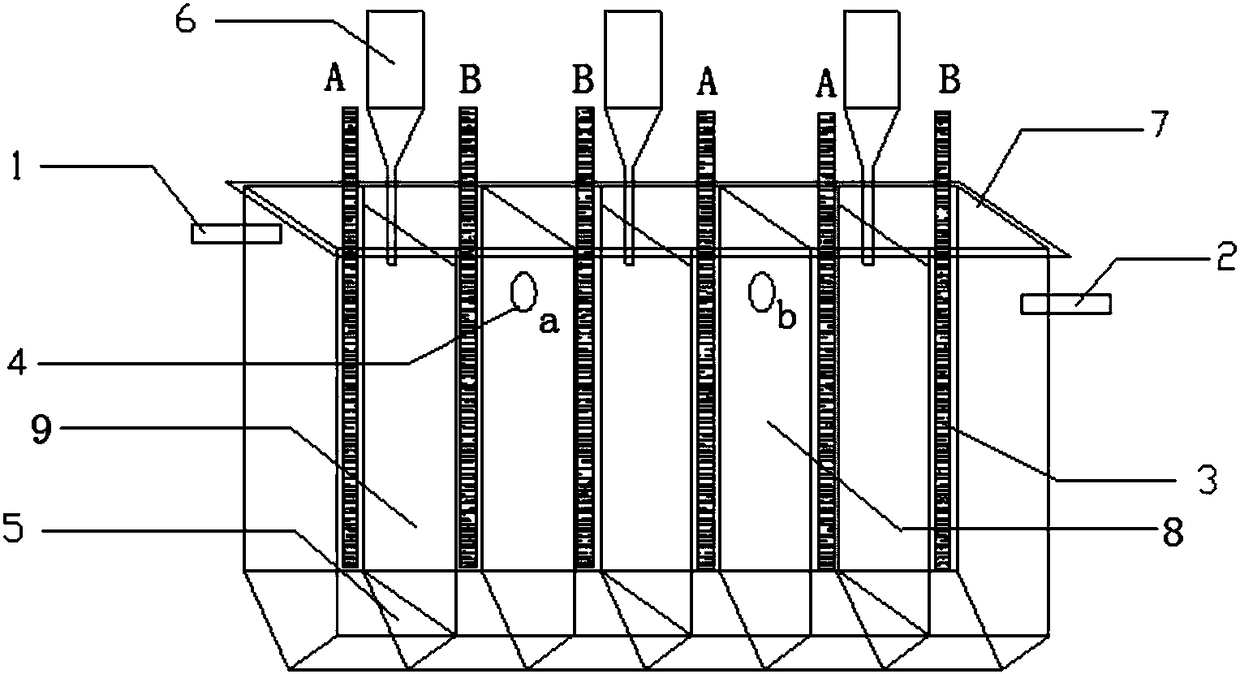

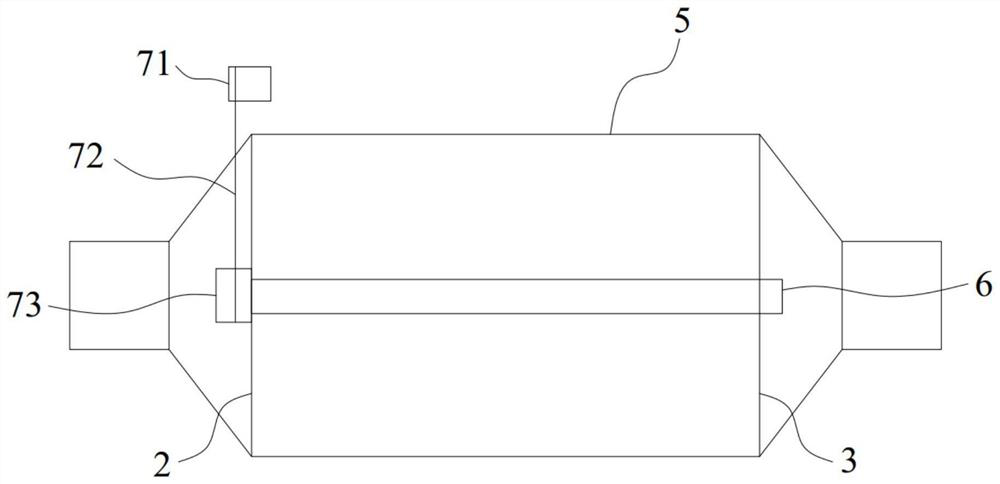

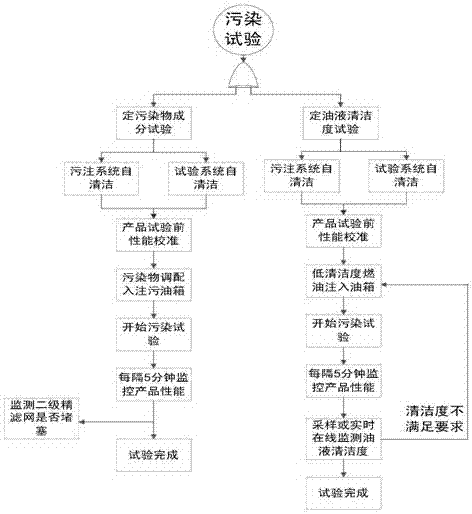

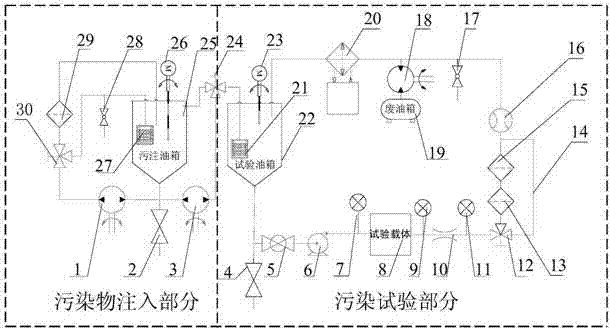

Pollution test injection system for pump regulator

InactiveCN105443368AEvenly blendedRealize automatic cleaningPump testingPositive-displacement liquid enginesEnvironmental engineeringTested time

The invention provides a pollution test injection system for a pump regulator. The pollution test injection system for the pump regulator is composed of two parts which are a pollutant injection part and a pollution test part. The pollutant injection part is used for self-cleaning and providing pollutant mixed oil liquid. The pollution test part is used for self-cleaning and examination of the pump regulator for a pollution test. By means of the pollution test injection system for the pump regulator, pollutant is mixed evenly, and the concentration of the pollutant and the pollution test time can be set autonomously as needed. Self-circulation of the system is achieved, and a pipeline can be automatically cleaned without the need for being detached.

Owner:BEIJING HANGKE ENGINE CONTROL SYST SCI & TECH

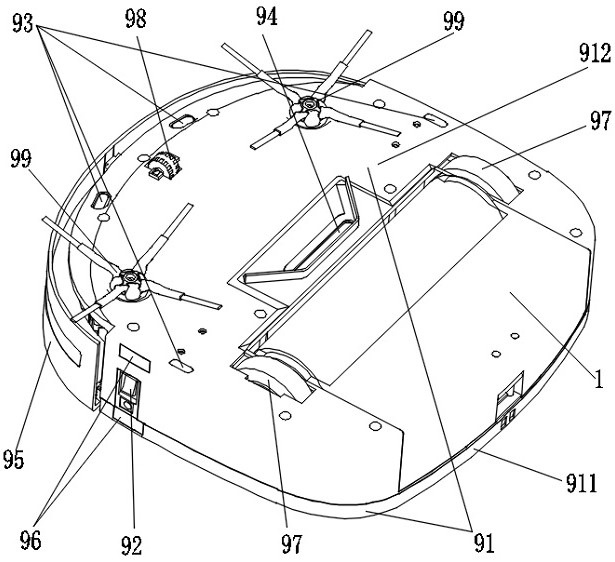

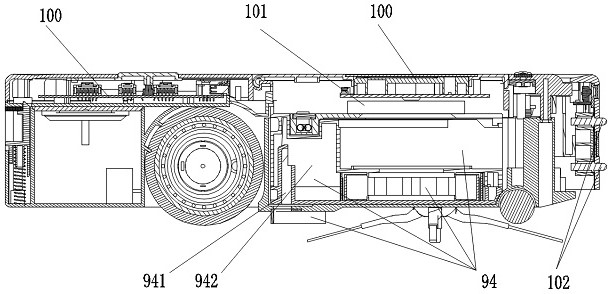

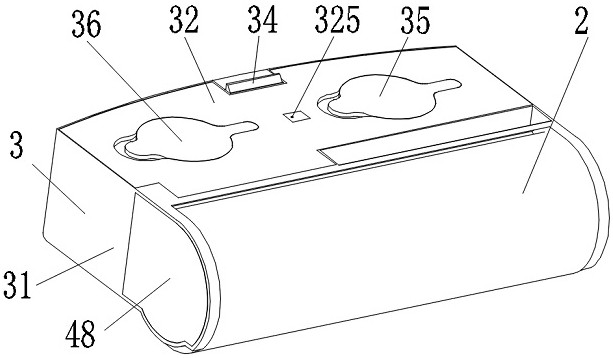

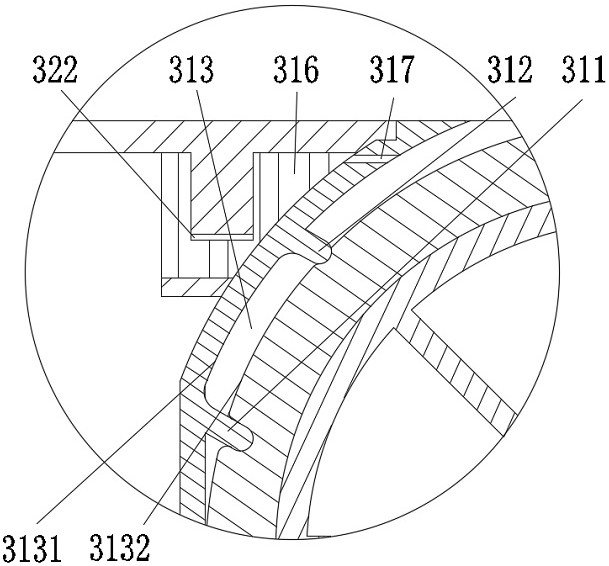

Mopping and cleaning device and intelligent cleaning robot thereof

PendingCN112971626AMeet needsNo need to disassemble and cleanAutomatic obstacle detectionTravelling automatic controlVertical planeEngineering

According to the technical scheme, the invention provides a mopping and cleaning device for an intelligent ground cleaning robot. The device includes a cleaning roller assembly which is used for mopping the ground after pre-cleaning, a roller driving device which is used for driving a cleaning roller to rotate, a water tank which covers the surface of the cleaning roller, a water pump assembly which is used for providing power for a cleaning liquid walking loop, and a water tank assembly which is used for providing cleaning liquid for the water tank. The cleaning roller assembly comprises a roller lining and a cleaning roller attached to the outer surface of the roller lining. The cleaning device comprises an interface cleaning mode for cleaning an interface and a cleaning roller self-cleaning mode after the cleaning roller is dirty in the working process; the water tank comprises an abutting end and an extrusion end; the abutting end of the water tank and the extruding end of the water tank are located on the same side of the radial vertical plane passing through the center shaft of the cleaning roller. The abutting end and the extruding end are both made of hard materials. The position of the abutting end is higher than that of the extrusion end.

