Waste gas filtering factory environment-friendly equipment

A technology for waste gas filtration and environmental protection equipment, which is applied in the fields of dispersed particle filtration, gas treatment, membrane technology, etc., to achieve the effect of easy cleaning and long use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

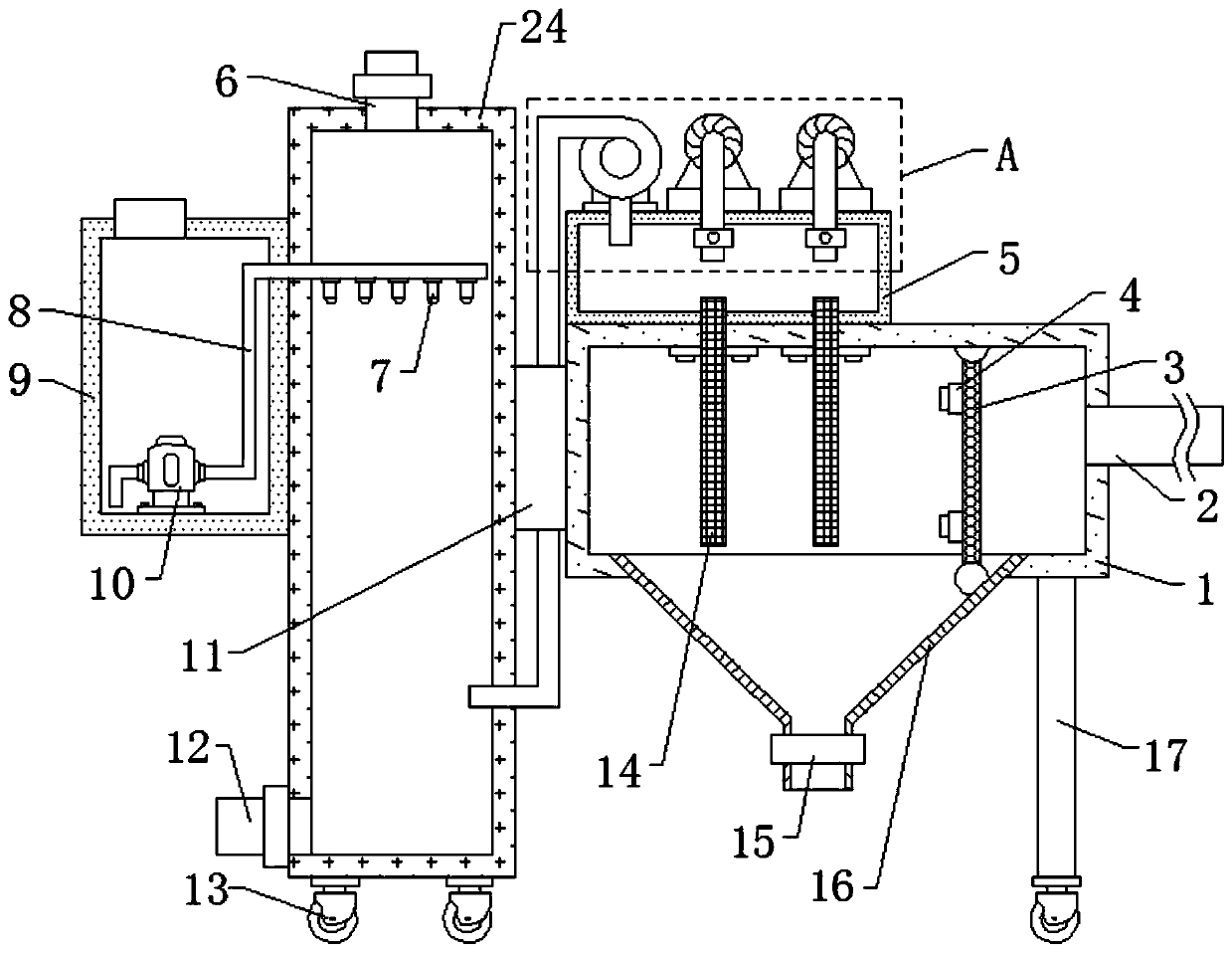

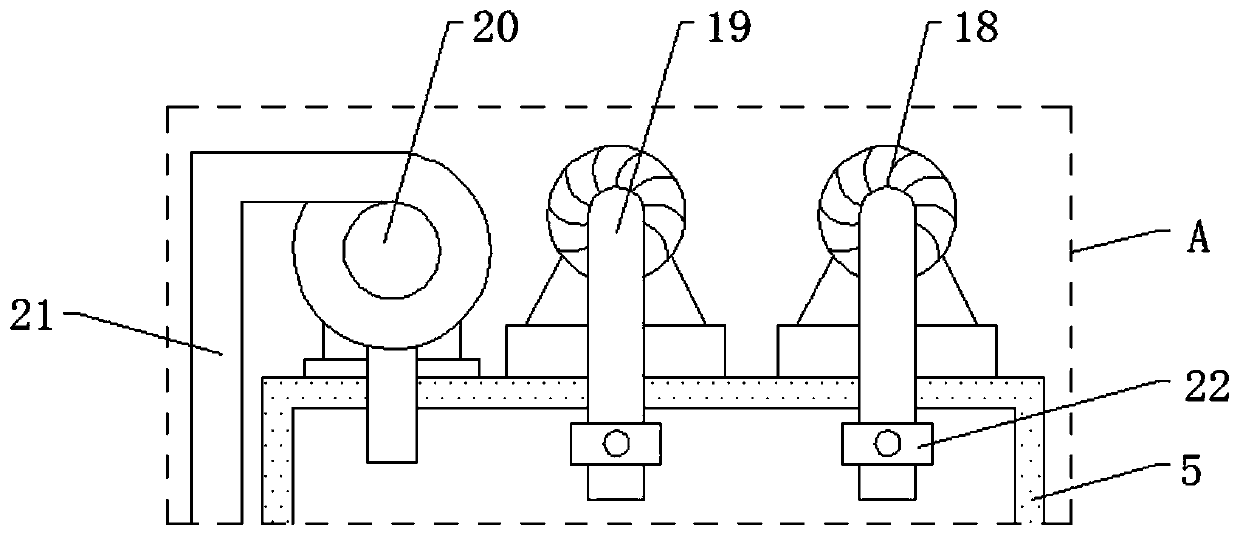

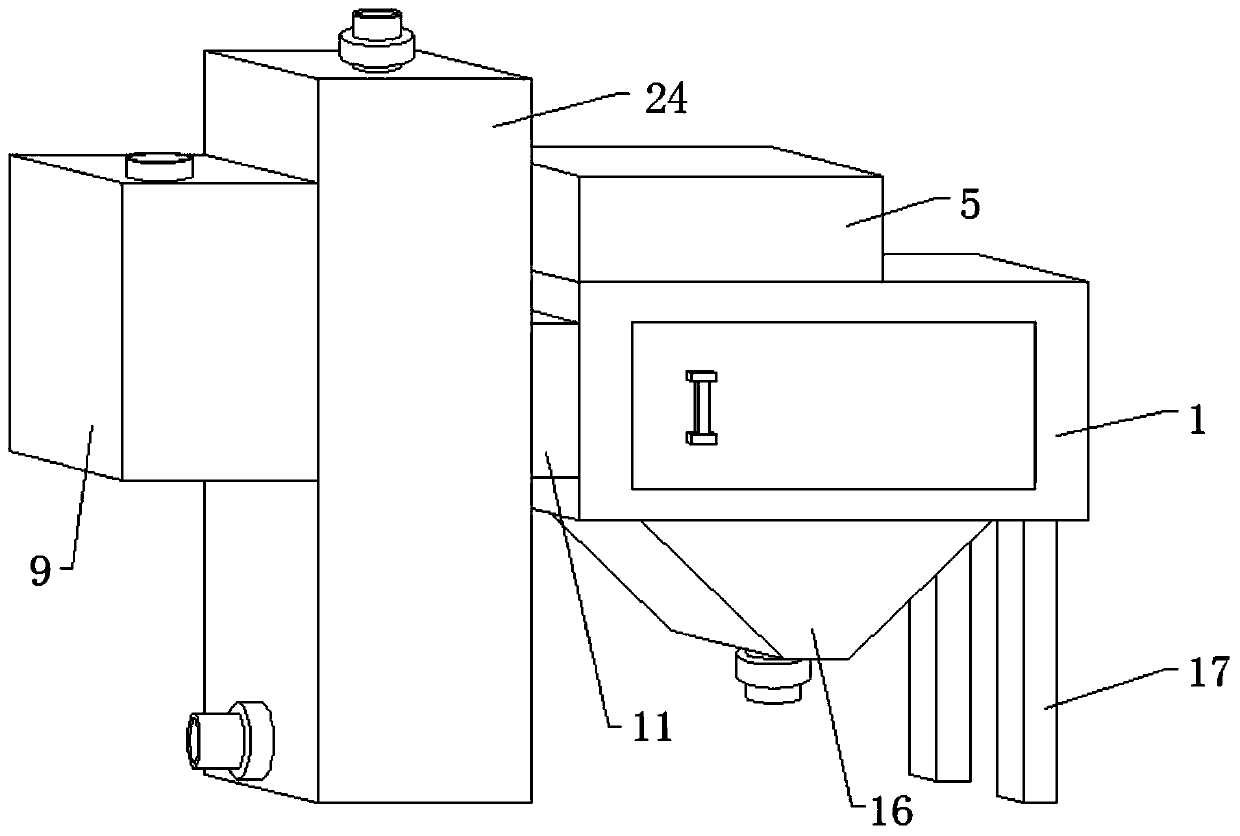

[0025] refer to Figure 1-3 , a kind of environmental protection equipment for waste gas filtration factory, including dust removal box 1 and spray box 24, on one side of the outer wall of spray box 24, a connecting block 11 is fixed by bolts, and dust removal box 1 is fixed on the far side of connecting block 11 by bolts On one side of the spray box 24, the dust inlet pipe 2 is plugged on the outer wall of one side of the dust removal box 1, and the bottom outer wall of the dust removal box 1 is provided with an installation opening, and an ash hopper 16 is fixed on the outer wall of one side of the installation opening by bolts. , the top inner wall of the dust removal box 1 is hinged with a filter screen 3 near the position of the dust inlet pipe 2, one end of the filter screen 3 is hinged on the inner wall of one side of the ash hopper 16, and the outer wall of the side of the filter screen 3 is fixed by bolts. The vibrator 4 and the top inner wall of the dust removal box ...

Embodiment 2

[0031] refer to Figure 4, a kind of environmental protection equipment used in waste gas filtration factories. Compared with Embodiment 1, this embodiment also includes a sloping plate 23, and one end of the sloping plate 23 is fixed on the inner wall of one side of the dust removal box 1 by bolts, and the sloping plate The other end of 23 is fixed on the side inner wall of ash hopper 16 by bolt.

[0032] During use, the dust removal box 1 close to the dust inlet pipe 2 and the ash hopper 16 is mainly fixed with a slant plate 23 by bolts. To the ash hopper 16, avoid dust and sundries etc. from staying in the dust removal box 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com