Pollution test injection system for pump regulator

A pump regulator and injection system technology, applied in pump testing, machine/engine, liquid displacement machinery, etc., to achieve the effect of cleaning without disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

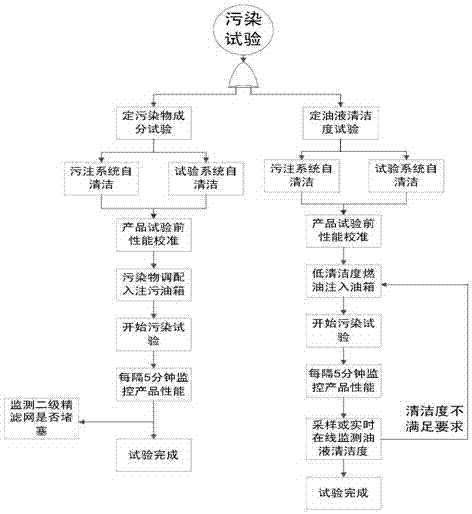

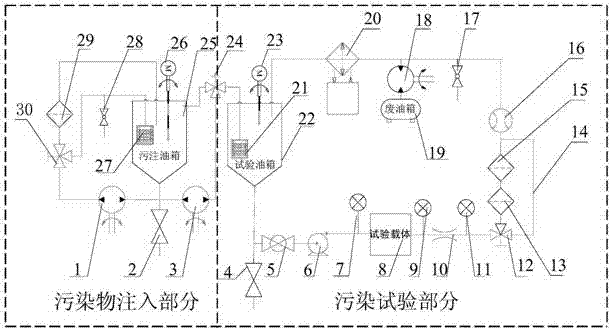

[0020] See attached figure 1 , the pump regulator pollution test injection system of the present invention consists of two parts: a pollutant injection part and a pollution test part:

[0021] The pollutant injection part is used for self-cleaning and providing pollutant mixed oil, including circulation pump (1), oil drain valve (2), dirty oil injection pump (3), dirty oil injection tank (25), electric agitator one (26 ), diffuser one (27), sampling switch one (28), fine filter (29), three-way valve one (30); among them, circulation pump (1), oil drain valve (2), dirty oil injection pump (3 ), dirty oil tank (25), fine filter (29), three-way valve one (30) are connected in series in sequence, electric agitator one (26), diffuser one (27) are inserted in dirty oil tank (25), three-way One end of valve one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com