Owner:深圳市宇辰智能科技有限公司

Mopping cleaning device and intelligent cleaning robot thereof

PendingCN112932356AImprove experienceAvoid ground water stainsAutomatic obstacle detectionTravelling automatic controlSewageWater tanks

The invention provides a mopping cleaning device for an intelligent cleaning robot, and the mopping cleaning device comprises a cleaning roller assembly that is used for mopping floor after pre-cleaning, a roller driving device that is used for driving the cleaning roller to rotate, a water trough covering the surface of the cleaning roller, a water pump assembly that is used for providing power for a cleaning liquid walking loop, and a water tank assembly that is used for providing cleaning liquid for the water trough. The cleaning roller assembly comprises a roller lining and the cleaning roller attached to the outer surface of the roller lining; the water trough comprises an abutting end and an extrusion end; in the cleaning process, the abutting end of the water trough and the extrusion end of the water trough are located on the same side of the radial vertical plane passing through the center axis of the cleaning roller; the position of the abutting end is higher than that of the extrusion end; the water tank assembly comprises a clean water tank combination and a sewage tank combination; the sewage tank combination further comprises an exhaust device arranged at the upper part of the sewage tank; and an exhaust port of the exhaust device communicates with the surface of the cleaning roller.

Owner:深圳市宇辰智能科技有限公司

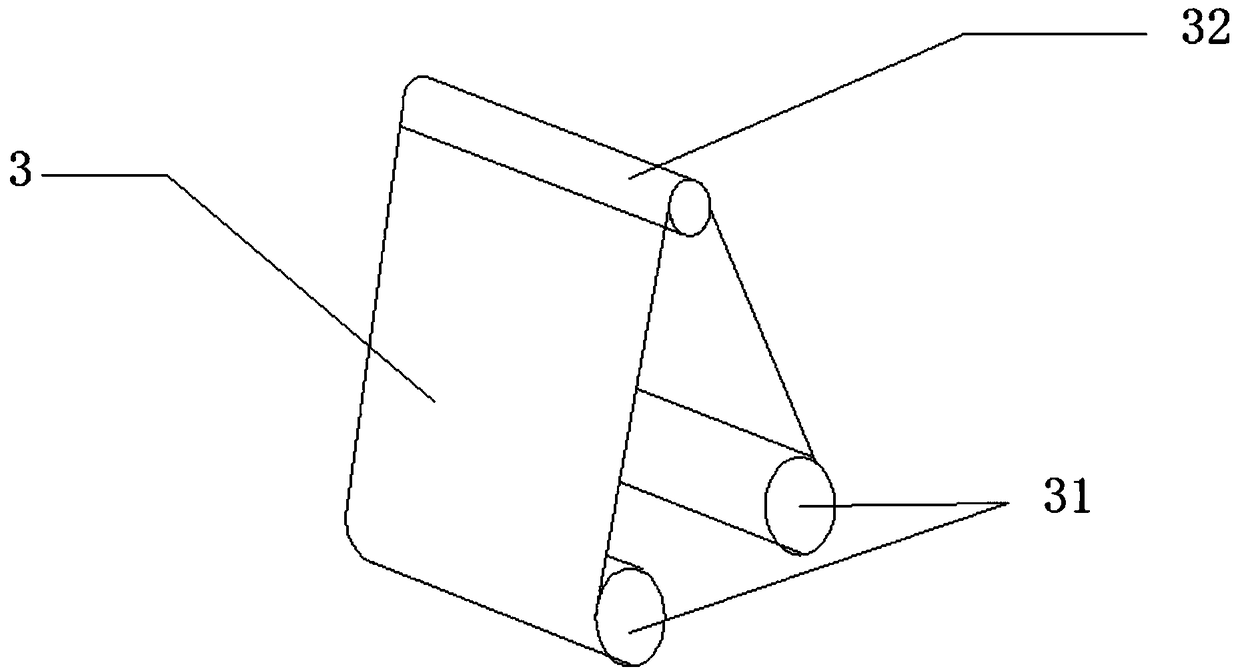

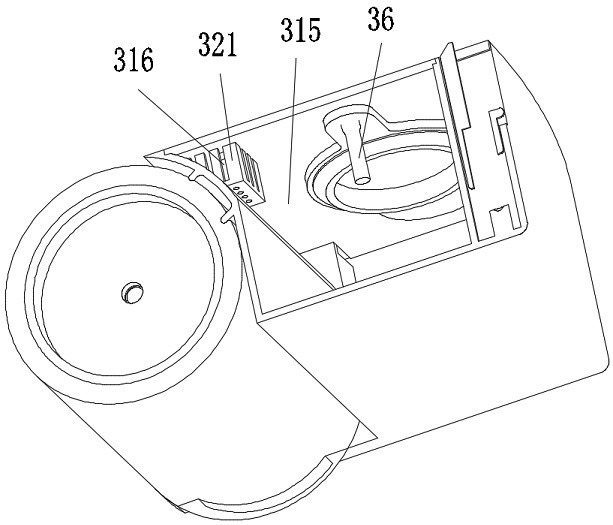

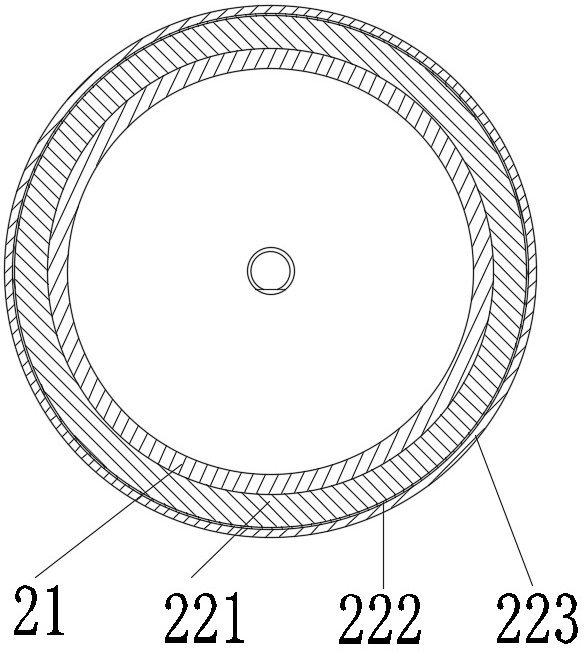

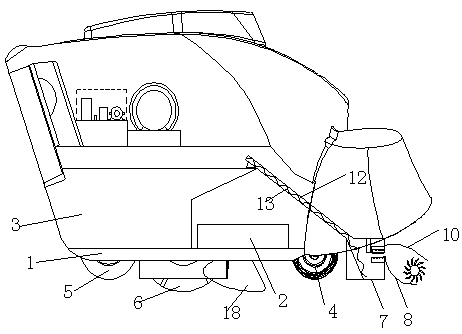

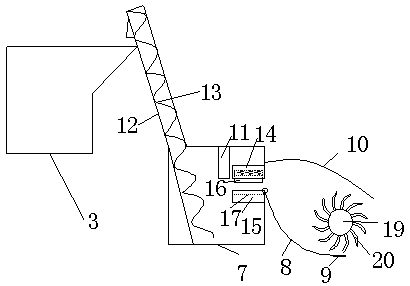

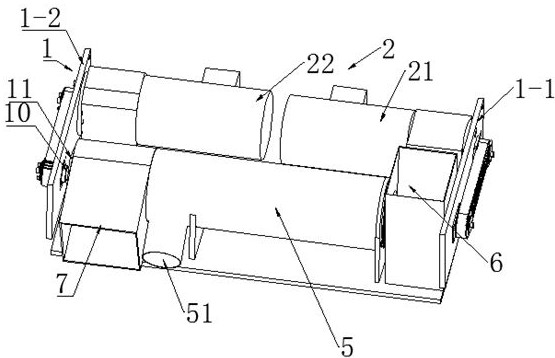

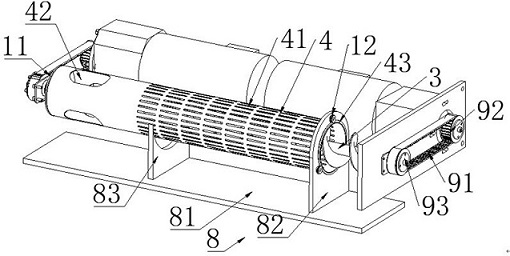

Leaf Sweeper

ActiveCN106677103BEfficient collectionImprove cleanlinessRoad cleaningAgricultural engineeringEngineering

The invention discloses a fallen leaf sweeper. The fallen leaf sweeper comprises a chassis, a driving system and a master dust collection box are arranged on the chassis, a front wheel and a rear wheel are arranged below the chassis, the driving system drives the front wheel to rotate, a main sweeping brush is arranged between the front wheel and the rear wheel and below the chassis, a tree leaf collection device is arranged at the front end of the front wheel and comprises a collection box, a hopper is connected to an inlet of the collection box and is connected to the side face of the collection box rotationally, an extension tooth is arranged at the end of the hopper, a protective cover is arranged above the inlet of the collection box, a shearing device is arranged at the inlet of the collection box, a suction fan is arranged in the collection box, the upper end of the collection box is connected to the master dust collection box through a connecting passage, and a lifting mechanism is arranged in the connecting passage. The fallen leaf sweeper has the advantage that the tree leaf collection device is arranged at the front end of the sweeper, and tree leaves on the ground are collected thoroughly before the main sweeping brush operates, so that normal use of the fallen leaf sweeper affected by jamming of the three leaves is avoided.

