Filter screen cylinder for outdoor crushing machine

A filter screen and crusher technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of dirty filter screen cylinder, single mesh type, easy to solidify and block, and achieve the elimination of disassembly and cleaning, The effect of reducing production costs and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with examples of implementation and accompanying drawings. The present invention can be implemented in the following ways:

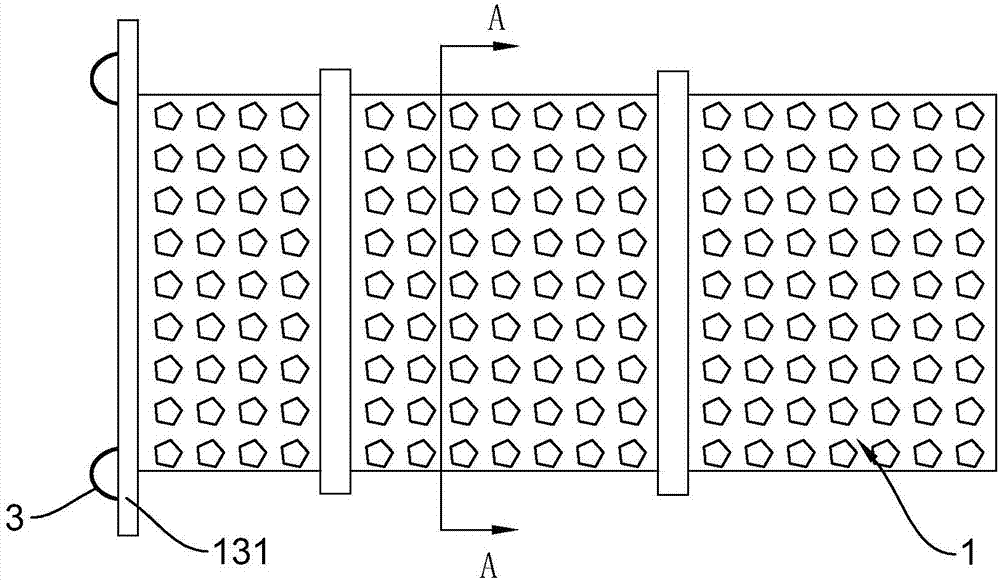

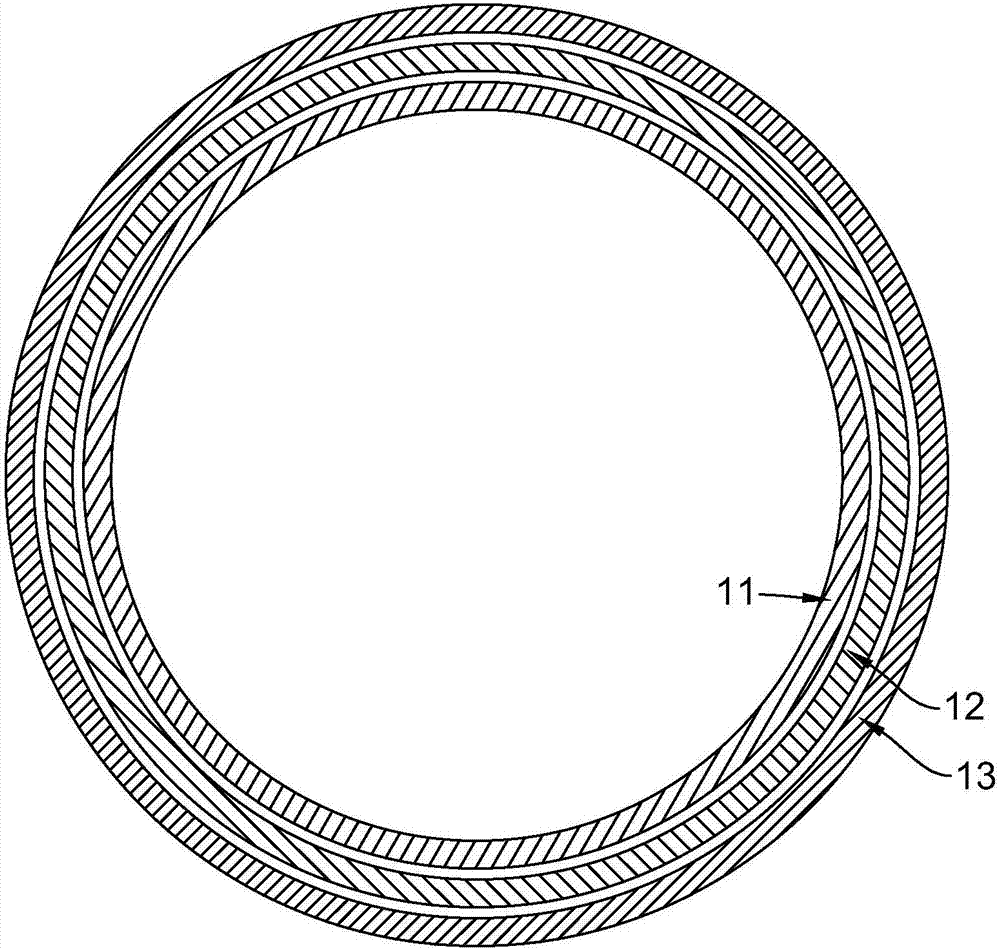

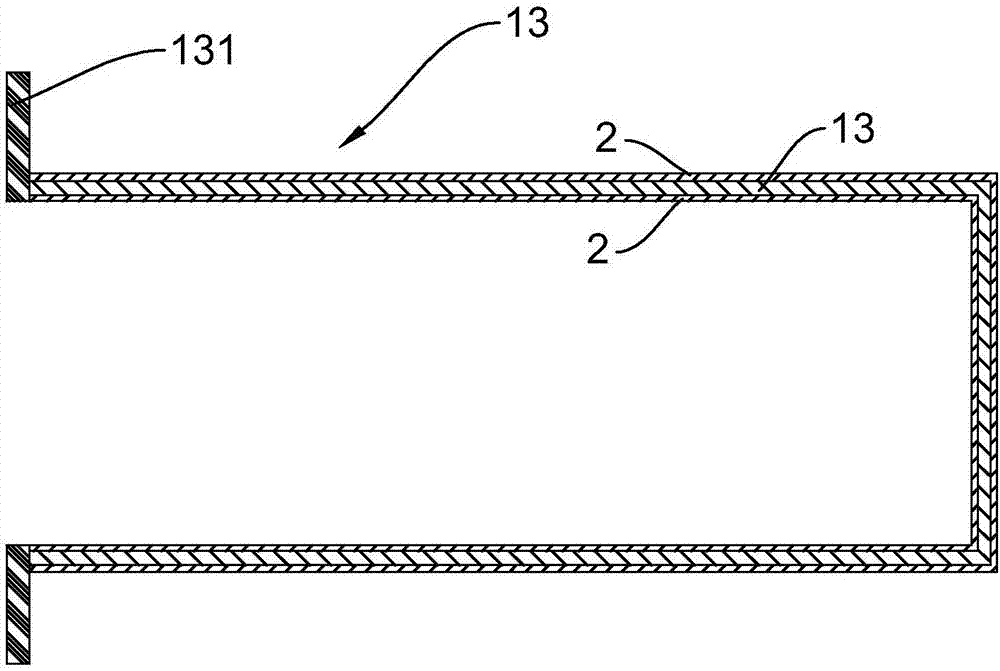

[0019] refer to Figure 1-2 , a filter screen cylinder for an outdoor crusher, comprising a screen cylinder 1, said screen cylinder 1 comprising a detachable coarse mesh cylinder 11, a coarser mesh cylinder Body 12 and fine grid cylinder 13, the top edge of the fine grid cylinder 13 is provided with a connection part 131 for clamping on the food waste shredder, the coarse grid cylinder 11 and the coarser The grid cylinder 12 is detachably connected to the through hole of the connecting portion 131 of the fine grid cylinder 13 through the hook 3 . When disassembling, you only need to lift up the grid cylinder to be disassembled, and the operation is convenient and quick. The coarse mesh cylinder 11 , the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com