Micro-pore filtering membrane producing technology

The technology of a microporous filtration membrane and preparation process is applied in the field of environmental protection material preparation, which can solve the problem of not using a microporous filtration membrane, and achieve the effects of low cost, smooth breathing and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

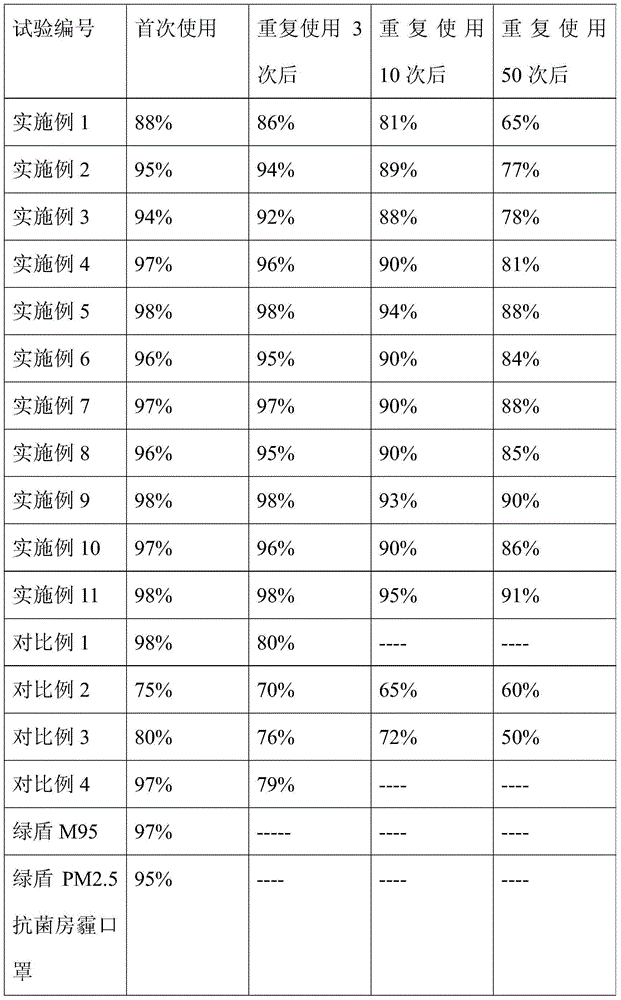

Examples

Embodiment 1

[0018] Embodiment 1. A porous sponge with a thickness of 5 mm is thermally compressed with a high temperature resistant plate at a temperature of 150° C., and the thermal compression pressure is , and compressed into a microporous filter membrane with a thickness of about 1.2 mm.

Embodiment 2

[0019] Embodiment 2. A porous sponge with a thickness of 10 mm is thermally compressed with a high temperature resistant plate at a temperature of 170° C., and the thermal compression pressure is , and compressed into a microporous filter membrane with a thickness of about 2 mm.

Embodiment 3

[0020] Embodiment 3. A porous sponge with a thickness of 10 mm is thermally compressed with a high temperature resistant plate at a temperature of 150° C., and the thermal compression pressure is , and compressed into a microporous filter membrane with a thickness of about 2.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com