Owner:NANTONG MINGNUO ELECTRIC TECH CO LTD

Valve with pollution collecting function

InactiveCN107387799AEasy to useNo need to disassemble and cleanPlug valvesStationary filtering element filtersThreaded pipeEngineering

The invention discloses a valve with a pollution collecting function, and relates to the technical field of valves. Connecting flanges are respectively mounted at two ends of a valve body base; a sphere is mounted in the valve body base; the upper end of the sphere is connected with a valve rod mechanism through a sealing ring; the valve rod mechanism penetrates through and extends to the external of the valve body base; a filter screen is aslant mounted in a water inlet of the valve body base; an angle of the filter screen is 30-60 degrees; a connecting thread pipe is arranged at the front end of the filter screen, and is inserted in the valve body base; the lower end of the connecting thread pipe is connected with a pollution collecting cylinder through a sealing ring; a pollution discharge pipe is arranged at the right lower end of the pollution collecting cylinder; and a pollution discharge valve is mounted on the pollution discharge pipe. The valve is convenient to realize quick pollution collection, pollution storage and pollution discharge, is convenient in use, needs no disassembly cleaning, and is high in efficiency.

Owner:GOLDACE METAL PROD WUJIANG

Replaceable permanently-proof combined odour-resistant floor drain core

InactiveCN104005467ANot easy to evaporateNot easy to loseSewerage structuresSerpentine channelEngineering

The invention discloses a replaceable permanently-proof combined odour-resistant floor drain core. The replaceable permanently-proof combined odour-resistant floor drain core comprises a water-sealing tube, a sealing plate and an installation support, wherein the water-sealing tube and the installation support are connected to form an integrated structure, a water-sealing chamber is formed in the water-sealing tube, the sealing plate is hinged at the top inlet and / or bottom outlet of the water-sealing chamber, and is of a valve-type structure; the sealing plate and the water-sealing chamber are in a closed state in a normal state of no drainage, the sealing plate is automatically impacted open by the impact force of water to drain water, and the sealing plate recovers the closed state in the normal state after drainage during drainage; the water-sealing tube is a direct-drainage water-sealing tube or a side-drainage water-sealing tube; a serpentine channel water-sealing chamber is formed in the water-sealing tube; the installation support is arranged on an installation base and subjected to sealing treatment. Moreover, the replaceable permanently-proof combined odour-resistant floor drain core disclosed by the invention can be randomly combined into a drainage single-assembly or a drainage multi-assembly. A drainage system after using the replaceable permanently-proof combined odour-resistant floor drain core disclosed by the invention is thoroughly odour-resistant, permanently-six-proof, that is, blockage-proof, odour-resistant, ratproof, insectproof, fungi-proof and anti-poison, as well as convenient to install, construct, replace and maintain.

