Closed circulation degreasing and cleaning system for helium diaphragm compressor pipeline

A diaphragm compressor, degreasing and cleaning technology, applied in the field of helium diaphragm compressor cleaning, can solve the problems of reducing purity, cleaning, waste of degreasing solvent, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

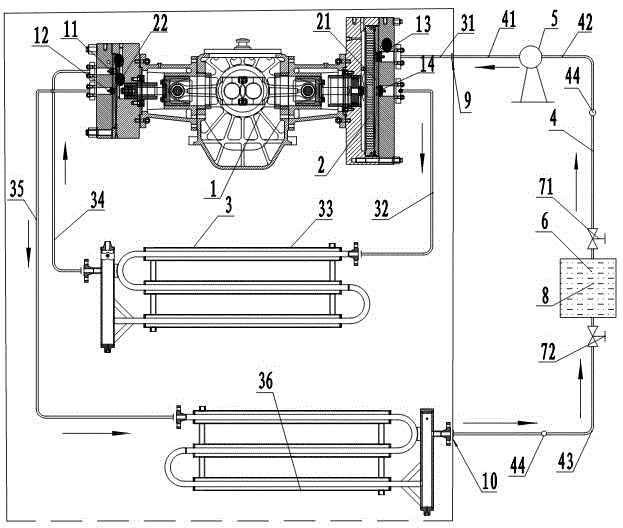

[0016] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0017] like figure 1 As shown, a helium diaphragm compressor pipeline closed cycle degreasing cleaning system includes a primary exhaust pipe 32 connected to the primary exhaust valve 14 on the primary cylinder head membrane cavity 11 of the compressor 1 , a primary cooler 33 and a secondary air intake pipe 34, and the secondary air intake pipe 34 is connected to the secondary cylinder head film cavity 22 in the body of the compressor 1 through the position of the secondary air intake valve 11 of the compressor, and the compression The first-stage exhaust valve 14 and the second-stage intake valve 11 of the machine; the cleaning system also includes the first-stage intake valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com