Efficient suction filtration device of press

A technology of suction filter device and press, which is applied in the direction of filter circuit, filter separation, mobile filter element filter, etc., which can solve the problems of high purchase cost of filter cloth, affecting the production efficiency of the press, and large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

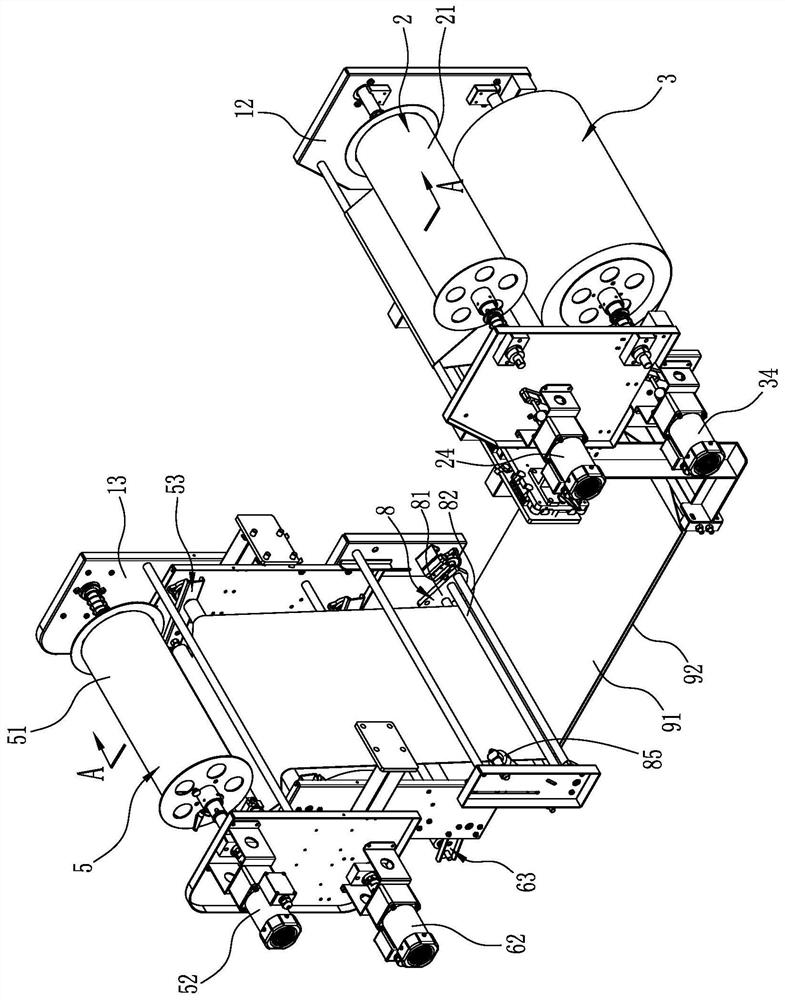

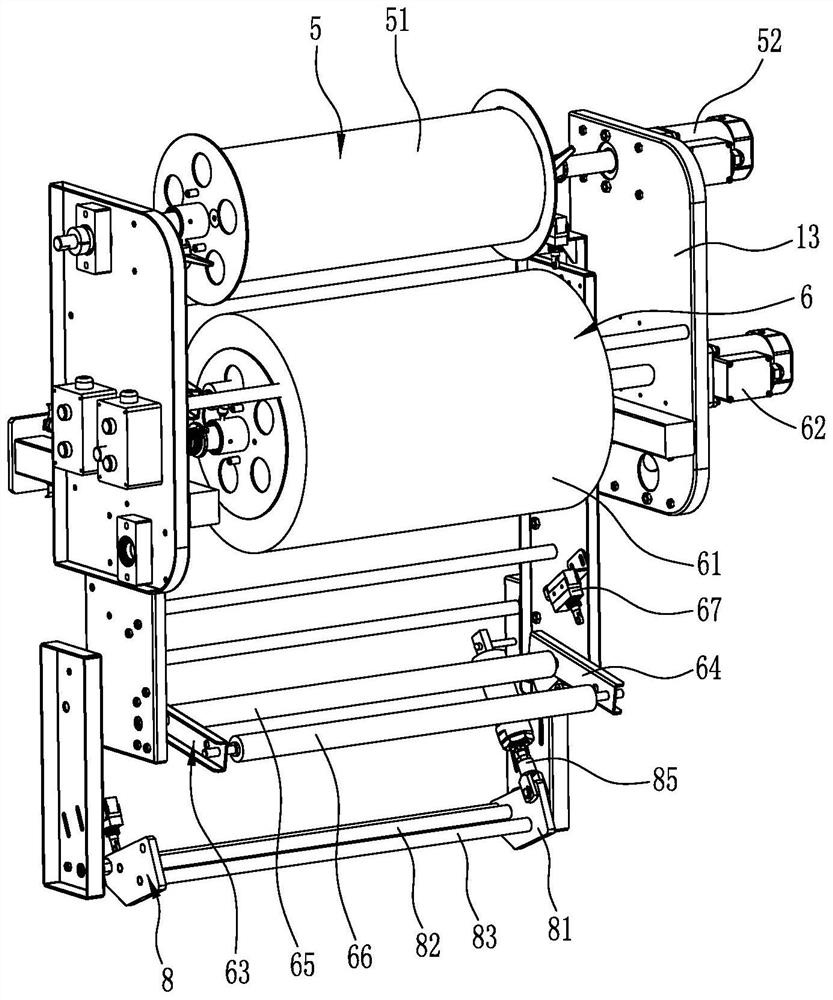

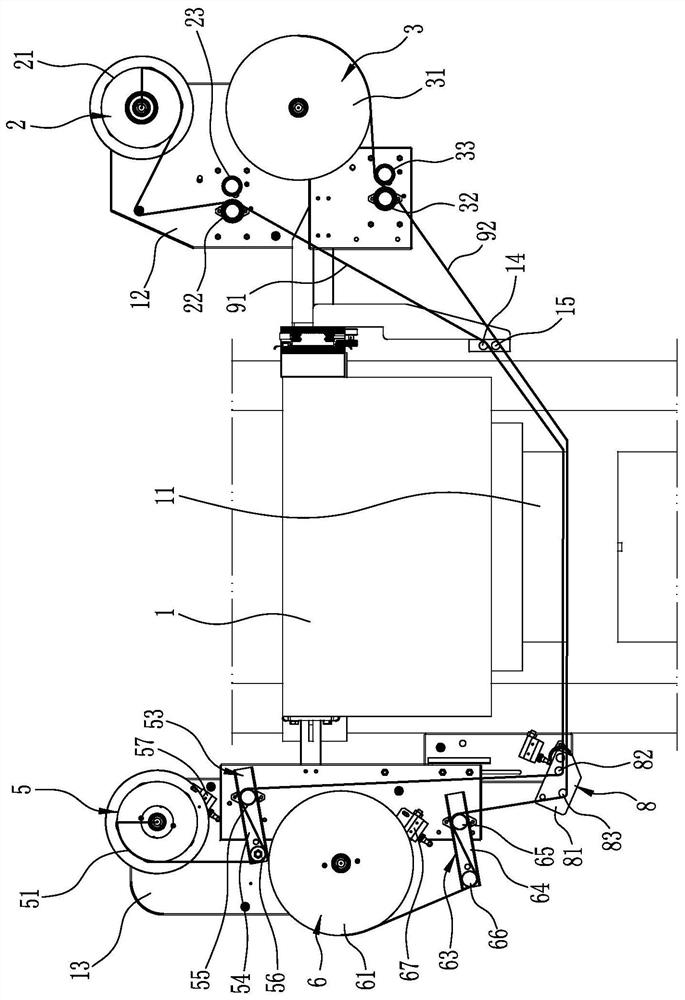

[0024] Embodiment one: if figure 1 , figure 2 and image 3 As shown, the high-efficiency suction filter device of the press includes a cloth releasing support 12 and a cloth receiving support 13 which are fixedly arranged relative to the upper die 11 of the press and are respectively located on both sides of the upper die 11 . The cloth releasing support 12 and the cloth receiving support 13 in this embodiment are fixed on the press base 1 of the press machine, but of course they can also be separated from the press base 1 and relatively fixedly arranged.

[0025] The cloth releasing support 12 is provided with a cloth releasing device 2 and a paper releasing device 3, and the cloth receiving support 13 is provided with a cloth receiving device 5 and a paper receiving device 6, and the cloth releasing device 2 and the cloth receiving device 5 is provided with a filter cloth 91 arranged below the upper die 11, and a filter paper 92 positioned below the filter cloth 91 is pro...

Embodiment 2

[0038] Embodiment two: if Figure 4 , Figure 5 and Figure 6 As shown, the difference between this embodiment and Embodiment 1 is: the yarn releasing device 4 is also provided on the cloth releasing support 12, the yarn receiving device 7 is provided on the cloth receiving support 13, and the yarn releasing device 4 and the yarn receiving device 7 is provided with a protective yarn 93 located between the upper die 11 and the filter paper 92 , and the yarn receiving elastic tensioning device 73 is provided on the cloth receiving support 13 . In this embodiment, adding the protective yarn 93 can reduce the abrasion of the filter cloth 91 by the upper die 11 , avoid replacement and damage, and improve the service life of the filter cloth 91 . Correspondingly, in the retractable pre-supporting device 8, the pre-supporting bracket 81 is provided with yarn supporting guide rollers 84, cloth supporting guide rollers 82 and paper supporting guides arranged in sequence along the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com