Owner:王丹

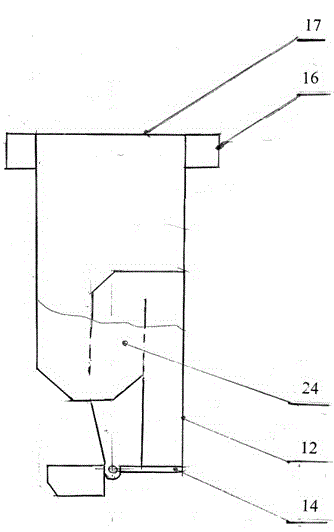

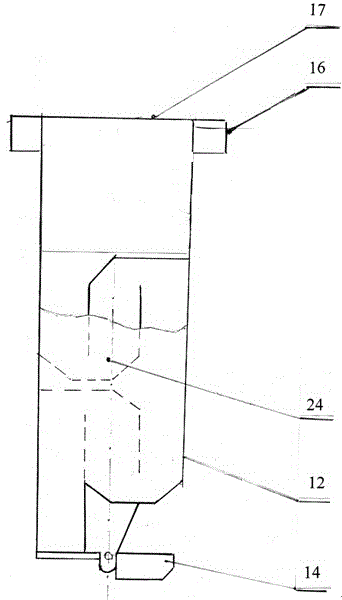

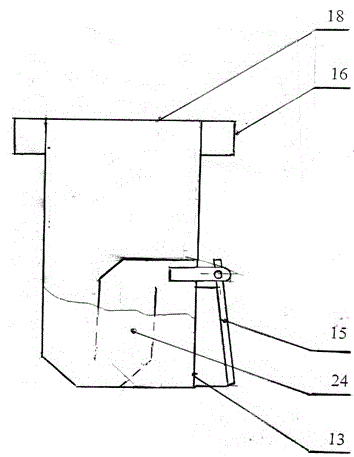

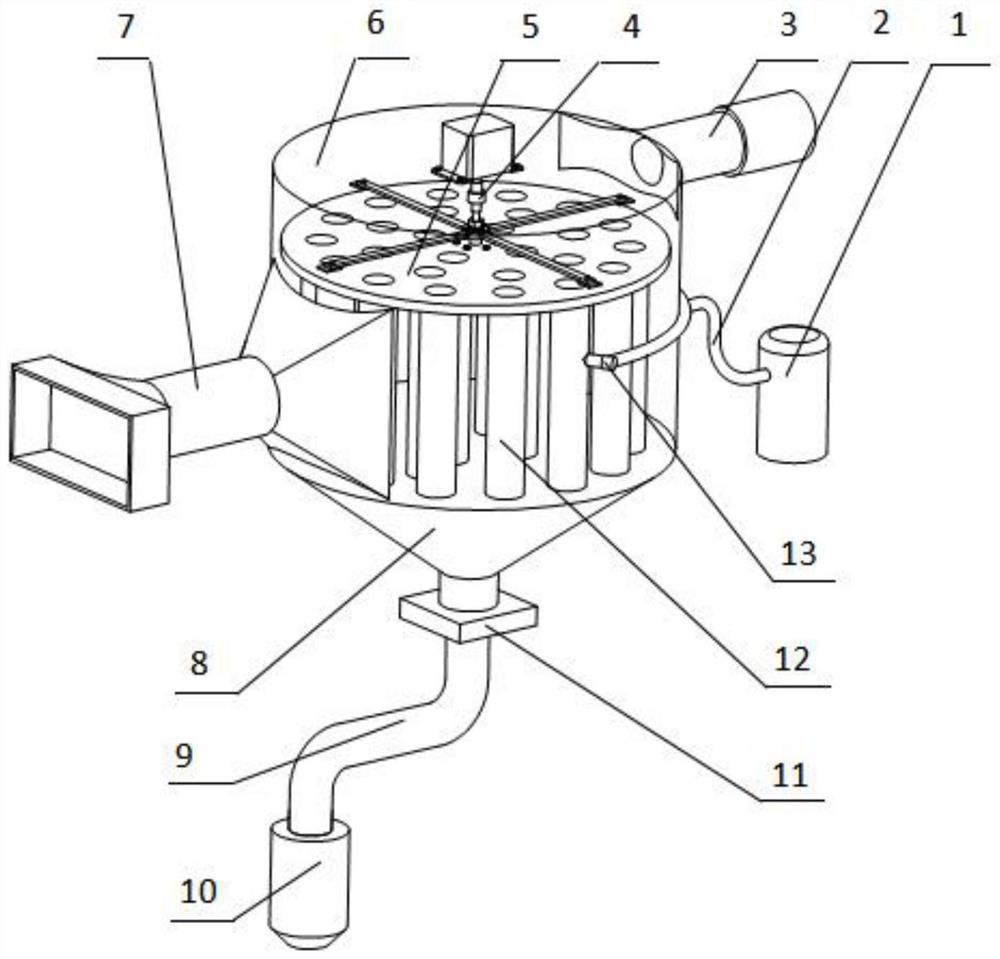

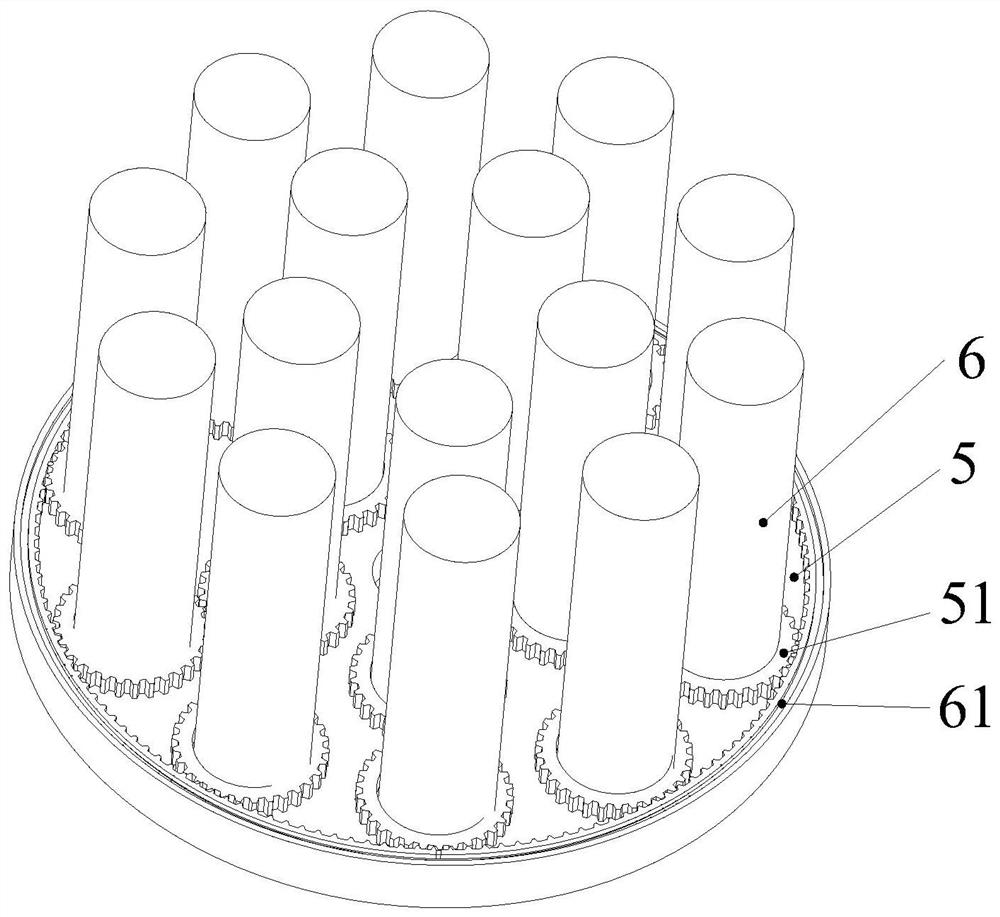

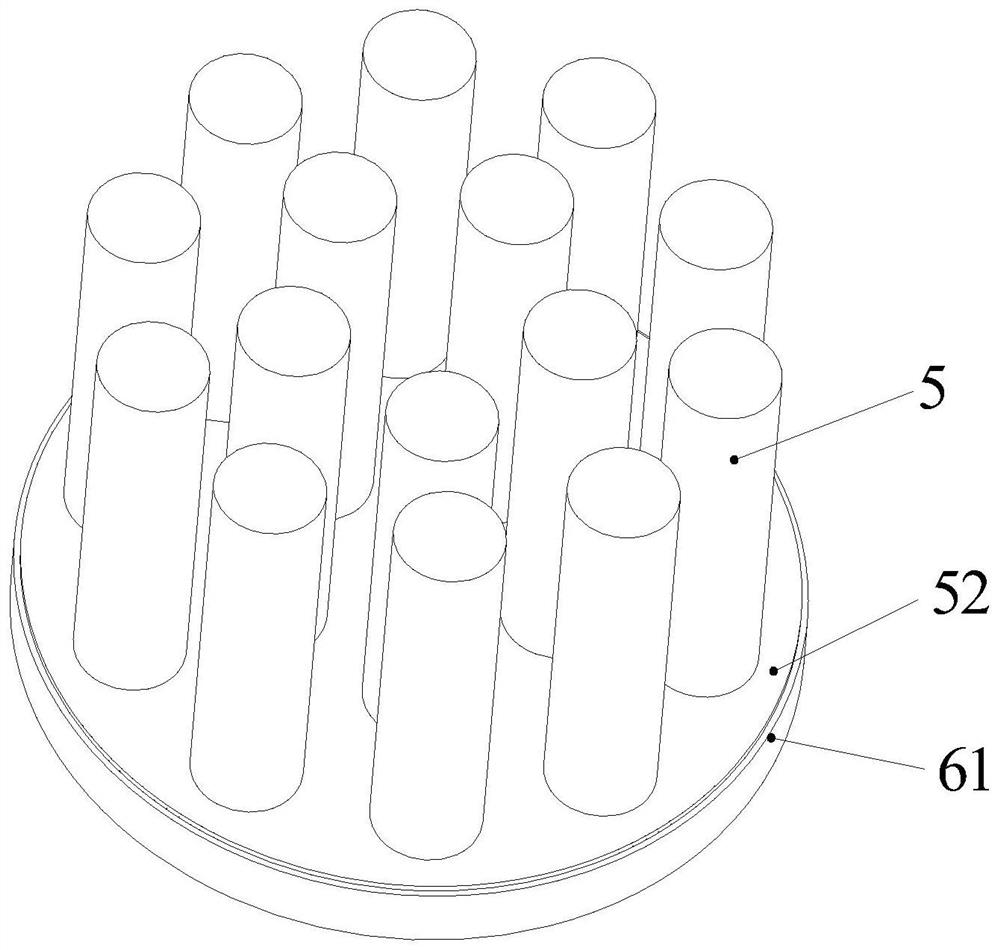

Dry dust remover capable of removing dust without disassembly

InactiveCN112206589ANo need to disassemble and cleanEasy to useDispersed particle filtrationTransportation and packagingDust controlEngineering

The invention belongs to the field of dust removers, and discloses a dry dust remover capable of removing dust without disassembly. The dry dust remover comprises a cylinder body, a rotary disc rotating around the axis of the rotary disc is arranged in the cylinder body, and the side wall of the rotary disc is attached to the inner wall of the cylinder body, so that an inner cavity of the cylinderbody is divided into an upper inner cavity and a lower inner cavity, the openings are arranged on the turntable in an annular array, communicated filter cartridges are arranged at the lower ends of the openings, the air inlet is communicated with the lower inner cavity of the cylinder body, the air outlet is communicated with the lower inner cavity of the cylinder body, and at least one air tap is arranged in the cylinder body,the rotating structure is driven to drive the filter cartridge to rotate, so that the arranged high-pressure air nozzle cleans dust on the filter cartridge,the dust remover does not need to be disassembled and cleaned and is simple and convenient to use.

Owner:ANHUI UNIV OF SCI & TECH +1

Electrochemical preparation method of chloroiridic acid

InactiveCN108977837ANo need to disassemble and cleanMeet Filtration NeedsElectrolysis componentsIridiumPhysical chemistry

The invention relates to an electrochemical preparation method of chloroiridic acid. The electrochemical preparation method comprises: 1, arranging an electrolytic cell, wherein the electrolytic cellis separated into at least two tanks by a first separation plate arranged in the electrolytic cell, the first separation plate is provided with an overflow hole, the tank is divided into two electrodechambers by a second separation plate arranged in the tank, the two electrode chambers are communicated to each other, and electrodes are respectively arranged in the electrode chambers; 2, adding iridium powder into the tank, making a hydrochloric acid solution sequentially pass through the tanks, and carrying out a continuous electrolysis reaction on the iridium powder and the hydrochloric acidsolution by applying voltage on the electrodes; 3, when the iridium in the hydrochloric acid solution in the electrolytic cell reaches a certain concentration, supplementing the tank with a hydrochloric acid solution and the iridium powder to continuously form a product stream containing stable iridium concentration; and 4, filtering the product stream, concentrating, and drying to obtain a chloroiridic acid solid. According to the present invention, the method has advantages of simple preparation process, high automation degree, environmental protection, no by-products and high product purity.

