Method for material feeding and liquid discharging of combined diaphragm filter plate

A diaphragm filter plate and combined technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of uneven thickness of filter cake, impact on economic benefits, high production cost, etc., achieve uniform thickness of filter cake, increase Effective filtering area and fast filtering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

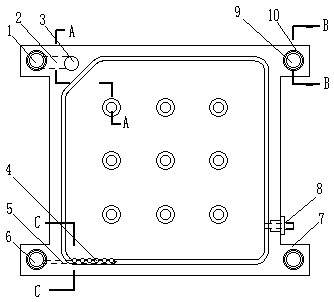

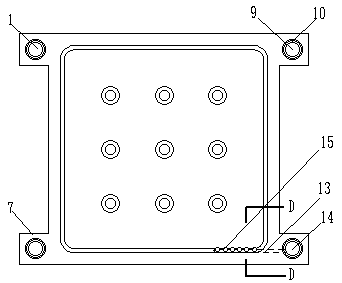

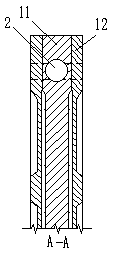

[0020] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention provides a method for feeding and discharging a combined membrane filter plate, which is implemented in the following way. The main board structure is composed of three pieces, the middle of the main board is a core board 11, and the two sides of the main board are diaphragms 12. The diaphragm 12 and the core plate 11 are thermally fused and connected as a whole. The material used for production is polypropylene. The core plate 11 mold is made according to the specifications. The feed channel 1 and the blowback channel 9 are formed by the mold, including the outer span ear 7 , The left underflow hole 6, the right underflow hole are made by the mold together, choose a flat vulcanizer to install the core plate 11 mold, inject the molten polypropylene into the mold for compression molding, take out the core plate 11 blank and wait for it to cool and then machine it. Pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com