Self-cleaning type organic matter solid-liquid separation equipment

A solid-liquid separation and organic matter technology, applied in filtration separation, separation methods, moving filter element filters, etc., can solve the problems of reduced solid-liquid separation efficiency, poor extrusion effect, filter clogging, etc., to improve solid-liquid separation. Effectiveness, high flexibility, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

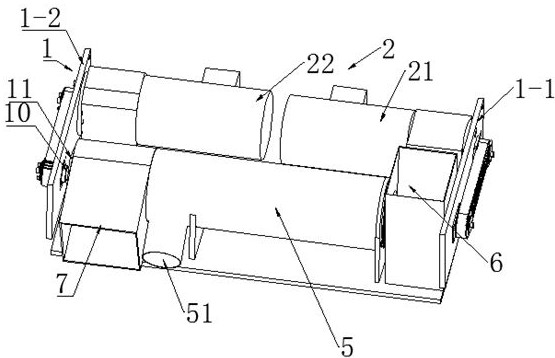

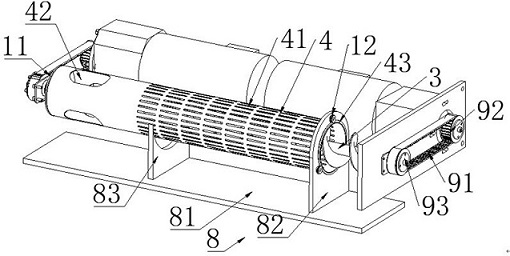

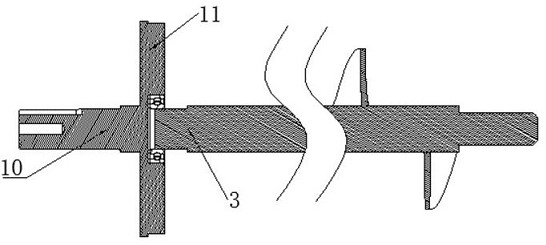

[0030] A self-cleaning type organic solid-liquid separation equipment, comprising: a transmission plate 1, a driving device 2, a dragon shaft 3, a cage 4, a cage shell 5, a feed port 6, and a discharge port 7, and the drive device 2 includes The first driving device 21, the second driving device 22, the first driving device 21, the second driving device 22 are Jiaolong motors and are controlled respectively; the transmission plate 1 includes the first transmission plate 1-1, the second transmission plate 1 -2, the output end of the first driving device 21 passes through the first transmission plate 1-1 and is connected to the Jiaolong shaft 3 through the first transmission assembly, and the output end of the second driving device 22 passes through Through the second transmission plate 1-2 and through the second transmission assembly and the transmission connection with the dragon cage 4, the dragon shaft 3 and the dragon cage 4 rotate in the opposite direction; the dragon shaft...

specific Embodiment example 2

[0033] A self-cleaning type organic solid-liquid separation equipment, comprising: a transmission plate 1, a driving device 2, a dragon shaft 3, a cage 4, a cage shell 5, a feed port 6, and a discharge port 7, and the drive device 2 includes First drive device 21, second drive device 22, described transmission plate 1 comprises first transmission plate 1-1, second transmission plate 1-2, the output end of described first drive device 21 passes through described first The transmission plate 1-1 is connected to the Jiaolong shaft 3 through the first transmission assembly, and the output end of the second driving device 22 passes through the second transmission plate 1-2 and is connected to the second transmission assembly through the second transmission assembly. The dragon cage 4 is connected by transmission, and the dragon shaft 3 and the cage 4 rotate in reverse; the two ends of the dragon shaft 3, the cage 4, and the cage shell 5 are respectively provided with a feed port 6 a...

specific Embodiment example 3

[0036]A self-cleaning type organic solid-liquid separation equipment, comprising: a transmission plate 1, a driving device 2, a dragon shaft 3, a cage 4, a cage shell 5, a feed port 6, and a discharge port 7, and the drive device 2 includes First drive device 21, second drive device 22, described transmission plate 1 comprises first transmission plate 1-1, second transmission plate 1-2, the output end of described first drive device 21 passes through described first The transmission plate 1-1 is connected to the Jiaolong shaft 3 through the first transmission assembly, and the output end of the second driving device 22 passes through the second transmission plate 1-2 and is connected to the second transmission assembly through the second transmission assembly. The dragon cage 4 is connected by transmission, and the dragon shaft 3 and the cage 4 rotate in reverse; the two ends of the dragon shaft 3, the cage 4, and the cage shell 5 are respectively provided with a feed port 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com