Owner:CHINA PETROLEUM & CHEM CORP +1

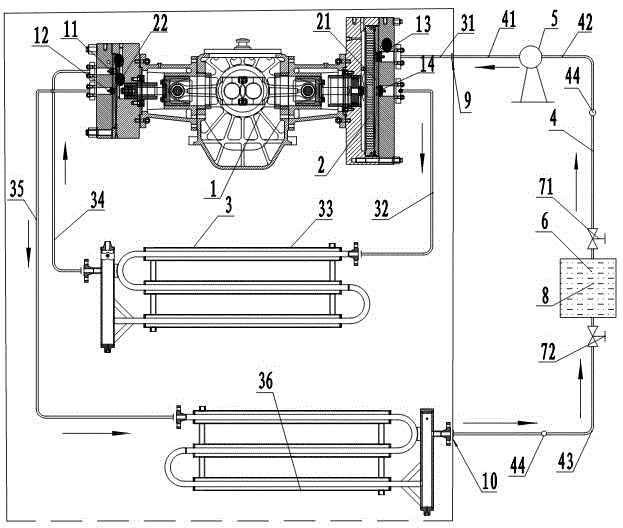

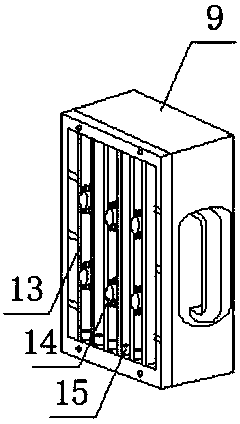

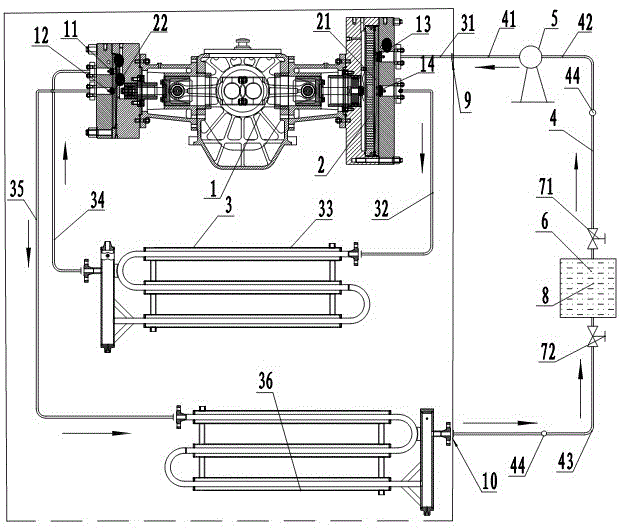

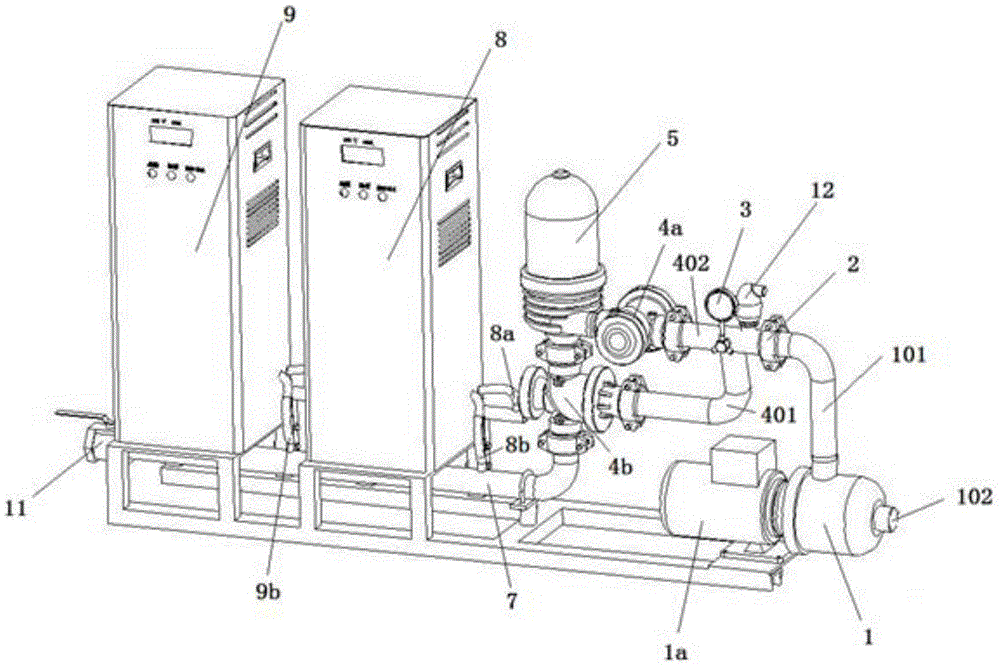

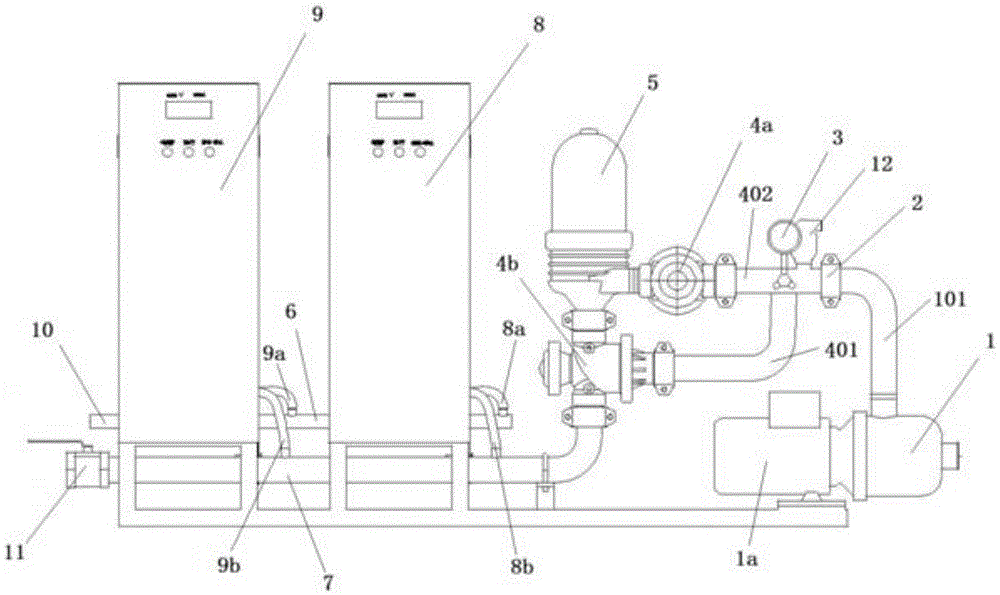

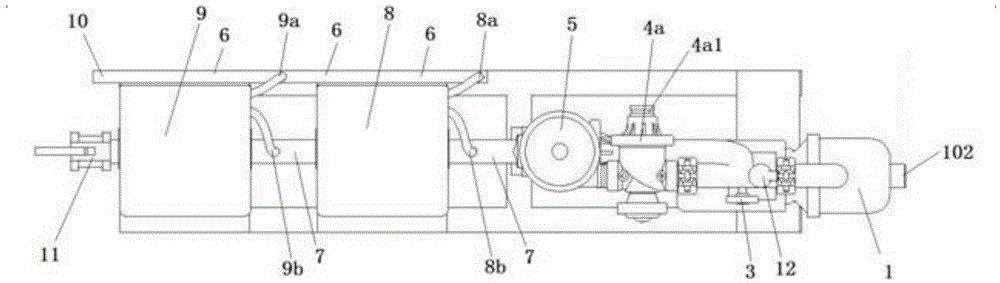

Closed circulation degreasing and cleaning system for helium diaphragm compressor pipeline

The invention discloses a closed circulation degreasing and cleaning system for a helium diaphragm compressor pipeline. The closed circulation degreasing and cleaning system comprises a first-stage exhaust pipe, a first-stage cooler and a second-stage air inlet pipe which are connected to the position of a first-stage exhaust valve of a first-stage cylinder cover diaphragm cavity of a compressor. The second-stage air inlet pipe is connected to a second-stage cylinder cover diaphragm cavity in a compressor body of the compressor through an air inlet valve of a second-stage exhaust valve of the compressor. The closed circulation degreasing and cleaning system further comprises a first-stage air inlet valve, a first-stage air inlet pipe, a corrosion-resistant centrifugal pump, a liquid inlet ball valve, a liquid containing tank, a liquid outlet ball valve and a second-stage cooler, wherein the first-stage air inlet valve, the first-stage air inlet pipe, the corrosion-resistant centrifugal pump, the liquid inlet ball valve, the liquid containing tank, the liquid outlet ball valve and the second-stage cooler are sequentially connected in a first-stage cylinder cover diaphragm cavity in the compressor body of the compressor. The second-stage coller is connected to the second-stage cylinder cover diaphragm cavity in the compressor body of the compressor through the second-stage exhaust valve of the compressor. Degreasing agents are added in cleaning liquid in the liquid containing tank. By the adoption of the closed circulation degreasing and cleaning system, the effect that the inner wall of the pipeline is degreased and cleaned rapidly in a dead-corner-free mode without dismounting in the original gas pipeline connecton state of the compressor is guaranteed.

Owner:JIANGSU PERMANENT MACHINERY

Back cleaning device for bathe

The invention relates to the technical field of bathing devices and in particular to a back cleaning device for a bathe. The back cleaning device comprises a sponge body which can store a part of water flow, four corners of the left side of the sponge body are provided with square fixing plates, the left side of the square fixing plates are fixedly connected with vacuum suckers, the vacuum suckerscan be stably adhered on a tile, and cannot be moved, so the fixed installation is convenient, the right side of the sponge body is provided with a cleaning plate, the upper right part of the cleaning plate is provided with a leaning block, the right side of the cleaning plate is provided with three-quarter spherical grooves, the interiors of the three-quarter spherical grooves are provided withrubber cleaning balls. The back cleaning device is skillful in design, and completely superior to the prior art through the using cooperation of a bath cream through groove and a water flow through channel, an electric operation is not needed, and the scrubbing is convenient through the cooperation with bath cream. In addition, the cleaning is convenient after scrubbing, and the operation is veryconvenient without disassembly.

Owner:张恒

Portable air pollution detection device

InactiveCN107560989ALight in massPortable qualityCombination devicesParticle suspension analysisElectrostatic adsorptionAir mass

The invention discloses a portable air pollution detection device, which comprises a casing, a button group, an outer cover, a handle, a pull ring, a filter screen, screws, fixing holes, a collection box, an air pipe, a motor, a bellows, an electrostatic adsorption plate, a brush and storage tube. The beneficial effect of the present invention is: by installing a layer of filter screen on the outer cover of the device, the device can pre-filter the inhaled air when detecting the air quality, so that only small particles such as dust in the air can be inhaled. The device is small in size, and a handle is installed on one side of the shell, and a pull ring is installed on the side of the bellows, so that the device is light in weight and easy to carry. The device adopts electrostatic adsorption, and removes the adsorbed dust and dust with a brush and collects them inside the bellows. The air quality is judged by detecting the amount of dust collected inside the bellows. The device does not need to be disassembled and cleaned after use, which is more convenient to use.

Owner:林海涛

Closed cycle degreasing cleaning system of helium diaphragm compressor pipeline

The invention discloses a closed cycle degreasing cleaning system of a helium diaphragm compressor pipeline. The closed cycle degreasing cleaning system comprises a first-stage exhaust pipe, a first-stage cooler, a second-stage intake pipe, a first-stage intake pipe, a corrosion resistant centrifugal pump, a liquid inlet ball valve, a liquid containing groove, a liquid outlet ball valve and a second-stage cooler, wherein the first-stage exhaust pipe, the first-stage cooler and the second-stage intake pipe are connected to the position of a first-stage exhaust valve on a first-stage cylinder cover cavity of a compressor, and the second-stage intake pipe passes through the position of a second-stage exhaust valve of the compressor and then is connected to a second-stage cylinder cover cavity in a compressor body; the first-stage intake pipe, the corrosion resistant centrifugal pump, the liquid inlet ball valve, the liquid containing groove, the liquid outlet ball valve and the second-stage cooler are connected to the position of a first-stage intake valve on the first-stage cylinder cover cavity in the compressor body in sequence, and the second-stage cooler passes through the position of the second-stage exhaust valve of the compressor and then is connected to the second-stage cylinder cover cavity in the compressor body; a degreasing agent is added to cleaning liquid in the liquid containing groove. According to the closed cycle degreasing cleaning system, in the condition that an original pipeline of the compressor is connected, the pipeline does not need to be removed, and the inner wall of the pipeline can be quickly cleaned in a degreasing mode without dead angles.

