Nano-aperture metal filter element and preparation method thereof

A technology of metal filter element and pore size, which is applied in the field of nano-aperture metal filter element and preparation, which can solve the problems of deformation and damage of filter material and end cap, increase the production cost of filter element, separation of end cap and filter material, etc., achieve simple assembly and improve stability And service life, the effect of small aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

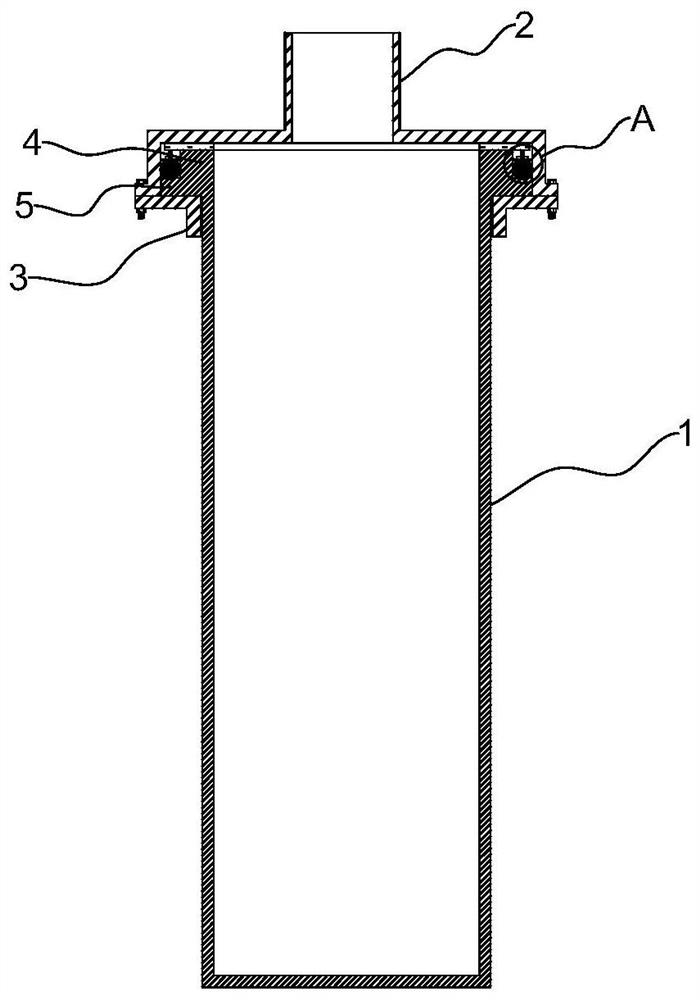

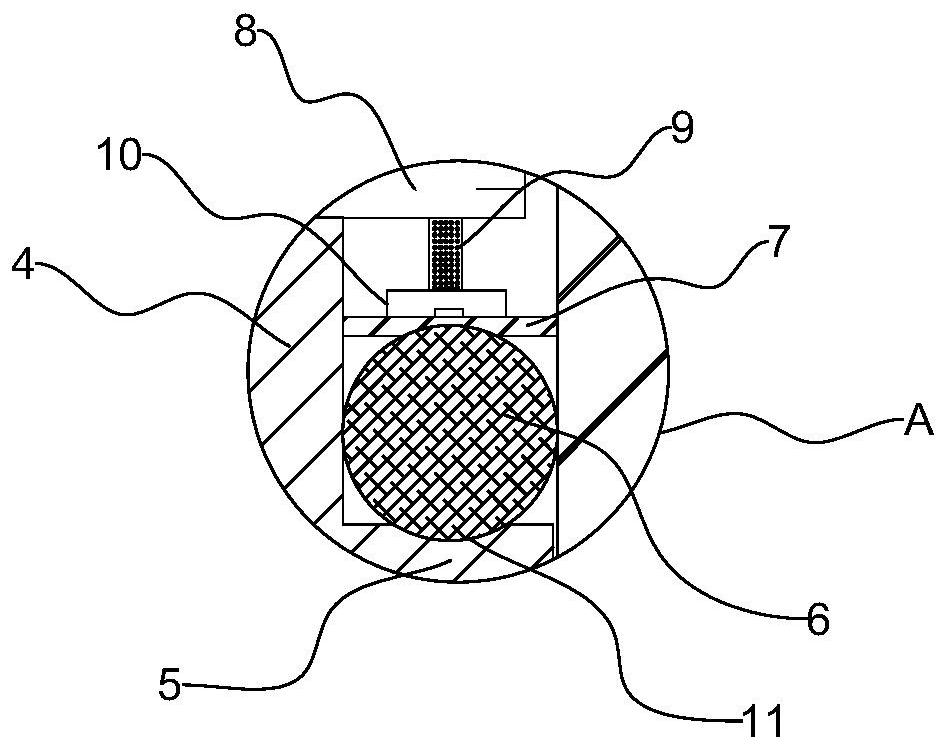

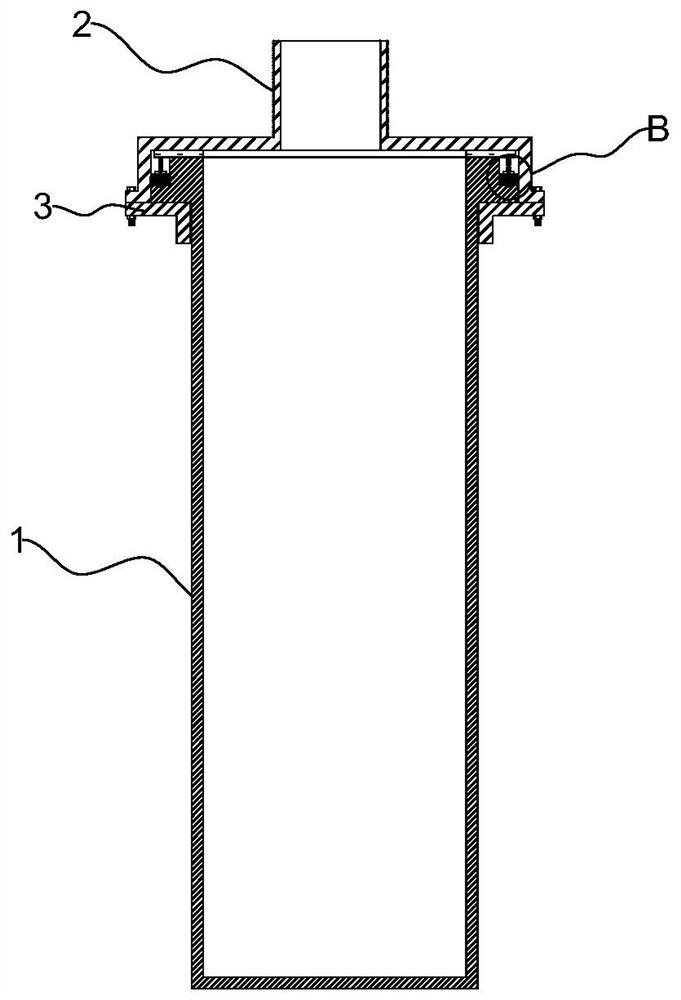

[0035] This embodiment provides a nano-aperture metal filter element and its preparation method, please refer to figure 1 , figure 2 As shown, it includes the filter material 1, the end cap 2 and the chuck 3 located at the opening end of the filter material 1, the end of the filter material 1 is formed with a convex positioning part, and the positioning part is a part that is integrally formed when the filter material 1 is sintered. There is no need for post-processing to set up, and the two are integrally sintered, which can also strengthen the bearing strength of the positioning part and prevent the positioning part from detaching from the filter material 1. The end cap 2 and the chuck 3 are respectively located on both sides of the positioning part and fix the positioning part. Between the end cover 2 and the chuck 3, of course, the two can be fixed by bolts, that is, the end cover 2 and the chuck 3 are only fixed on both sides of the positioning part by bolts, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com