Owner:JIANGSU PERMANENT STEEL STRUCTURE

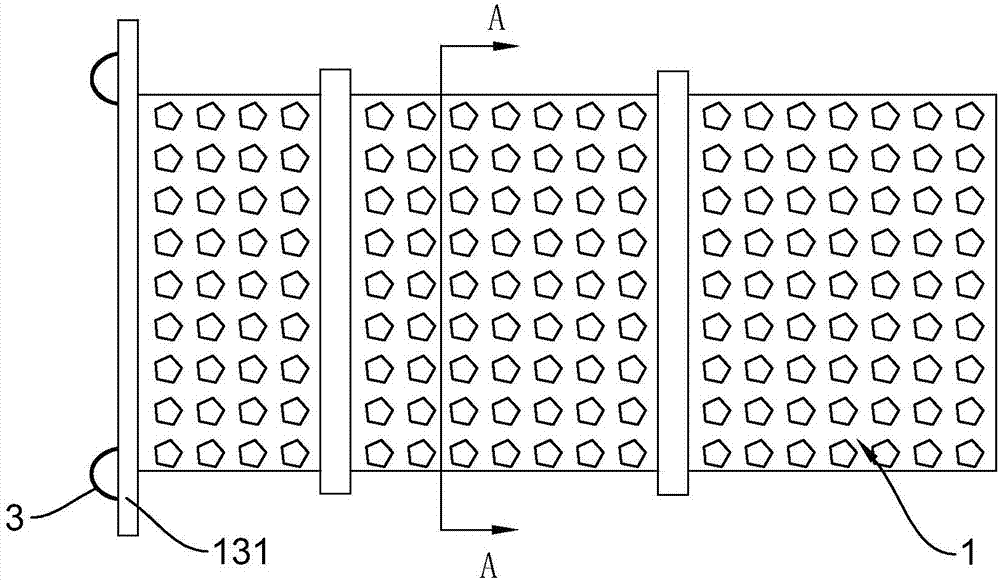

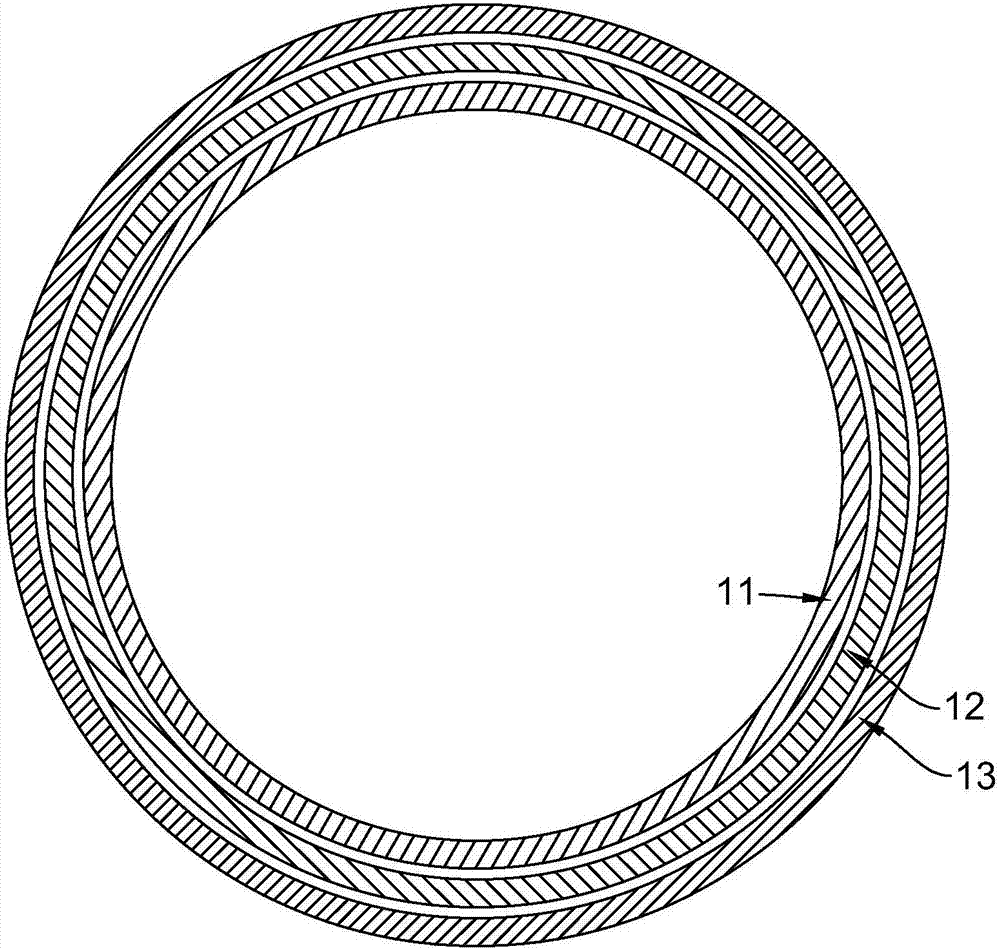

Filter screen cylinder for outdoor crushing machine

PendingCN107999366AReduce manufacturing costImprove filtering effectSievingScreeningPulp and paper industryCrusher

The invention relates to a filter screen cylinder for an outdoor crushing machine. The filter screen cylinder comprises a screen cylinder body, the screen cylinder body comprises a coarse mesh cylinder body, a relative coarse mesh cylinder body and a fine mesh cylinder body which are detachably and sequentially arranged from the inside to the outside, and the surfaces of the coarse mesh cylinder body, the relative coarse mesh cylinder body and the fine mesh cylinder body are provided with anti-fouling and self-cleaning inorganic coatings. The filter screen cylinder for the outdoor crushing machine is used for kitchen waste crushers, can eliminate the disassembly cleaning of the filter screen cylinder, and has good filtering effect and long service life.

Owner:四会市华通金属筛网制品有限公司

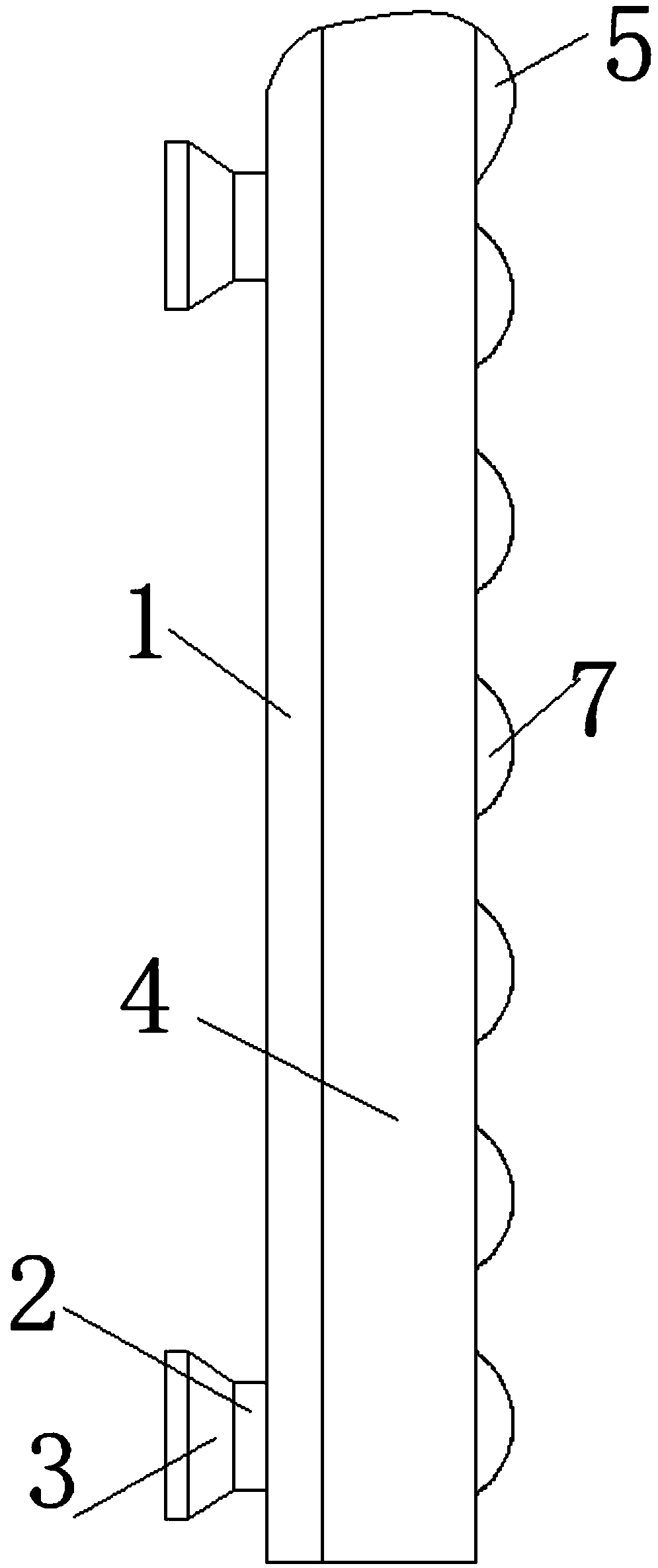

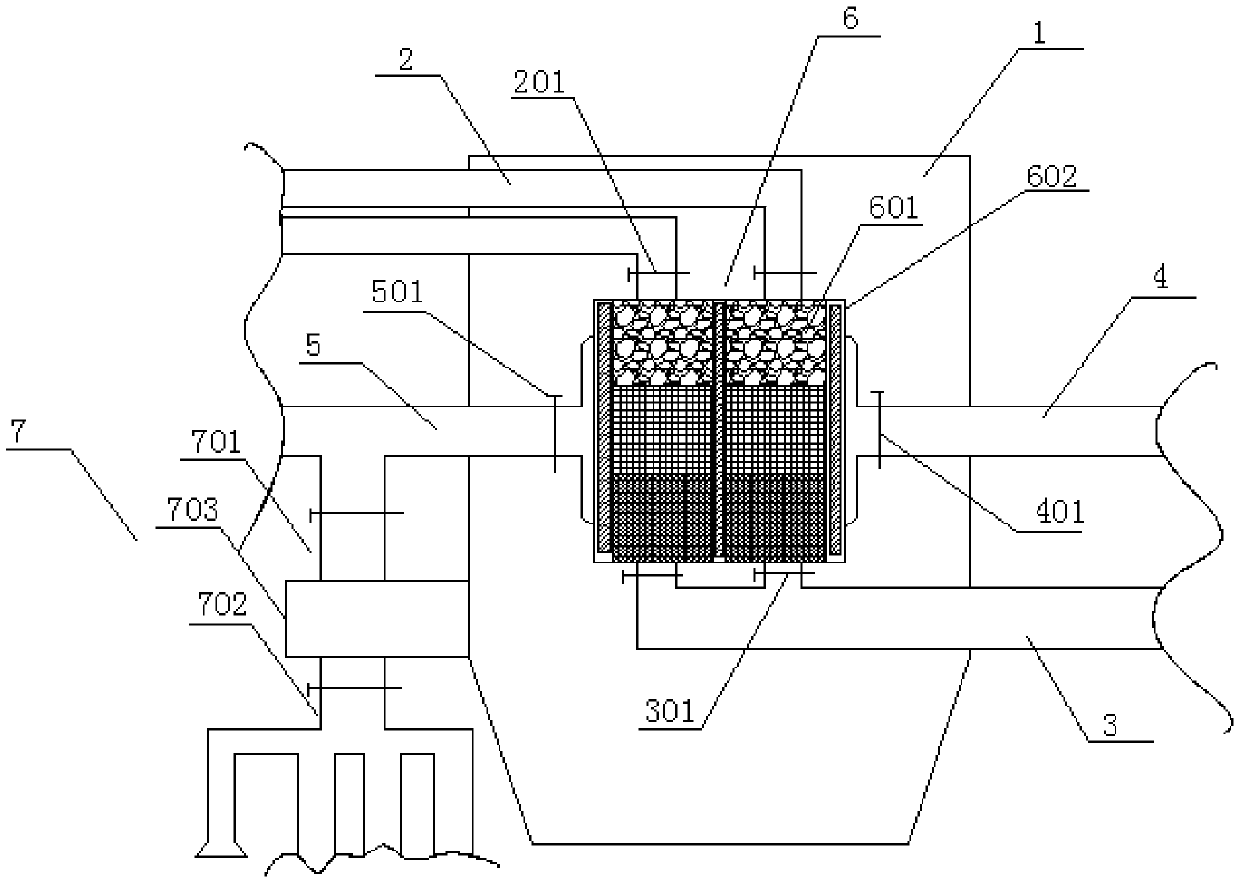

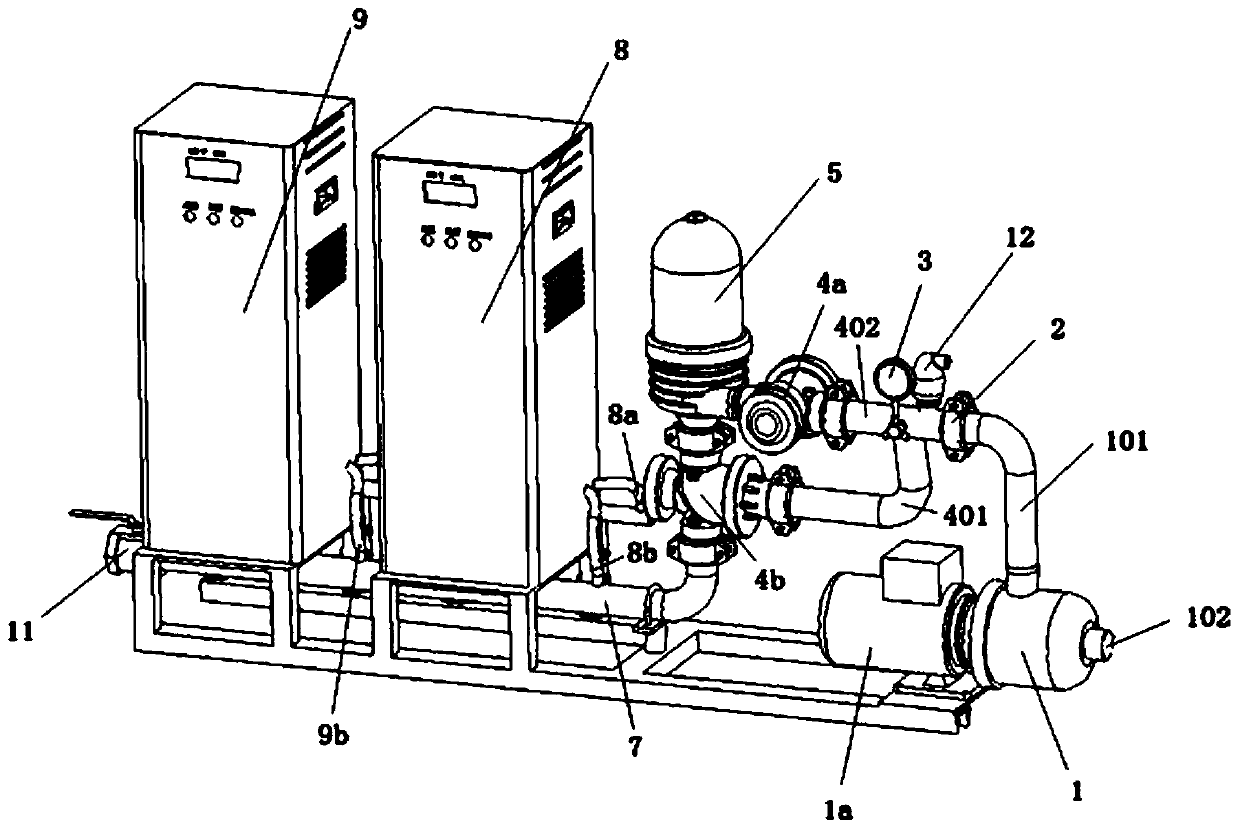

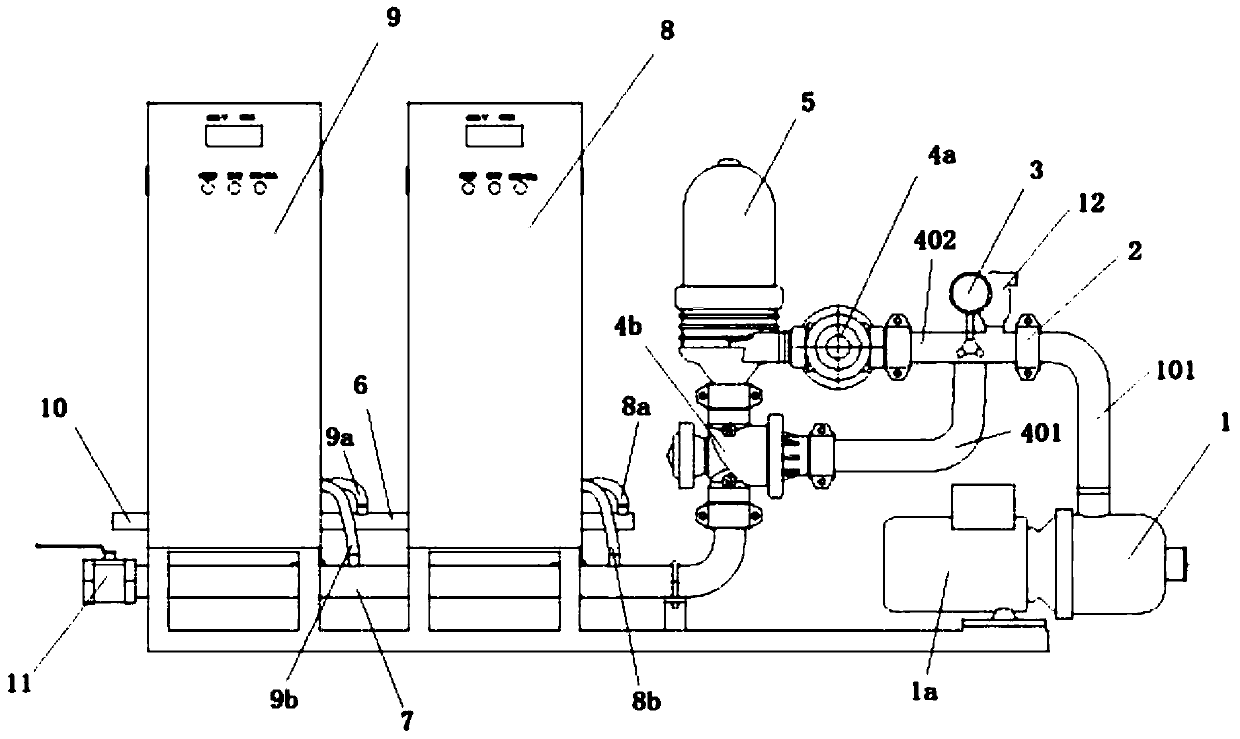

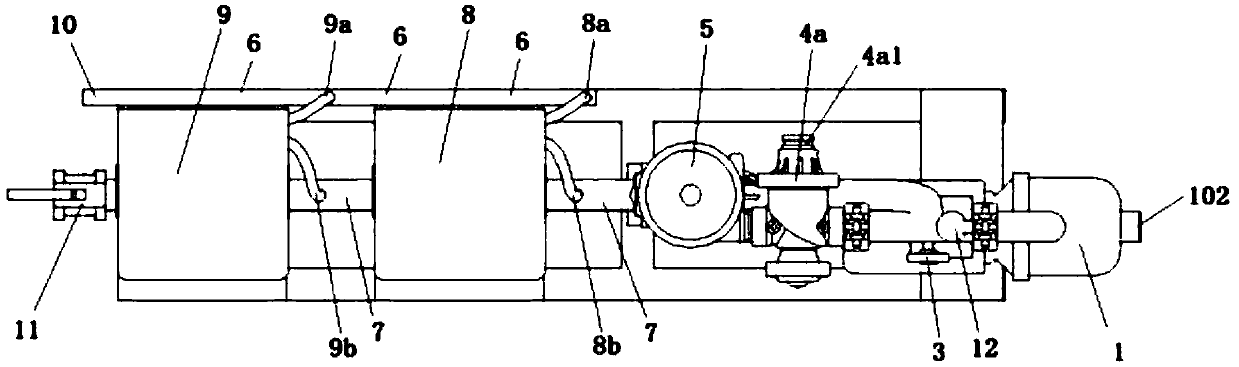

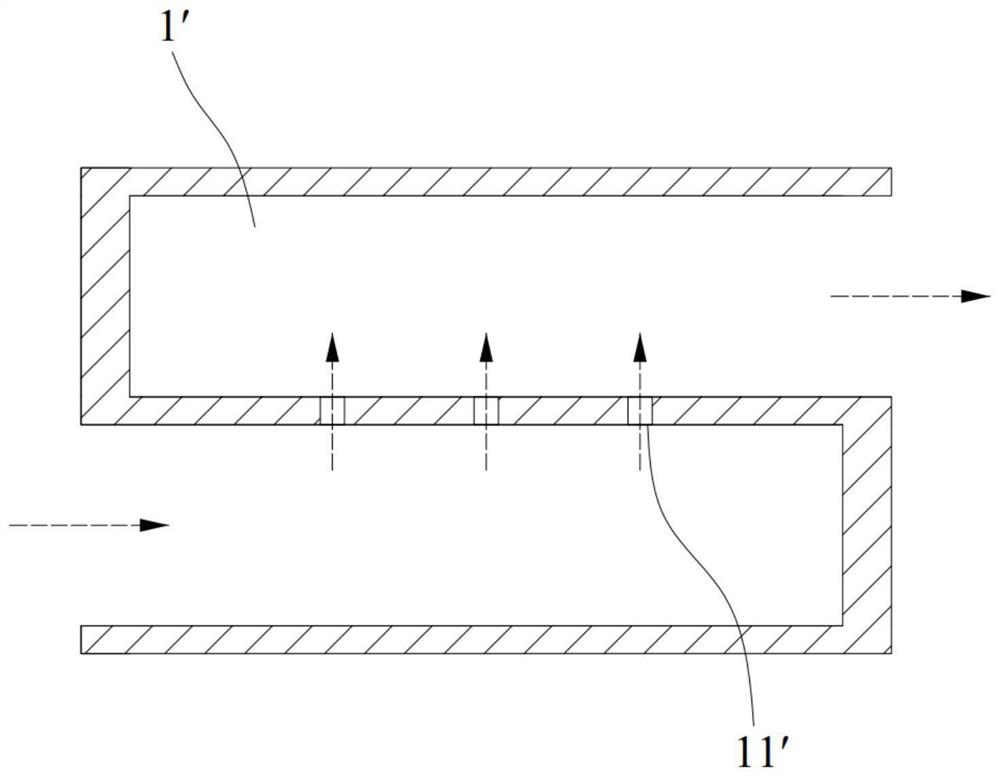

Backwashing and filtering device for heat exchanger of seawater desalination system and backwashing method of backwashing and filtering device

ActiveCN114712927ASafe and stable operationReduce cloggingGeneral water supply conservationStationary filtering element filtersAutomatic controlSmall footprint

The invention relates to the technical field of seawater desalination, in particular to a seawater desalination system heat exchanger backwashing filter device and a backwashing method thereof, the IPC classification number is C02F, the seawater desalination system heat exchanger backwashing filter device comprises a frame body, an automatic control device, a heat exchange backwashing filter device, a heat source outlet pipe, a heat source inlet pipe and an auxiliary bypass, and the automatic control device is fixedly connected to the upper end of the frame body; the heat exchange backwashing and filtering device is mounted in the frame body; the heat source outlet pipe and the heat source inlet pipe are connected to one side of the frame body; the frame body comprises a supporting frame, an upper sliding guide rail, a lower sliding guide rail and a fixed end plate. According to the invention, safe and stable operation of the sea water desalination device can be effectively guaranteed, and flow channel blockage and disassembly cleaning frequency of the heat exchange backwashing filter device are reduced; the device has the advantages of being flexible to operate, high in automation degree, small in occupied area, high in heat exchange efficiency, good in backwashing effect, low in maintenance cost, stable in performance, wide in application, free of disassembly and cleaning, remarkable in comprehensive effect and the like.

Owner:TIANJIN SDIC JINNENG ELECTRIC POWER

Lemon cleaning water preparing device system

ActiveCN105543884AKeep it clean for a long timeNo need to disassemble and cleanCellsDiaphragmsElectrolysed waterEngineering

The invention discloses a lemon cleaning water preparing device system which comprises an electrolysed water processor, a water inlet pump, a main three-way membrane valve, an auxiliary three-way membrane valve and a filtering mechanism, wherein the electrolysed water processor is used for generating sodium hypochlorite. A water outlet pipeline of the water inlet pump is connected to the water inlet end opening of the main three-way membrane valve. The filtering mechanism is connected between the water outlet end opening of the main three-way membrane valve and the auxiliary three-way membrane valve. The auxiliary three-way membrane valve is further connected with a pipeline in front of the water inlet end opening of the main three-way membrane valve. The filtering device system capable of conducting flushing in the positive direction and the negative direction is formed by the two sets of three-way structures and the filtering mechanism. The opening of the water outlet pipeline of the auxiliary three-way membrane valve is connected to an electrolysed water inlet pipeline and connected with the electrolysed water processor through the electrolysed water inlet pipeline. The water outlet of the electrolysed water processor is connected to the electrolysed water inlet pipeline. The lemon cleaning water preparing device system is provided with a backward flushing loop, when the device system does not operate or work directly, equipment can be cleaned through backward flushing in situ, and long-term operation of the system is stable and reliable.

Owner:成都飞创环保设备有限公司

An easy-to-clean water treatment device without dismantling

ActiveCN106630233BEasy to backwashFull backwashWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiltrationWater quality

Owner:宜兴市中发水处理环保设备有限公司

Self-cleaning type organic matter solid-liquid separation equipment

PendingCN113577888AEasy to separateAvoid cloggingFiltration circuitsMoving filtering element filtersAugerEngineering

Owner:HANBOK KITCHEN ELECTRIC APPLIANCE TECH

Single-chip microcomputer-based multifunctional computer device

PendingCN113190092ARealize the purpose of heat dissipation and dust preventionAvoid enteringDispersed particle filtrationTransportation and packagingBristleEngineering

The present invention discloses a single-chip microcomputer-based multifunctional computer device which comprises a computer device body, the computer device body comprises a case main body and a rear cover fixed on the left side of the case main body, and a cooling fan is fixedly mounted on the inner wall of the bottom of the case main body. A plurality of air outlet holes are formed in the inner wall of the front side of the case body, an air outlet filter screen matched with the air outlet holes is fixedly installed on the inner wall of the front side of the case body, and an air inlet square pipe is embedded in the left side of the rear cover. The computer device is reasonable in design, heat dissipation and dust prevention can be conveniently conducted on the interior of the case body, automatic poking and inserting cleaning and back blowing cleaning can be conveniently conducted on the air inlet filter screen from inside to outside, impurities blocked in the air inlet filter screen can be poked out, the impurities left after long brush bristles are poked and inserted can be further blown out in a back blowing cleaning mode, the cleaning effect on the air inlet filter screen is improved, manual dismounting and cleaning are not needed, time and labor are saved, and use is facilitated.

Owner:HENAN MEDICAL COLLEGE

A kind of lemon cleaning water preparation device system

ActiveCN105543884BKeep it clean for a long timeNo need to disassemble and cleanCellsDiaphragmsElectrolysed waterWater production

The invention discloses a lemon cleaning water preparing device system which comprises an electrolysed water processor, a water inlet pump, a main three-way membrane valve, an auxiliary three-way membrane valve and a filtering mechanism, wherein the electrolysed water processor is used for generating sodium hypochlorite. A water outlet pipeline of the water inlet pump is connected to the water inlet end opening of the main three-way membrane valve. The filtering mechanism is connected between the water outlet end opening of the main three-way membrane valve and the auxiliary three-way membrane valve. The auxiliary three-way membrane valve is further connected with a pipeline in front of the water inlet end opening of the main three-way membrane valve. The filtering device system capable of conducting flushing in the positive direction and the negative direction is formed by the two sets of three-way structures and the filtering mechanism. The opening of the water outlet pipeline of the auxiliary three-way membrane valve is connected to an electrolysed water inlet pipeline and connected with the electrolysed water processor through the electrolysed water inlet pipeline. The water outlet of the electrolysed water processor is connected to the electrolysed water inlet pipeline. The lemon cleaning water preparing device system is provided with a backward flushing loop, when the device system does not operate or work directly, equipment can be cleaned through backward flushing in situ, and long-term operation of the system is stable and reliable.

Owner:成都飞创环保设备有限公司

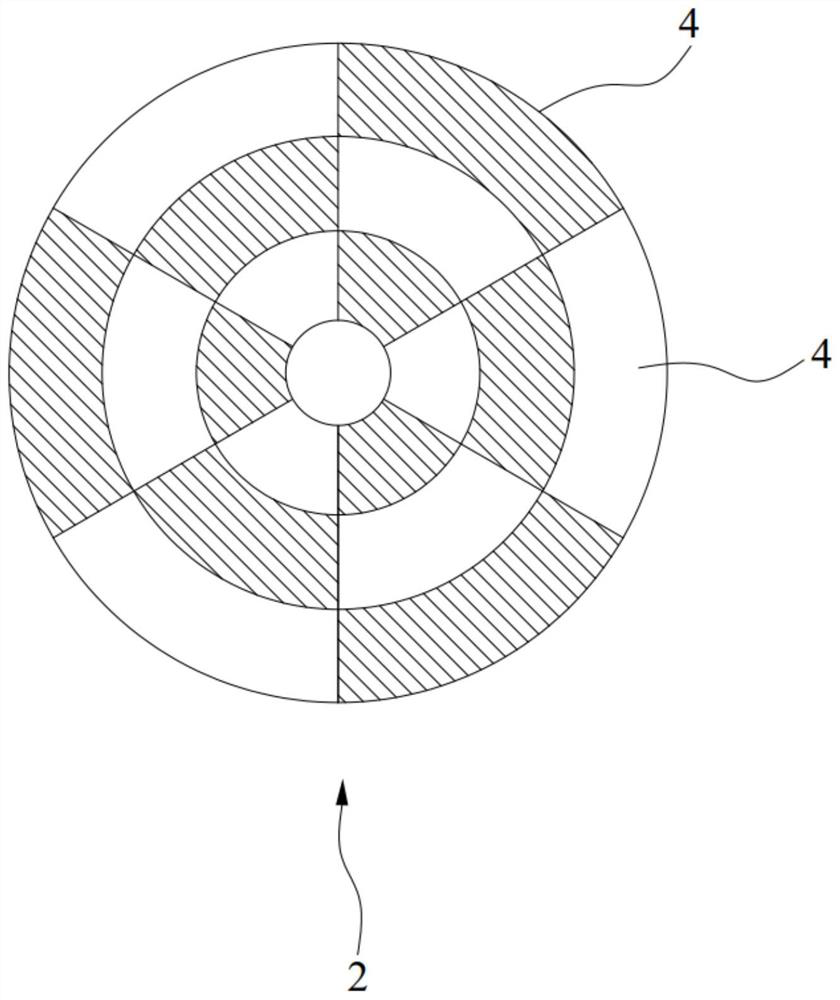

Particulate matter collecting device

ActiveCN113882935ASolve the blockageNo need to disassemble and cleanExhaust apparatusSilencing apparatusParticulatesEngineering

The invention relates to the technical field of engine tail gas treatment, and discloses a particle collecting device which comprises a shell. An inlet and an outlet are formed in the shell; a filtering assembly is arranged in the shell and is configured to filter gas entering the shell from the inlet; the filtering assembly comprises a first end cover, a second end cover and multiple parallel filtering channels; openings are formed in the two ends of each filtering channel; every two adjacent filtering channels share one side wall and are communicated through multiple filtering through holes in the side walls; the first end cover and the second end cover are located at the two ends of the multiple filtering channels respectively; the first end cover and / or the second end cover can respectively adjust the opening degree of the openings corresponding to the multiple filtering channels so as to adjust the flow direction of gas in a filtering assembly, so that the gas blows off particulate matters blocked on the filtering channels, and the problem that the particulate matters block the filtering assembly after the filtering assembly is used for a period of time is solved; and the filtering assembly does not need to be disassembled and cleaned, so that operation is convenient, and the cleaning effect is good.

Owner:CHINA FIRST AUTOMOBILE

Cleaning-free curtain fabric

The invention discloses a cleaning-free curtain fabric, which comprises a middle fabric substrate and a surface protection coating, wherein the middle fabric substrate is prepared by blending flame-retardant polyester fiber and polyacrylonitrile fiber; the surface protection coating is formed on the surface of the middle fabric substrate, and is a water-proof agent coating or a polyurethane water-proof coating; the flame-retardant polyester fiber accounts for 23-25 percent by weight of the middle fabric substrate; the polyacrylonitrile fiber accounts for 75-77 percent by weight of the middle fabric substrate. Through the manner, the cleaning-free curtain fabric is made by compounding superior materials, is high in pollution resistance on the surface, and is easy to clean by wiping. A curtain made of the curtain fabric does not need to be detached for cleaning, and is convenient to use, soft and wearable in texture, and high in durability.

Owner:APPROACH SUZHOU GARMENT

A pump regulator pollution test injection system

InactiveCN105443368BEvenly blendedRealize automatic cleaningPump testingPositive-displacement liquid enginesEngineeringTested time

The invention provides a pollution test injection system for a pump regulator. The pollution test injection system for the pump regulator is composed of two parts which are a pollutant injection part and a pollution test part. The pollutant injection part is used for self-cleaning and providing pollutant mixed oil liquid. The pollution test part is used for self-cleaning and examination of the pump regulator for a pollution test. By means of the pollution test injection system for the pump regulator, pollutant is mixed evenly, and the concentration of the pollutant and the pollution test time can be set autonomously as needed. Self-circulation of the system is achieved, and a pipeline can be automatically cleaned without the need for being detached.

Owner:BEIJING HANGKE ENGINE CONTROL SYST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com